I'm a bit confused after reading through the manual on setting the crush height of the crank bearing shells. For a crush amount of .0015", does that indicate .0015" protruding on both ends of a bearing half?

And also, should there be "crush" showing on only half of the bearing i.e. the half installed in the block has crush, but the half in the cap is flush? If I install a bearing cap, should I see the crush gap at both sides, or only one?

What is the best way to measure the total crush?

Lastly, why does the manual say "for each .002 reduction in height of a pair of shell inserts, remove a .0025 shim from each side"? Why isn't this a one to one relationship?

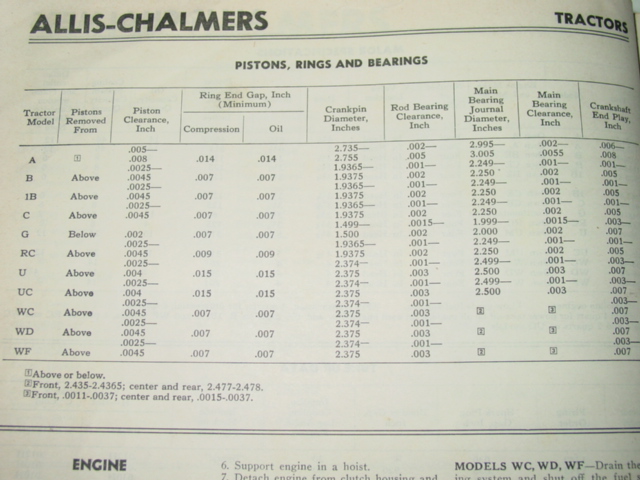

This is for a '49 C (if it matters). Manual seems to indicate this was common across models.

Hopefully the questions make sense! thanks

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

d17brown wrote:

d17brown wrote: