| Author |

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2014 at 9:04am Posted: 01 Feb 2014 at 9:04am |

Took the radiator in and had it tested. It was good. The tank is still with the radiator shop trying to get the varnish out. I also met up with a fellow board member here who made me a deal on a carb, hub, axle, and front wheel. So I broke the hub down to rebuild and also was rebuilding the carb.

I took the inspection plate off the bottom to find a nice rat's nest.

The original carb on the left and the replacement carb on the right both are a TSX-869.

Definitely some pressure on those floats.

Cleaned up the hub

|

|

|

|

|

Sponsored Links

|

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2014 at 9:09am Posted: 01 Feb 2014 at 9:09am |

Worked on the cleaner last night too. I got the nut off but twisted the supports up, so I started remaking them.

|

|

|

|

sandman2234

Orange Level

Joined: 21 Feb 2013

Location: Jax

Points: 2547

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2014 at 9:26am Posted: 01 Feb 2014 at 9:26am |

|

Take your time, don't force anything, and keep after it. As DaveKamp said, you can address several functions at a time, but don't get overwhelmed with the whole project. If you get in over your head, go back to just a single piece until you get that part done. When you get stuck on a part, add penetrating oil and move to something else.

Nice project, great pictures, keep it up, we are all behind you for the long haul.

David from jax

|

|

A proud member of the Allis Express movement!

Northeast Florida

|

|

JayIN

Orange Level

Joined: 18 Dec 2009

Location: SE/IN

Points: 1982

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2014 at 3:59pm Posted: 01 Feb 2014 at 3:59pm |

|

I am enjoying this!

|

|

sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?"

|

|

SHAMELESS

Orange Level

Joined: 13 Sep 2009

Location: EAST NE

Points: 29486

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2014 at 9:03pm Posted: 01 Feb 2014 at 9:03pm |

|

you have a lot there, a lot more than what some people start with, that is a very do-able restoration! and like the others said...it's "family"! keep us posted and with pics, we all like seeing the pics of labor/love!

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2014 at 3:24pm Posted: 02 Feb 2014 at 3:24pm |

|

Structures,

Keep up the good work. There are so many parts on these and at this stage some will need more attention than others. Looks like you enjoy the work your doing. You will probably meet a lot of new friends along the way as you get the spare parts you need to bring it back to working order.

Thanks for posting the pictures too.

Regards,

Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Apr 2014 at 10:29pm Posted: 08 Apr 2014 at 10:29pm |

Working on a few areas.

Trying to take the wheels apart but having a hard time with the eccentrics. I was able to remove the 8 carriage bolts that mount to the center wheel. Also able to remove a couple of snap rings from the back side but I can't seem to get much else to budge. I used a drift punch from the back side to try and drive the shaft out or at least free something up. Also a large break over on the hex bolt but nothing.

The snap rings aren't too hard to remove. 2 screw drivers. I use 1 to wedge one half the snap ring and the other to work the other half over the pin. The 8 carriage bolts have been removed but I snapped the picture before hand.

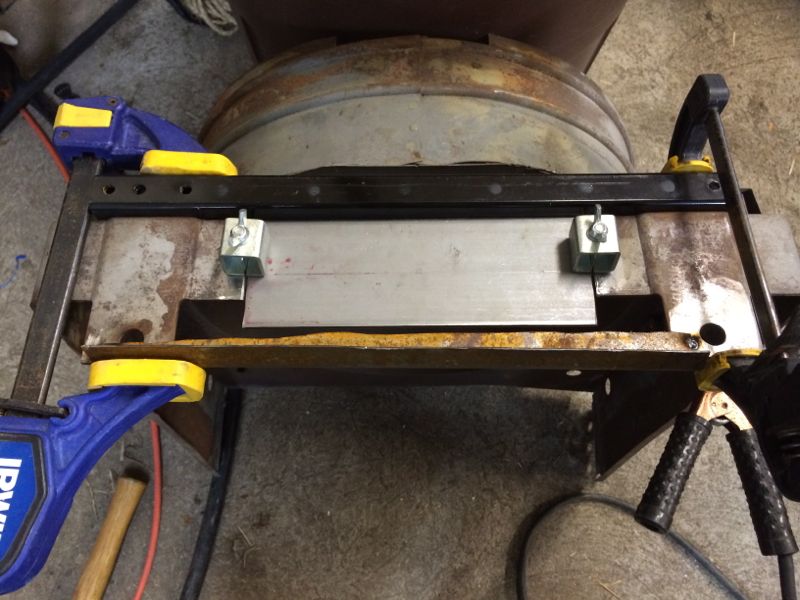

Also had the radiator disassembled so I could do some work on it. The lower part of the frame was pretty heavily rusted. I spliced in a new section of the frame and bent up a new lower mount bracket too.

Edited by structures - 08 Apr 2014 at 10:34pm

|

|

|

|

Rltool

Orange Level

Joined: 17 Jun 2013

Location: Middleville ,MI

Points: 1832

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2014 at 5:32am Posted: 09 Apr 2014 at 5:32am |

|

I just found this post. Great restore project! Your doing a great job fabing up parts. When your done you won't regret taking the extra time to do things right. I'm currently finishing up a WD project. If the eccentrics are like the WDs. Some people have suggested putting them in a vise and using heat on the casting. Might try an air hammer on pins. That has worked well for me. Lots of penetrating oil & air to get "any" loose debris out of there. Keep up the good work. Great post.

Ray W.

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2014 at 9:05am Posted: 13 Apr 2014 at 9:05am |

Thanks Ray.

Had success with the eccentrics (thanks to some helpful posts!). Used a sledge hammer and a block of wood on the wheel center's edge. One smack and rotate to opposite corners (in between the eccentrics). Didn't take too much swing either. Also didn't damage the center.

I was able to press the cam bolts out of the castings too. Two gave me a lot of trouble. A torch probably would have been helpful here but I don't have one.

Got 4 of these rims. Hopefully I can make at least two when I'm done.

|

|

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54831

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2014 at 7:36pm Posted: 13 Apr 2014 at 7:36pm |

|

apply neversieze compound to 'em, now that you have the eccentrics free...

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2014 at 6:33pm Posted: 17 Apr 2014 at 6:33pm |

Good idea Dave thanks. I shot the radiator frame with epoxy primer and then dropped the radiator assy off at the rad shop to have it cleaned and reassembled.

|

|

|

|

JOHN N/IL

Orange Level

Joined: 11 Sep 2009

Points: 584

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2014 at 8:08pm Posted: 17 Apr 2014 at 8:08pm |

|

Great job Robert that is some nice work your doing there,yoy will have a super nice 15 when your done,thanks for all the nice photos,good luck,i just got off of my 1511 loading 6 loads of manure,besides the odor I just love this tractor.Keep up the great work and it will be done in no time.John

|

|

D-15IIG65,D-17IVG67,D-17D58,620

|

|

JOHN N/IL

Orange Level

Joined: 11 Sep 2009

Points: 584

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2014 at 8:10pm Posted: 17 Apr 2014 at 8:10pm |

|

I forgot to ask are you using a sandblaster to get the old crap off or what,sure came out nice on the shroud.

|

|

D-15IIG65,D-17IVG67,D-17D58,620

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2014 at 9:30pm Posted: 18 Apr 2014 at 9:30pm |

Thanks. I have a 40x40 econoline cabinet I picked up from a shop going out of business some years back. I use alum oxide.

I'm hoping to put a loader on it one day as well.

Edited by structures - 23 Apr 2014 at 9:33pm

|

|

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jul 2014 at 8:11am Posted: 21 Jul 2014 at 8:11am |

Bad news on the radiator. I guess all the heat from taking it apart and putting it back together broke out some weak points in the core. The radiator shop tested it last week before putting it back together and it had a lot of pin holes in it.

I've seen some new radiators listed online so I'll probably go that route.

|

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7585

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jul 2014 at 9:36pm Posted: 21 Jul 2014 at 9:36pm |

|

I think at lot of the new rads are made overseas and are not very good quality. Your rad shop should be able to recore it for you. That is the path I would take.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jul 2014 at 9:48pm Posted: 21 Jul 2014 at 9:48pm |

|

Yeah. I was going to have it recored. He thought he'd have $400 in it, and figured I'd better get a new one... I don't know. Maybe I'll take it somewhere else. It's pretty rough. I wish I could find out more about the new ones. I asked a seller. They said the new ones have copper cores...

|

|

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13749

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jul 2014 at 10:24pm Posted: 21 Jul 2014 at 10:24pm |

|

Hey TimNearFortWorth,,,I sure would like to see pics of your Series II LP,,,,?

Edited by desertjoe - 21 Jul 2014 at 10:34pm

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13749

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jul 2014 at 10:42pm Posted: 21 Jul 2014 at 10:42pm |

|

Hey Structures,,,I'm goin to be following your project also..looking good,,. I have a D15 II LP and working on it as much as the hot weather will let me,,,,.

I am close to being ready to paint the tin, hopefully in a week or so.

On your radiator, are you wanting to stay original?

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jul 2014 at 7:55am Posted: 22 Jul 2014 at 7:55am |

|

definitely want to stay original.

|

|

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Aug 2014 at 9:13am Posted: 25 Aug 2014 at 9:13am |

Good morning a little update.

Picked up a radiator. It's fairly close to the original. Same overall dimensions, copper, looks like it has some additional mounting nuts, probably for other years. Tanks are little different.

Also worked on an already pretty good rim. It was a mix between sandblasting and electrolysis. I'd recommend electrolysis first and then sand blast the rim. By the time the rim was in the bath for 24 hours the heavy rust was gone and the remaining rust just brushed off.

This is my 80 gallon pool I made. Set the miter saw to 22.5 degrees and start cutting short pieces. It's roughly 32" wide. I used a 4 mil plastic drop cloth. 80 gallons water with about 4 cups washing soda (sodium carbonate). Their is (6) 3/8" to 1/2 Dia rebar sticks around the perimeter and 2 in the middle. The rebar is wired together with copper wire. The electrolysis is definitely line of sight so the rust has to "see" the rebar anodes. Hook up the neg to the rim and the positive to the anode rebar. My 12 volt battery charger was showing almost 10 amps. This is my second rim. I doubled my rebar count and it boosted my amp draw.

24 hours later!

The rust can be wire brushed off pretty easily. I chose to throw it in the blast cabinet. I used por 15 on the outside of the rim. Marine clean, metal ready (with a wash down), and 2 coats por 15. I brushed this on. It's actually not too bad looking. It has brush strokes at first but they thin out before it dries. The 2nd coat went on about 2 hours after the first.

For the inside of the rim I used PPG epoxy primer.

I missed pictures of the body work. The rim was pretty rough by the valve stem. I welded in a little patch and used evercoat to fill the pits. I thought I took pics of that but I guess I didn't.

Edited by structures - 25 Aug 2014 at 6:16pm

|

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7585

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Aug 2014 at 10:28pm Posted: 25 Aug 2014 at 10:28pm |

|

You are making great progress. But that new rad appears to have a shorter tank to me. Neck height looks the same, but a shorter tank could cause big trouble when trying to fit the sheet metal.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Nov 2014 at 11:02pm Posted: 30 Nov 2014 at 11:02pm |

Did a little work this evening. Started cutting on another rim. Should clean up pretty well. It was 65deg F when I started cutting by dusk it was 45deg F!

DSeries4 wrote: DSeries4 wrote:

You are making great progress. But that new rad appears to have a shorter tank to me. Neck height looks the same, but a shorter tank could cause big trouble when trying to fit the sheet metal.

|

thanks man! I think the new radiator looks short because the other one is not fully seated in its frame.

|

|

|

|

JohnCO

Orange Level

Joined: 11 Sep 2009

Location: Niwot Colo

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2014 at 2:20am Posted: 01 Dec 2014 at 2:20am |

|

Getting there! Looks good so far.

It was in the 50's at 7:30 Sunday morning, 20's by 9am. You might be getting a bit colder before you get warmer.

|

|

"If at first you don't succeed, get a bigger hammer"

Allis Express participant

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 10:19am Posted: 02 Dec 2014 at 10:19am |

|

Nice work on the rims, and rad re-build too. The 15 is coming along!

Similar work as I did on a WD this summer. Your doing a good job! No easy way to do this stuff unless you buy new or have someone else do the work:)

I did find a trick to get those pesky snap rings off the pins in the eccentrics. I tried the two screwdrivers with limited success. I started a drywall screw right at the joint of the snap ring. Allowed it to travel a little side ways and it pulled the snap ring out enough that a screwdriver could snap it off. (this was on new snap rings that I have to remove to coat with never seize:))

Maybe this will spur me to get back on the WD project!

Regards,

Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

DanC911

Orange Level

Joined: 22 Jul 2014

Location: CT, USA

Points: 598

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 12:06pm Posted: 02 Dec 2014 at 12:06pm |

I just dumped too much money and time into a Cub Cadet that was my dads. Using it brings back great memories of working with him. Well worth the investment. Take your time and do it right and you will have a memorial to your father that you can use every day.

Good luck

|

|

1950 WD, 1955 B, 66 Jacobsen Chief-O-Matic, 68 Simplicity 2110, 77 IH Cub Cadet 1450 w/front loader

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 2:05pm Posted: 02 Dec 2014 at 2:05pm |

DanC911 wrote: DanC911 wrote:

I just dumped too much money and time into a Cub Cadet that was my dads. Using it brings back great memories of working with him. Well worth the investment. Take your time and do it right and you will have a memorial to your father that you can use every day.

Good luck |

Dan, Did the same on a 147 Cub Cadet a couple years ago. I think they might cost as much as a big tractor to restore:) Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Steve Wilkens

Orange Level

Joined: 12 Sep 2009

Location: Ceresco, Michig

Points: 447

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 5:29pm Posted: 02 Dec 2014 at 5:29pm |

|

Like all the guys said, it is family, you can save her. Do talk to dad and ask why it was parked, might save you a lot of time. An old trick for freeing stuck engines. Block up a rear wheel and fasten a 2x4 to it so that the long end is as high as you can comfortably hang weights. Soak the cylinders with brake fluid and go about your business. When you notice the weights on the ground the engine is free.

|

|

Steve Wilkens

Orange Level

Joined: 12 Sep 2009

Location: Ceresco, Michig

Points: 447

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 5:29pm Posted: 02 Dec 2014 at 5:29pm |

|

oh, be sure to pull the plugs out

|

|

WD45

Orange Level

Joined: 20 Sep 2009

Location: STAYNER,ONTARIO

Points: 957

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2014 at 7:24pm Posted: 02 Dec 2014 at 7:24pm |

|

Recommend taking the head off then soak each cylinder. (used diesel and paint thinner 50/50) .Check the head that all valves are free. Put the tractor in gear and rock it back and forth to get engine to turn over. Good luck. Have freed up a three Allis engines.

|

|

Fred Dunlop, G,B,CA, WC,WF, 3 WD45`s,gas, diesel and LP,U,D10 series III, D12,D14,D15 SERIES II,D17 Series IV in Gas and Diesel ,D19 GAS and D21,170 185,210 ,220 an I-600 8070 fwd, 716H and 1920H

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DSeries4 wrote:

DSeries4 wrote: