| Author |

Topic Search Topic Search  Topic Options Topic Options

|

1939Dodge

Orange Level

Joined: 18 Jan 2014

Location: Pa.

Points: 554

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Model B Oil Pressure Topic: Model B Oil Pressure

Posted: 13 Jun 2014 at 2:06pm |

|

What would you expect to be the idle and full throttle oil pressures on a B? Thank you.

|

|

|

Sponsored Links

|

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2014 at 2:42pm Posted: 13 Jun 2014 at 2:42pm |

do you have an original AC gauge or a replacement with numbers?

On the original high would be about at the letter R or M, in numbers that is about 18 - 20 lbs.

low can be as low as 5lbs. An incorrect oil filter will effect the oil presure.

the B does not have a "preasurized system", rather a splash system.

Bob

|

|

4 B's, 1 C's,3 CA's, 2 G's WD, D14, D15, B-1, B10, B12, 712S,

|

|

1939Dodge

Orange Level

Joined: 18 Jan 2014

Location: Pa.

Points: 554

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2014 at 5:28pm Posted: 13 Jun 2014 at 5:28pm |

|

I put on a new gauge, 10 psi at idle, 16 at full throttle, cold....

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2014 at 7:22pm Posted: 13 Jun 2014 at 7:22pm |

|

See what Dick L says.

Edited by wbecker - 03 Aug 2016 at 7:54am

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 13 Jun 2014 at 8:14pm Posted: 13 Jun 2014 at 8:14pm |

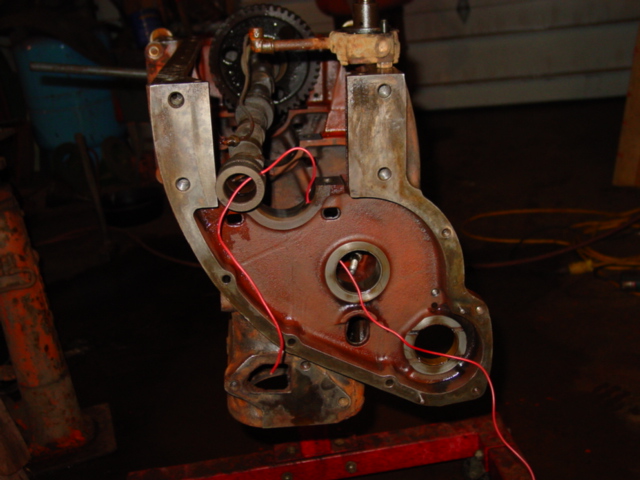

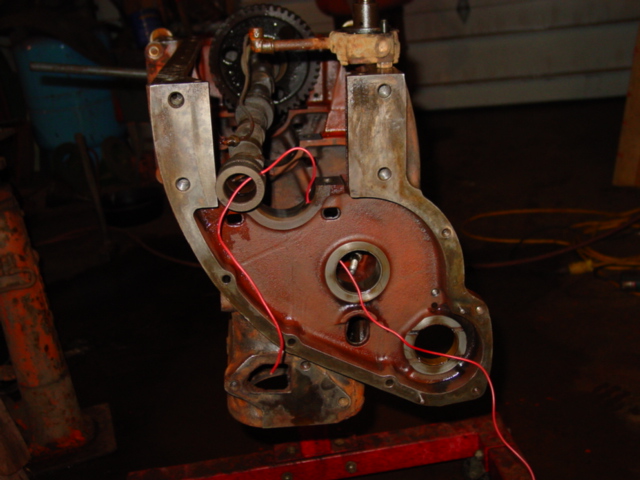

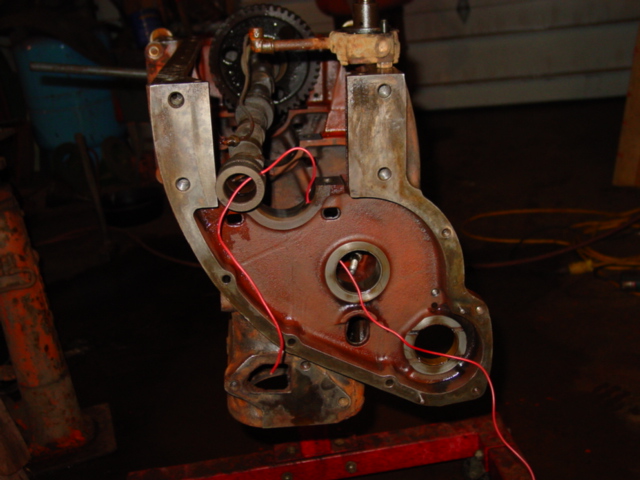

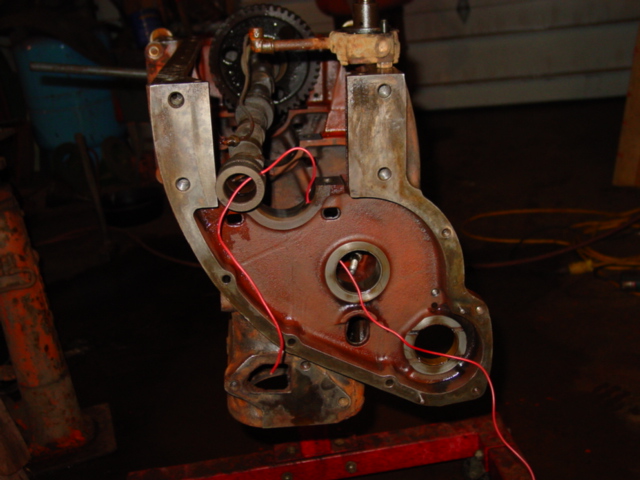

The main and rod bearing oiling system in these as simple as they are can be a challenge or even impossible to describe in common terms such as splash or bypass. A bypass system is a way to describe how oil is filtered and in most cases will have pressurized bearings. This engine does have a bypass filtering of the oil but is not the system by which the rods or mains are lubed. A true splash system has scoops on the bottom of the rods to scoop and splash oil. How ever this engine has the funnel scoops in the top of the large part of the rod on the top side of the rod bearings. A lot of splashing going on. I have posted the way these engines have the bearings lubed many times. I have been told over the years by up to date auto mechanics that they never heard of such a thing. No matter what anyone thinks it is still how this engine oils its bearings. Oil pressure is not made at the bearings on this engine. The bearings can all be shot and still have full pressure. The relief valve is in the stem of the oil pump leading to the center of the camshaft. No pressure is built in the camshaft. The cam bearings and main bearings are oiled by the spinning of the cam shaft forcing the oil out holes in the camshaft by centrifugal force. The oil pipe you see leading to the filter and head is where the pressure is built between the relief valve and the resistance thru the oil filter. The spinning of the crankshaft causes the little funnels in the top of the rods to catch oil being spun out of the camshaft holes that are in line with the rods. The oil is forced into the rod bearings thru centrifugal force. That be the oil systems operation in this engine.  The red wire shows the path thru the oil passages.

Edited by Dick L - 13 Jun 2014 at 8:22pm

|

|

flatspot

Bronze Level

Joined: 28 Jul 2012

Location: Illinois

Points: 26

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2014 at 9:55pm Posted: 15 Jun 2014 at 9:55pm |

|

I have good oil pressure when the engine is cold on my B. When it warms up I don't have any or very little. With what was said earlier is my oil pump shot. I have the correct oil filter and the tube is in the oil filter housing.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jun 2014 at 11:29am Posted: 22 Jun 2014 at 11:29am |

|

Bump

|

|

George Jr.

Silver Level

Joined: 31 May 2014

Location: New York

Points: 169

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jun 2014 at 11:57am Posted: 22 Jun 2014 at 11:57am |

|

if there is any pressure run it i can't count how many have been running on less than 10 lbs for as many years i've got 2 to prove it

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Aug 2016 at 11:51pm Posted: 02 Aug 2016 at 11:51pm |

Dick L wrote: Dick L wrote:

The main and rod bearing oiling system in these as simple as they are can be a challenge or even impossible to describe in common terms such as splash or bypass. A bypass system is a way to describe how oil is filtered and in most cases will have pressurized bearings. This engine does have a bypass filtering of the oil but is not the system by which the rods or mains are lubed. A true splash system has scoops on the bottom of the rods to scoop and splash oil. How ever this engine has the funnel scoops in the top of the large part of the rod on the top side of the rod bearings. A lot of splashing going on.

I have posted the way these engines have the bearings lubed many times. I have been told over the years by up to date auto mechanics that they never heard of such a thing. No matter what anyone thinks it is still how this engine oils its bearings.

Oil pressure is not made at the bearings on this engine. The bearings can all be shot and still have full pressure. The relief valve is in the stem of the oil pump leading to the center of the camshaft. No pressure is built in the camshaft. The cam bearings and main bearings are oiled by the spinning of the cam shaft forcing the oil out holes in the camshaft by centrifugal force. The oil pipe you see leading to the filter and head is where the pressure is built between the relief valve and the resistance thru the oil filter. The spinning of the crankshaft causes the little funnels in the top of the rods to catch oil being spun out of the camshaft holes that are in line with the rods. The oil is forced into the rod bearings thru centrifugal force. That be the oil systems operation in this engine.

The red wire shows the path thru the oil passages. |

Resurrecting an old thread, but Dick's explanation is helping me out with my low pressure B. From what I gather, the pump, oil filter, and relief valve are the only things that affect oil pressure, no? If this is the case, does that mean my pump needs a rebuild? Also, Dick, you mention how the rods are lubricated by the oil squirting into the cups on the rods (That makes sense) but how do the mains get their oil? Same method? Thanks

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2574

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 9:20am Posted: 03 Aug 2016 at 9:20am |

|

I assumed the B/C engine oiled the same as a W engine. Is that not the case?

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 9:33am Posted: 03 Aug 2016 at 9:33am |

|

no

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 9:51am Posted: 03 Aug 2016 at 9:51am |

Look up the shop manual, it has a plumbing diagram for the b/c engine. I have a copy of a combined manual for G, B, C, and CA. Its over 10 mb so too big for an email attachment. I also have a military B manual that is less than 2 mb. I just posted them on my web server. http://www.geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdfand http://www.geraldj.networkiowa.com/Trees/BMilitary.pdfGerald J.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 6:23pm Posted: 03 Aug 2016 at 6:23pm |

CrestonM wrote: CrestonM wrote:

Dick L wrote: Dick L wrote:

The main and rod bearing oiling system in these as simple as they are can be a challenge or even impossible to describe in common terms such as splash or bypass. A bypass system is a way to describe how oil is filtered and in most cases will have pressurized bearings. This engine does have a bypass filtering of the oil but is not the system by which the rods or mains are lubed. A true splash system has scoops on the bottom of the rods to scoop and splash oil. How ever this engine has the funnel scoops in the top of the large part of the rod on the top side of the rod bearings. A lot of splashing going on.

I have posted the way these engines have the bearings lubed many times. I have been told over the years by up to date auto mechanics that they never heard of such a thing. No matter what anyone thinks it is still how this engine oils its bearings.

Oil pressure is not made at the bearings on this engine. The bearings can all be shot and still have full pressure. The relief valve is in the stem of the oil pump leading to the center of the camshaft. No pressure is built in the camshaft. The cam bearings and main bearings are oiled by the spinning of the cam shaft forcing the oil out holes in the camshaft by centrifugal force. The oil pipe you see leading to the filter and head is where the pressure is built between the relief valve and the resistance thru the oil filter. The spinning of the crankshaft causes the little funnels in the top of the rods to catch oil being spun out of the camshaft holes that are in line with the rods. The oil is forced into the rod bearings thru centrifugal force. That be the oil systems operation in this engine.

The red wire shows the path thru the oil passages. |

Resurrecting an old thread, but Dick's explanation is helping me out with my low pressure B. From what I gather, the pump, oil filter, and relief valve are the only things that affect oil pressure, no? If this is the case, does that mean my pump needs a rebuild? Also, Dick, you mention how the rods are lubricated by the oil squirting into the cups on the rods (That makes sense) but how do the mains get their oil? Same method? Thanks |

The oil gets to the mains thru the holes from the camshaft bearings to the main bearings that the red wire shows in the picture. Follow the wire from the center of the engine block up thru the camshaft bore and out where the main bearing set. Centrifugal force is the pressure. This type of oiling system takes a volume of oil into the center of the camshaft rather than pressure as most systems require. 10 pounds of pressure is ample. It also takes oil volume to cause the resistance to make the 10 pounds of pressure on the pressure gauge. The system must be to simple for people to understand. I have taken flack for years when trying to explain it and even with the pictures I am doubted by some. When I am dead and gone there will still be people that will say low oil pressure on this type of engine is cause by bad bearings.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 8:30pm Posted: 03 Aug 2016 at 8:30pm |

|

I'm not doubting you a bit!

I was just wondering if I should rebuild my pump since it isn't putting out much pressure at all, even with the oil filter tube cleaned out and the Wix 57011 filter.

|

|

ac45dave

Orange Level Access

Joined: 23 May 2015

Location: SE(IN)

Points: 1346

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 9:43pm Posted: 03 Aug 2016 at 9:43pm |

|

just remember, the oil filter has to get good and saturated with oil to get proper restriction.a new filter may have slightly lower pressure for a short time.i've seen that stated in the wd45 operators manual.i would think the same thing would apply to your B.

|

|

54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 9:55pm Posted: 03 Aug 2016 at 9:55pm |

CrestonM wrote: CrestonM wrote:

I'm not doubting you a bit!

I was just wondering if I should rebuild my pump since it isn't putting out much pressure at all, even with the oil filter tube cleaned out and the Wix 57011 filter. |

How thick was the gasket you used under the cover on your oil pump. Not much to rebuild on these pumps. If the springs are good and the vanes move freely your good to go there. Then the rotor is supposed to be flush with the body, the clearance which should be about .007 is achieved in the thickness of the gasket. If you have to make one a sheet of copy paper will work. If the gasket is very thick it will loose prime after setting for a time as well as not make the volume it should because of the by pass of oil past the cover. The ball in the stem can not have pits and the seat can not have them as well. If the spring looks good it most likely is. The only bad springs I have had were rusty. You having the pump apart would be a better judge as to what needs to be done than me without me seeing it.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 10:24pm Posted: 03 Aug 2016 at 10:24pm |

The gasket was not quite paper thin, but pretty close! The cover also has a circle worn in it, so should I machine that smooth? Also, when you mention the ball in the stem...Are you talking about the oil filter tube? If so, there is no ball in it.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Aug 2016 at 10:30pm Posted: 03 Aug 2016 at 10:30pm |

|

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 5:55am Posted: 04 Aug 2016 at 5:55am |

CrestonM wrote: CrestonM wrote:

The gasket was not quite paper thin, but pretty close! The cover also has a circle worn in it, so should I machine that smooth?Also, when you mention the ball in the stem...Are you talking about the oil filter tube? If so, there is no ball in it. |

Yes it needs to be smooth. This picture is of one I had just made smooth with a file. The other one still needed to be fixed smooth before using. The ball is in the stem of the oil pump under the spring.

Somewhere I have a picture of the pump stem but I didn't find it just now. Look it over and you will figure it out. I hold the spring down with a small screwdriver to remove the spring in the stem.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 11:27am Posted: 04 Aug 2016 at 11:27am |

|

Yes, My cover looks like the one on the right.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 11:29am Posted: 04 Aug 2016 at 11:29am |

|

So how do I get to said stem? Is it behind (I guess technically it would be in front of) the rotor with the vanes?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 12:20pm Posted: 04 Aug 2016 at 12:20pm |

CrestonM wrote: CrestonM wrote:

So how do I get to said stem? Is it behind (I guess technically it would be in front of) the rotor with the vanes? |

What I call the stem is the end with the slot that goes inside the camshaft over the pin that drives the pump. Just below the slot is the pin that holds the spring in place.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 2:00pm Posted: 04 Aug 2016 at 2:00pm |

|

Ok. So how do I go about disassembling the pump? Does the rotor just pull out?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 2:37pm Posted: 04 Aug 2016 at 2:37pm |

CrestonM wrote: CrestonM wrote:

Ok. So how do I go about disassembling the pump? Does the rotor just pull out? |

That is how it comes out but if is not sloppy I wouldn't bother. If it is sloppy I wouldn't bother trying to rebuild it. I would just get a different pump that was tight.

Looking at your picture I would bet if you clean up the cover and use a .007 thick gasket you will be back in good shape. Check the ball and seat in the stem to make sure they are both smooth.

You did take the pump off the block after you removed the bolts as in your picture?? If you didn't when the bolts are out just turn the fitting out at the top of the pipe the goes to the filter.

Edited by Dick L - 04 Aug 2016 at 2:40pm

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 4:52pm Posted: 04 Aug 2016 at 4:52pm |

|

No, I didn't remove the pump. What do you mean by if it's sloppy or not? The rotor wiggles inside the housing?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 5:50pm Posted: 04 Aug 2016 at 5:50pm |

CrestonM wrote: CrestonM wrote:

No, I didn't remove the pump. What do you mean by if it's sloppy or not? The rotor wiggles inside the housing? |

Yes!

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 6:13pm Posted: 04 Aug 2016 at 6:13pm |

Ok. I guess I'll separate the engine from the torque tube as soon as I get time (May be a couple weeks. In the process of moving to and starting college) and have a look. If it is sloppy, where can you get rebuilt pumps? I did a google search, and I can find kits all day long, but no pumps. Why do you say you would not bother with just rebuilding it? Is it tricky? Thanks

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 7:03pm Posted: 04 Aug 2016 at 7:03pm |

CrestonM wrote: CrestonM wrote:

Ok. I guess I'll separate the engine from the torque tube as soon as I get time (May be a couple weeks. In the process of moving to and starting college) and have a look. If it is sloppy, where can you get rebuilt pumps? I did a google search, and I can find kits all day long, but no pumps. Why do you say you would not bother with just rebuilding it? Is it tricky? Thanks |

Not much to rebuild so go ahead if you want. If the bushing is bad it would most likely have the bottom of the housing under the rotor damaged much like the cover.

I can come up with a good pump for you if needed. I saw a couple on my head bench when I side stepped thru the mess to get by it last week. I can't get my walker or wheelchair in the shed anymore. I need a large electro magnet to hang on my loader like they use in the junk yards to move stuff out where it can be sorted. I kid you not! The pumps would be almost to the back left side.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8457

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Aug 2016 at 9:54pm Posted: 04 Aug 2016 at 9:54pm |

Your shop looks about like mine lol! Except mine has 3 tractors crammed in there too!

I found where Steiner sells a pump kit, but it doesn't have the bushing or the relief ball I don't think. But is that big spring and the pin what you mentioned earlier? Are they what hold the ball in place?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Aug 2016 at 6:04am Posted: 05 Aug 2016 at 6:04am |

CrestonM wrote: CrestonM wrote:

Your shop looks about like mine lol! Except mine has 3 tractors crammed in there too!

I found where Steiner sells a pump kit, but it doesn't have the bushing or the relief ball I don't think. But is that big spring and the pin what you mentioned earlier? Are they what hold the ball in place?

|

That is the parts.

That is just one of the three bays in the shed as I call it. The center bay has a 25 Chevy and an RC 180 Cessna project.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Dick L wrote:

Dick L wrote: