| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 50619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 5:33pm Posted: 15 Dec 2022 at 5:33pm |

Ah yes, the price of ignorance is the cost of education.... As others have said dremel tool and stone to remove the burr and it should slide off. If you have a flex shaft dremel or similar, they have a smaller body that won't get in the way, as much...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 77982

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 4:44pm Posted: 15 Dec 2022 at 4:44pm |

I posted a similar problem with the PTO shaft binding on a 15 ft batwing a few weeks ago... My idea was the front shaft is TOO SHORT and should be a couple feet LONGER and the TOWER mount back further on the hitch.. Then when you turn a corner, the ANGLE in the shaft would be much reduced..... Apparently it is not a big problem if you DONT TURN TOO SHARP..... I rebuilt the batwing original tower so it pivots easier and rebuilt the SHORT front pto shaft ( new u-joint) ..........

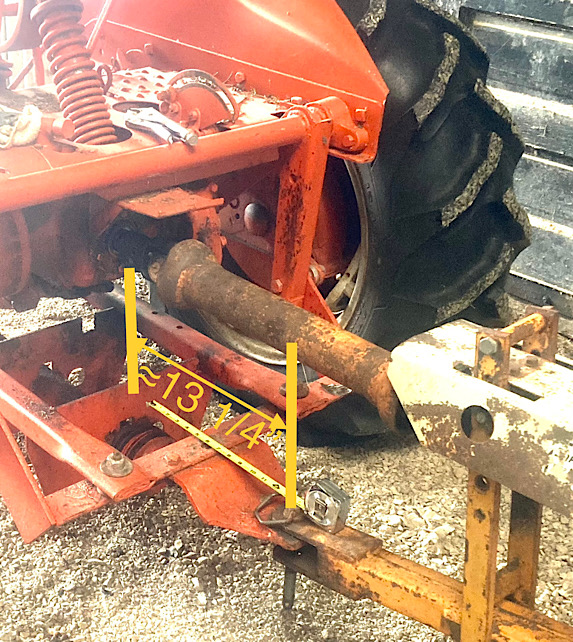

your photo.....mine looks similar.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 77982

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 4:36pm Posted: 15 Dec 2022 at 4:36pm |

Im working on a 15 ft Batwing right now... Correct me if i am wrong, but there is a TOWER on the mower hitch at the BACK END of the drive shaft... There is a support bearing that hangs inside that tower... The "front pto shaft) is maybe 24 inches long and SOLID.. it does not slide and change length... BEHIND the tower there is a 5 ft long drive shaft with a square drive inside a tube... that is what gives you the LENGTH NEEDED.. When you turn a corner, the TOWER is suppose to PIVOT forward or back a couple inches and make sure what happened, does not happen..

I dont think you shaft is TOO LONG... I think you turned TOO TIGHT for this design of pto shaft / hitch ...

You need to take a small air or electric die grinder and reach in and grind off the burrs or any high spots on the end of the shaft... Go slow and take off plenty.. A little undersize at the edge will not hurt... Eventually the shaft will then slide off.

|

|

Like them all, but love the "B"s.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 937

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 4:00pm Posted: 15 Dec 2022 at 4:00pm |

|

540 RPM is 14" and 16" is for 1000 RPM I believe.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8030

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 2:01pm Posted: 15 Dec 2022 at 2:01pm |

|

Aren't 540's supposed to be 16 inches from end of shaft to center of drawbar hole?

|

|

TomC

Orange Level Access

Joined: 24 Nov 2017

Location: Hillsboro, MO

Points: 1544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 11:49am Posted: 15 Dec 2022 at 11:49am |

|

Neighbor did pretty much same thing, we dropped the bush hog and pulled the driveshaft apart,we pulled the plastic guard off the half still on the tractor, then we put a breaker bar on the back of the pto shaft,and lifted up on the drive shaft, pulled it right off there.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 21550

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 11:43am Posted: 15 Dec 2022 at 11:43am |

Maybe remove the 'cross' of that Ujoint first, so you get GOOD access to the end of the PTO shaft, then deburr and see if the yoke moves. You may be able to put a 'gear puller' on the stuck yoke and pull it off. If possible PUSH the yoke closer to the tractor to expose more of the PTO shaft for deburring operations.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 11:35am Posted: 15 Dec 2022 at 11:35am |

|

You might have raised a bit of a burr or distortion where it was striking the end of the shaft, I think I’d start by dressing that on both sides with a file or small grinder and then see if shaft will slide off.

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

brkfldj

Bronze Level

Joined: 13 May 2010

Location: Sharpsburg, MD

Points: 166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 11:28am Posted: 15 Dec 2022 at 11:28am |

|

|

|

Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)