| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: CA Hand Clutch Restore - Final Update 4/23 Topic: CA Hand Clutch Restore - Final Update 4/23

Posted: 08 Mar 2019 at 1:55pm |

Final update! See post dated 4/23 on p2.

I've mentioned in an earlier post that the hand clutch on my CA won't release. I had rehabbed it 10+ years ago, and, though it worked fine at first, I then had problems with it slipping. I tried adjusting the release actuator - that didn't help at all. The most recent issue is that it won't release.

Today I tackled removal of the hand clutch to investigate. As I reported in my "CA Brake Mystery" thread, the drive shaft, clutch/brake unit and pinion shaft all separated from each other with no effort at all! I should be and am grateful!!

I will replace the brake drum part of the brake/clutch unit with a used one that has been sitting on the shelf for years, waiting for this moment to arrive.

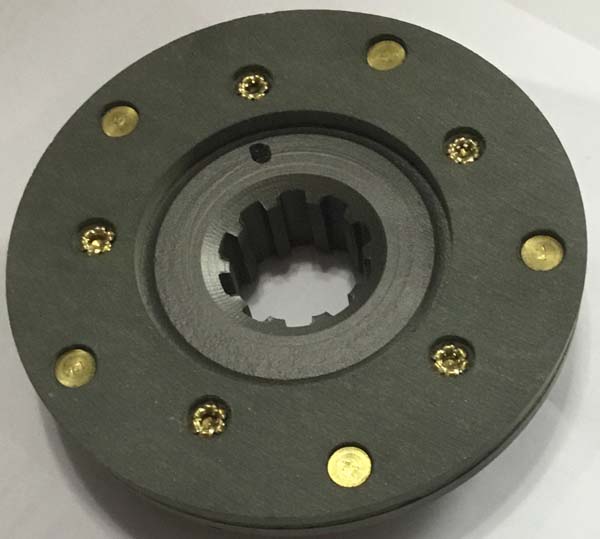

Here are some pictures of the unit:

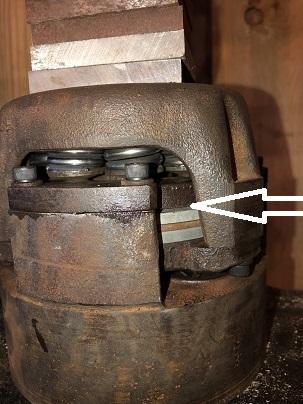

And here is a shot of the actuator. You'll see that there's no set screw locking the adjusting hub......

And here's what fell out of the housing when I tipped it:

The missing set screw! Not having this bolt installed probably contributed to my issues!

Next step is to review - again - all the information on here about restoring the clutch and actuator. In the meantime, any comments based on the pictures would be really welcome.

Dave

Edited by Dave(inMA) - 24 Apr 2019 at 8:22am

|

|

WC, CA, D14, WD45

|

|

|

Sponsored Links

|

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2019 at 2:10pm Posted: 08 Mar 2019 at 2:10pm |

Okay. I have read the CA Hand Clutch rebuild thread in the Knowledge section - very helpful. I am questioning the actuator gap quoted in photo #7 - the manuals I have state 0.005" (IT manual) or 0.055" (AC reprint) compared to the 0.50" in the caption for #7!

Next step is to disassemble the unit and clean up the parts. I'll report back when this is done.

Dave

Edited by Dave(inMA) - 08 Mar 2019 at 4:29pm

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2019 at 4:38pm Posted: 08 Mar 2019 at 4:38pm |

I have disassembled the clutch pack. Both of the primary, secondary pressure plates were rusted to the clutch plate. Clutch plate will need to have the material removed and new riveted on. Both pressure plates are pitted to some degree. I'll try to post some pictures later.

I'm still trying to dope out the actuator/clutch pack separation. The post in the Knowledge forum says 0.5" which clearly can't be right. The IT manual specifies 0.005" while the AC service manual says 0.055". I'm strongly wanting to believe the AC service manual, of course, but it'd be nice to have some corroboration!

Thanks, all. Dave

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2019 at 7:48pm Posted: 08 Mar 2019 at 7:48pm |

The clutch pack innards were pretty well welded together by rust. Here are pictures of the clutch plate and the two pressure plates after I separated them and cleaned up the pressure plates:

Clutch:

Primary pressure plate:

Secondary pressure plate:

Clearly the clutch needs to be rebuilt. What do you all think of the pressure plates? Can they be resurfaced, or would it be better to replace them? Parts sources?

Thanks much. Dave

|

|

WC, CA, D14, WD45

|

|

GregLawlerMinn

Orange Level

Joined: 11 Sep 2009

Location: Lawler, Mn

Points: 1226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 9:03am Posted: 09 Mar 2019 at 9:03am |

|

The actuator clearance stated in the knowledge base is a "Phat Phinger" error. It should be 0.050". These clutches, and parts, are hard to come by. You can try to resurface the plates; however, you will have to adjust the gap setting by grinding material off the ears.

|

|

What this country needs is more unemployed politicians-and lawyers.

Currently have: 1 D14 and a D15S2.

With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 12:26pm Posted: 09 Mar 2019 at 12:26pm |

Thanks, Greg. There's a machine shop near me that might be able to do this work. Per the Knowledge Base, the clutch wants a gap of 0.020" when compressed. Do you know if the gap is measured between the primary pressure plate and the clutch disc or secondary pressure plate and the clutch disc?

Thanks Dave

|

|

WC, CA, D14, WD45

|

|

GregLawlerMinn

Orange Level

Joined: 11 Sep 2009

Location: Lawler, Mn

Points: 1226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 1:18pm Posted: 09 Mar 2019 at 1:18pm |

|

Compress the assembled clutch in a shop press, vise, C-Clamp or ?? and measure the gap between the friction surfaces. I would suspect that you will see 1/8 to 1/4" gap initially. Measure the actual gap and subtract 0.020" to get the amount you will need to remove from the ears to reach the final 0.020" gap. Note the 0.020" gap is nominal, the clutch will function fine with less of a gap. Measure your springs; they should all be the same height, if not consider replacing them. I also apply a little never seize (sparingly) to the ball seats before final assembly.

|

|

What this country needs is more unemployed politicians-and lawyers.

Currently have: 1 D14 and a D15S2.

With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC

|

|

DennisA (IL)

Orange Level

Joined: 11 Sep 2009

Location: Ridott IL.

Points: 2077

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 1:37pm Posted: 09 Mar 2019 at 1:37pm |

|

The plates and ball seats are no longer available. You can still get the springs, liners w/rivets, disc assembly & rollers from AGCO. McMaster Carr should have the rollers as well for less money. I don’t know of any 3rd party suppliers. I currently have parts being machined. I plan on putting together a “CA” hand clutch rebuild video.

I would recommend replacing the springs as they do lose tension over time.

Edited by DennisA (IL) - 09 Mar 2019 at 2:39pm

|

|

Thanks & God Bless

Dennis

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 3:07pm Posted: 09 Mar 2019 at 3:07pm |

Greg and Dennis - thanks very much for all that info - big help. I'll check the springs and balls. I'll update this once I resurface the clutch, get the pressure plates cleaned up, etc. Looking forward to seeing the video, Dennis.

Dave

Edited by Dave(inMA) - 09 Mar 2019 at 3:08pm

|

|

WC, CA, D14, WD45

|

|

DennisA (IL)

Orange Level

Joined: 11 Sep 2009

Location: Ridott IL.

Points: 2077

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 3:55pm Posted: 09 Mar 2019 at 3:55pm |

|

If the roller seats are worn you may be able to remove them and rotate them 90 degrees. I’ve never done that so it may work or just open a can of worms. If you do rotate them make sure you do it before you machine the ears/ tabs down. That way your clearance is right.

Edited by DennisA (IL) - 09 Mar 2019 at 3:59pm

|

|

Thanks & God Bless

Dennis

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 5:53pm Posted: 09 Mar 2019 at 5:53pm |

|

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2019 at 9:23pm Posted: 09 Mar 2019 at 9:23pm |

Dennis, the ball seats look uniform - thankfully. But this would be a good thing to make right before reassembling.

Dave

|

|

WC, CA, D14, WD45

|

|

Bill Long

Orange Level

Joined: 12 Sep 2009

Location: Bel Air, MD

Points: 4556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2019 at 9:53pm Posted: 10 Mar 2019 at 9:53pm |

Be certain to look on the Knowledge section of this forum. You will find a section on the rebuild of the CA hand clutch there. It has been most helpful to some.

As to grinding the ears when we were selling and servicing them we ground 1/8" off the ears. Seemed to work well. As to parts, Sandy Lake - one of the advertisers on this forum - does outstanding work on parts and supplies for Allis Chalmers. They are most helpful. Give them a call

Looks like you have a difficult job ahead. When we got into them we replaced the springs and dishes but that was "back in the day" Let us know how it goes. Good Luck! Bill Long

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2019 at 7:51am Posted: 11 Mar 2019 at 7:51am |

Hi Bill - thanks for all that! I think it'll go well once I line up some parts and a machine shop. I'll be back with updates.

Dave

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2019 at 3:55pm Posted: 11 Mar 2019 at 3:55pm |

So the pressure plates are at a machine shop to have the pitting removed. And some parts are ordered: clutch plate kit, springs and balls.

Meanwhile, I ran across a fellow who claims to have a trailer full of NOS parts and MIGHT have unused replacements for some of the clutch parts. He was a little vague about whether the stash is AC parts or parts for various brands. Gonna go look tomorrow morning.

Edited by Dave(inMA) - 11 Mar 2019 at 3:56pm

|

|

WC, CA, D14, WD45

|

|

DennisA (IL)

Orange Level

Joined: 11 Sep 2009

Location: Ridott IL.

Points: 2077

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2019 at 3:18pm Posted: 13 Mar 2019 at 3:18pm |

|

|

|

Thanks & God Bless

Dennis

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2019 at 4:53pm Posted: 14 Mar 2019 at 4:53pm |

Those plates look great all cleaned up, Dennis. It'll be interesting to see how much you have to remove from the "ears".

I'm also waiting for a kit to resurface the clutch plate and springs as well. And waiting to have the pressure plates resurfaced.

Edited by Dave(inMA) - 14 Mar 2019 at 7:36pm

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2019 at 7:58am Posted: 16 Mar 2019 at 7:58am |

|

Parts came yesterday! Included new disc balls. They look larger than the ones that came out of mine. I haven't taken the actuator apart yet to compare them to the release balls.

Edited by Dave(inMA) - 16 Mar 2019 at 4:11pm

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2019 at 4:19pm Posted: 16 Mar 2019 at 4:19pm |

Parts to rehab the clutch surfaces arrived yesterday. The old surfaces were totally destroyed by the rust.

Here's my riveting machine - sorry for the clutter in the background. It's foot-pedal actuated and sets up a rivet like a dream. This belonged to my local AC buddy who passed away in 2010. It's been sitting in his shop since then. Knowing that I needed to install rivets for this project, I stopped by when his son was there and asked if I could borrow it. He GAVE it to me.

And here's the clutch plate with new friction surfaces:

The pressure plates are at the machine shop. Unfortunately they won't be touched for a week. But I'm looking forward to posting some shots like Dennis's soon.

|

|

WC, CA, D14, WD45

|

|

Rick

Orange Level

Joined: 11 Sep 2009

Location: Jonesburg,Mo.

Points: 3695

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2019 at 5:58pm Posted: 16 Mar 2019 at 5:58pm |

|

The CA disc balls are much smaller than say...the brake disc balls for the 100 series tractor...there's a very big difference. Hopefully, they didn't send you the wrong ones, but can be returned, I'm sure. Rick

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2019 at 8:44pm Posted: 16 Mar 2019 at 8:44pm |

Thanks, Rick. I was able to compare the balls shipped to me to the disc balls that came out of the clutch pack - they're the same size. So, all good. Dave

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 12:04pm Posted: 19 Mar 2019 at 12:04pm |

Machine shop called to say that the pressure plates were ready! They took off 0.045 total in addition to whatever I removed with the belt sanding machine - so maybe a total of 0.055". They look a LOT better - see my 3/8 post for the "before" pictures. Here are the refreshed plates:

I'll be able to reassemble the clutch pack later today and measure the gap, then back to the machine shop to trim the ears. PROGRESS!!

BTW, note the three holes in each plate. There were corresponding holes in the clutch plate - clearly this clutch had been thru-bolted at one point.

Edited by Dave(inMA) - 19 Mar 2019 at 12:07pm

|

|

WC, CA, D14, WD45

|

|

DennisA (IL)

Orange Level

Joined: 11 Sep 2009

Location: Ridott IL.

Points: 2077

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 12:20pm Posted: 19 Mar 2019 at 12:20pm |

|

Looking good!

|

|

Thanks & God Bless

Dennis

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 4:43pm Posted: 19 Mar 2019 at 4:43pm |

I assembled the clutch pack today. New springs, new disc balls. Put the pack in my shop press and applied pressure. Here are the pictures of the compressed pack - the white arrow indicates where the gap opened up in the pack. The second picture shows the compressed pack with 0.072" of feeler gauge inserted. So my gap is 0.052" over the recommended width.

So two questions:

1. The pack is compressed in a 20 ton press. Does this compress the pack more than the clutch handle? Said differently, how far should I compress the pack in the shop press to match what will happen in the tractor?

2. The disc balls are slightly loose when the clutch pack is uncompressed. Is this okay?

Thanks very much guys! Dave

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 9:03pm Posted: 19 Mar 2019 at 9:03pm |

With a little nudge from GregLawler, I think I'm clear on my first question. The 0.020" is a nominal measurement in the shop press that translates into a smaller gap - but enough - when in use in the tractor. It'd help if I would read what he wrote in his post 10 days ago!

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 3:53pm Posted: 20 Mar 2019 at 3:53pm |

I have double-checked the disc balls. They and the ones I removed from the clutch pack are 0.75" diameter. So it's likely that these are the right balls.

Spent some time thinking about what these balls do. When the clutch is opened to stop the tractor, the clutch disc and the primary pressure plate move toward the right wheel inside the clutch pack - away from the secondary pressure plate which doesn't move as the secondary pressure plate is bolted to the brake drum which is keyed to the final drive shaft. The resulting gap interrupts power to the right wheel. The purpose of the disc balls is to support the clutch and primary pressure plates against the force of the springs when the clutch is opened.

So here's the punch line: If the disc balls were immovable with the clutch closed (power to right wheel), there'd be no space for the clutch to open into. That is, the balls have to be loose with the clutch closed in order for it to be able to open.

I hope this is making sense to you who read it.

|

|

WC, CA, D14, WD45

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 8:13pm Posted: 20 Mar 2019 at 8:13pm |

Dave(inMA) wrote: Dave(inMA) wrote:

The purpose of the disc balls is to support the clutch and primary pressure plates against the force of the springs when the clutch is opened.

If the disc balls were immovable with the clutch closed (power to right wheel), there'd be no space for the clutch to open into. That is, the balls have to be loose with the clutch closed in order for it to be able to open.

|

NO, the purpose of the clutch balls is to ramp the clutch OPEN, when you pull the actuator, which compresses the springs. The ball set in a recess on either side and you "mis-align" those recesses when you actuate the clutch. I hope this is making sense to you who read it.

|

|

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 9:13pm Posted: 20 Mar 2019 at 9:13pm |

CTucker, there are two sets of balls involved. You are absolutely correct about the release balls. They sit behind the release actuator and translate the force on the hand lever into force on the actuator. On the other hand, the disc balls sit between the primary pressure plate and the brake drum inner surface - they're at the other end of the whole assembly and have nothing to do with opening the clutch. It's the disc balls that I've been concerned about. I'll try to figure out how to copy the parts diagram - that'll help with understanding all this.

Dave

|

|

WC, CA, D14, WD45

|

|

Ted J

Orange Level

Joined: 05 Jul 2010

Location: La Crosse, WI

Points: 18943

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 9:47pm Posted: 20 Mar 2019 at 9:47pm |

HUH?

|

|

"Allis-Express"

19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 10:42pm Posted: 20 Mar 2019 at 10:42pm |

Here's the hand clutch diagram:

CTucker's post describes how the release balls function to move the release actuator.

I've been thinking about the disc balls which sit at the other end of the entire hand clutch assembly between the primary pressure plate and the inside of the brake drum. The function of the disc balls is to support the primary pressure plate when the clutch is fully open.

Edited by Dave(inMA) - 21 Mar 2019 at 6:01am

|

|

WC, CA, D14, WD45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Dave(inMA) wrote:

Dave(inMA) wrote: