Model B Oil Pressure

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=90991

Printed Date: 19 Oct 2025 at 10:29am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Model B Oil Pressure

Posted By: 1939Dodge

Subject: Model B Oil Pressure

Date Posted: 13 Jun 2014 at 2:06pm

| What would you expect to be the idle and full throttle oil pressures on a B? Thank you. |

Replies:

Posted By: Chalmersbob

Date Posted: 13 Jun 2014 at 2:42pm

|

do you have an original AC gauge or a replacement with numbers?

On the original high would be about at the letter R or M, in numbers that is about 18 - 20 lbs.

low can be as low as 5lbs. An incorrect oil filter will effect the oil presure.

the B does not have a "preasurized system", rather a splash system.

Bob ------------- 4 B's, 1 C's,3 CA's, 2 G's WD, D14, D15, B-1, B10, B12, 712S, |

Posted By: 1939Dodge

Date Posted: 13 Jun 2014 at 5:28pm

| I put on a new gauge, 10 psi at idle, 16 at full throttle, cold.... |

Posted By: wbecker

Date Posted: 13 Jun 2014 at 7:22pm

|

See what Dick L says. ------------- Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152 |

Posted By: Dick L

Date Posted: 13 Jun 2014 at 8:14pm

|

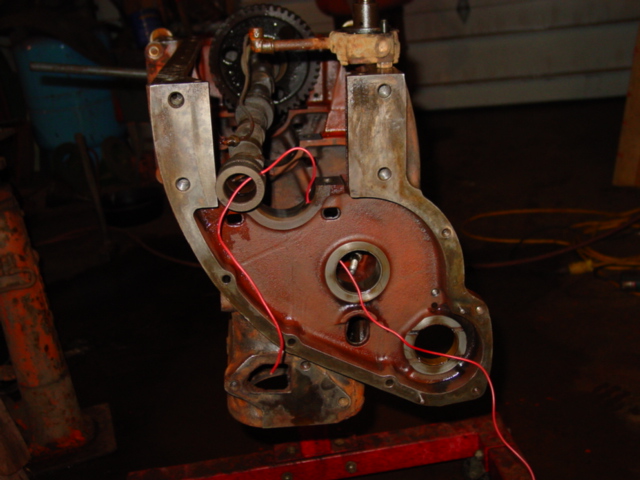

The main and rod bearing oiling system in these as simple as they are can be a challenge or even impossible to describe in common terms such as splash or bypass. A bypass system is a way to describe how oil is filtered and in most cases will have pressurized bearings. This engine does have a bypass filtering of the oil but is not the system by which the rods or mains are lubed. A true splash system has scoops on the bottom of the rods to scoop and splash oil. How ever this engine has the funnel scoops in the top of the large part of the rod on the top side of the rod bearings. A lot of splashing going on. I have posted the way these engines have the bearings lubed many times. I have been told over the years by up to date auto mechanics that they never heard of such a thing. No matter what anyone thinks it is still how this engine oils its bearings. Oil pressure is not made at the bearings on this engine. The bearings can all be shot and still have full pressure. The relief valve is in the stem of the oil pump leading to the center of the camshaft. No pressure is built in the camshaft. The cam bearings and main bearings are oiled by the spinning of the cam shaft forcing the oil out holes in the camshaft by centrifugal force. The oil pipe you see leading to the filter and head is where the pressure is built between the relief valve and the resistance thru the oil filter. The spinning of the crankshaft causes the little funnels in the top of the rods to catch oil being spun out of the camshaft holes that are in line with the rods. The oil is forced into the rod bearings thru centrifugal force. That be the oil systems operation in this engine.  The red wire shows the path thru the oil passages. |

Posted By: flatspot

Date Posted: 15 Jun 2014 at 9:55pm

| I have good oil pressure when the engine is cold on my B. When it warms up I don't have any or very little. With what was said earlier is my oil pump shot. I have the correct oil filter and the tube is in the oil filter housing. |

Posted By: Dick L

Date Posted: 22 Jun 2014 at 11:29am

|

Bump |

Posted By: George Jr.

Date Posted: 22 Jun 2014 at 11:57am

| if there is any pressure run it i can't count how many have been running on less than 10 lbs for as many years i've got 2 to prove it |

Posted By: CrestonM

Date Posted: 02 Aug 2016 at 11:51pm

Resurrecting an old thread, but Dick's explanation is helping me out with my low pressure B. From what I gather, the pump, oil filter, and relief valve are the only things that affect oil pressure, no? If this is the case, does that mean my pump needs a rebuild? Also, Dick, you mention how the rods are lubricated by the oil squirting into the cups on the rods (That makes sense) but how do the mains get their oil? Same method? Thanks

|

Posted By: AaronSEIA

Date Posted: 03 Aug 2016 at 9:20am

| I assumed the B/C engine oiled the same as a W engine. Is that not the case? |

Posted By: CAL(KS)

Date Posted: 03 Aug 2016 at 9:33am

|

no ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: Gerald J.

Date Posted: 03 Aug 2016 at 9:51am

|

Look up the shop manual, it has a plumbing diagram for the b/c engine. I have a copy of a combined manual for G, B, C, and CA. Its over 10 mb so too big for an email attachment. I also have a military B manual that is less than 2 mb. I just posted them on my web server. http://www.geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://www.geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf and http://www.geraldj.networkiowa.com/Trees/BMilitary.pdf" rel="nofollow - http://www.geraldj.networkiowa.com/Trees/BMilitary.pdf Gerald J. |

Posted By: Dick L

Date Posted: 03 Aug 2016 at 6:23pm

The oil gets to the mains thru the holes from the camshaft bearings to the main bearings that the red wire shows in the picture. Follow the wire from the center of the engine block up thru the camshaft bore and out where the main bearing set. Centrifugal force is the pressure. This type of oiling system takes a volume of oil into the center of the camshaft rather than pressure as most systems require. 10 pounds of pressure is ample. It also takes oil volume to cause the resistance to make the 10 pounds of pressure on the pressure gauge. The system must be to simple for people to understand. I have taken flack for years when trying to explain it and even with the pictures I am doubted by some. When I am dead and gone there will still be people that will say low oil pressure on this type of engine is cause by bad bearings.

|

Posted By: CrestonM

Date Posted: 03 Aug 2016 at 8:30pm

|

I'm not doubting you a bit! I was just wondering if I should rebuild my pump since it isn't putting out much pressure at all, even with the oil filter tube cleaned out and the Wix 57011 filter. |

Posted By: ac45dave

Date Posted: 03 Aug 2016 at 9:43pm

|

just remember, the oil filter has to get good and saturated with oil to get proper restriction.a new filter may have slightly lower pressure for a short time.i've seen that stated in the wd45 operators manual.i would think the same thing would apply to your B. ------------- 54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors |

Posted By: Dick L

Date Posted: 03 Aug 2016 at 9:55pm

How thick was the gasket you used under the cover on your oil pump. Not much to rebuild on these pumps. If the springs are good and the vanes move freely your good to go there. Then the rotor is supposed to be flush with the body, the clearance which should be about .007 is achieved in the thickness of the gasket. If you have to make one a sheet of copy paper will work. If the gasket is very thick it will loose prime after setting for a time as well as not make the volume it should because of the by pass of oil past the cover. The ball in the stem can not have pits and the seat can not have them as well. If the spring looks good it most likely is. The only bad springs I have had were rusty. You having the pump apart would be a better judge as to what needs to be done than me without me seeing it.

|

Posted By: CrestonM

Date Posted: 03 Aug 2016 at 10:24pm

|

The gasket was not quite paper thin, but pretty close! The cover also has a circle worn in it, so should I machine that smooth? Also, when you mention the ball in the stem...Are you talking about the oil filter tube? If so, there is no ball in it.

|

Posted By: CrestonM

Date Posted: 03 Aug 2016 at 10:30pm

Here is a photo of my pump after I took the cover off.

|

Posted By: Dick L

Date Posted: 04 Aug 2016 at 5:55am

Yes it needs to be smooth. This picture is of one I had just made smooth with a file. The other one still needed to be fixed smooth before using. The ball is in the stem of the oil pump under the spring. Somewhere I have a picture of the pump stem but I didn't find it just now. Look it over and you will figure it out. I hold the spring down with a small screwdriver to remove the spring in the stem.  |

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 11:27am

| Yes, My cover looks like the one on the right. |

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 11:29am

| So how do I get to said stem? Is it behind (I guess technically it would be in front of) the rotor with the vanes? |

Posted By: Dick L

Date Posted: 04 Aug 2016 at 12:20pm

What I call the stem is the end with the slot that goes inside the camshaft over the pin that drives the pump. Just below the slot is the pin that holds the spring in place. |

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 2:00pm

| Ok. So how do I go about disassembling the pump? Does the rotor just pull out? |

Posted By: Dick L

Date Posted: 04 Aug 2016 at 2:37pm

That is how it comes out but if is not sloppy I wouldn't bother. If it is sloppy I wouldn't bother trying to rebuild it. I would just get a different pump that was tight. Looking at your picture I would bet if you clean up the cover and use a .007 thick gasket you will be back in good shape. Check the ball and seat in the stem to make sure they are both smooth. You did take the pump off the block after you removed the bolts as in your picture?? If you didn't when the bolts are out just turn the fitting out at the top of the pipe the goes to the filter.

|

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 4:52pm

| No, I didn't remove the pump. What do you mean by if it's sloppy or not? The rotor wiggles inside the housing? |

Posted By: Dick L

Date Posted: 04 Aug 2016 at 5:50pm

Yes! |

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 6:13pm

|

Ok. I guess I'll separate the engine from the torque tube as soon as I get time (May be a couple weeks. In the process of moving to and starting college) and have a look. If it is sloppy, where can you get rebuilt pumps? I did a google search, and I can find kits all day long, but no pumps. Why do you say you would not bother with just rebuilding it? Is it tricky? Thanks

|

Posted By: Dick L

Date Posted: 04 Aug 2016 at 7:03pm

Not much to rebuild so go ahead if you want. If the bushing is bad it would most likely have the bottom of the housing under the rotor damaged much like the cover. I can come up with a good pump for you if needed. I saw a couple on my head bench when I side stepped thru the mess to get by it last week. I can't get my walker or wheelchair in the shed anymore. I need a large electro magnet to hang on my loader like they use in the junk yards to move stuff out where it can be sorted. I kid you not! The pumps would be almost to the back left side.  |

Posted By: CrestonM

Date Posted: 04 Aug 2016 at 9:54pm

|

Your shop looks about like mine lol! Except mine has 3 tractors crammed in there too! http://www.steinertractor.com/ACS3420Oil-Pump-Repair-Kit?&TF=E28A5711FD83" rel="nofollow - http://www.steinertractor.com/ACS3420Oil-Pump-Repair-Kit?&TF=E28A5711FD83 I found where Steiner sells a pump kit, but it doesn't have the bushing or the relief ball I don't think. But is that big spring and the pin what you mentioned earlier? Are they what hold the ball in place?

|

Posted By: Dick L

Date Posted: 05 Aug 2016 at 6:04am

That is the parts. That is just one of the three bays in the shed as I call it. The center bay has a 25 Chevy and an RC 180 Cessna project.

|

Posted By: Morgan in AR

Date Posted: 05 Aug 2016 at 6:33pm

|

Creston, keep us updated. I just overhauled a CA, and I have the same problem. ------------- If we loose freedom here there is no place left to escape to. This is the last stand on earth. -Ronald Reagan |

Posted By: CrestonM

Date Posted: 05 Aug 2016 at 7:30pm

| Will do. I'm thinking since I'm going to be really busy and maybe only home every other weekend or so, I may find a good pump and swap them. If it helps, great!! If it doesn't....well....I don't know... |

Posted By: 49clipper

Date Posted: 22 Mar 2024 at 11:57am

| Interesting forum. I did not have an issue with the oil pump leaking down until I changed oil to 10-30W. Now the freshly rebuilt pump leaks down and will not show external oil pressure until primed. I prime by removing the filter and using a small oil can pump into the port where the vertical tube goes and pump three or four times. Quickly reinstall tube and filter and then I get oil pressure after about 15 seconds. Now why. apparently the external 1/4" tube leading out of the oil pump is bleeding oil back down that tube. Why??? I made a fixture when I rebuilt the pump to measure the clearance between the cover plate and the rotor. My manual says it has to be .00" or less. I got mine down to .001" by using two .005" gaskets in the kit and dressing the cover down. My new rotor sits proud of the pump housing by about .007-8" thousandths, just like the old one. I see how the system works, but looking for the answer to this riddle. From what I see, the filter cannot affect oil pressure. the oil is pumped up the tube and gravity feeds the filter media and then just drains back into the case. the line to the guage is just measuring the oil that gets dripped into the filter. Its free flow. Someone mentioned a Wix filter. How is that different? |

Posted By: steve(ill)

Date Posted: 22 Mar 2024 at 1:02pm

|

The filter material is PACKED COTTON... It does cause a few psi backpressure to the syste. YEs there is a 1/4 inch tube with a 1/8 inch orifice inside the filter housing that is doing MOST of the restriction, but the filter helps. 20 years ago WIX made filters with paper material instead of PACKED COTTON and they lost pressure due to that. If your system drains back to sump, then you possibly have an air leak.. Look for a damp spot on the 1/8 inch pipe out of the bell housing, the 1/4 inch tube fittings, or the filter o-ring itself.. You have to get AIR into the system to allow the tubing to drain backward. ------------- Like them all, but love the "B"s. |

Posted By: 49clipper

Date Posted: 22 Mar 2024 at 2:00pm

|

Yes, air is a must, but I have checked for those multiple times with no leaks. For the filter to be part of the oil pressure result, it would have to be flooded all the time. It is not flooded. I filled the canister as much as I could, but it just drains to the crankcase with gravity flow and then would be partially drained by the next start. My filter is filled with cotton, and I have tried two new filters with no change. Amazingly, I went out to the shop today and started it and it showed oil pressure without any priming. Wow, First time since I rebuilt the pump!! I guess this is going to be a guessing game on oil pressure. It is sort of a baffling system. Thanks for your reply.

|

Posted By: steve(ill)

Date Posted: 22 Mar 2024 at 6:31pm

|

filter does not have to be flooded... It is like a WET TEE SHIRT crammed into a box.. Try to blow thru that.... PRESSURE on the top forces the oil down thru the WET COTTON and then it drains back to the sump... BUT on top of the filter, there is a few pounds of pressure.... On a good engine you have 15 psi at the gauge ... When they get OLD, you might have 5 psi at idle and over 10 psi at full throttle.

Take a foot long piece of 1/2 inch pipe... Cut up a tee shirt into a 6 x 6 square.. Soak it in oil and POUND it into the pipe with a hammer and screw driver... Then BLOW on the end if it...  ------------- Like them all, but love the "B"s. |

Posted By: Dakota Dave

Date Posted: 22 Mar 2024 at 7:54pm

| My CA had low pressure when it locked up It had water changed to Ice in the pickup. When I took it apart the plug was missing from the front end of the cam. I got one and the spring from the Agco dealer when I put it back together. It had normal pressure. The only thing I did to the pump was replace the sheared drive pine in the rear end of the cam. |

Posted By: john2189

Date Posted: 23 Mar 2024 at 7:43am

|

Ok I’ve read this post a couple of times. What I get from it is that low or no oil pressure doesn’t effect the rods and mains since it is a splash system. And that all the oil pump does is pump oil into the oil filter and cam bearings. I have not seen anything about how the oil pump pumps oil to the valve rocker arms and in the newer engines to the governor ------------- '41 Allis B '45 Allis B '49 Farmall Cub '72 IH Cub |

Posted By: steve(ill)

Date Posted: 23 Mar 2024 at 7:54am

|

No.... the pump does NOT pump oil thru passages in the crank and FORCE oil thru the main and crank bearings, like a regular car/ truck engine.. What it does is pump oil down a HOLLOW CAM SHAFT from back to front.. There are several pin holes in the cam that point at the pistons / rods that SPRAY the 15 psi oil at the bearings and rod... the oil drips down into a hole in each rod bearing and gets into the bearing area.... Think of a SPLASH LUBE on the old Briggs & Stratton engines.. That is 85% of the oil... The other 15% of the oil comes out from the bellhousing thru the 1/4 inch pipe toward the filter... You will see a couple small tubes on the filter housing that go to the TOP END ROCKER ARMS and to the GOVERNOR Bearing.... The 15% oil in the filter is cleaned and dumped back to sump... If you PLUG the filter, you get 100% oil THRU THE CAM and SPRAY at the internal bearings... If you have a HOLE in the filter or NO FILTER, you allow too much of the oil to run back to sump and maybe only have 50% for lube and 50% lost to sump. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 23 Mar 2024 at 7:59am

|

Reread the 5th post from DICK L several years ago... He explains that BEARING WEAR does not effect the PRESSURE since the bearings are SPRAY LUBED... You have to have PRESSURE and OIL to make the system work. There are two BIG differences in the "B" engine compared to a TRUCK... -- One is that 15% of the oil goes thru the filter and dumps to sump on the B.. On a truck 100% of the oil goes thru the filter and then LUBES THE BEARINGS. --Second, the "B" SPRAYS the oil at the bearings, similar to a SPLASH LUBE mower engine, as compared to a truck that FORCES OIL PRESSURE into the bearings thru oil galleys.

------------- Like them all, but love the "B"s. |

Posted By: john2189

Date Posted: 23 Mar 2024 at 8:10am

|

Ok I kinda get it now.Its been years since I’ve rebuilt a B engine but I have an old engine from a C. I guess I will have to take it apart so I visualize it better. ------------- '41 Allis B '45 Allis B '49 Farmall Cub '72 IH Cub |

Posted By: steve(ill)

Date Posted: 23 Mar 2024 at 8:12am

|

Drawing in manual with circles around the SPRAY HOLES in the cam shaft.. You NEED flow thru the cam and spray out of these holes for bearing lube... Dick says the oil is THROWN OUT of the cam by centrifugal force... I like to think there is some PRESSURE in the cam and it is SPRAYED out of the holes.. Note items 10 and 11 at the front end of the cam..That plugs the hole and helps maintain SOME pressure inside the cam oil passage. ------------- Like them all, but love the "B"s. |

Posted By: BrianC

Date Posted: 23 Mar 2024 at 8:59am

|

Re-read this post and others. One thing I need to know is, where is GeraldJ? He always had good info to add.

|

Posted By: Les Kerf

Date Posted: 23 Mar 2024 at 9:11am

Ummm... doesn't some of that oil still go to the top end even if the filter is plugged?

|

Posted By: steve(ill)

Date Posted: 23 Mar 2024 at 9:17am

|

YES... my point was if the FILTER is plugged, then no oil is dumped to sump... I goes thru the cam and it goes ( at the filter housing) thru the 1/8 inch tubes to the rocker arms and governor.

Gerald left in Jan of 2021 ............ ??? ------------- Like them all, but love the "B"s. |

Posted By: Les Kerf

Date Posted: 23 Mar 2024 at 9:47am

|

I re-read the manual and noticed that the oil pressure relief dumps the excess oil to the inside of the camshaft where it can still be utilized; clever. |

Posted By: IBWD MIke

Date Posted: 24 Mar 2024 at 9:25am

|

Gerald left in Jan of 2021 ............ ??? [/QUOTE]I believe Gerald J. should be added to the Memorial section. I had forgotten about him, he did have lots of knowledge. |

Posted By: HudCo

Date Posted: 24 Mar 2024 at 11:24am

| take the pickup tube off and replace it , i belive it is 3/8 npt about 8 1/2 inches long ,ifinley replaced mine it had a tiny crack in the pipe up close to where it threads inthe block and would suck air . i had done the pump when i put a clutch in it didnt help worked the fiilter base didnt help filled it a gallon over full and had oil presure but would loose it going ing down a hill . i ran mine that far over full for two years cnat believe the main didnt leak |

Dick L wrote:

Dick L wrote: