| Author |

Topic Search Topic Search  Topic Options Topic Options

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 9:50am Posted: 06 May 2024 at 9:50am |

|

Do I place the jack on the plank under the drawbar

|

|

|

Sponsored Links

|

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 10:57am Posted: 06 May 2024 at 10:57am |

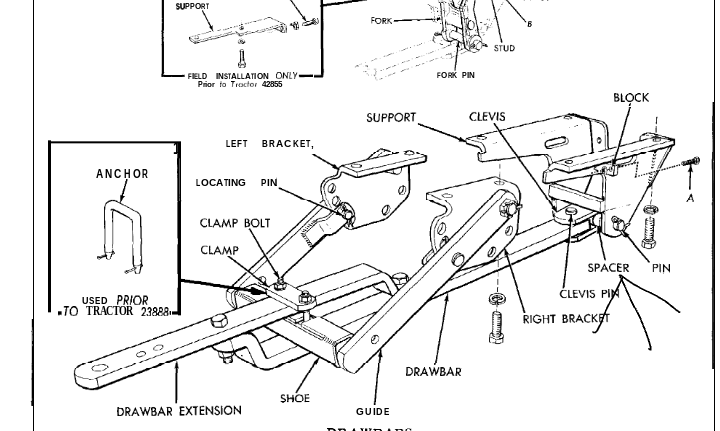

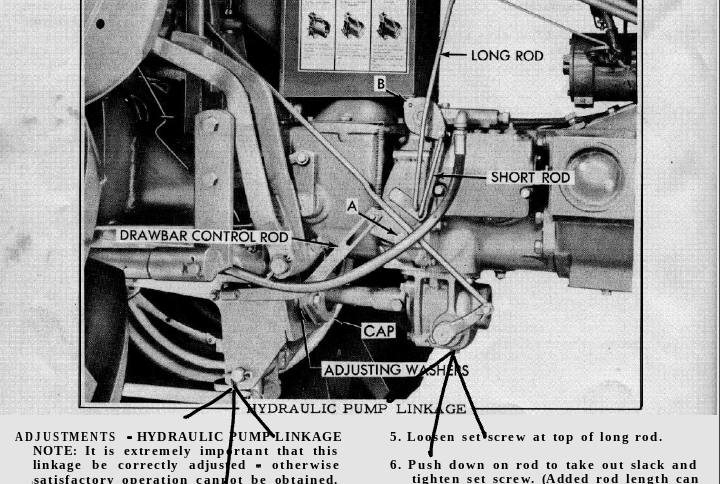

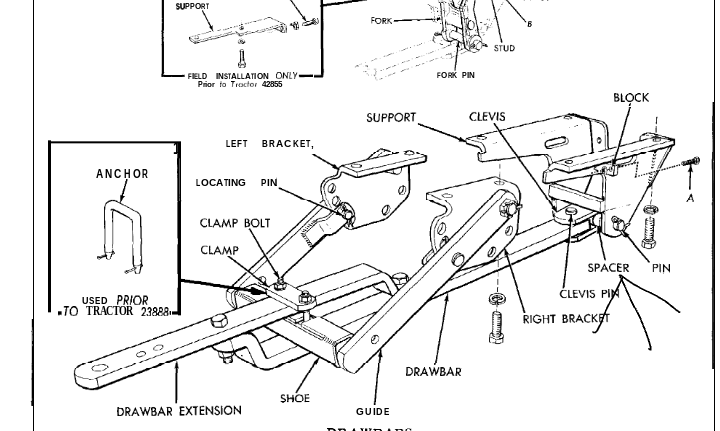

i need to place a jack under the black arrows right

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 11:09am Posted: 06 May 2024 at 11:09am |

here is a better picture of what I am asking. I place a floor jack on a plank under the arrow on the left and a stationary jack under the arrow on the right

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1385

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 11:22am Posted: 06 May 2024 at 11:22am |

hunter321 wrote: hunter321 wrote:

just wondering, are the videos helping you guy understand what I am doing |

To be blunt, it almost made me seasick

Try moving a bit slower and focus on each area for a few seconds longer, and also try backing away for a 'big picture' shot, then move in for the details.

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 11:23am Posted: 06 May 2024 at 11:23am |

|

Ok

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 1:25pm Posted: 06 May 2024 at 1:25pm |

|

Can someone confirm where the jack on the plank goes so I can get it done today before work

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8681

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 2:25pm Posted: 06 May 2024 at 2:25pm |

In your last picture you have identified the 2 spots to place jacks. I think with the hand clutch lever disconnected you can roll the shift fork fwd off of the brass collar. I think...been too long.

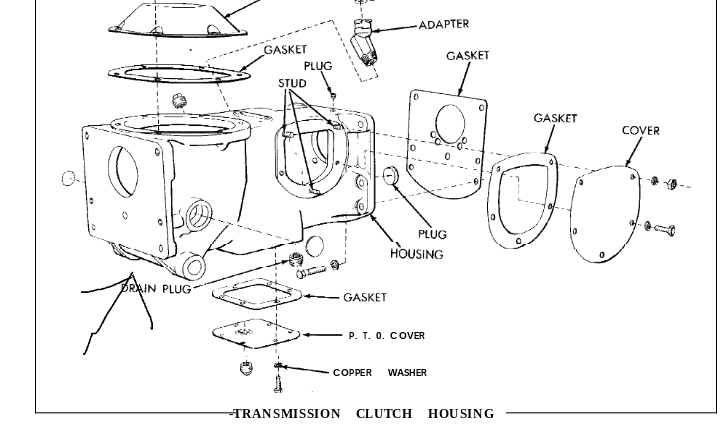

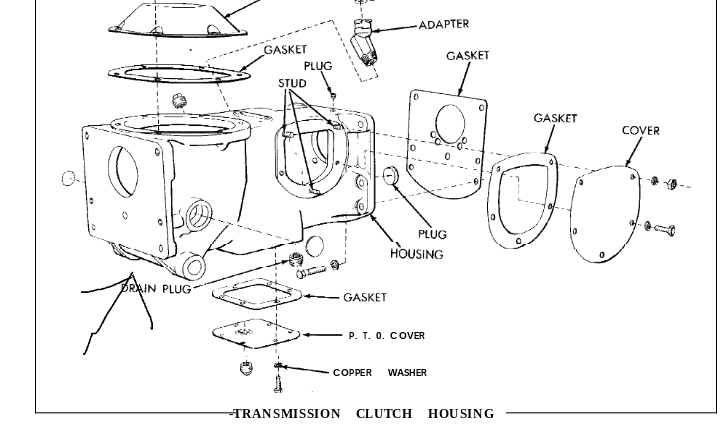

A WD45 will have a snap coupler bell with the drawbar stuck in it not like the "pin hitch" in the picture. REMEMBER The trans input shaft has to stay with the trans or it will not leave room to lift clutch out the top once split. At that point I think you can lift clutch and brass collar out as a unit.

Once your jacks are in place,you will need to put some lifting pressure on them to take the pressure off the joint where you are splitting. It won't come apart now because it is in a bind. Lucky for you. If you take that clutch apart pay attention to which plates are where and which sides the hubs are riveted to. First and third are same plate but reversed. Center plate has hub riveted in on opposite side. It has to be put together right for internal clearance.

Edited by SteveM C/IL - 06 May 2024 at 2:52pm

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2024 at 5:02pm Posted: 06 May 2024 at 5:02pm |

|

Finally got the clutch out

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 9:21am Posted: 07 May 2024 at 9:21am |

|

thank you everyone for all of your help getting me this far. I could not have done it without your help. I will probably have more questions when I put it back together, but for know I have to get the snap ring welded on or bent to shape and wait for the gaskets to arrive

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 11:36am Posted: 07 May 2024 at 11:36am |

|

I do have another question.

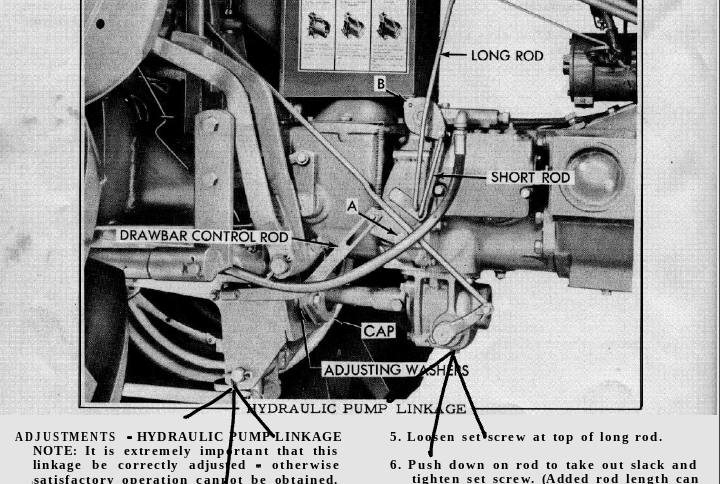

I think you could see it in the videos, that chocolate milk looking fluid is my transmission fluid. I know it looks like that because of water in it. My question is how did the water get in. The clutch cover has a new gasket. I am missing a bolt in the shift tower and I didn't get a gasket for that originally but I have one coming. What could I be missing that is letting water in the transmission fluid

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 11:50am Posted: 07 May 2024 at 11:50am |

|

Bad rubber boot on the gearshift.

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 11:54am Posted: 07 May 2024 at 11:54am |

|

itcould be but I just replaced it with a new one

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 12:28pm Posted: 07 May 2024 at 12:28pm |

|

I have a old stick welder.

What setting and heat would be good to weld the snap ring to the clutch

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8681

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 5:23pm Posted: 07 May 2024 at 5:23pm |

|

What type and size rod?

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 5:46pm Posted: 07 May 2024 at 5:46pm |

|

It's a Lincoln welder not sure what size rod

Edited by hunter321 - 07 May 2024 at 5:49pm

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1385

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 8:11pm Posted: 07 May 2024 at 8:11pm |

|

Post a picture of the welder and the rod with the rod numbers, we need to know if it is an AC or DC welder, the diameter of the rod, and the numbers on the rod.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 9:54pm Posted: 07 May 2024 at 9:54pm |

|

With at least 2 vice grips, clamp the snap ring solidly into the groove at one end and tack weld the end. Work around the snap ring making sure it is in the groove well and tack weld the other tip of the snap ring.

|

|

LaJaMe

Bronze Level

Joined: 14 Sep 2014

Location: wisconsin

Points: 172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2024 at 10:27pm Posted: 07 May 2024 at 10:27pm |

|

I replaced the clutch collar at the rear of the clutch basket. My hand clutch lever had a very long stroke but would engage and diengage at the end of the stroke. Good news did not half to split, but did have to remove right side rail. Works as should now good luck

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2024 at 12:39pm Posted: 08 May 2024 at 12:39pm |

|

I know that is an ac welder

I will get a picture of it tonight along with the rods we have

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2024 at 5:15pm Posted: 08 May 2024 at 5:15pm |

|

I'm going to attempt to weld the snap ring tonight

What is the clutch and snap ring made of

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2024 at 5:32pm Posted: 08 May 2024 at 5:32pm |

|

Weldable steel. NOT CAST IRON. Just a good tack on each end of the snap ring with the ring seated deep into the groove. This is NOT a 100% weld thing. Just the ends.

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2024 at 5:38pm Posted: 08 May 2024 at 5:38pm |

|

I decided that I will wait until Friday to get it welded because I am going to bill deppes salvage yard Friday to look at a d17 and he said that he would help me weld it

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 11:20am Posted: 09 May 2024 at 11:20am |

|

Even though I am going to have a professional weld the snap ring in place I want to know

The weld is only supposed to be in the groove and on the snap ring so it doesn't ruin the clutch

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8681

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 1:05pm Posted: 09 May 2024 at 1:05pm |

|

Since it is supposed to keep things together it was designed to be kept in it's location by the lip at the rear. If it's welded to the housing (probably easier) it can't expand and let the lip slip fwd. That's where I would weld it. Just an opinion. Deppe probably knows what to do. Trust him. A little weld on the housing won't ruin the clutch and could be cut out with a cut off wheel if ever needed to take apart. Welding on the lip would do more harm for future removal in my world.

Edited by SteveM C/IL - 09 May 2024 at 1:09pm

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 1:10pm Posted: 09 May 2024 at 1:10pm |

|

Ok

Thanks I will trust him.

Just curious

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 1:45pm Posted: 09 May 2024 at 1:45pm |

|

Snap ring must be tack welded to/into the GROOVE or the grooves lip. No where else or the clutch will not function correctly.

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 2:48pm Posted: 09 May 2024 at 2:48pm |

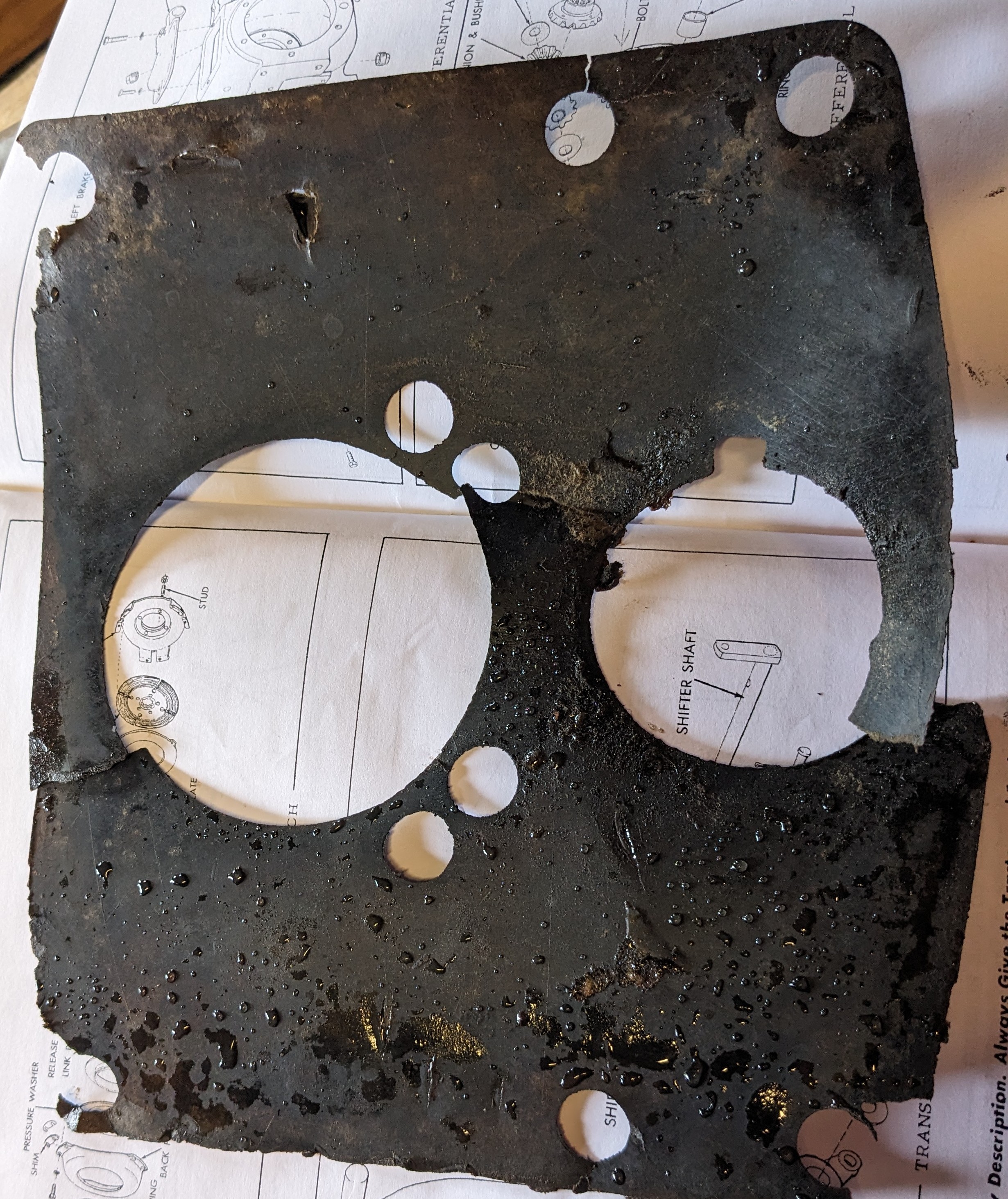

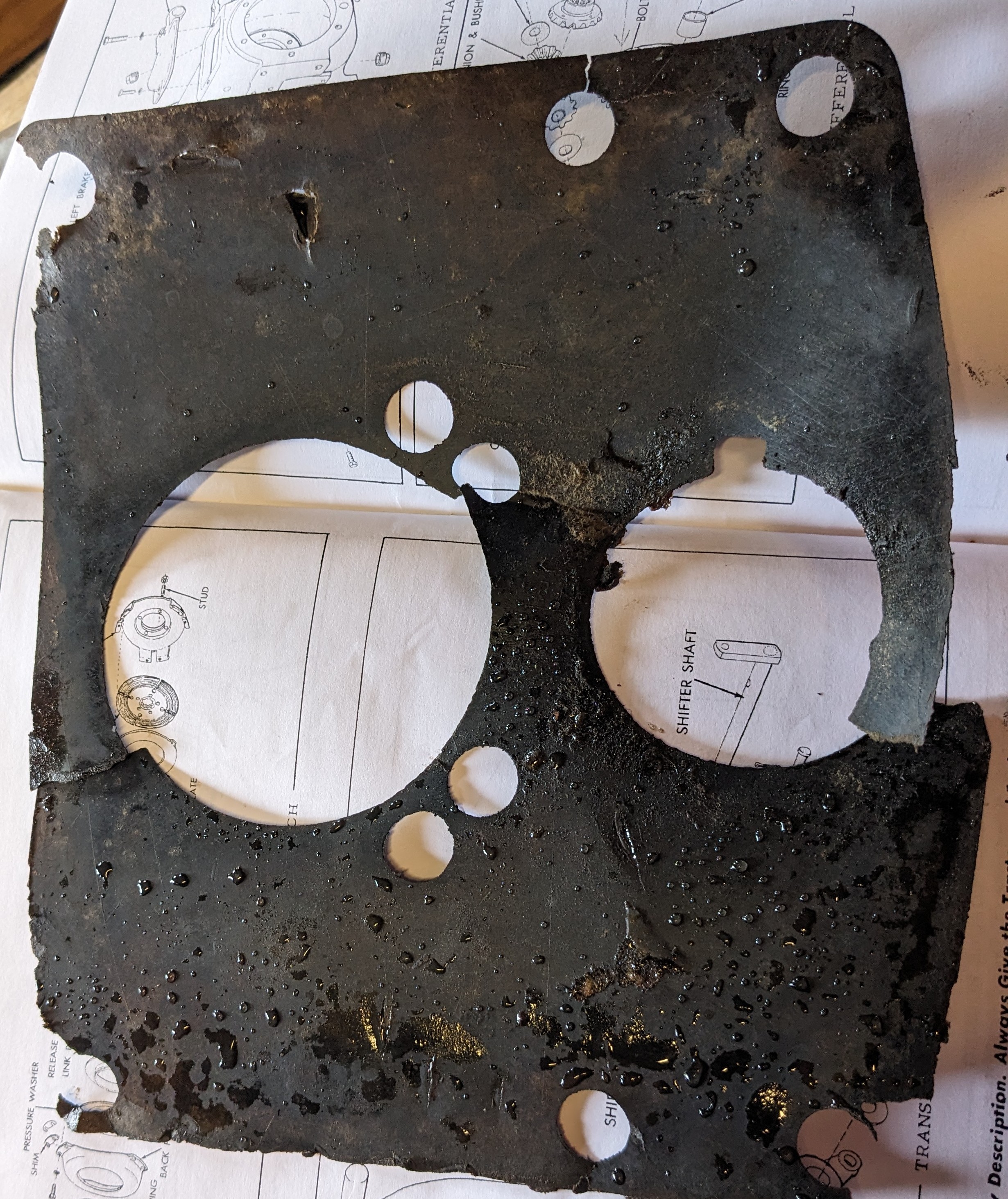

The first picture is the gasket that came out of my tractor and the second one is what I ordered. I can't find one like the original one anywhere what do I do

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 2:56pm Posted: 09 May 2024 at 2:56pm |

|

Lay the old one on top of the new one and take a scissors and make it work. I think it's closer to being correct than you think but I ain't there looking at them both either.

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 2:59pm Posted: 09 May 2024 at 2:59pm |

|

I could try that but the old gasket is in two pieces

|

|

hunter321

Orange Level

Joined: 11 Jan 2021

Location: 52320

Points: 520

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2024 at 3:04pm Posted: 09 May 2024 at 3:04pm |

|

Just as a precaution could I add transmission fluid stop leak when I get new fluid

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

here is a better picture of what I am asking. I place a floor jack on a plank under the arrow on the left and a stationary jack under the arrow on the right

here is a better picture of what I am asking. I place a floor jack on a plank under the arrow on the left and a stationary jack under the arrow on the right

hunter321 wrote:

hunter321 wrote: