Operator ignorance & how do you fix the damage

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=192384

Printed Date: 27 Apr 2024 at 9:11am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Operator ignorance & how do you fix the damage

Posted By: brkfldj

Subject: Operator ignorance & how do you fix the damage

Date Posted: 15 Dec 2022 at 11:28am

|

While using my CA and Woods brush hog, I turned as sharp as I desired. Initially I didn’t pay attention to the drive line chatter and vibration that occurred during the sharp turns. But the damage was already done. The binding of the Woods drive shaft forced the yoke forward of the tractor’s pto shaft detent. Now I can’t remove the Wood’s shaft. The Woods shaft can slide forward until it contacts the tractor and can be pulled rearward to what I believe is almost the intended operating position. What is the best approach to removing the mower’s shaft from the tractor?      ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Replies:

Posted By: JoeM(GA)

Date Posted: 15 Dec 2022 at 11:35am

|

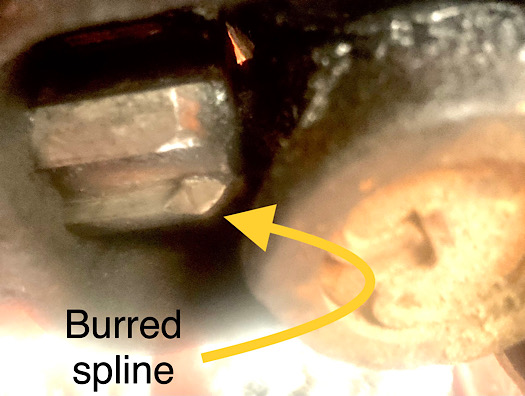

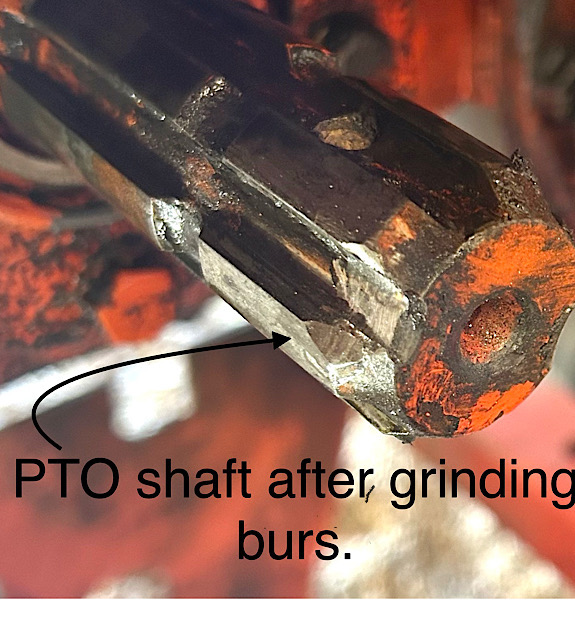

You might have raised a bit of a burr or distortion where it was striking the end of the shaft, I think I’d start by dressing that on both sides with a file or small grinder and then see if shaft will slide off. ------------- Allis Express North Georgia 41 WC,48 UC Cane,7-G's, Ford 345C TLB |

Posted By: jaybmiller

Date Posted: 15 Dec 2022 at 11:43am

|

Maybe remove the 'cross' of that Ujoint first, so you get GOOD access to the end of the PTO shaft, then deburr and see if the yoke moves. You may be able to put a 'gear puller' on the stuck yoke and pull it off. If possible PUSH the yoke closer to the tractor to expose more of the PTO shaft for deburring operations. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: TomC

Date Posted: 15 Dec 2022 at 11:49am

| Neighbor did pretty much same thing, we dropped the bush hog and pulled the driveshaft apart,we pulled the plastic guard off the half still on the tractor, then we put a breaker bar on the back of the pto shaft,and lifted up on the drive shaft, pulled it right off there. |

Posted By: SteveM C/IL

Date Posted: 15 Dec 2022 at 2:01pm

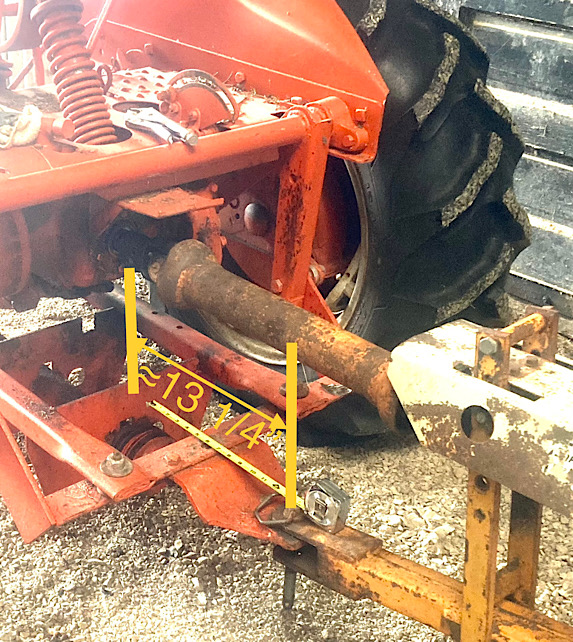

| Aren't 540's supposed to be 16 inches from end of shaft to center of drawbar hole? |

Posted By: Jim.ME

Date Posted: 15 Dec 2022 at 4:00pm

| 540 RPM is 14" and 16" is for 1000 RPM I believe. |

Posted By: steve(ill)

Date Posted: 15 Dec 2022 at 4:36pm

|

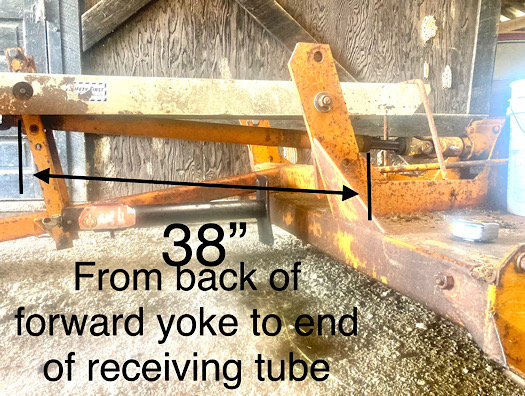

Im working on a 15 ft Batwing right now... Correct me if i am wrong, but there is a TOWER on the mower hitch at the BACK END of the drive shaft... There is a support bearing that hangs inside that tower... The "front pto shaft) is maybe 24 inches long and SOLID.. it does not slide and change length... BEHIND the tower there is a 5 ft long drive shaft with a square drive inside a tube... that is what gives you the LENGTH NEEDED.. When you turn a corner, the TOWER is suppose to PIVOT forward or back a couple inches and make sure what happened, does not happen.. I dont think you shaft is TOO LONG... I think you turned TOO TIGHT for this design of pto shaft / hitch ... You need to take a small air or electric die grinder and reach in and grind off the burrs or any high spots on the end of the shaft... Go slow and take off plenty.. A little undersize at the edge will not hurt... Eventually the shaft will then slide off. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 15 Dec 2022 at 4:44pm

|

I posted a similar problem with the PTO shaft binding on a 15 ft batwing a few weeks ago... My idea was the front shaft is TOO SHORT and should be a couple feet LONGER and the TOWER mount back further on the hitch.. Then when you turn a corner, the ANGLE in the shaft would be much reduced..... Apparently it is not a big problem if you DONT TURN TOO SHARP..... I rebuilt the batwing original tower so it pivots easier and rebuilt the SHORT front pto shaft ( new u-joint) .......... your photo.....mine looks similar.  ------------- Like them all, but love the "B"s. |

Posted By: DiyDave

Date Posted: 15 Dec 2022 at 5:33pm

Ah yes, the price of ignorance is the cost of education.... As others have said dremel tool and stone to remove the burr and it should slide off. If you have a flex shaft dremel or similar, they have a smaller body that won't get in the way, as much... https://youtu.be/dYp5mu_WM58" rel="nofollow - https://youtu.be/dYp5mu_WM58 ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: SteveM C/IL

Date Posted: 15 Dec 2022 at 9:34pm

| I'm wondering what shape your sliding section of shaft is like. Is it well lubed and slips in and out easily? Doesn't the shaft get shorter on a turn? I'm wondering if slip is bottoming out on tight turn. On my Woods 72 single my WD45 can turn till the tire hits the driveline shield and never bottom out. |

Posted By: brkfldj

Date Posted: 15 Dec 2022 at 9:46pm

|

[QUOTE=DiyDave] Ah yes, the price of ignorance is the cost of education.... There is no ending in site to the cost of my education. STEVE(ill), your description of the tower pivot and the fixed length forward shaft is spot on. When I suspected operator error, I disengaged the pto, turned sharp and dismounted to inspect. The forward fixed shaft was tight against the tractor and the telescoping rear shaft was bound against the mower transmission. The general consensus is to debur the tractor pto shaft. I’ll let you know how the process goes. Thanks for the council. Jim ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: SteveM C/IL

Date Posted: 15 Dec 2022 at 10:09pm

| ....so are you going to lengthen your hitch an inch or shorten you shaft? |

Posted By: AaronSEIA

Date Posted: 16 Dec 2022 at 5:56am

|

It sure looks to me like the wear part in your picture actually made a burr that is keeping the yoke from sliding off the splines. Like suggested, you may need too get a small die grinder and grind the splines back to the correct profile. Also, that C-clamp may be holding the release button in too far and actually re-locking the pin. Sometimes it's gotta be left "out" an 1/8-1/4". AaronSEIA

|

Posted By: DaveKamp

Date Posted: 16 Dec 2022 at 6:14am

I believe what you're suggesting, is to move the pivot point to a spot directly above the hitch pivot, and while that seems sensible, you can't do that... The geometry as they have it now, divides ANY angle of turn by two, and evenly distributes that angle between the two joints of the shaft. If you move the pivot point back to directly above the hitch pin, ALL the angle will go into just one joint, and you'll bottom out the yoke in only half the turn angle. Also keep in mind that the pivot that occurs at this point, is not just on one plane, it's on three... the tractor and mower conform to undulations independantly, so there's pitch and roll, as well as yaw. To get it loose, a dremel and about four very-full cups of patience. The bit I would choose is the coarse cylindrical type used for sharpening chainsaws- it'll have the reach, the right grit, and they're wonderfully inexpensive in bag-of-ten quantities. Last time I had a PTO shaft extraction, the poor feller had 'balled up' the tube, so I knocked apart the yoke, then used a hook attached to my slide-hammer to rap it out. If you do same, be gentle and patient, as the cast iron backends usually aren't really thick, as they don't generally take any load that way... a harsh beating there can break castings if you're not careful. Rap a few times, then knock it back, and look for wear-signs, they'll tell you where to touch it up. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: DaveKamp

Date Posted: 16 Dec 2022 at 6:26am

|

Which brings up a silly note- My earliest tractor work was Grandpa putting me to task with the hay rake. He had a cane fishing pole with a cowbell on it, and he lashed it to the offset boom of the hayrake, and positioned it so that if I started approaching the 'too tight' turn, that cowbell would contact the tire, and the V-lugs would ring it like a Christover Walken on a Saturday Night Live skit... So next time you head to the field, remember- More Cowbell!!

------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: SteveM C/IL

Date Posted: 16 Dec 2022 at 8:20am

| Grandpa came up with great idea for a warning system. |

Posted By: brkfldj

Date Posted: 16 Dec 2022 at 8:25am

|

Originally, my thinking was that the problem was the push button, lock-in-place pin. But I expect that the burrs are the issue. AaronSEIA - I think you are right about the C clamp. Currently, the yoke doesn’t slide to the rear far enough to make contact with the wear spot shown in my photo. DaveKamp - Thank you for the warning to not abuse the cast iron AND for the laugh from the vision of the cow bell on a pole. I would have benefitted from that innovation at the age of 12…. D14 & side delivery rake, too fast, too sharp, through a runoff swale. SteveM C/IL - I am a world class procrastinator. I bought the tractor with the # 5 mower already in place, but would like to remove the sickle mower and install a factory hitch. That requires identifying and purchasing the needed parts. So most likely the hitch will remain as is and I will discipline myself to wider turns. I’ll update after I work on it. Thanks. Jim ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: steve(ill)

Date Posted: 16 Dec 2022 at 9:00am

|

steve(ill) wrote: ... My idea was the front shaft is TOO SHORT and should be a couple feet LONGER and the TOWER mount back further on the hitch.. Then when you turn a corner, the ANGLE in the shaft would be much reduced NO.. that would make things worse.. I was considering to move the tower BACK toward the mower and make the front shaft LONGER so it does not create such and angle when you turn.. Right now, MY front shaft is about 24 inches FIXED and the back shaft is over 4 ft and has the slip square drive... I considered redesigned the tower with a 3 ft front shaft for LESS ANGLE when you turn.. FURTHER FROM THE HITCH.. BUT.. their original design was to have the hitch half way between the tractor PTO shaft and the TOWER to keep the angle at both ends the same when you turn.. JIM.... when you look at the PTO shaft, your TOWER should be basically VERTICAL position , the front shaft is FIXED and the rear shaft to the gear box should have 12 inches ( or so) of the square shaft showing... That gives you plenty of room for the shaft to EXTEND forward or backward as you turn or go over a hill. If you only have an inch or two of the SQUARE shaft showing, it will bind in a quick turn..... other than that, the PIVOT for the tower has to be lubed so it will move freely, and the Square drive shaft at the gear box needs to be oiled up good for freedom of movement.

------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 16 Dec 2022 at 9:12am

|

Jim... here is a photo off the internet of the mower with the PTO shaft off of the tractor. Note that THE TOWER IS TILTED BACKWARD several inches toward the gear box.. The rear shaft that is square should SLIDE EASILY several inches backward as you take the pto shaft off the tractor.... When you connect the mower to the hitch, you should have to PULL THE PTO shaft several inches forward to connect to the tractor shaft... If you dont have enough clearance, the rear shaft is too long .... you could possibly extend the drawbar so the PTO is further from the mower, but your 14 inch dimension of pto to hitch is correct .. Jim said...I disengaged the pto, turned sharp and dismounted to inspect. The forward fixed shaft was tight against the tractor and the telescoping rear shaft was bound against the mower transmission.... YEA... thats not how it was designed.. Something has changed ???  ------------- Like them all, but love the "B"s. |

Posted By: brkfldj

Date Posted: 16 Dec 2022 at 10:00am

|

The mower is a Woods Cadet 60. The drive line is like the internet picture posted. The tower moves easily and I expect that the drive line is original. Operator error. The small tires on the CA allow a very tight turn without contacting any of the hitch. ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: SteveM C/IL

Date Posted: 16 Dec 2022 at 12:36pm

| Frame it however you want...your coupled too short. The drive line should never be able to bottom out at maximum travel possible. |

Posted By: steve(ill)

Date Posted: 16 Dec 2022 at 12:46pm

|

Jim, i would agree you could turn a CA REAL QUICK and possibly get things in a bind... my only concern was you said the square slip shaft BEHIND the tower might have bottomed out on the gear case.. The tower should be able to TIP BACK several inches as shown in the above photo...... But i agree, it MIGHT be possible to turn quick and get the FRONT shaft in i bind if the PUSH on the tower is sideways and dont allow it to move BACK toward the gear box ??? BUT... you should have square shaft showing at the gear box end. ?? ------------- Like them all, but love the "B"s. |

Posted By: exSW

Date Posted: 16 Dec 2022 at 2:12pm

|

If you have a weak keeper on the pto yoke it can happen. My son did the same exact thing with the WD and the manure spreader a couple months back. It jumped the detent and the pto shaft end got chewed up by the bottom of the yoke. Cleaned it up with a carbide bit in a Fordam handset. ------------- Learning AC...slowly |

Posted By: DiyDave

Date Posted: 16 Dec 2022 at 6:36pm

Did I hear a request?  https://youtu.be/cVsQLlk-T0s" rel="nofollow - https://youtu.be/cVsQLlk-T0s ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: DaveKamp

Date Posted: 16 Dec 2022 at 9:57pm

So, U-joint yoke bind occurs as a result of the Ujoint being asked to negotiate an angle past it's geometric clearance. The position of the two U-joints being centered on either side of the pivot axis basically makes the total turn angle divide equally between the two... meaning, a 45 degree angle between PTO shaft and the mower's slip shaft is evenly split at 22.5 degrees per joint. Changing this relationship makes it so that one joint will be moving a tighter angle than the other, thus, not taking full advantage of the pair. But the one thing about Steve's note here... is the slipshaft. IF... IF there's a bend, kink, or otherwise obstruction in that slipshaft outer (and it happens that they get torqued and twisted on occasion), then that end of the slipshaft will no longer accept the inner, thus, it is effectively SHORTENED. You clearly made too tight a turn for the circumstances, but I think Steve's suggestion is that it SHOULD have been able to allow more... PERHAPS that reason, is that the slipshaft go to full depth travel. Besides being kinked/twisted/torqued, some of the OTHER things that'll prevent a slipshaft from fully collapsing... is embedded debris, or grease (fresh, but also especially saponified). So that's a good thing to check. Another note- you've got a C-clamp on that detent pin. You MIGHT have it forced too FAR in, to release. The pin is usually relieved in a radius to clear the splines through the cut, but if you push it too far, it's same as not enough. Back the clamp off, and work the joint a bit more by hand, and feel that detent, mebbie between that and a little light dressing of the gunge-out malling, it'll come off nicely. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: Dirt Farmer

Date Posted: 16 Dec 2022 at 11:30pm

| Is there an outside chance that the u joint was replaced on one end or the other and when sliding the shafts back together they were off by 90 degrees putting the joints out of alignment. Just a thought |

Posted By: Gary

Date Posted: 17 Dec 2022 at 7:58am

|

I believe the male shaft and female tube are shaped so that they only go together one way. This Video at around 2.20 illustrates that. G https://www.youtube.com/watch?v=_qGE7QgEzm0" rel="nofollow - https://www.youtube.com/watch?v=_qGE7QgEzm0 |

Posted By: tadams(OH)

Date Posted: 17 Dec 2022 at 12:33pm

|

The problem might be the drawbar or lack of. Is the hitch that's on that CA the same length as the stock drawbar or is it shorter?

|

Posted By: brkfldj

Date Posted: 20 Dec 2022 at 8:00pm

|

The thread has morphed into, 1) how to disconnect the mower shaft, and 2) is the drive line correct. 1) I pushed the driven yoke to the tractor and cleaned the exposed end of the tractor’s shaft. There is a burr or two to grind away.  2)The mower drive line looks “normal”, for what that is worth. With the tractor and mower on a flat floor there is 3 3/8” of available male shaft to receive the movement of the outer shaft during a tight turn. I haven’t researched correct dimensions.    Corrections and evaluations are on hold for a while.  Merry Christmas. Jim ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: steve(ill)

Date Posted: 20 Dec 2022 at 8:44pm

|

Jim, i just sketched it out on graph paper.. Assume you have 14 inches from the support bearing to the hitch pin and 14 inches from the pin to the PTO support bearing (tower) ... 28 inches total.. When you turn 45 degrees on the tractor, that 28 inches becomes 26 inches, so the PTO SHAFT moves 2 inches backward toward the gearbox.. Still clearance. When you turn 60 degrees on the tractor, that 28 inches becomes 24.5 inches so the PTO move 3.5 inches backtoward the gearbox ..... and you will bind... anything over 60 degree turn gets REAL BAD, REAL QUICK !! Probably OK if you limit your "TURNS" to 45 degrees...

------------- Like them all, but love the "B"s. |

Posted By: brkfldj

Date Posted: 20 Dec 2022 at 9:23pm

|

Thanks steve(ill). I was mowing as tight as possible around cedar clumps that tend to take over at the rock outcrops in the field. I have no idea of the degrees created by my turns, but the turns were too tight for the mower drive line. Jim ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: SteveM C/IL

Date Posted: 20 Dec 2022 at 9:28pm

| I'd have to go measure it but I'm sure my Woods has more shaft exposed than that one. Pull shaft apart and see how much is sticking in slip. If its only just fully engaged in slip while straight you're screwed. If plenty cut slip at weld and shorten front piece a couple inches and reweld. KEEP IT IN TIME!!! Then you can turn so short your tire catches shield and buckles it up but you won't jam the shaft into the tractor. |

Posted By: jaybmiller

Date Posted: 21 Dec 2022 at 6:43am

|

Maybe Santa will bring you a BIG pile of wood chips/mulch, so you can landscape those 'tight corner' areas into more gentle swoops ? Neighbour had a similar 'grass cutting' problem. I suggested making a flower garden out of the trouble area, naturally I got the 'grr another *&^^* garden to deal with ??!!' but he did make it. Turned into a real nice display and a simple, single,fast troublefree pass with the mower. Options, always try to find the ones that make YOUR life easier ! ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Tbone95

Date Posted: 21 Dec 2022 at 11:08am

|

Can't say for sure without hopping on his tractor and mowing on his job, but 45 degrees sure sounds very unrealistic for a sharp turn limit. Unhook your PTO, drive the tractor and turn very sharp, like your rear tire about to interfere, and stop and take the measurements on your PTO to see if you can shorten it up that much, and still be engaged properly when straight.

|

Posted By: steve(ill)

Date Posted: 21 Dec 2022 at 1:35pm

|

as the pto outer tube is 38 inches long, i would guess the SQUARE shaft is 24 - 30 inches... Thats why i said last week that it would be "NICE" if there was 12 inches of shaft showing... Outer tube would be better at 32 inches instead of 38....... Could be " cut and weld", but thats some work and depends on your welding ability ... and yes, the square end has to be ALIGNED with the yoke end if it is cut.... 45 degree angle is not much of a turn, but could be done... apparently you have been doing that prior to the OOOPS.. ------------- Like them all, but love the "B"s. |

Posted By: garden_guy

Date Posted: 22 Dec 2022 at 3:01pm

|

Very interesting math on the movement for turns... I really should make a note of how tight I can turn my WD with the 6' AC 172 mower behind it... There's some "play" in the side to side of the shaft so I think it lets me get away with more than it should. |

Posted By: brkfldj

Date Posted: 15 Mar 2023 at 6:35pm

|

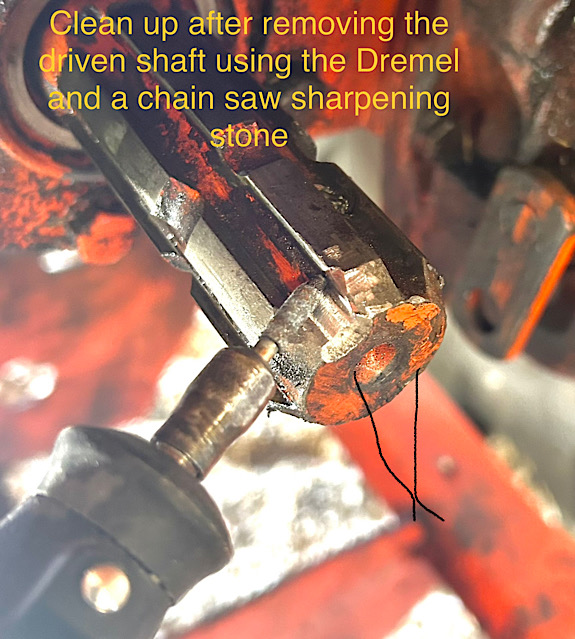

UPDATE: removal of the Woods Mower driven shaft was straight forward because of the council of you forum members. I used my Dremel with a cylindrical, chainsaw sharpening, grind stone. The burrs on the end of the PTO shaft were the source of my inability to remove the Wood’s driven shaft. A few minutes with the Dremel and the shaft was removed. There was no problem with the release button. Thanks to all. Jim    [IMG] [IMG]------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: rw

Date Posted: 16 Mar 2023 at 7:14pm

|

The long shaft that telescopes has to be really slick to slide with torque like mowing around a corner. Another experience i had with a sliding shaft was wear on the corners of the square shaft at the standard operating length. If the corners are rounded over and they have torque applied they bind as they try to slip into the squarer part of the tube. Creates a wedge. This happened to our 5 foot three point cutter. We mowed a gazillion acres of pasture and the shaft was really worn bad. Replaced inner and outer shaft problem solved.

|

Posted By: Nathan (SD)

Date Posted: 26 Mar 2023 at 8:44am

| Get your drawbar hole to 16 inches from the end of the PTO shaft. Technically not spec but it will solve your problem. Gives you more clearance back by the gearbox and moves the pivot point closer to the u-joint in front. |

steve(ill) wrote:

steve(ill) wrote: