| Author |

Topic Search Topic Search  Topic Options Topic Options

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Homemade Snap Coupler Implement Topic: Homemade Snap Coupler Implement

Posted: 02 Jan 2024 at 5:52pm |

I would like to build some pallet jacks for the snap coupler. Has anybody built something that would work and have pointers?

I have a 200 gallon water tank I want to build into a sprayer. It seems pretty straight forward to me, but ideas, suggestions and warnings would be appreciated!

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20582

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 6:02pm Posted: 02 Jan 2024 at 6:02pm |

|

Lots been made with heavy 3" x 3" angle iron in an "A" frame tongue to the snap-coupler bell and twisted link chains done in a "V" to a cross bar to control sway. Attach your tool to the crossbar, which could be the same size angle iron on the pull tongue.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 6:42pm Posted: 02 Jan 2024 at 6:42pm |

the simple way would be to build something like this with lower arms 2-3 ft longer and set the tank on a couple welded on cross braces... Realize that as you raise the load, it will pivot on the bail and the back end raises faster than the front, so the load does not stay level.. Probably not a big deal on a water tank....

If you want to stay LEVEL like using forks, then you need the snap couple hitch like this, with a 3 point BOX or deck behind that with correct geometry to the top link..

|

|

Like them all, but love the "B"s.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 7:40pm Posted: 02 Jan 2024 at 7:40pm |

|

Would it be easier/better to try and attach a spray boom to the cultivator bar? I can take the tines off so it's basically a tool bar. I could then lift the water with the loader.

I'm just not sure my loader will lift 200 gallons of water, and I was hoping to take it off when I was done moving snow.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 8:02pm Posted: 02 Jan 2024 at 8:02pm |

|

you might be able to lift with the loader... but will you be able to steer ??

|

|

Like them all, but love the "B"s.

|

|

DMac

Bronze Level

Joined: 18 Feb 2023

Location: Springville ny

Points: 74

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 8:04pm Posted: 02 Jan 2024 at 8:04pm |

|

i plan to build one myself. I have a 3point hitch 2 spear bale spike that I plan on starting with. I got an old wd drawbar with the ring that i plan on welding to the front and figure ill make a couple pieces to fit the snap latches and weld them in the correct location on the arch of the implement.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 9:22pm Posted: 02 Jan 2024 at 9:22pm |

steve(ill) wrote: steve(ill) wrote:

you might be able to lift with the loader... but will you be able to steer ?? |

I have power steering. But probably not gonna steer well enough to stay within rows. Good point.

DMac wrote: DMac wrote:

i plan to build one myself. I have a 3point hitch 2 spear bale spike that I plan on starting with. I got an old wd drawbar with the ring that i plan on welding to the front and figure ill make a couple pieces to fit the snap latches and weld them in the correct location on the arch of the implement. |

The lifting connection arms are what I'm not totally clear on how I'm gonna do. I feel like there should be an easy way to repurpose top links. But nothing's coming to mind.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 9:46pm Posted: 02 Jan 2024 at 9:46pm |

|

are you trying to eliminate the snap latch and just run a adjustable bar from the lower arm to the lift arm ??

|

|

Like them all, but love the "B"s.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 10:35pm Posted: 02 Jan 2024 at 10:35pm |

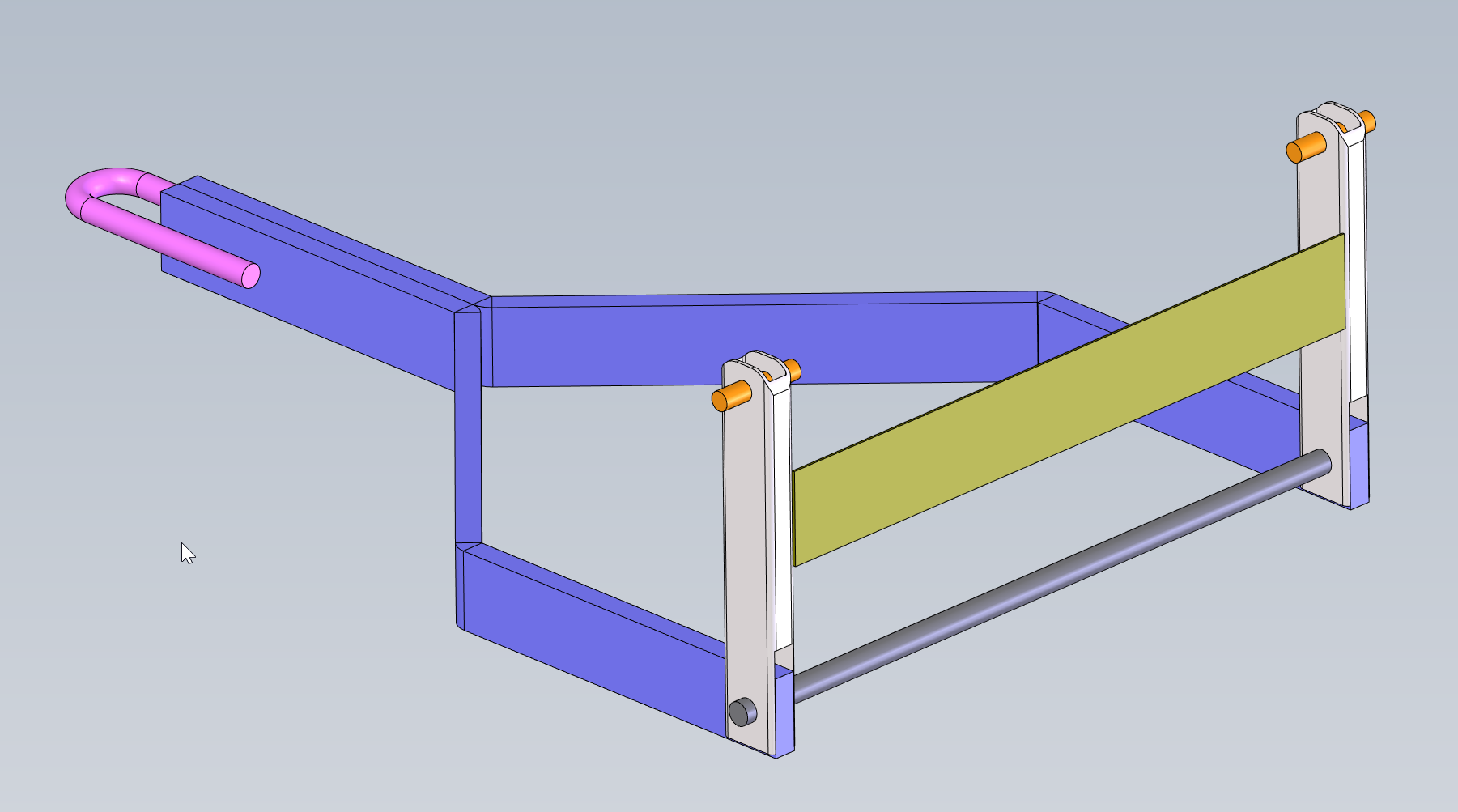

Something like this is what I'm thinking. None of the dimensions

are figured, and the enigneering isn't done. I would the build a box to

sit the tank on between the 3" x 3" tubes. The lift arms aren't

adjustable, but not sure they would need to be.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 10:41pm Posted: 02 Jan 2024 at 10:41pm |

|

With a slight modification, could put some hydraulic cylinder on it and the forks to make the forks levelable - wouldn't be self levelling like a 3 point. But if I really cared there would be options.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 10:41pm Posted: 02 Jan 2024 at 10:41pm |

that should work OK.... The vertical bars dont have to adjust... but they have to pivot at both ends....

just realize that the "LIFT" is going to pivot on the front Bail hitch... so the back end of the tank is going to swing thru an arc as it raises... Not a big problem.... thats basically how all implements on the snap coupler work.

Nice drawing...... what program ? ..... part of your work/ job ?

Edited by steve(ill) - 02 Jan 2024 at 10:44pm

|

|

Like them all, but love the "B"s.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jan 2024 at 11:39pm Posted: 02 Jan 2024 at 11:39pm |

steve(ill) wrote: steve(ill) wrote:

that should work OK.... The vertical bars dont have to adjust... but they have to pivot at both ends....Nice drawing...... what program ? ..... part of your work/ job ?

|

I'll also probably add plates in an "X" shape between the vertical arms to stop it swinging left and right. My grader and cultivator do that. SOLIDWORKS. I'm an ME in education and detailing engineer by trade. Play farmer on the weekends.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 796

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 7:23am Posted: 03 Jan 2024 at 7:23am |

MadCow wrote: MadCow wrote:

...

SOLIDWORKS. I'm an ME in education and detailing engineer by trade. Play farmer on the weekends. |

I miss having Solidworks available to me now that I am retired, it sure is a sweet design program

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 7:58am Posted: 03 Jan 2024 at 7:58am |

|

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:00am Posted: 03 Jan 2024 at 8:00am |

oopsy forgot to add.. made this 20 years ago, 42" forklift forks hang from it, will lift 2500# logs. OK, she ain't a purdy store bought gal, but has worked GREAT since day one !!!

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:12am Posted: 03 Jan 2024 at 8:12am |

jaybmiller wrote: jaybmiller wrote:

|

That looks great!, and simple! You must back up to it, clip the lift arms on, and then swing the drawbar hook in?

Do you have any sketches or dimensions for it? I'll probably take my own, but a concensus would be great.

Are those lift arms pinned to the bottom? Does that make the forks lift level?

Edited by MadCow - 03 Jan 2024 at 8:14am

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:15am Posted: 03 Jan 2024 at 8:15am |

Les Kerf wrote: Les Kerf wrote:

MadCow wrote: MadCow wrote:

...

SOLIDWORKS. I'm an ME in education and detailing engineer by trade. Play farmer on the weekends. |

I miss having Solidworks available to me now that I am retired, it sure is a sweet design program

|

I always say I get to play on the computer all day. There's nothing quite as slick as solidworks. Fusion 360 is close - but it's not free anymore.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:32am Posted: 03 Jan 2024 at 8:32am |

Jay has a nice , simple hitch right there... The Pivot bolts at the boot would appear to be the weak link if any. A clevis or saddle that holds both sides of the arm would strengthen the frame.. Since the 2 x 2 hitch is connected to the lift arm instead of the lower arms it would tend to LIFT more horizontal... Dimension / placement of the vertical lift frame would determine how LEVEL it lifts.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:41am Posted: 03 Jan 2024 at 8:41am |

one thing you can do is make a little frame from plywood and 2x4 for a test.... make it so you can easily move the lower pin point forward and back. and change the HEIGHT of the frame up the to lift arms.... I did that with a set of forks to put on a "B" 3 point and figure the best Dimensions to get it to lift LEVEL.

you can also draw it out on a piece of graph paper showing the LOWER and RAISE positions of the lower arms and upper arms... then measure various places on the lower arm and the height of vertical bars to try to get somewhat LEVEL lift design... PRIOR to cutting out any parts.

Edited by steve(ill) - 03 Jan 2024 at 9:30am

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 8:46am Posted: 03 Jan 2024 at 8:46am |

1/2" grade 8 bolts, lower arms are 1 1/2" square tubing, the "U" I bent by hand,lift latch pins are 5/8" bar so uprights are 1 1/2", 2" sleeve with 2" center 'post', 2" angle iron for cross pieces. built it after getting the forks for free( dumpster dive), replaced the FREEMAN loader, so no real plans.... made the 'arms' first,long, then cut to length after making the snap coupler section.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 9:51am Posted: 03 Jan 2024 at 9:51am |

jaybmiller wrote: jaybmiller wrote:

1/2" grade 8 bolts, lower arms are 1 1/2" square tubing, the "U" I bent by hand,lift latch pins are 5/8" bar so uprights are 1 1/2", 2" sleeve with 2" center 'post', 2" angle iron for cross pieces. built it after getting the forks for free( dumpster dive), replaced the FREEMAN loader, so no real plans.... made the 'arms' first,long, then cut to length after making the snap coupler section.

|

You actually made me rethink my whole design. Probably do something closer to what you have. Then the frame that holds my water tank can have the same "hooks" that a pallet for has, and I can just back up and grab it.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 10:01am Posted: 03 Jan 2024 at 10:01am |

Mine has hauled 1,000s of skids as well as 20 IBC totes..here,there, everywhere... it even hauled tandem pull discs 2 miles to friends farm several times(stuck 'pole boom' into vertical tubing, several chains....kinda swayed a bit but everyone stayed away from me !

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 12:33pm Posted: 03 Jan 2024 at 12:33pm |

|

MadCow .... if you make a drawing, post it so all can see. I would be interested in seeing your design.

|

|

Like them all, but love the "B"s.

|

|

exSW

Orange Level

Joined: 21 Jul 2017

Location: Pennsylvania

Points: 914

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2024 at 4:31pm Posted: 03 Jan 2024 at 4:31pm |

I've got the real thing. AC SC pallet forks. They work pretty slick. If I can I'll find pics.

Edited by exSW - 03 Jan 2024 at 4:38pm

|

|

Learning AC...slowly

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2024 at 9:08am Posted: 04 Jan 2024 at 9:08am |

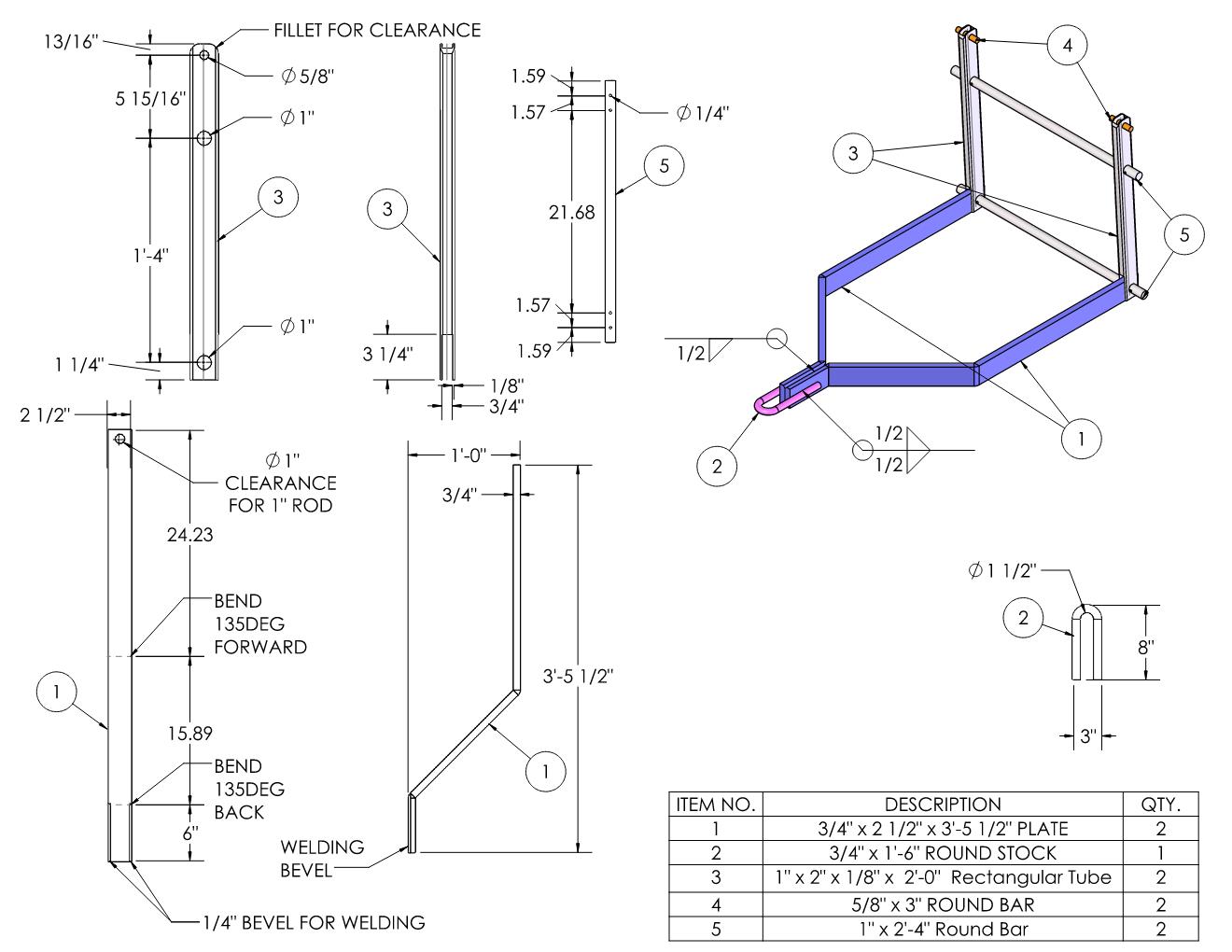

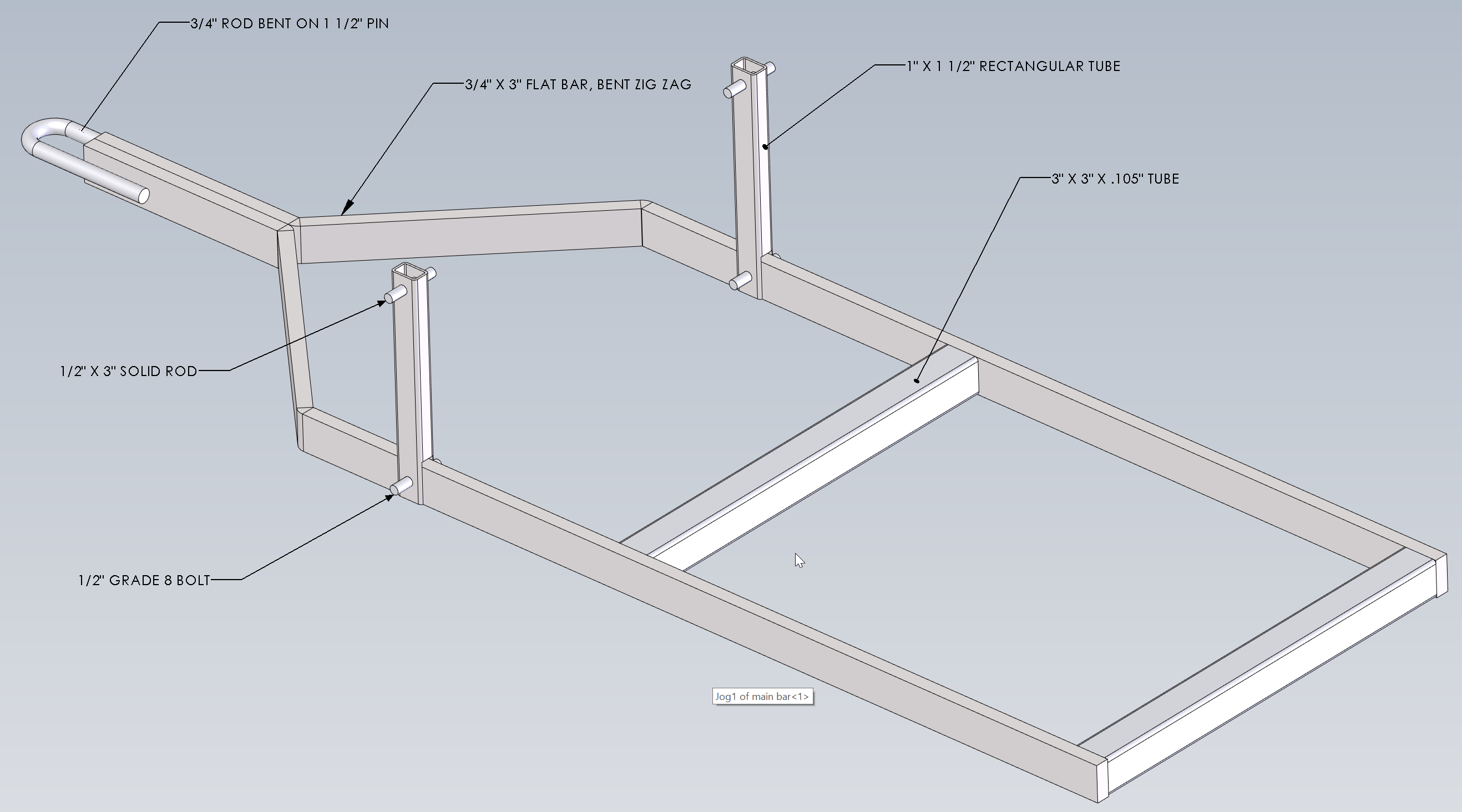

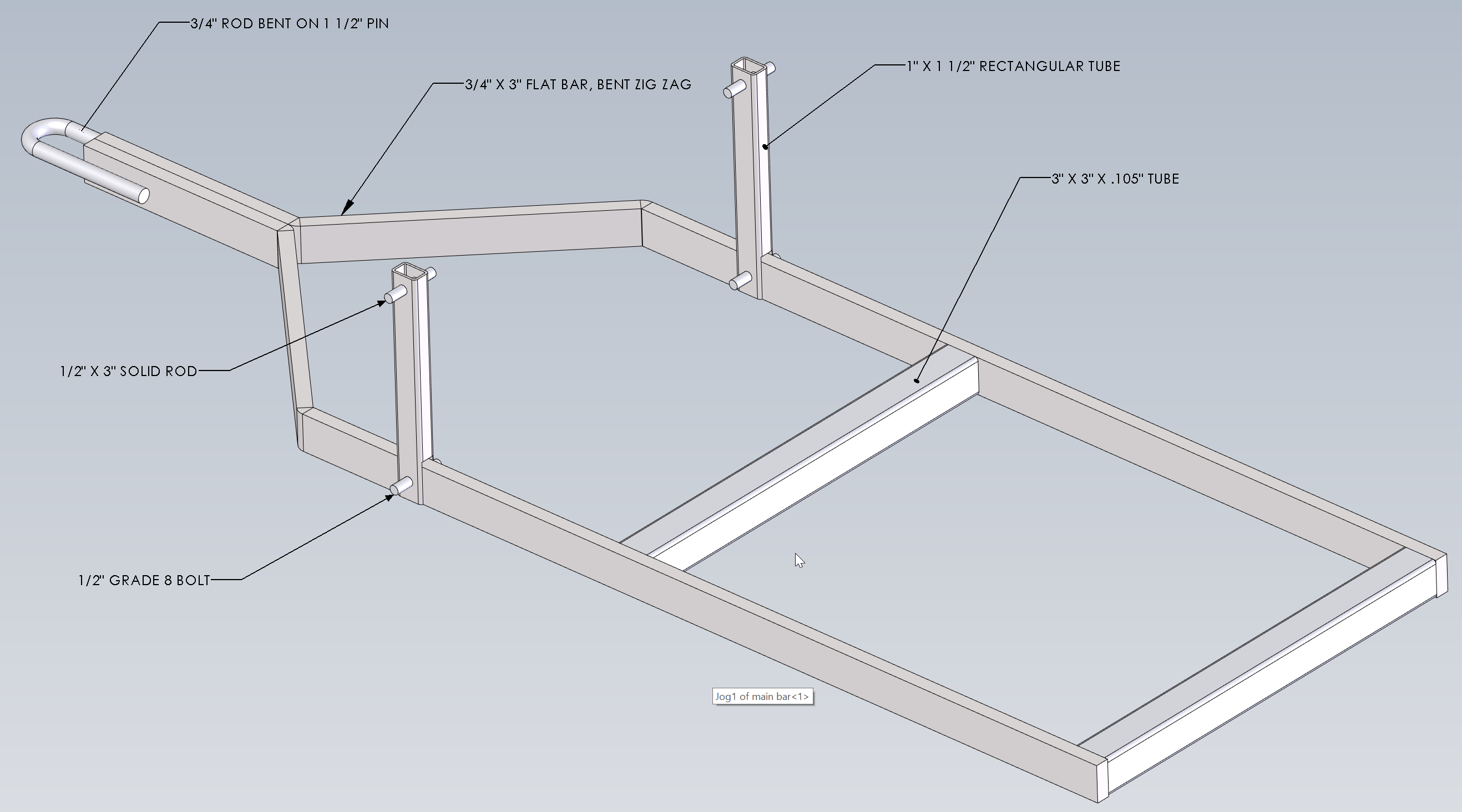

Rev 2 layout. I'm thinking the lower bar should be offset from the upper bar, so that when the lift is down with the forks on the fork tynes would be angled to parallel to the ground. The height of the top tyne carrier will need to be figured so that when the lift is all the way down, the tynes will be on the ground. Which may vary depending on the tynes used.

I used round bar on the bottom, because I'm thinking with a little modification of the layout you could adapt a universal skid steer connector to fit on this, with a couple hydraulic cylinders to control the pitch.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Mar 2024 at 1:41pm Posted: 07 Mar 2024 at 1:41pm |

Got around to making a drawing. Anybody think this will work? The 1/4" holes in item 5 are for washers and pins to hold the lift arms in the right place - may or may not be needed. Very little welding, but I would probably need someone to do the bending - not sure how to get around that. It *should* be able to go from all the way down - to touching the ground so the lift arms can pick it right up from the ground - to all the way up. On a D15 at least. Struggled to get it to avoid the pumpkin - but I will hopefully be building this in the next month or so.

With little modification to the 1" bar should be able to get a skid steer universal quick attach to work on it - maybe even with some hydraulics.

uploads/24122/whole_assembly.pdf

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Mar 2024 at 4:19pm Posted: 07 Mar 2024 at 4:19pm |

From a Welders point of view... I would not bend anything.. Cut and weld all the corners......... guess it depends on access to a bender, and you welding ability..

do the uprights #3 rotate with respect to the frame #1 ? .... what locks them together.

|

|

Like them all, but love the "B"s.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 51775

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Mar 2024 at 4:39pm Posted: 07 Mar 2024 at 4:39pm |

Easiest way would be to find an old SC plow or bush hog and pull the tongue, eye and lift arms off of it. That way you only have to attach the rest of it to the pivot hole already in the SC frame. I do know that a SC bush hog frame is mighty close, width wise, to cat 1 3 point hitch...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Mar 2024 at 5:03pm Posted: 07 Mar 2024 at 5:03pm |

steve(ill) wrote: steve(ill) wrote:

From a Welders point of view... I would not bend anything.. Cut and weld all the corners......... guess it depends on access to a bender, and you welding ability.. |

Welding ability is yet to be determined - I figured it'd be easier to find someone that could bend them while I wait, for cheaper, than I could find someone to weld the quality needed at the angles. Where the flats meet together there's a lot of space and a lot of weld I'm not too worried about sucking.

steve(ill) wrote: steve(ill) wrote:

do the uprights #3 rotate with respect to the frame #1 ? .... what locks them together. |

Yes they rotate. They are "locked" together by the 1" rod (5) going through them. Putting pins and washers on the outside of #3 to hold it together. There may need to be pins on the inside to stop the beams (1) from pinching together - but I don't think I'll need them.

|

|

MadCow

Bronze Level

Joined: 27 Aug 2023

Location: South Dakota

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Mar 2024 at 5:06pm Posted: 07 Mar 2024 at 5:06pm |

DiyDave wrote: DiyDave wrote:

Easiest way would be to find an old SC plow or bush hog and pull the tongue, eye and lift arms off of it. That way you only have to attach the rest of it to the pivot hole already in the SC frame. I do know that a SC bush hog frame is mighty close, width wise, to cat 1 3 point hitch... |

Implements in general around me are. About 4 times higher than elsewhere in the country - and AC stuff is almost non-existent. It's almost cheaper to ship LTL from 14hrs away than it is to try and buy old implements locally.

I've seen people post single row model 70 JD planters on a cobbled 3pt hitch with obvious rattle can paint for $1,500 and the post isn't up for more than 72 hrs before it's sold.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

steve(ill) wrote:

steve(ill) wrote:

I've got the real thing. AC SC pallet forks. They work pretty slick. If I can I'll find pics.

I've got the real thing. AC SC pallet forks. They work pretty slick. If I can I'll find pics.