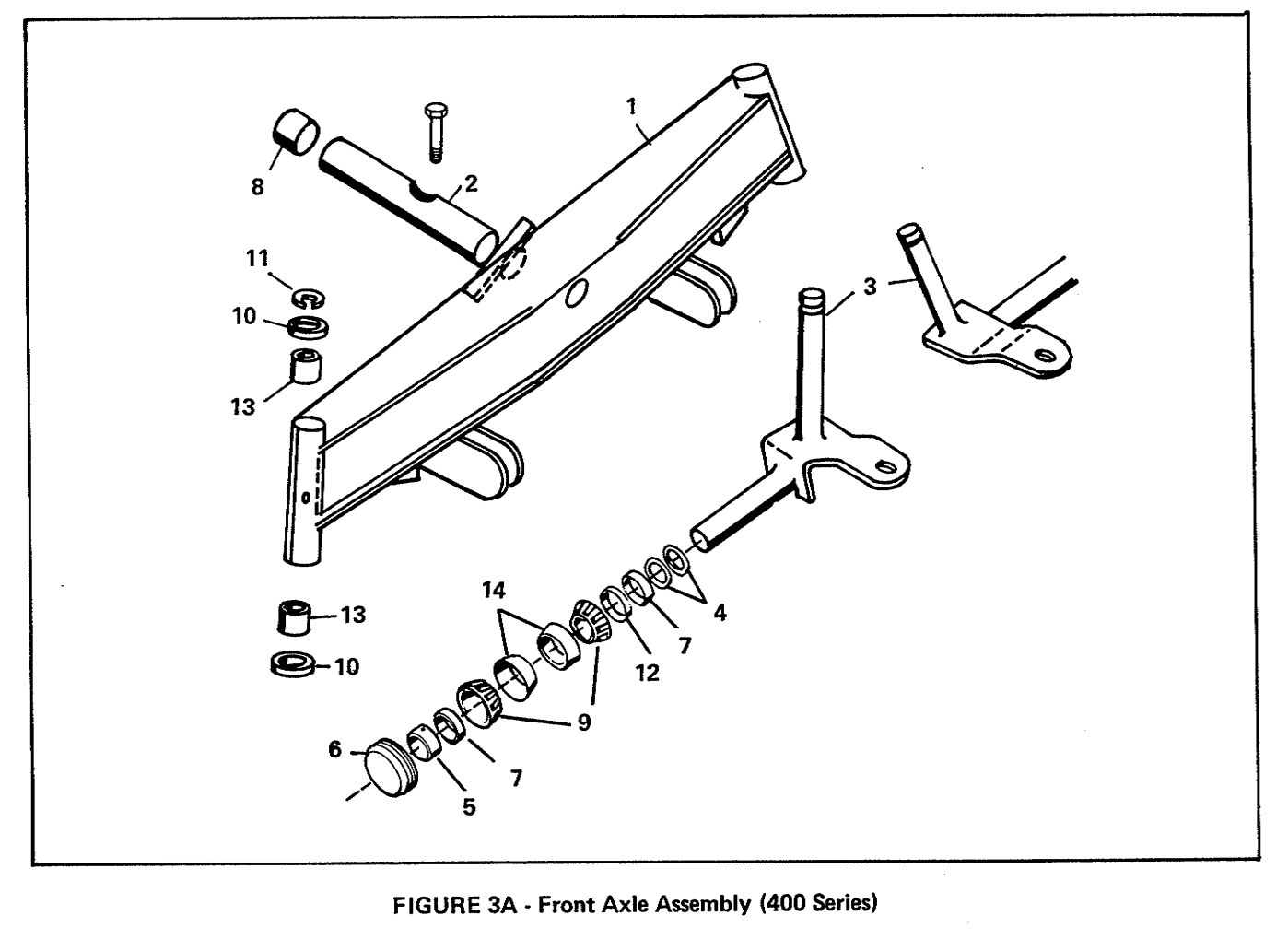

KH, That's pretty much as straight forward as it gets.

Unscrew the set screw to slide the collar off and you "should" be able to slide the whole assembly right off the spindle.

It all should come off by hand pulling if it's been lubed any at all over the years.

The inside seal may or may not come, but that's not a biggie to remove neither - just gently pull on it unless you're going to replace it.

I would while it's taken down that far.

While apart, clean and inspect the spindle for any burrs and fine emery strip sand them down smooth for easy sliding back on.

Going back on "shouldn't" take any special tools or a hammer.

Just grease everything as you go back together.

With wheel and spindle in the air, push the collar on far enough to push and hold the outer bearing in it's race to remove any play and tighten down the set screw.

Spin the wheel for free wheeling to a gradual stop due to loss of momentum vs. a faster stop from being too tight.

If you have play, just push the collar and bearing into the race until the play is gone.

You don't want the collar to come loose to let bearing become loose in the race.

Edited by Jim Hancock - 01 May 2018 at 11:36am

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)