D17 S1 split at torque housing (Power Director

Bought and used my tractor for the first time last summer. Did about 25 hours of brush hogging over the summer and the D17 did great I thought. One thing I wanted to look into over the winter (just now getting to it) was that I really had to slam the PD (power director) lever forward to get it to engage in high range. (it would always stay in high once there) No trouble in low range.

I do have the shop and operators manual so that is a good start but have never worked on a tractor before...

So, I now have the tractor split apart in my 2 car garage and have taken some measurements and noticed some things.

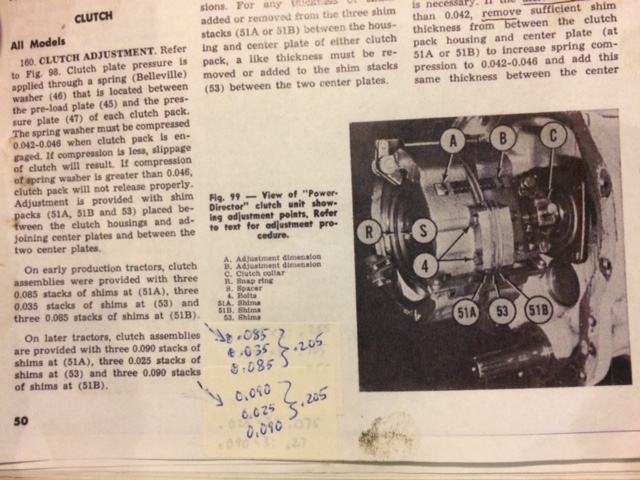

1. measurement of (B in the pic) - (between pre-load plate and pressure plate) average difference between engaged and disengaged was:

FRONT (low range)- .010 (supposed to be between .042 and .046)

REAR (high range)- .028 (supposed to be between .042 and .046)

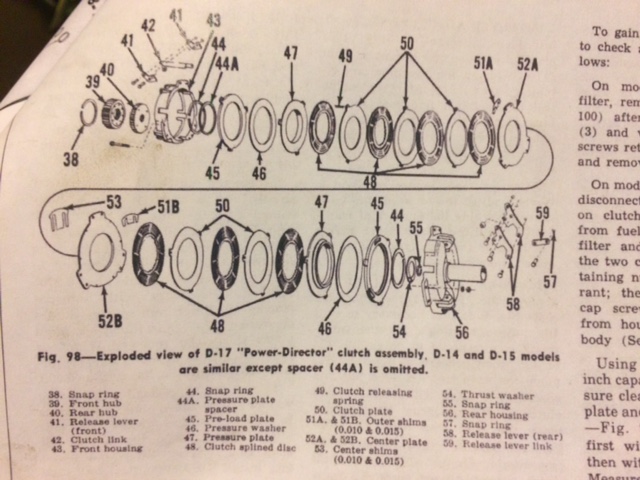

2. I then loosened the bolts (#4 in the pic) and carefully took out each set of shims and cleaned and wrote down the size of each one before putting them back in the precise order and this is how things stack up..

REAR shims- (3x .012) = .036

MIDDLE shims- (6x .012 + 3x .010) = .102

FRONT shims- (2x .012 + 1x .010) = .034

For a total of .172

Per the manual the total measurement of shims should be .205 so I am short .033

I think my plan should be to add shims to the MIDDLE shims to get the total thickness to .205 and then take my engaged/disengaged measurements again...

Am I on the right track here?

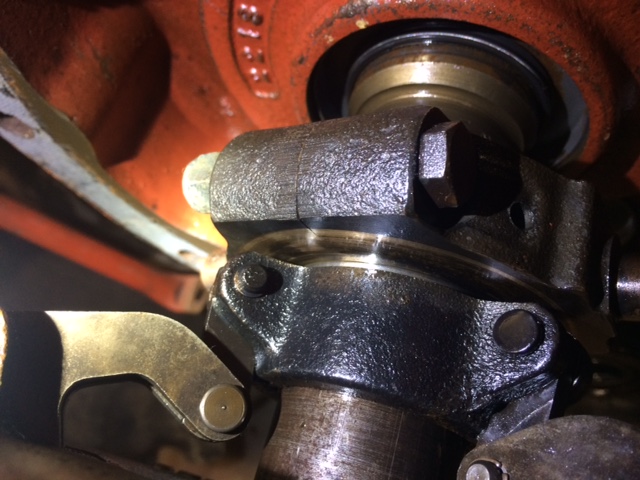

Also, one thing I noticed that seems a little sloppy is the collar assy goes back and forth aprox 3/32" (pic below at the furthest point, then goes forward and touches (to push) the shifter.

This tractor sat for 7 years without moving before I bought it so I guess the PD was out of the oil and rusted the top 1/4.. should I do anything here besides wire brush carefully?

Thanks,

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)