| Author |

Topic Search Topic Search  Topic Options Topic Options

|

WD45 Aaron

Bronze Level

Joined: 03 Dec 2009

Location: Alto, MI

Points: 128

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

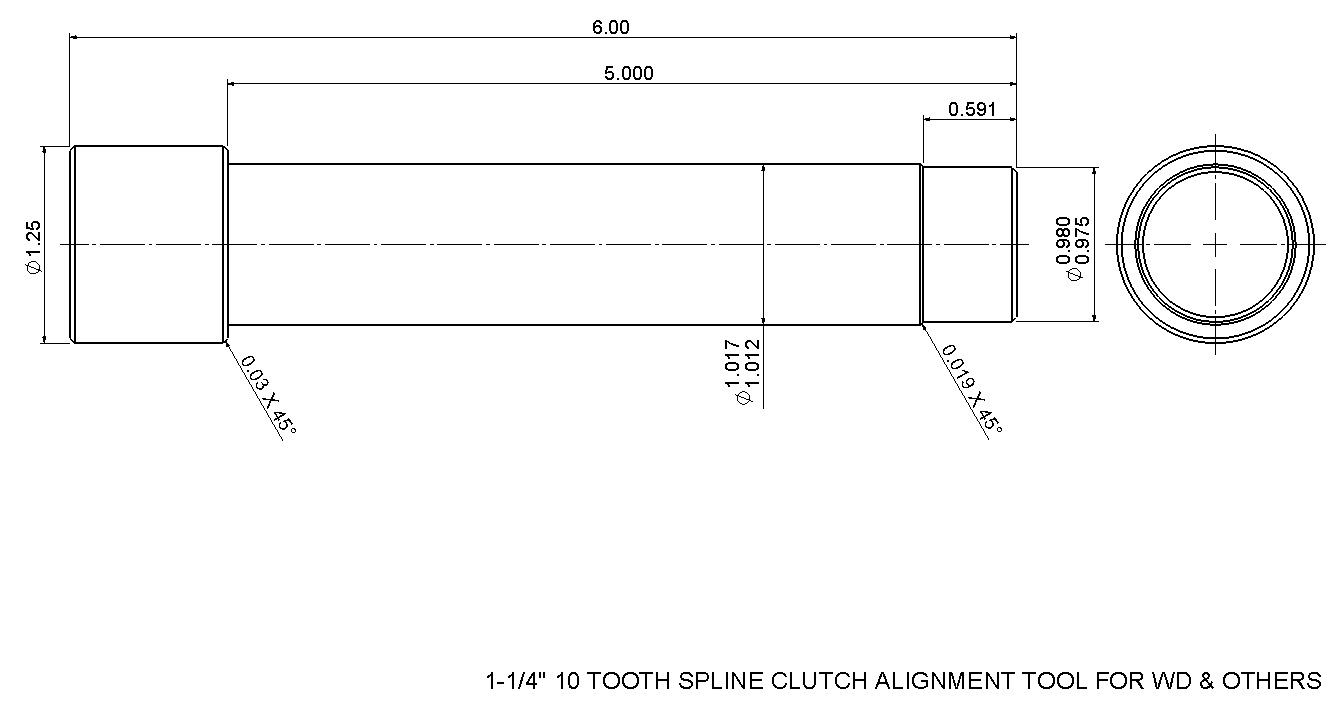

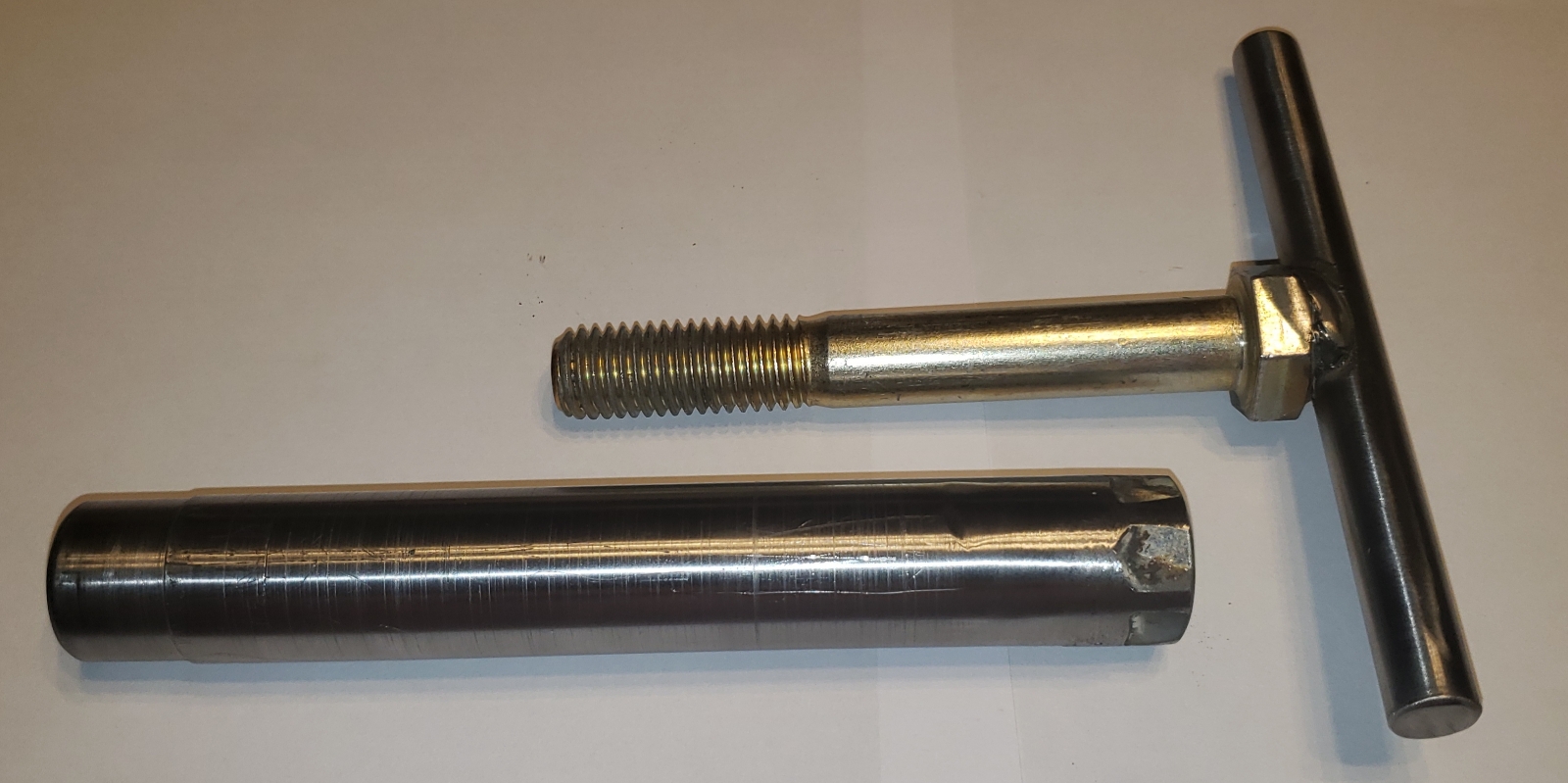

Topic: WD clutch alignment tool Topic: WD clutch alignment tool

Posted: 25 Nov 2019 at 8:56am |

|

|

|

Machinery rescue for all things rusty or broken. Current residents include 3-1/2 WD45s, Oliver Row 77 gas, 88 diesel, Farmall super C, parts C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota.

|

|

|

Sponsored Links

|

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8530

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2019 at 10:04am Posted: 25 Nov 2019 at 10:04am |

Aaron, Good design and build on the clutch alignment tool. That will make the installation go much better! Regards, Chris |

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Stan IL&TN

Orange Level

Joined: 13 Sep 2009

Location: Elvis Land

Points: 6730

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2019 at 11:45am Posted: 25 Nov 2019 at 11:45am |

|

There I went and thought I had did something great when I used a deep well socket over the use of a broom handle. Just teasing you Aaron. It looks great!👍👍

|

|

1957 WD45 dad's first AC

1968 one-seventy

1956 F40 Ferguson

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24707

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2019 at 1:05pm Posted: 25 Nov 2019 at 1:05pm |

dang, all I did WAS use a broom handle when I did "D-14 Troy" back in 2000. Still going strong today... Local garage tossed out ALL of their alignment tools as clutch 'packages' now come with tool....

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2019 at 8:45am Posted: 26 Nov 2019 at 8:45am |

|

I cut the splined end off a junk input shaft, works good!

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2573

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2019 at 4:53pm Posted: 26 Nov 2019 at 4:53pm |

I use a junk input shaft too. I think DJS Parts sells a plastic alignment tool for $10 or so. If I had a lathe, I'd probably turn yours just for the fun of it though. AaronSEIA

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8642

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2019 at 5:29pm Posted: 26 Nov 2019 at 5:29pm |

|

Did similar for T limiter in 8070. Pilots in back of crank(no brg). Lets you get it together before the "burnish" to true it.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)