| Author |

Topic Search Topic Search  Topic Options Topic Options

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: my new HD6 Topic: my new HD6

Posted: 04 May 2020 at 6:39pm |

Folks....

Came across a local crawler loader. I have a JD40C, two D4s I need to combine into one and this was priced right. Fires on ether and the guy said he used it last year but it seems to only work for a minute after priming it. So it sat and now he is cleaning up. Undercarriage looks to be very good. No welds on it at all. Found the injector manual but if anyone has any other manuals....operations and or repair in PDF please do let me know. Will try and diagnose the injector issues and worst case I have a nice 4-71 to swap in! Looks to be an SAE2 bellhousing and same as my 4-71.

Krusty

|

|

|

Sponsored Links

|

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2020 at 7:15pm Posted: 04 May 2020 at 7:15pm |

|

Basic 344 Buda Lanova style engine, later model strictly Allis in this one as has the Heavy "V" Lift arm. Most likely stuck the injector plunger in the pump and once cranked is now broken, FEW to any will look into a PSB Pump anymore. Is a shut off valve bottom of tank Left Side. also has a plunger style lift pump on the injection pump and a manual shut off connection to left side of pump head which also could be stuck.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34372

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2020 at 10:10pm Posted: 04 May 2020 at 10:10pm |

Could be fuel filters plugged or line to tank.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

NomoreJohnDeere

Silver Level

Joined: 24 Jul 2017

Location: Missouri Ozarks

Points: 308

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 May 2020 at 10:23pm Posted: 04 May 2020 at 10:23pm |

|

|

|

HD3

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 May 2020 at 4:55am Posted: 05 May 2020 at 4:55am |

|

Cannot tell of rails but shoes are decent, seems to have decent bottom rollers, may be just something small failed. Also check tank for debris and STOP running on ether, is not good on these.

Edited by DMiller - 05 May 2020 at 4:56am

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 May 2020 at 5:39am Posted: 05 May 2020 at 5:39am |

|

You could disconnect the air filter he could be clog and disconnected the fuel line who is comming from fuel tank to the fuel filter if he has full fuel.

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 May 2020 at 7:42am Posted: 05 May 2020 at 7:42am |

Dont worry I do not like ether either. Will head back there tomorrow with some charged batteries and should be able to get the low pressure fuel system figured out pretty quick and ensure it is functional. Thanks for the tidbits, have been doing lots of reading on the forum and think I now understand the fuel path. Just out of curiosity where are the batteries located? I did not spend much time at the rear of the machine.

Anyone have a pdf of the PSB4 service manual?

Krusty

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 May 2020 at 8:19am Posted: 05 May 2020 at 8:19am |

> manual shut off connection to left side of pump head which also could be stuck

Do you have a pic of where this is located? Or are you saying the main fuel shutoff for the pump? For some reason I interpreted your comments meaning a less obvious shutoff.

Edited by krusty - 05 May 2020 at 9:55am

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 994

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 May 2020 at 4:22pm Posted: 05 May 2020 at 4:22pm |

|

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 4:43pm Posted: 06 May 2020 at 4:43pm |

I took a bucket of tools out to the machine today with some fresh batteries. I never actually turned it over when I went to see it. Just assumed what the guy said as he was brutally honest.

Put in the batteries and it fired right up and purred like a kitten for about 15 seconds. Then died. Went into debug mode:

-fuel in tank and valve open -fuel coming out of first filter without issue -fuel not coming out of fuel supply pump

So either:

-hose from first filter to fuel supply pump is collapsed or clogged -fuel supply pump is toast

I had the hose at the outlet disconnected and not much if any came out other than when I first cracked it open.

Is there some sort of check valve at the input side of the pump that could be stuck closed? I did not have a ratcheting screwdriver to get in there and take the pump cover off. Regular screwdriver was blocked by some of the chassis bits.

Could I use an electric lift pump to bypass the fuel input pump to confirm the rest works fine or does the plunger pump on the injectors need a min input PSI?

Krusty

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 5:01pm Posted: 06 May 2020 at 5:01pm |

DMiller wrote: DMiller wrote:

also has a plunger style lift pump on the injection pump and a manual shut off connection to left side of pump head which also could be stuck. |

Question on this and I am not doubting your knowledge....the manual available from jensales on the PSB pump states that it is a gear lift pump. I do not want to waste my $$ on their manual if it is not correct!

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 5:06pm Posted: 06 May 2020 at 5:06pm |

|

Electric pump would doubtfully provide proper feed, is seals are weak on old pump could flood crankcase. If it started and died would remove the primary filter element, the head is set up for Tank to primary, primary to lift pump, lift pump to secondary to inj pump. Is possible has a blocked primary filter.

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 5:21pm Posted: 06 May 2020 at 5:21pm |

DMiller wrote: DMiller wrote:

Electric pump would doubtfully provide proper feed, is seals are weak on old pump could flood crankcase. If it started and died would remove the primary filter element, the head is set up for Tank to primary, primary to lift pump, lift pump to secondary to inj pump. Is possible has a blocked primary filter.

|

Sorry I was not clear. Tank is above primary filter. I took the hose of at the outlet of the primary filter, the hose that goes to the input of the lift pump. Where I disconnected it, there was substantial flow via gravity from the fuel tank. Connected it again and this time took the hose off the output of the lift pump. There was a bit of fuel at first but nothing more. Turning the engine over did not provide any flow out the lift pump. Hence why I am wondering what could be blocking in there or if it is a plunger, broken etc.

There is no fuel in the engine oil.

I would have thought that there would have been some flow come out while engine cranking, but not a drop.

Edited by krusty - 06 May 2020 at 5:22pm

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 7:09pm Posted: 06 May 2020 at 7:09pm |

|

Line off at entry side(Front of engine) of the lift pump, fuel present? It is a gear type pump, cannot remember if has a debris screen in the inlet fitting, check valves are inside the body of the lift pump, where has to be removed to access.

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 7:25pm Posted: 06 May 2020 at 7:25pm |

DMiller wrote: DMiller wrote:

Line off at entry side(Front of engine) of the lift pump, fuel present? It is a gear type pump, cannot remember if has a debris screen in the inlet fitting, check valves are inside the body of the lift pump, where has to be removed to access. |

I will get it out of there tomorrow and see what is going on. Did not take the line off at the input of the pump as I may need to bring a stubby wrench or cut one down to fit on the fuel line fitting. Thx for the clarification on the gear pump. Something is constipated in there! That inlet fitting definately does something otherwise it would not be in the circuit. I have ordered the PSB manual and should get it this eve or tomorrow AM.

Thanks as always!

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34372

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2020 at 11:47pm Posted: 06 May 2020 at 11:47pm |

|

Krusty, sent you a pm.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2020 at 12:28pm Posted: 07 May 2020 at 12:28pm |

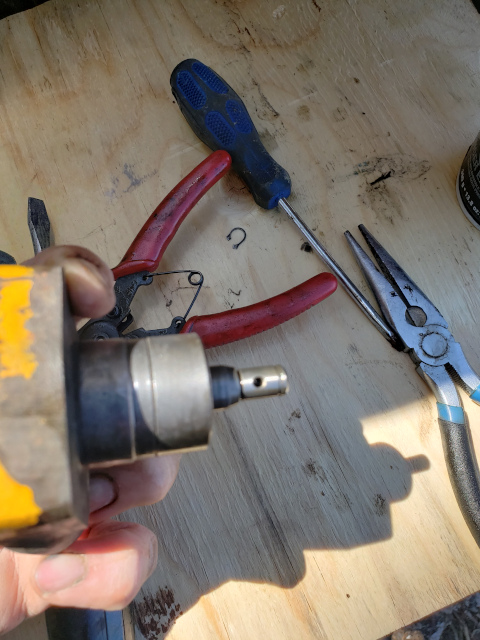

Thanks for all the tips....it is alive! Must have sat for a bit as the key between the fuel pump shaft and the gear wash sheared. It is like nothing I have ever seen before, the key that is, and very small. Slight oxidation locked up the non shaft pump gear and must have then broke the key. It was easy to free up. I pushed the remaining length of key through and stuffed hockey tape there to keep in in place temporarily. Took a bit to prime the injector lines......anyone know where I can get such a key? I know the machine needs one front idler bearing as he said it was starting to go, and will do that once it is home. Hopefully that will be it and then I can take it to the woods to do some real work!

[TUBE]sESdOvTRotM[/TUBE]

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2020 at 2:25pm Posted: 07 May 2020 at 2:25pm |

|

Be REALLY careful when disassemble the Idler, note where the shims are located, Try to NOT damage the seals as are made of Unobtanium and a specific design to Allis, bearings should be available any parts house by bearing numbers on them. If get on Minnpar web site they do stock SOME pieces yet for our machines. Measure your key stock, just purchase locally.

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2020 at 3:11pm Posted: 07 May 2020 at 3:11pm |

DMiller wrote: DMiller wrote:

Be REALLY careful when disassemble the Idler, note where the shims are located, Try to NOT damage the seals as are made of Unobtanium and a specific design to Allis, bearings should be available any parts house by bearing numbers on them. If get on Minnpar web site they do stock SOME pieces yet for our machines. Measure your key stock, just purchase locally. |

Unobtainium.....never heard of that before but like it!

The key is not a standard key of any sorts. The shaft only has a round hole perpendicular to the key, it does not have a parallel key groove in it. The gear has a standard key shaft. The key that was in there was a half thickness square key with a perpendicular rod sticking up. Should not take much to make another using a spring pin and square key milled half thick.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2020 at 5:33pm Posted: 07 May 2020 at 5:33pm |

|

Unobtanium, as in No Longer Manufactured regardless where look, Unobtainable.

Is there a Fuel Injection shop nearby? May have to check with them as to where to procure, Minnpar will not have that.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2020 at 5:42pm Posted: 07 May 2020 at 5:42pm |

|

May have to buy a complete transfer pump used, Try Hector Gemme(GEMDOZER) on here or General Gear in Boise ID.

|

|

NomoreJohnDeere

Silver Level

Joined: 24 Jul 2017

Location: Missouri Ozarks

Points: 308

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2020 at 8:40am Posted: 08 May 2020 at 8:40am |

|

sounds good

|

|

HD3

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2020 at 3:10pm Posted: 12 May 2020 at 3:10pm |

I put new filters on today as one was leaking badly at the gasket. The batteries did not have enough juice to get it bled and started up again. Will go back Th aft and get er done. Then I can have it hauled home.

I was looking at the track to see if there was some type of removable pin on the track so I can get at the front idler once it is home. Am I missing one or how does the track come apart? My little JD40C does have 1 removable pin in it.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54378

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2020 at 5:25pm Posted: 12 May 2020 at 5:25pm |

Most master pins are marked, somehow, usually a center punch in the center, or 2 flat ears...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2020 at 5:53pm Posted: 12 May 2020 at 5:53pm |

Master will have a dimple in the face, none of the others will, and will take a Pin Pusher designed for track work or a Twenty Pound Sledge with a Drift to get it out then back in. Been doing this for close to forty years.  The weld marks were from establishing my Helper now on the floor on the track link to Hold the Drift.

Edited by DMiller - 12 May 2020 at 5:55pm

|

|

krusty

Silver Level

Joined: 09 Jan 2012

Points: 60

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2020 at 7:52pm Posted: 12 May 2020 at 7:52pm |

|

Thanks! Is the 20 pound sledge something I should consider or just pay someone? I am rather stubborn so dont mind trying myself at least. Also have a 10 ton ram I could use, but the online videos show 100 ton rams. I assume it comes out towards the inside. When putting it back in, do you go from the inside to the outside? aka opposite?

|

|

HD6GTOM

Orange Level

Joined: 30 Nov 2009

Location: MADISON CO IA

Points: 6627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2020 at 10:54pm Posted: 12 May 2020 at 10:54pm |

|

Does it not have the ripper bar and counter weights on the rear. If not you might find it a little light on the rear? Look on line and find a original AC service Manuel and operator Manuel. I had these machines and found off brand Manuel's to be a pain in the butt. Pictures would be black, pages out of order or missing. Good luck with it. They are fun. I hope yours has the decelerator pedal. And you will be very busy with the hand clutch, hyd levers, etc. But once you get used to it it will be fun.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2020 at 6:30am Posted: 13 May 2020 at 6:30am |

|

Will need to be 40-60 ton to move pins if are not already loose from age, ten ton will just sit there. If have never swung a 20#, do not buy one and have a HE Mechanic with a Track pin press come take them off. Most small dealers will have a portable they can haul around but will cost you. These are NOT for the faint of heart or the aged as will flat wear you out.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2020 at 8:47am Posted: 13 May 2020 at 8:47am |

|

you can do it with a sledge if you have the fortitude but you need to buck the rail on the backside tightly so it doesnt bounce. ive had the pleasure of doing hd16 rail by hammer and driver. best driver is shaft welded to a long handle so helper can hold and be well out of way swinging sledge. even then you may need a little heat to expand the rail a touch and get it started.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34290

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2020 at 4:46pm Posted: 13 May 2020 at 4:46pm |

CAL(KS) wrote: CAL(KS) wrote:

you can do it with a sledge if you have the fortitude but you need to buck the rail on the backside tightly so it doesnt bounce. ive had the pleasure of doing hd16 rail by hammer and driver. best driver is shaft welded to a long handle so helper can hold and be well out of way swinging sledge. even then you may need a little heat to expand the rail a touch and get it started. |

I am about to send my 20# to the scrapper or donate for a boat anchor. Have had one the better part of forty years and just about to the Done Moment!!!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DMiller wrote:

DMiller wrote: