| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Allis Fields

Orange Level

Joined: 17 Sep 2009

Location: Reedsburg,Wisc.

Points: 332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: one wire alternator Topic: one wire alternator

Posted: 12 Feb 2010 at 8:26pm |

|

I saw a sight that had one wire alternaters for sale But I can't remember who had them. I know I need low inpadence, low rpm start and a 5/8 inch wide belt pully.

|

|

|

Sponsored Links

|

|

|

Denis in MI

Orange Level

Joined: 15 Sep 2009

Location: Norvell, MI

Points: 832

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 8:41pm Posted: 12 Feb 2010 at 8:41pm |

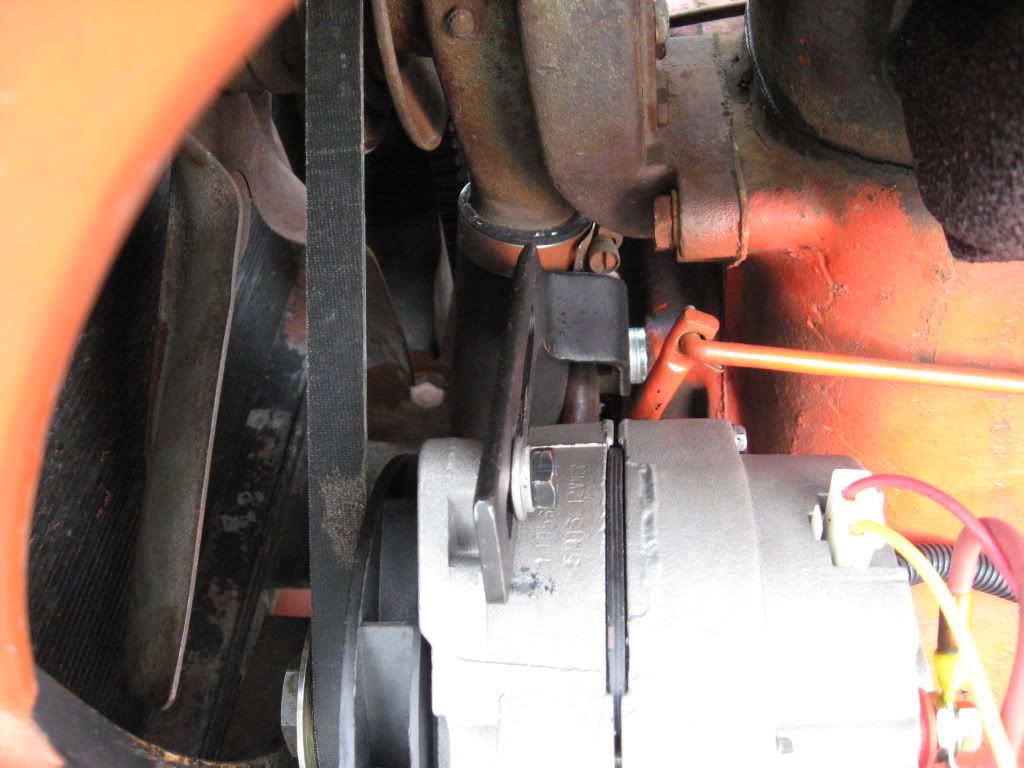

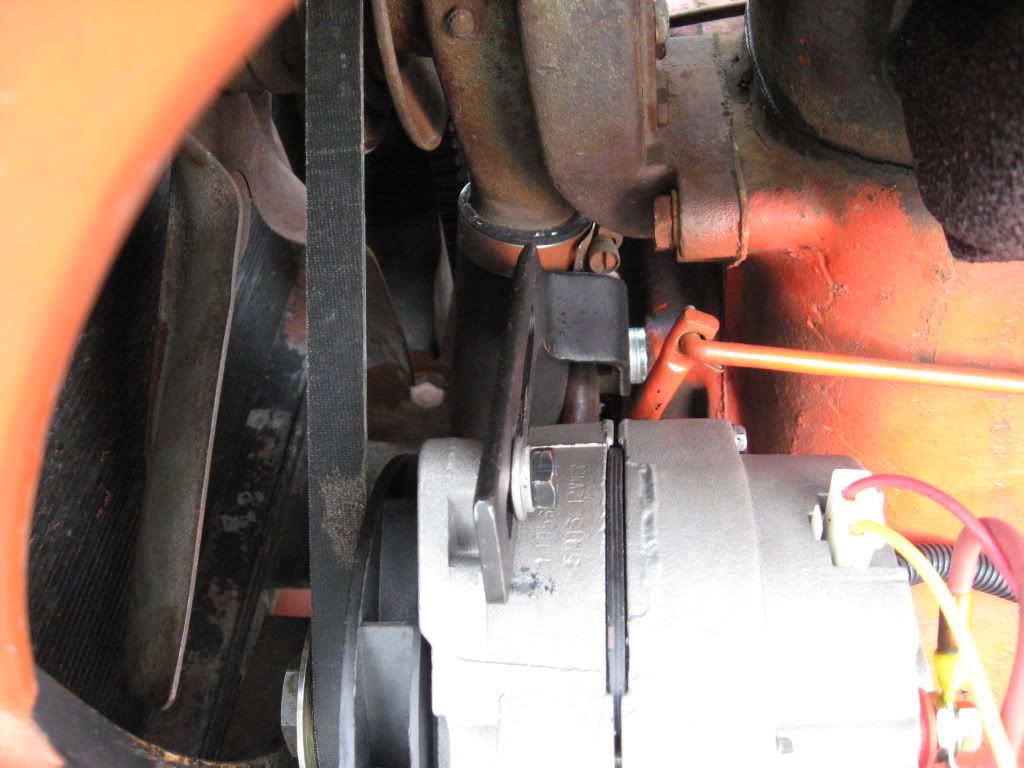

I don't know about low impedance but most one wires I have seen require engine is reved to 800 to start charging like this one

|

|

1938 B, 1945 B, 1941 IB, 1949 C, 2 1938 WCs, 3 1950 WDs, 1951 WD, 2 1955 WD45, 1957 D-14

|

|

kinghunter

Silver Level

Joined: 30 Jan 2010

Location: Kansas/Missouri

Points: 408

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 8:45pm Posted: 12 Feb 2010 at 8:45pm |

|

i run 1 wire alternaters off 80 model chevy vehicles and dont change belts , had to make brackets for them but they work will post pictures tomorrow. have them mounted to my wd's d17,d19,and both 190's

|

|

DREAM

Orange Level

Joined: 06 Jan 2010

Location: Elberton,GA

Points: 1828

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 9:44pm Posted: 12 Feb 2010 at 9:44pm |

|

Yeah, what Kinghunter said. That's what I would do. I don't know about the RPM requirements. What is your idle speed?

|

|

kinghunter

Silver Level

Joined: 30 Jan 2010

Location: Kansas/Missouri

Points: 408

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 9:50pm Posted: 12 Feb 2010 at 9:50pm |

|

my idle speed is low and on them chev alternaters there laying around everywhere i dont know anyone who cant say they dont know where a 80 model is broke down or where they could get parts. and the alternaters are cheap at the junk yards.

|

|

Denis in MI

Orange Level

Joined: 15 Sep 2009

Location: Norvell, MI

Points: 832

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 10:00pm Posted: 12 Feb 2010 at 10:00pm |

|

I use the old delcos too but mine are rigged with two wires

|

|

1938 B, 1945 B, 1941 IB, 1949 C, 2 1938 WCs, 3 1950 WDs, 1951 WD, 2 1955 WD45, 1957 D-14

|

|

firebrick43

Orange Level

Joined: 10 Dec 2009

Location: Warren County

Points: 592

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 10:16pm Posted: 12 Feb 2010 at 10:16pm |

|

There were no OEMs that used 1 wire alternators. The 80s chevy alternators that you are using are 3 wire but can be rigged with a short jumper to the positive post and one long wire to the battery. I highly suggest actually hooking up all three wires. It works much better and the posibility of the alternator discharging the battery when stopped is eliminated.

Definitely don't do a 1 wire. They are more expensive, the regulators are more fragile, and they cut in at higher rpms so you can be discharging the battery when you are putting around. Also they don't put out the proper 14.7 volts to the battery with longer wires.

A 3 wire sense and maintains 14.7volts constantly. Its very much worth the time and effort to hook up 2 more wires and a diode.

|

|

LouSWPA

Orange Level Access

Joined: 11 Sep 2009

Location: Clinton, Pa

Points: 25370

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2010 at 11:01pm Posted: 12 Feb 2010 at 11:01pm |

|

I just use a double pole switch for the ignition switch. one side is for the exciter wire for alternator, and other side is for ignition. One wire alt's are OK, but plane old GM alternators are dirt cheap at NAPA, and work well with my crude, but effective method.

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 12:56am Posted: 13 Feb 2010 at 12:56am |

|

14.7 is too much voltage for long battery life. 14.2 is best.

Gerald J.

|

|

dannyraddatz

Orange Level

Joined: 12 Sep 2009

Location: Plainfield, Ill

Points: 848

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 5:52am Posted: 13 Feb 2010 at 5:52am |

Here is some information off a web site follow the link at the bottom. Steve from B&B is a forum member and could help you on this project. This information should help you get started but give Steve a call for the final parts and help Steve@B&B B&B Custom Circuits Newton, NJ

One-wire 10SI:

The

Delco SI 1-wire has its uses. It is used on agricultural irrigation engines and

in marine applications. It has been used on automobiles and other vehicles

because it's easy to install and does not require a pigtail connector. That's

not to say the 3-wire is difficult to install. The pigtail connector is

available and will give access to the superior regulation provided by the

alternator's solid-state voltage regulator. The one-wire cannot

"sense" and adjust its output to provide a constant vehicle operating

voltage depending on the load demand. The one-wire is a good fit for an

irrigation engine that runs at one speed, has a constant load, and constant

demand. An external relay must be used with a 1-wire to operate an idiot light

in the dash. One-wire alternators also have "turn-on" issues because

it must self-excite using residual magnetism in the iron parts of the

alternator. If there is magnetism in the parts and the alternator is run up

fast enough then enough power is produced to excite the alternator and it will

ramp up the output. If it sits so long that no magnetism remains then that does

not happen. The one-wire sitting idle will drain a battery over time. The

1-wire is not the better choice for engines that may sit idle for long periods,

may be operated only at lower engine RPM's, use a dash light, engine RPM

routinely varies, or where blower motors, headlights and other load demands

come and go. My Ford tractor idles at less than 400-rpm and normally operates

just over 1500 so I would always have to be certain to rev up a self-excite,

1-wire alternator so it would begin to output regardless of how I will

otherwise operate the tractor. I don't mean to take anything away from the

one-wire alternator but the standard three-wire is a more sensible alternator

for most any application. One-wire alternators are also more expensive and not

as readily available.

The

3-wire will always turn-on at the lowest possible RPM because it is excited by

the battery voltage via the ignition switch to the alternator excite terminal

right from the get-go. The 63-amp 10SI won't put out amps until 1,000+RPM but

it is turned on and ready once the switch is on. The 3-wire with a diode in the

excite wire will give you the lowest RPM turn-on possible and eliminate any

battery-draining leakage current during long down times. The 3-wire hook-up is

straight forward with one wire going no farther than the alternator itself. The

10SI alternator wire harness with the DA-plug makes it a snap to wire up the

alternator. The harness also makes it simple to keep the dash light in the

circuit. No additional resistor is required when using the diode. The 63-amp

10SI begins charging at a lower RPM than any other size (amperage) 10SI, even

the lower amp 10SI's. Big plus when using the diode is that it allows you to

continue using an OEM on/off key-switch. You can use the standard 10SI pig tail

if you have an off/on/start/run ignition switch so you can isolate the

alternator from the battery by connecting the alternator to the accessory

terminal.

Belts, pulleys, and brackets:

Modern

belts do not fit older vehicles so the pulley that comes with a standard 10SI

will not match many early model vehicles and engines. Vintage autos likely have

at least a 1/2" wide crank and water pump pulleys and agricultural or

industrial engines may have 5/8" or larger pulleys. To get the 12-volt

conversion right means you need to measure the pulley on the crank or water

pump and install the proper wide-belt pulley on the alternator. My pulleys are

small diameter so to get that alternator up to speed at lower engine RPM. Don't

measure the existing v-belt because no telling how that type and size belt came

to be on your engine; measure the pulley. There is a lot to v-belts and running

the improper belt can be no end to problems and premature failure. You also pay

for a belt/pulley mismatch in horsepower (mileage). You can find most vehicles'

belt size on this parts

interface look-up. Note: after completing the type, make, model, year

selection, keep clicking on the part number until you get a pop-up Product

Detail which shows Top Width (In.).

I

list brackets for most applications but if you have something else again then

let me know what and why and see if I can fix you up. Compare fit and function

to your project and you will see this 12-volt alternator conversion thing isn't

going to be such a big deal. My products are heavy-duty, high-quality, and

nearly all of it is made in the USA. You need a good, hard mount or the belt

will slip under load so you won't get a good charge and you will wear and throw

belts.

http://www.kansasselectproducts.com/12V%20Conversion%20Guide.htm

Edited by dannyraddatz - 13 Feb 2010 at 6:56am

|

|

Danny Raddatz

|

|

Dave A

Orange Level

Joined: 11 Sep 2009

Location: Almond Wisconsi

Points: 855

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 6:40am Posted: 13 Feb 2010 at 6:40am |

|

I use the one wire alternaters here at work, on the fork lifts. It in a easy conversion, and I don't have to work with old school voltage regs. Have used the the two wire Delco with no problems. I like them on equipment that sits for a while, then is used. The one wire units have a small currant draw and over time the batteries wil go dead. Also make sure it is a Delco there are some off brands that look like Delco's. But like to give problems

|

|

Play the game for more than you can afford to lose... only then will you learn the game.

Winston Churchill

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 7:10am Posted: 13 Feb 2010 at 7:10am |

There is a link to the best wiring setup I have seen for a 12 volt with a alt, It's from Bryan Smith's web site. He has lots of good INFO on there.

Thanks Bryan.

Here is the INFO he has on his site.

Don

Edited by Don(MO) - 13 Feb 2010 at 7:14am

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 7:27am Posted: 13 Feb 2010 at 7:27am |

Hey Danny did you make your top bracket?

Don

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12045

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 8:00am Posted: 13 Feb 2010 at 8:00am |

|

Couldn't say any better myself. Good article. Hits right on what I've been telling our AC family here for the past 6-7 years. Three wire units are the way to fly for Tractors, and low rpm applications. Leave the 1 wire units to automotive applications where 1200-1400 rpm's to excite the unit is not an issue... Thanks Dan the man for the referral also! If I can help anyone out with a wiring system or components, just drop me an e-mail or give me a call. Be glad to help you out!

Steve@B&B Custom Circuits (973) 632-5596

|

|

Max(ia)

Orange Level

Joined: 15 Sep 2009

Location: Polk County,Ia

Points: 536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 8:55am Posted: 13 Feb 2010 at 8:55am |

|

Both my WC and D15 II have one wire units. Both have to be revved up in order to get them to charge. Both will drain the battery over time so the WC has a pull switch to cut the circuit, D15 has a knife switch on the battery terminal. Not my conversions. Not a very good setup as far as I'm concerned...

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 9:34am Posted: 13 Feb 2010 at 9:34am |

Hey Steve, If there was a relay wired up with the power for the one wire Alt that was powered up by the key switch and the main power for the Alt ran from the AMP gage or volt gage through the relay will that stop the battery from draining down?

Just thinking again ( I know that's how I get in trouble) I don't think a lot of a one wire units.

Don

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

boscoe

Silver Level

Joined: 23 Jan 2010

Location: ND

Points: 165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 11:05am Posted: 13 Feb 2010 at 11:05am |

|

Tha ks SDteve and Danny for good info if I have any issues with my switch I be callin ya, I recently was in fleet farm and bought a single wire delco because they said that was the one to replace my 3 wire that didnt work anymore, knowingn what I do now, UF-DA what a mistake. It was 34.95 I dont think they will let me return it, bur I will ask.

|

|

fixer1958

Orange Level

Joined: 13 Feb 2010

Location: kansas

Points: 2434

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 11:06am Posted: 13 Feb 2010 at 11:06am |

The first alternator I used was a old AC Delco (35 amp) and put a self exciting regulator in for $40 15 years ago. The only problem I had with that one was I had to run it at full throttle to kick it in. It finally bit the dust.

I found a 1 wire alternator at Napa for $40. Charging kicks in as soon as I start it,

Much better now.

Same as the ones on the web for #150+.

|

|

boscoe

Silver Level

Joined: 23 Jan 2010

Location: ND

Points: 165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 11:47am Posted: 13 Feb 2010 at 11:47am |

|

Currently I have a 1 wire 63A delco, 1 wire from alt going to main power solenoid ,one wire from solenoid going to volt gauge.

|

|

boscoe

Silver Level

Joined: 23 Jan 2010

Location: ND

Points: 165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 2:25pm Posted: 13 Feb 2010 at 2:25pm |

|

What abour volt meter can I run from alt to volt meter to switch?

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12045

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2010 at 8:21pm Posted: 13 Feb 2010 at 8:21pm |

|

Absolutely. In my 12V conversion systems, I use only a Voltmeter. I use the Voltmeter as a junction from the Alternator. The key switch is wired to the Voltmeter. This way, the key switch controls all power on board the Tractor, and there will be no parasitic draw. When the key switch is off, everything is off. When the key is turned to the ON position, it powers up everything on board the Tractor. Simple and effective!

Steve@B&B

|

|

pineyjd

Silver Level

Joined: 12 Sep 2009

Location: Southern NJ

Points: 100

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Feb 2010 at 7:43am Posted: 15 Feb 2010 at 7:43am |

|

Did not know about drain on battery, my D10/I40 has a chevy 1 wire alt on it & battery is always going dead when it sits without trickle charger

|

|

boscoe

Silver Level

Joined: 23 Jan 2010

Location: ND

Points: 165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Feb 2010 at 8:16am Posted: 15 Feb 2010 at 8:16am |

|

Steve and others, Alternator to volt meter, voltmeter to switch, switch to coil, don't I need a wire to go to solenoid to charge battery?

|

|

Burgie

Orange Level

Joined: 13 Sep 2009

Location: Scottsburg, IN

Points: 1192

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Feb 2010 at 8:33am Posted: 15 Feb 2010 at 8:33am |

|

I`m going to put one on the WC Puller.Put a switch on it so it won`t charge when pulling or when parked.The pulley on the one from Steiner`s will charge at a lower rpm.

|

|

"Burgie"

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12045

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Feb 2010 at 11:03pm Posted: 15 Feb 2010 at 11:03pm |

|

The Battery will get its power through the Ignition switch providing you run your Battery feed to the Ignition switch from the starter motor. This is how I designed my 12V conversion systems, so the Ignition switch controls all power on board the Tractor so there is no parasitic draw on the system. The Ignition switch takes the Battery out of the loop when the switch is OFF.

Steve@B&B

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2010 at 9:30am Posted: 16 Feb 2010 at 9:30am |

My D14 has a one-wire alt on it with the original ammeter. Not sure how it's wired, but I've never noticed that the battery is drained or weak, even though it's mostly used for clearing snow. I do have to run the rpms up once after I start it to get the alt to work, but then it's fine on its own.

Steve - do you mean that the line from the alt runs to the post on the starter so that power runs back through the ignition switch to the battery when switch is in the "run" position?

|

|

WC, CA, D14, WD45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)