Structures 1964 Allis D15 Series II

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=82702

Printed Date: 30 Jan 2026 at 8:44am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Structures 1964 Allis D15 Series II

Posted By: structures

Subject: Structures 1964 Allis D15 Series II

Date Posted: 04 Jan 2014 at 10:02am

|

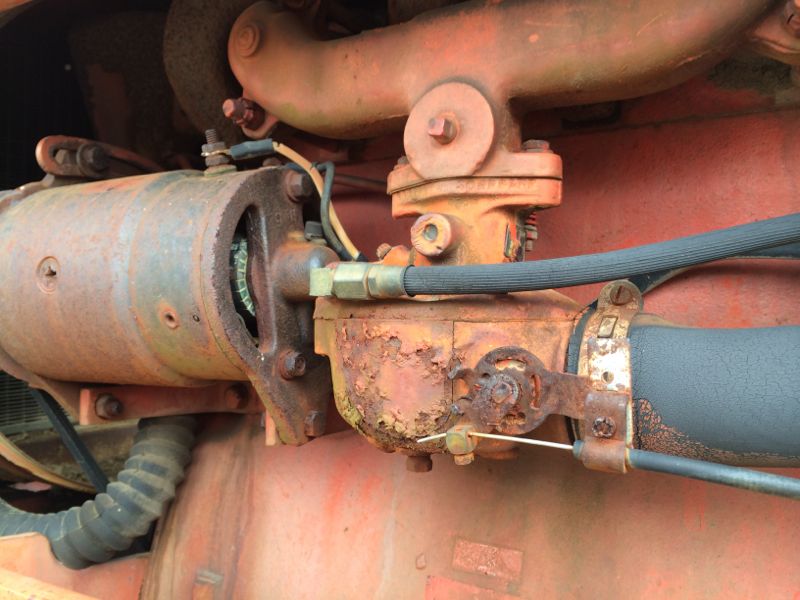

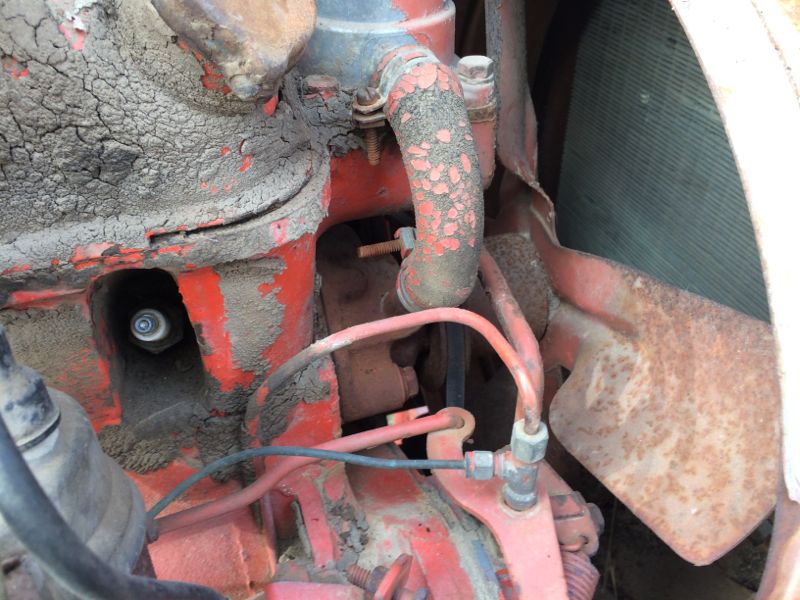

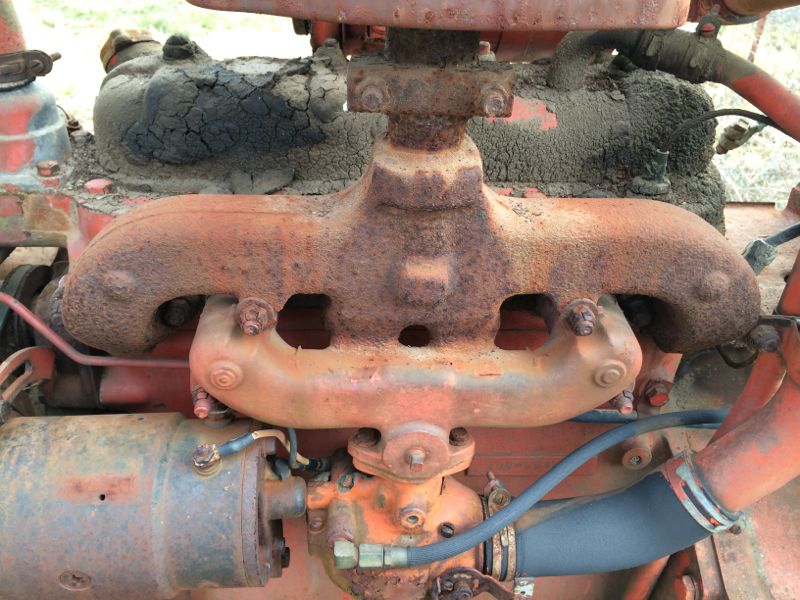

Hello, I am planning to get my dad's old D15 tractor running. Hopefully... It has been parked in his pasture for who know's how long. It's pretty rough b/c he has robbed parts from it over the years for other equipment. The carb a marvel schebler tsx869, has a cracked bowl. The tires had fluid in them originally so the rims are no good. The crank is stuck (not the first time I've dealt with that on equipment). Everything has oil in it which is a plus. However I didn't see any fluid in the radiator... Here's some pics from the other day. If you guys have any advise or comments I'd appreciate it! Thanks Robert.                    Power steering  |

Replies:

Posted By: tiger27

Date Posted: 04 Jan 2014 at 10:04am

|

Good thing you took before pics.. cant wait to see the After....pics good luck |

Posted By: DSeries4

Date Posted: 04 Jan 2014 at 10:59am

|

I've seen worse. I'm sure you can save it. Rust free fenders are a big plus and it's not too beaten up. Take your time freeing up the engine. Those rear rims don't look too bad, just weld in some fresh metal where it has rotten away (remove tires first!). Do you know why he parked it? Does he know something about it that you don't? Good luck with it! ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Eldon (WA)

Date Posted: 04 Jan 2014 at 11:00am

|

It doesn't look too bad...do you know why it was parked? A low houred Series II is definitely worth saving. Good Luck! ------------- ALLIS EXPRESS! This year: |

Posted By: omahagreg

Date Posted: 04 Jan 2014 at 11:03am

|

A little duck tape should fix it right up! LOL ------------- Greg Kroeker 1950 WD with wide front and Freeman trip loader |

Posted By: FloydKS

Date Posted: 04 Jan 2014 at 11:10am

|

Not as bad as you describe...cept that front rim, as has been said take your time and we will looking at those after pics. ------------- Holding a grudge is like taking poison and expecting the other person to die |

Posted By: Austin(WI)

Date Posted: 04 Jan 2014 at 11:18am

|

Bring her back to life, and don't forget to show your AC friends on here! :D

------------- "Better By Design" |

Posted By: Dipstick In

Date Posted: 04 Jan 2014 at 1:31pm

|

It's your Dad's tractor! It is worth EXACTLY how much you are willing to put into it, and don't let ANYBODY tell you different!!!!!!!

I have my Dad's 37 WC that he bought new, (traded a Farmall F12 in) and it really is a basket case, because I took it apart 10 or more years ago, realized I didn't have the talent or "know how" then and have since been learning. I've done several since for practice, A 1950 WD, 1940 Farmall H, and a 1951 MM Z, plus some other resto's, and miscellaneous painting. My goal is to have this tractor running by fair time this summer, and I will. I have about 10 son's, sons-in-law, grandsons, buddies, like Eric Clark, and his 2 sons,and my other brother, Darrell for a backup team. I wish you well, and I know it will be a lesson in love for you! By the time you are done, you will have connected with your Dad in unimaginable ways! ------------- You don't really have to be smart if you know who is! |

Posted By: structures

Date Posted: 04 Jan 2014 at 2:34pm

|

Man you guys are full of encouragement! I've had good luck freeing up seized engines. This one seems a little tricky b/c there's no real good way to get ahold of the crank how it sits now. I'll definitely keep you up to date. I'm going to try and splice some sections of rim at first. They're 13x26 which appears to be not so common. The left is pretty bad and the right doesn't look too bad. I have scrap rim off a d17 which I might be able to cut up and use. A little more to the story. My dad was a farmer from ohhh 1960ish to roughly 1988. He bought a lot of equipment in the 60s, much he still uses today. (Allis D17, 190xt). He was pretty notorious for just parking his equipment. You know I've never asked him why he stopped using it. I think it started when he pulled the hub off the front to use on his d17.

|

Posted By: tiger27

Date Posted: 04 Jan 2014 at 2:49pm

|

I skimmed over ..it was Dads tractor..Dip is right..they only make one Dad ..and he bought the right tractor. . Priceless. ..for sure fix it..and have a parade tractor.... |

Posted By: wood

Date Posted: 04 Jan 2014 at 3:41pm

| I like it, good project. |

Posted By: TREVMAN

Date Posted: 04 Jan 2014 at 3:47pm

| Ive started with way worse, definitely saveable in my opinion, will make a really nice tractor restored, Trev. |

Posted By: John Ontario Canada

Date Posted: 04 Jan 2014 at 4:52pm

| Awesome my brother still has my Dads original series 2 on farm. Great tractor 8500 hours and still Purrigggggggg. Bring yours back. John |

Posted By: lowell66dart

Date Posted: 04 Jan 2014 at 5:11pm

|

Wish I could find my Dad's Allis. Oh yeah, you have my vote for taking great pics. ------------- AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear. |

Posted By: DiyDave

Date Posted: 04 Jan 2014 at 6:00pm

| Drop the pan, jack against a rod that's on the way up, pull the plugs, oil the cyls with your favorite penetrating oil. Pull the valve cover and check the freeze plugs in the head. You're on your way, found the right site for advise. |

Posted By: Froggieo

Date Posted: 04 Jan 2014 at 6:35pm

| I bought Grandpas 1937 WC, it was rusted and had a cracked block. I gave $1,000 which was too much but it was Grandpas and I wanted it. |

Posted By: Josh Day

Date Posted: 04 Jan 2014 at 7:04pm

|

Like Dip and tiger said, only one dads tractor. Good luck! ------------- AC's 75' 7040, 64' D-17S4, 55'WD-45, 54' WD-45, 53' WD-45, 53' WD, 52' CA, 36' WC. IH 656. Deere's 38' A, and 47' A |

Posted By: JayIN

Date Posted: 05 Jan 2014 at 12:13pm

|

D17 should have 28" rim. D15 26". I had a 15II. I put Combine tires and wheels on it. A GREAT TRACTOR! I want another one. ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: BV

Date Posted: 05 Jan 2014 at 3:20pm

| Get her running I have 2 of the Series II 15's and they are handy little tractors, I also like D-10 's and the CA's. |

Posted By: TimNearFortWorth

Date Posted: 06 Jan 2014 at 9:37am

|

I would first have a good chat with your dad concerning why he really parked it, then seriously consider rebuilding the engine. Was it a gear jumper, and how bad? If it has sat outside for years, I would not be inclined to "soak" it and try to pull it around in an attempt to break it free.

Open air cleaner housing, cracked carb, questionable anti-freeze and mud dobbers gettin into every nook and cranny (can relate as we deal with them in N. TX) ..........

160 engines take a tad bit more funds for a proper rebuild when compared to a 138/149 engine but you will be glad you did as the risk of tearing up parts like connecting rods at a minimum by forcing it will hit your wallet even harder.

I have three SII units and love them; a factory 3-pt. with 6 bolt fronts and factory spool valves, a gas SC and a propane SC and they are a great size unit in the 46-47hp range.

Just wish they had two-way hydraulics and the lower pressure system but hey, plenty of WD/WD45 attachments still out there and they are great behind the D15II. Love mine on the SC blades as you can do plenty of work with it.

That factory top link bracket is getting a bit rare and it looks like yours can be straightened, plus it has been quite some time since I have seen such a nice original battery tray on any D15 Series. If you pull the engine, address the PS fittings as you will wish you did once you get her back running; most leaked and it is near impossible to access the fittings unless you pull the front bolster and remove the engine side rails.

Ray's Allis Parts in Beattie, KS (785-353-2392) always seems to have plenty of D-Series parts and he has helped me with numerous goodies for mine so parts are out there.

Good units and still my favorite A-C.

|

Posted By: structures

Date Posted: 12 Jan 2014 at 10:04am

Guys thanks for the comments. It's appreciated. Right now I'm just trying to get it running. I soaked the cylinders in pb blaster yesterday and put a spanner wrench on the front pulley with no luck. I did get some parts off for cleaning. The tank actually didn't look too bad. Although it was full of varnish. The air cleaner on the other hand I'm having trouble with. I broke the ears off the wing nut for the paper element, so I guess I'll be trying something else.

fuel gauge wasn't too bad. Need to clean it up.  Here's a shot in the tank from the fuel gauge hole. A little piece of the cork stuck in the varnish when I pulled the gauge out  The air cleaner is giving me some trouble. I threaded a bolt in the end for some leverage, but that just left me breaking the wing nut! ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JayIN

Date Posted: 12 Jan 2014 at 10:31am

|

Interesting,,......... keep it up! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: Sugarmaker

Date Posted: 12 Jan 2014 at 11:14am

|

Structures, I dont post here much but your D15 project tractor caught my attention. Nice if you can still talk to your Dad about this tractor. I always liked the look of these D series tractors. Relative of mine had the D17 version. And I recently drooled over a D14 narrow front end tractor close by with a disassembled engine. Owner wants $1000 for it. Anyway I think these family tractors are great projects. I currently have my dad's WD in the garage torn down to the engine and castings. Not planning to rebuild the engine as it ran very well and was owned and overhauled by my Uncle for 30 years. I hope your restoration work goes well on the D15. Very nice looking tractor. You have taken good pictures as you started into this. Keep up the good work. Regards, Chris |

Posted By: DaveKamp

Date Posted: 12 Jan 2014 at 11:52am

|

First of all- it's a project with family history, therefore, it has connected soul. Next, it's fairly complete, and doesn't appear to have any blazingly expensive-looking defects... i.e., I don't see any cracks in major castings. Cracked float bowl suggests that moisture may have gotten into the carb and froze it. That muffler type has a weakness, in that the upper side can rot through and allow rain to funnel into the engine, so you may be in for some hard work. I agree with Tim on this one- personally would NOT bother putting a wrench on the crank or soaking this one, because removal of the engine inevitably within the progress path of that tractor... it WILL happen, because you need to get into everything else as well. If you bite the bullet NOW, it will save you substantial heartache later. I'd get the tractor into the shop, on stands, pull it down, and as you do, make a first-check assessment of each component, and take good notes. Get the engine out, yank the head and pan, and figure out just how serious it is. Do same for clutch, power director, transmission, rearend, brakes, and final drives. There's gonna be water, oil glop, and plenty of mice and mud-wasp mess to clear out. Once you have it torn down, make a list of every part that needs to be replaced, and every component that needs to be refurbished, then methodically go through each section. You may find that some serious housekeeping and some new gaskets and seals will help some things, and you may find elsewhere clues to the reason it was 'parked'. But that's not all- the act of being parked for one reason, often subjects your patient to other conditions and forces which can render the machine at-risk for future damage if proper attention isn't taken prior to running it again. Frequently, the unforseen problem turns out to be caused by extended damage that would have been averted if a thorough cleanout and inspection had been performed. Once you've had it open enough to check EVERYTHING out, you can determine the scope of what you'll have to invest (both time and money), and know what kinds of things you'll need to acquire. When searching for parts, it's best to carry a list of ALL that you need, because 1) find many of the parts you need at the same source, and 2) will save you trips later and 3) correct parts on hand, allow you to tackle three or four different facets of the project in a given allotment of shop time. You won't be stalled by the lack of 1 engine item, because you can apply your remaining shop time to say... reassembling the final drives. Once you have a good grasp for the whole machine, make your decision to either pursue, or just clean and slap it back together for future attention... whatever your economics holds. If you don't, what will most likley happen, is that an unforseen problem will bring progress to a halt, and force you to roll it back out into the field, and leave it lay in pieces.  ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: cottonpatch

Date Posted: 12 Jan 2014 at 5:15pm

|

I just did a 66 D15 II engine, full engine kit, magnaflux head and block, new cam bearings, head reworked with new valves, springs, keeper, oil pump rebuilt with new vanes and springs. Total parts and machine shop bill exceeded $2K. Rick in MO did the clutch, pressure plate and new throwout bearing => $220 shipped. I hope this may give you an idea of capital outlay. :) ------------- '52 CA, '61 D10 II, ‘61 D15, '66 D15II, '63 D17D III, ‘69 170, '73 185 Crop Hustler, '79 185, '79 7000, '77 7040 |

Posted By: DiyDave

Date Posted: 12 Jan 2014 at 5:29pm

| I'll add one thing. Take pictures of how it looks coming apart, and mark every component for order and direction, and take pics of the marks, too. Them cell phone cameras are mighty handy in the shop! |

Posted By: B26240

Date Posted: 12 Jan 2014 at 6:19pm

| The series II D15 is the one we all want in that size tractor !! plus it's your Dads -- WOW I'm with Dave Kamp and anyone else who says you should take the engine apart, yes 2K may seem like a lot of money but after you fix it right it will last your life time. When you get her all fixed from one end to the other you will have way more than it will sell for but thats the way this hobby goes. Keep us posted !! Mark |

Posted By: Walter(MO)

Date Posted: 12 Jan 2014 at 7:29pm

| When you get the tractor restored you probably will be looking at a new set of rubber. Two years ago I put new firestones on the fronts and new 14.9 x 26 Titans on the rear. Best investment I made because I feed two big bales every other day with my D15 II. |

Posted By: cottonpatch

Date Posted: 12 Jan 2014 at 8:45pm

|

Walter, I got the same setup on my 15 II, new titans on the rear and new firestones on the front. With the rubber and all we've done to her, I hate to admit what I have in that little tractor. She sure runs sweet now. ------------- '52 CA, '61 D10 II, ‘61 D15, '66 D15II, '63 D17D III, ‘69 170, '73 185 Crop Hustler, '79 185, '79 7000, '77 7040 |

Posted By: DSeries4

Date Posted: 12 Jan 2014 at 9:34pm

|

You mentioned difficulty getting the wing nut off the air cleaner. No wonder! I do not see any penetrating oil on there anywhere! For something sitting outside that long, you should be oiling the hell out of every nut and bolt. It will make your life much easier. Don't be in such a hurry to get that engine loose. Let the oil do its thing. When you see it dripping out the bottom of the engine, keep oiling it! I had to soak my D14 engine for over 3 months - that was just to take it apart (not try to get loose). ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: structures

Date Posted: 01 Feb 2014 at 9:04am

Took the radiator in and had it tested. It was good. The tank is still with the radiator shop trying to get the varnish out. I also met up with a fellow board member here who made me a deal on a carb, hub, axle, and front wheel. So I broke the hub down to rebuild and also was rebuilding the carb. I took the inspection plate off the bottom to find a nice rat's nest.  The original carb on the left and the replacement carb on the right both are a TSX-869.  Definitely some pressure on those floats.  Cleaned up the hub ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: structures

Date Posted: 01 Feb 2014 at 9:09am

Worked on the cleaner last night too. I got the nut off but twisted the supports up, so I started remaking them.   ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: sandman2234

Date Posted: 01 Feb 2014 at 9:26am

|

Take your time, don't force anything, and keep after it. As DaveKamp said, you can address several functions at a time, but don't get overwhelmed with the whole project. If you get in over your head, go back to just a single piece until you get that part done. When you get stuck on a part, add penetrating oil and move to something else. Nice project, great pictures, keep it up, we are all behind you for the long haul. David from jax ------------- A proud member of the Allis Express movement! Northeast Florida |

Posted By: JayIN

Date Posted: 01 Feb 2014 at 3:59pm

|

I am enjoying this! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: SHAMELESS

Date Posted: 01 Feb 2014 at 9:03pm

| you have a lot there, a lot more than what some people start with, that is a very do-able restoration! and like the others said...it's "family"! keep us posted and with pics, we all like seeing the pics of labor/love! |

Posted By: Sugarmaker

Date Posted: 02 Feb 2014 at 3:24pm

|

Structures, Keep up the good work. There are so many parts on these and at this stage some will need more attention than others. Looks like you enjoy the work your doing. You will probably meet a lot of new friends along the way as you get the spare parts you need to bring it back to working order. Thanks for posting the pictures too. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: structures

Date Posted: 08 Apr 2014 at 10:29pm

|

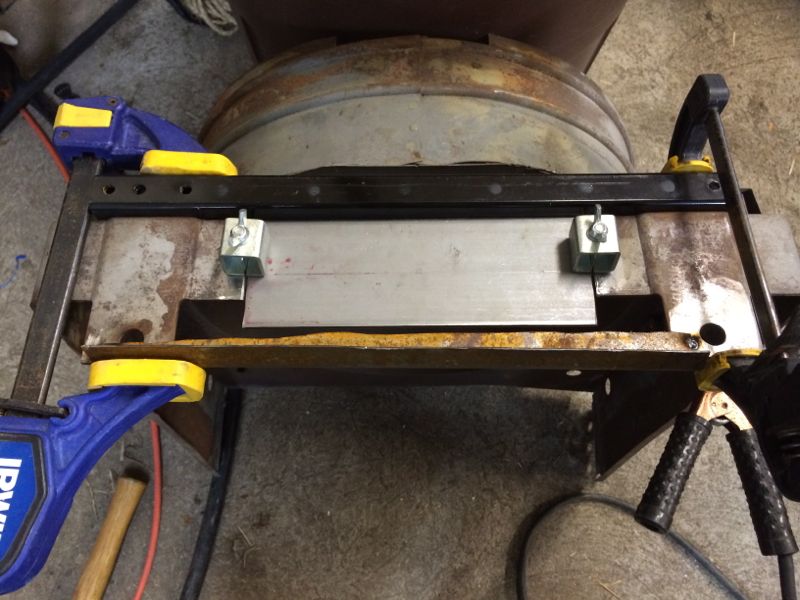

Working on a few areas. Trying to take the wheels apart but having a hard time with the eccentrics. I was able to remove the 8 carriage bolts that mount to the center wheel. Also able to remove a couple of snap rings from the back side but I can't seem to get much else to budge. I used a drift punch from the back side to try and drive the shaft out or at least free something up. Also a large break over on the hex bolt but nothing.   The snap rings aren't too hard to remove. 2 screw drivers. I use 1 to wedge one half the snap ring and the other to work the other half over the pin. The 8 carriage bolts have been removed but I snapped the picture before hand. Also had the radiator disassembled so I could do some work on it. The lower part of the frame was pretty heavily rusted. I spliced in a new section of the frame and bent up a new lower mount bracket too.         ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Rltool

Date Posted: 09 Apr 2014 at 5:32am

|

I just found this post. Great restore project! Your doing a great job fabing up parts. When your done you won't regret taking the extra time to do things right. I'm currently finishing up a WD project. If the eccentrics are like the WDs. Some people have suggested putting them in a vise and using heat on the casting. Might try an air hammer on pins. That has worked well for me. Lots of penetrating oil & air to get "any" loose debris out of there. Keep up the good work. Great post. Ray W. |

Posted By: structures

Date Posted: 13 Apr 2014 at 9:05am

|

Thanks Ray. Had success with the eccentrics (thanks to some helpful posts!). Used a sledge hammer and a block of wood on the wheel center's edge. One smack and rotate to opposite corners (in between the eccentrics). Didn't take too much swing either. Also didn't damage the center. I was able to press the cam bolts out of the castings too. Two gave me a lot of trouble. A torch probably would have been helpful here but I don't have one.   Got 4 of these rims. Hopefully I can make at least two when I'm done.    ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: DiyDave

Date Posted: 13 Apr 2014 at 7:36pm

| apply neversieze compound to 'em, now that you have the eccentrics free... |

Posted By: structures

Date Posted: 17 Apr 2014 at 6:33pm

|

Good idea Dave thanks. I shot the radiator frame with epoxy primer and then dropped the radiator assy off at the rad shop to have it cleaned and reassembled.  ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JOHN N/IL

Date Posted: 17 Apr 2014 at 8:08pm

|

Great job Robert that is some nice work your doing there,yoy will have a super nice 15 when your done,thanks for all the nice photos,good luck,i just got off of my 1511 loading 6 loads of manure,besides the odor I just love this tractor.Keep up the great work and it will be done in no time.John ------------- D-15IIG65,D-17IVG67,D-17D58,620 |

Posted By: JOHN N/IL

Date Posted: 17 Apr 2014 at 8:10pm

|

I forgot to ask are you using a sandblaster to get the old crap off or what,sure came out nice on the shroud. ------------- D-15IIG65,D-17IVG67,D-17D58,620 |

Posted By: structures

Date Posted: 18 Apr 2014 at 9:30pm

|

Thanks. I have a 40x40 econoline cabinet I picked up from a shop going out of business some years back. I use alum oxide.

I'm hoping to put a loader on it one day as well.

------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: structures

Date Posted: 21 Jul 2014 at 8:11am

|

Bad news on the radiator. I guess all the heat from taking it apart and putting it back together broke out some weak points in the core. The radiator shop tested it last week before putting it back together and it had a lot of pin holes in it. I've seen some new radiators listed online so I'll probably go that route. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: DSeries4

Date Posted: 21 Jul 2014 at 9:36pm

|

I think at lot of the new rads are made overseas and are not very good quality. Your rad shop should be able to recore it for you. That is the path I would take.

------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: structures

Date Posted: 21 Jul 2014 at 9:48pm

|

Yeah. I was going to have it recored. He thought he'd have $400 in it, and figured I'd better get a new one... I don't know. Maybe I'll take it somewhere else. It's pretty rough. I wish I could find out more about the new ones. I asked a seller. They said the new ones have copper cores... ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: desertjoe

Date Posted: 21 Jul 2014 at 10:24pm

|

Hey TimNearFortWorth,,,I sure would like to see pics of your Series II LP,,,,? |

Posted By: desertjoe

Date Posted: 21 Jul 2014 at 10:42pm

|

Hey Structures,,,I'm goin to be following your project also..looking good,,. I have a D15 II LP and working on it as much as the hot weather will let me,,,,. I am close to being ready to paint the tin, hopefully in a week or so. On your radiator, are you wanting to stay original? |

Posted By: structures

Date Posted: 22 Jul 2014 at 7:55am

|

definitely want to stay original. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: structures

Date Posted: 25 Aug 2014 at 9:13am

|

Good morning a little update. Picked up a radiator. It's fairly close to the original. Same overall dimensions, copper, looks like it has some additional mounting nuts, probably for other years. Tanks are little different. Also worked on an already pretty good rim. It was a mix between sandblasting and electrolysis. I'd recommend electrolysis first and then sand blast the rim. By the time the rim was in the bath for 24 hours the heavy rust was gone and the remaining rust just brushed off. This is my 80 gallon pool I made. Set the miter saw to 22.5 degrees and start cutting short pieces. It's roughly 32" wide. I used a 4 mil plastic drop cloth. 80 gallons water with about 4 cups washing soda (sodium carbonate). Their is (6) 3/8" to 1/2 Dia rebar sticks around the perimeter and 2 in the middle. The rebar is wired together with copper wire. The electrolysis is definitely line of sight so the rust has to "see" the rebar anodes. Hook up the neg to the rim and the positive to the anode rebar. My 12 volt battery charger was showing almost 10 amps. This is my second rim. I doubled my rebar count and it boosted my amp draw. 24 hours later! The rust can be wire brushed off pretty easily. I chose to throw it in the blast cabinet. I used por 15 on the outside of the rim. Marine clean, metal ready (with a wash down), and 2 coats por 15. I brushed this on. It's actually not too bad looking. It has brush strokes at first but they thin out before it dries. The 2nd coat went on about 2 hours after the first. For the inside of the rim I used PPG epoxy primer. I missed pictures of the body work. The rim was pretty rough by the valve stem. I welded in a little patch and used evercoat to fill the pits. I thought I took pics of that but I guess I didn't.

------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: DSeries4

Date Posted: 25 Aug 2014 at 10:28pm

|

You are making great progress. But that new rad appears to have a shorter tank to me. Neck height looks the same, but a shorter tank could cause big trouble when trying to fit the sheet metal.

------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: structures

Date Posted: 30 Nov 2014 at 11:02pm

|

Did a little work this evening. Started cutting on another rim. Should clean up pretty well. It was 65deg F when I started cutting by dusk it was 45deg F!

thanks man! I think the new radiator looks short because the other one is not fully seated in its frame. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JohnCO

Date Posted: 01 Dec 2014 at 2:20am

|

Getting there! Looks good so far. It was in the 50's at 7:30 Sunday morning, 20's by 9am. You might be getting a bit colder before you get warmer. ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: Sugarmaker

Date Posted: 02 Dec 2014 at 10:19am

|

Nice work on the rims, and rad re-build too. The 15 is coming along! Similar work as I did on a WD this summer. Your doing a good job! No easy way to do this stuff unless you buy new or have someone else do the work:) I did find a trick to get those pesky snap rings off the pins in the eccentrics. I tried the two screwdrivers with limited success. I started a drywall screw right at the joint of the snap ring. Allowed it to travel a little side ways and it pulled the snap ring out enough that a screwdriver could snap it off. (this was on new snap rings that I have to remove to coat with never seize:)) Maybe this will spur me to get back on the WD project! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DanC911

Date Posted: 02 Dec 2014 at 12:06pm

|

I just dumped too much money and time into a Cub Cadet that was my dads. Using it brings back great memories of working with him. Well worth the investment. Take your time and do it right and you will have a memorial to your father that you can use every day. Good luck ------------- 1950 WD, 1955 B, 66 Jacobsen Chief-O-Matic, 68 Simplicity 2110, 77 IH Cub Cadet 1450 w/front loader |

Posted By: Sugarmaker

Date Posted: 02 Dec 2014 at 2:05pm

Dan, Did the same on a 147 Cub Cadet a couple years ago. I think they might cost as much as a big tractor to restore:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Steve Wilkens

Date Posted: 02 Dec 2014 at 5:29pm

| Like all the guys said, it is family, you can save her. Do talk to dad and ask why it was parked, might save you a lot of time. An old trick for freeing stuck engines. Block up a rear wheel and fasten a 2x4 to it so that the long end is as high as you can comfortably hang weights. Soak the cylinders with brake fluid and go about your business. When you notice the weights on the ground the engine is free. |

Posted By: Steve Wilkens

Date Posted: 02 Dec 2014 at 5:29pm

| oh, be sure to pull the plugs out |

Posted By: WD45

Date Posted: 02 Dec 2014 at 7:24pm

|

Recommend taking the head off then soak each cylinder. (used diesel and paint thinner 50/50) .Check the head that all valves are free. Put the tractor in gear and rock it back and forth to get engine to turn over. Good luck. Have freed up a three Allis engines. ------------- Fred Dunlop, G,B,CA, WC,WF, 3 WD45`s,gas, diesel and LP,U,D10 series III, D12,D14,D15 SERIES II,D17 Series IV in Gas and Diesel ,D19 GAS and D21,170 185,210 ,220 an I-600 8070 fwd, 716H and 1920H |

Posted By: EricPA

Date Posted: 02 Dec 2014 at 8:05pm

|

very nice

------------- Life is tough,but it's tougher when you're stupid. - John Wayne |

Posted By: structures

Date Posted: 07 Dec 2014 at 10:03am

|

Guys appreciate the comments! Thank you. Was able to get the patches in.  ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Fourced

Date Posted: 07 Dec 2014 at 11:24am

|

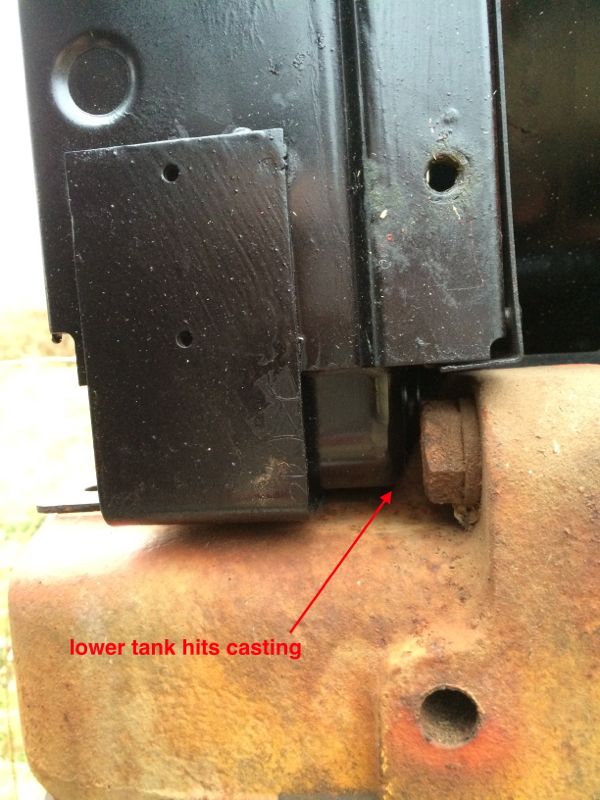

Double check the bottom tank on that radiator, I bought an aftermarket and the bottom tank was about 1" thicker front to back than the Stock one. The mounting holes won't line up because the tank hits. |

Posted By: Clay

Date Posted: 07 Dec 2014 at 12:36pm

|

Looks very good. I would suggest grit blasting the rough areas and applying some good quality epoxy to smooth out any low spots. After the epoxy has set, sand blast the entire wheel. Prime and paint. |

Posted By: structures

Date Posted: 07 Dec 2014 at 11:08pm

Yeah you're right. The tank is hitting the power steering casting. I might be able to work the tank in to clear the casting though.     ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JGAnderson

Date Posted: 08 Dec 2014 at 3:53am

|

Nice project... I woke up my dads series ii D15 just this fall. Had sat in a pole barn for the last 5 or 6 years at least. Going to use it to push snow this winter, then start tearing it down this next spring. I am taking plenty of notes on what you're doing! ------------- 63 D-15 series ii |

Posted By: DiyDave

Date Posted: 08 Dec 2014 at 4:58am

| Simple solution might be to grind some off the casting where it hits the tank. I re-used the tanks on my original, just had it re-cored, to avoid this problem. Still cost about $450... |

Posted By: Fourced

Date Posted: 08 Dec 2014 at 11:31am

|

I got mine from Reliable Aftermarket Parts INC on E-bay. I am now fighting with them because they will not refund $60 in shipping charges, the auction says it will fit, it won't. I don't think that is my fault.(rant over) I returned it because the hood would not fit correctly with everything stretched out to fit the bottom tank. |

Posted By: structures

Date Posted: 09 Dec 2014 at 9:55pm

Trying to do a little bit each night. weld, grind, grind, grind... weld, grind, grind, grind...  I had pretty good penetration with the backside welds but I went ahead and welded the inner side of the rim patches. Trying to not use any filler.   ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JayIN

Date Posted: 10 Dec 2014 at 4:45am

|

Nice! Its not that hard to fix the wheels. The hardest part is just getting started. You are saving my favorite tractor. Wish Ida kept mine! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: structures

Date Posted: 01 Jan 2015 at 10:41pm

Had some time off for the holidays and spent a little time sand blasting and I also dipped a rim in an electrolysis bath. It helps cut down on the sandblasting time. Hopefully I'll put some paint down soon. The first pic shows where I hammered a flat into the repaired rear rim for the schrader valve.    ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Sugarmaker

Date Posted: 02 Jan 2015 at 8:05am

|

Robert, Found this thread again! Sorry I have been busy. I think your coming up on a one year anniversary? Your doing a good job on your Dads tractor restoration! All your fabrication work looks good. (I like to fab things) I can say that these tractors are a lot of work. Use this forum to keep yourself motivated. Take lots of pictures and post them. Its a good break for you and helps show your progress! We are here for support! The folks on the Allis Forum really did help me a lot as I worked on the WD projects this past year too. Looks like your finding a lot of the same issues I had. The work on the rims looks very good. I also use a electrolysis tank/s. But did not have one big enough for the rear rims. So I had those blasted, then started the repairs. 6 rims to make 4:) Great that you have a sandblaster too! On that radiator fit issue. I think I would look at modifying the casting too. But before that, is there anything else that is going to be a issue? Old man Casbohm says "you change one thing and five other things may need changed"! One thing repaired/restored at a time and you will get there! That rear rim with the POR black looks awesome. I will remember that! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: structures

Date Posted: 02 Jan 2015 at 6:05pm

|

Hey Chris. Yeah 1year into it... Hope 2015 yields more progress! I'm gonna set the radiator issue aside until I get the tractor rolling on 4 wheels. That's true about changing one thing and creating more issues. I got a '65 Chevy truck I'm restoring wish I hadn't done so much customizing! ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Sugarmaker

Date Posted: 02 Jan 2015 at 6:09pm

|

Robert, I have enough trouble trying to get near stock. I applaud you for doing custom work. Post a picture of the truck too. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: structures

Date Posted: 02 Jan 2015 at 6:25pm

The truck is a long story. Lots of pics over here: http://67-72chevytrucks.com/vboard/showthread.php?t=374373" rel="nofollow - Structures 65 Chevy

Couldn't have said it better myself! ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: macvette

Date Posted: 03 Jan 2015 at 11:16pm

|

Robert - What a great job of picture taking and posting on your restoration. I just came upon this thread today, so was treated to a whole year of progress at one time. You do great work!

|

Posted By: structures

Date Posted: 04 Jan 2015 at 7:43pm

Thanks macvette Was able to lay some paint down last night and today. Been so cold I've left the heater in the garage on all night, and I'll have to continue through tonight $$$   ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Sugarmaker

Date Posted: 09 Jan 2015 at 6:34pm

|

Robert, The fresh paint looks great on the wheels and hubs! Hey I read your entire thread on your Chevy Truck restoration! Awesome! Dad had one very similar to yours. This tractor should be a piece of cake for you! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: structures

Date Posted: 11 Jan 2015 at 6:57pm

|

Thanks Chris. Folks got a little more done this weekend. Instead of brushing the por15 I sprayed it. Looked okay. Put some paint on one front wheel. I have another wheel on order. Last I dipped my eccentrics into an e-bath for tonight.    ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: darrel in ND

Date Posted: 11 Jan 2015 at 7:18pm

| Good progress. Seems like once some new paint gets laid on, the pace picks up. Stuff starts to look new then, and generates some enthusiasm. Darrel |

Posted By: structures

Date Posted: 14 Jan 2015 at 1:13pm

|

Blasted the eccentric fittings and pins. Some of the pins are pretty bad, but I think I'll go ahead and use them. If they break I'll replace them.

Very true. Thanks! ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: DiyDave

Date Posted: 14 Jan 2015 at 5:50pm

| Fill the pits with some epoxy, worst thing that could happen, is to have to remove them and replace them... |

Posted By: Sugarmaker

Date Posted: 14 Jan 2015 at 7:03pm

|

Robert, I need to bring my e-tank inside. Its a solid block of ice. I could be using it. I ended up wire brushing my wheel brackets and pins. What I did on those eccentric pins that are pitted is to grind the rough areas smooth so that when rotated they don't bind. We are working on some of the same stuff:) I just got my WD rims together. Did you get new "C" snap rings? Your cream looks very good. I just tossed a front rim in the truck yesterday that needs the tire removed, blasted and the valve stem hole repaired. Looks like your ready for new rubber. Keep the pictures coming. Agreed that some fresh paint helps keep the interest level up, and can keep you going. Assuming the pocket book can keep up:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: structures

Date Posted: 15 Jan 2015 at 8:12am

Yeah kinda what I was thinking. Thanks.

I'm not having much luck with the e-tank at 30 deg F. The soda is not mixing well and I think the cold is slowing the process down. It definitely works, just not as well as I'm used to. I'm trying to keep up with your progress, you got 2 builds going on! I don't have new snap rings, but I seen your post about picking them up from the parts store. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Sugarmaker

Date Posted: 15 Jan 2015 at 8:24am

|

Robert, Check your connections, scrape the plates in the tank, and recharge the tank with some more washing soda. I have had good luck even in cold weather before. I never had very good luck doing much more than 1 piece at a time, Not sure why, maybe just surface area. Sandy Lake had new clips. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: j.w.freck

Date Posted: 15 Jan 2015 at 7:48pm

|

dave has it all straight and level.tractor overall looks not too bad.on my 700 dollar wd-45 diesel,things looked like a good parts tractor.but as it turned out.it was a diamond in the rough,has won me several.first place pulling titles,and all systems worked.it set in the woods near dubac la.for 9 years.its amazing what a little tlc can yield you..... |

Posted By: structures

Date Posted: 08 Mar 2015 at 1:25pm

|

I painted some more on the wheels. Should be ready for rubber now. I did buy a new front wheel and I'm going to paint the center because the white it came with is darker than the white I have. I also have been playing with plating. I'm putting a zinc plate on the eccentrics to help with the areas I wasn't going to paint. Turned out okay. Should provide some good protection, I think.    ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: JayIN

Date Posted: 08 Mar 2015 at 2:24pm

|

Interesting. Keep up the good work on what is my favorite tractor! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: rasman57

Date Posted: 08 Mar 2015 at 7:48pm

| Great work! Love watching your progress. |

Posted By: Sugarmaker

Date Posted: 08 Mar 2015 at 8:09pm

|

The rims looks real good! Nice work. What is the plating process? Zinc? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: michaelwis

Date Posted: 08 Mar 2015 at 8:15pm

|

Being the proud owner of D15 series 2 my DAD purchased new , I agree with all the above , ours has 6000 plus hours , but has never left the farm Priceless, now if I could find our 190 XT, and 7040....... ------------- WD WD45 DIESEL D 14 D-15 SERIES 2 190XT TERRA TIGER ac allcrop 60 GLEANER F 6060 7040.and attachments for all Proud to be an active farmer |

Posted By: structures

Date Posted: 09 Mar 2015 at 7:53am

|

Thanks guys appreciate it. Chris the process is zinc. I bought most of the stuff from Caswell Inc. I did have to buy other stuff (like heaters, rectifier). I thought it was worth it to me as I have a lot of old hardware I want to restore. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: wfmurray

Date Posted: 09 Mar 2015 at 11:38am

| Got my dads D/14 and don,t see but one reason to not restore it is that you cannot afford it. Then sell to some one that wants to restore it and you can see it off and on. |

Posted By: structures

Date Posted: 19 Mar 2015 at 11:03am

|

Good morning. I'm getting closer to getting the 15 rolling again. May be a bit before it's under its own power though.  These are 14.9-26 BKT TR-135 on the rear and 6.50-16 deestone on the front. Nothing fancy (well they were expensive though...). We'll see how they do.

My plan is to put the D15 to work. I had been looking to get a tractor and my dad offered this one up so I jumped on it. I just figured that I was going to put money into a newer tractor why not put that into something I already have. Plus I just enjoy fixing stuff. ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: structures

Date Posted: 23 Mar 2015 at 8:01am

Still trying out this zinc plating. I've been toying with parts that I plan on painting over mostly so they don't look the best, but the protection is there.  ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: structures

Date Posted: 30 Mar 2015 at 8:18am

Got a little painting done this weekend.  ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Gary

Date Posted: 30 Mar 2015 at 8:32am

|

Oh no, not black !! Power Shift lock assm. should be all Cream. See attached Allis Brochure. Gary http://www.ebay.ca/itm/original-ALLIS-CHALMERS-D15-D-15-Tractor-sales-Brochure-Catalog-24-pages-/361173245765?pt=LH_DefaultDomain_0&hash=item54179a5f45 |

Posted By: structures

Date Posted: 30 Mar 2015 at 8:44am

|

That's primer bud. See 2nd pic for cream. By the way I have that brochure. Refer to it all the time. Thanks! ------------- Robert http://www.allischalmers.com/forum/forum_posts.asp?TID=82702&KW=structures&title=structures-1964-allis-d15-series-ii" rel="nofollow - 1964 D15 Series II |

Posted By: Kansas99

Date Posted: 30 Mar 2015 at 9:04am

Looking good.

|

Posted By: aras

Date Posted: 30 Mar 2015 at 9:59am

| What do you think is the secret to a good plating finish? I assume the first pic is the parts after a plating attempt? |

DSeries4 wrote:

DSeries4 wrote: