Bearing crush and clearance

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=165758

Printed Date: 15 Sep 2025 at 12:07am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Bearing crush and clearance

Posted By: Luke114

Subject: Bearing crush and clearance

Date Posted: 11 Nov 2019 at 3:20pm

|

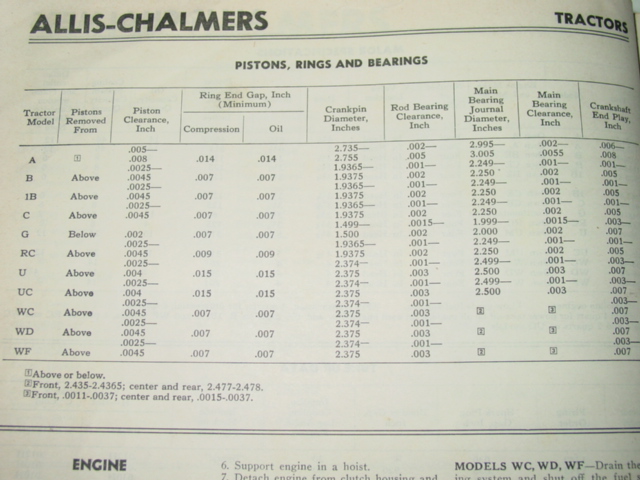

I'm a bit confused after reading through the manual on setting the crush height of the crank bearing shells. For a crush amount of .0015", does that indicate .0015" protruding on both ends of a bearing half? And also, should there be "crush" showing on only half of the bearing i.e. the half installed in the block has crush, but the half in the cap is flush? If I install a bearing cap, should I see the crush gap at both sides, or only one? What is the best way to measure the total crush? Lastly, why does the manual say "for each .002 reduction in height of a pair of shell inserts, remove a .0025 shim from each side"? Why isn't this a one to one relationship? This is for a '49 C (if it matters). Manual seems to indicate this was common across models. Hopefully the questions make sense! thanks

|

Replies:

Posted By: Dick L

Date Posted: 11 Nov 2019 at 5:13pm

|

I use a feeler gage with the nuts only snug or a bit over finger tight on one side. They are assuming you only want .0015 clearance.

|

Posted By: d17brown

Date Posted: 11 Nov 2019 at 6:17pm

|

Use plasticgauge. It crushes when bearing is torqued. Then you know your clearence ------------- phil |

Posted By: Dick L

Date Posted: 12 Nov 2019 at 5:24am

The question comes into effect when you are removing shims to take up excessive clearance. Once the bearings have been torqued and (crushed) they do not expand. That would mean you would not get any crush when re installed. If ignored I doubt it would cause a problem. When installing new bearings on a crankshaft that has wear and the crush is not checked the crush will be forced in against the journal and stop the crankshaft from turning. This is where filing becomes necessary. |

Posted By: Luke114

Date Posted: 12 Nov 2019 at 11:32am

|

Thanks for the responses, guys. I probably made my question overly complicated, getting crush and clearance conflated. In this picture in the manual they show .0015" of crush on both sides, but I think a normal way of measuring would be with one bolt torqued up and the other loose, or just snug as Dick L said. So should I look for .0015 gap on both sides or just one? |

Posted By: Dick L

Date Posted: 12 Nov 2019 at 11:51am

| It would be both sides to be sure you didn't have one side at .0015 and the other at .003 or something. I actually make one side flush in the rod and one end flush in the cap and measure the other end with a feeler gage using my finger to feel them flush. When torqued against the shims it will center the bearing shell. |

d17brown wrote:

d17brown wrote: