I have been having some trouble shifting 1 through 4 gears. I have a 16 speed not a 20 speed Power Director. I had the bolt break that holds the upper cable eyebolt to the clutch pedal. I had to push the pedal all the way to the floor and then it would shift without grinding gears. After doing this repeatedly though, I think this is what broke the bolt holding the clutch cable to the pedal. I took off the side panels and have access to replace the bolt. I put a test bolt into place before replacing everything and decided to screw in the upper eyebolt thinking that might improve shifting. Did a test shift and it won't go into gear now without grinding. I screwed it out but I don't have many threads left to make it long enough to make it shift without grinding. My guess is that the eyebolt screw was bent, before it broke and was allowing the shifting to happen. Now that I have a straight bolt, it doesn't have the necessary play but only a guess.

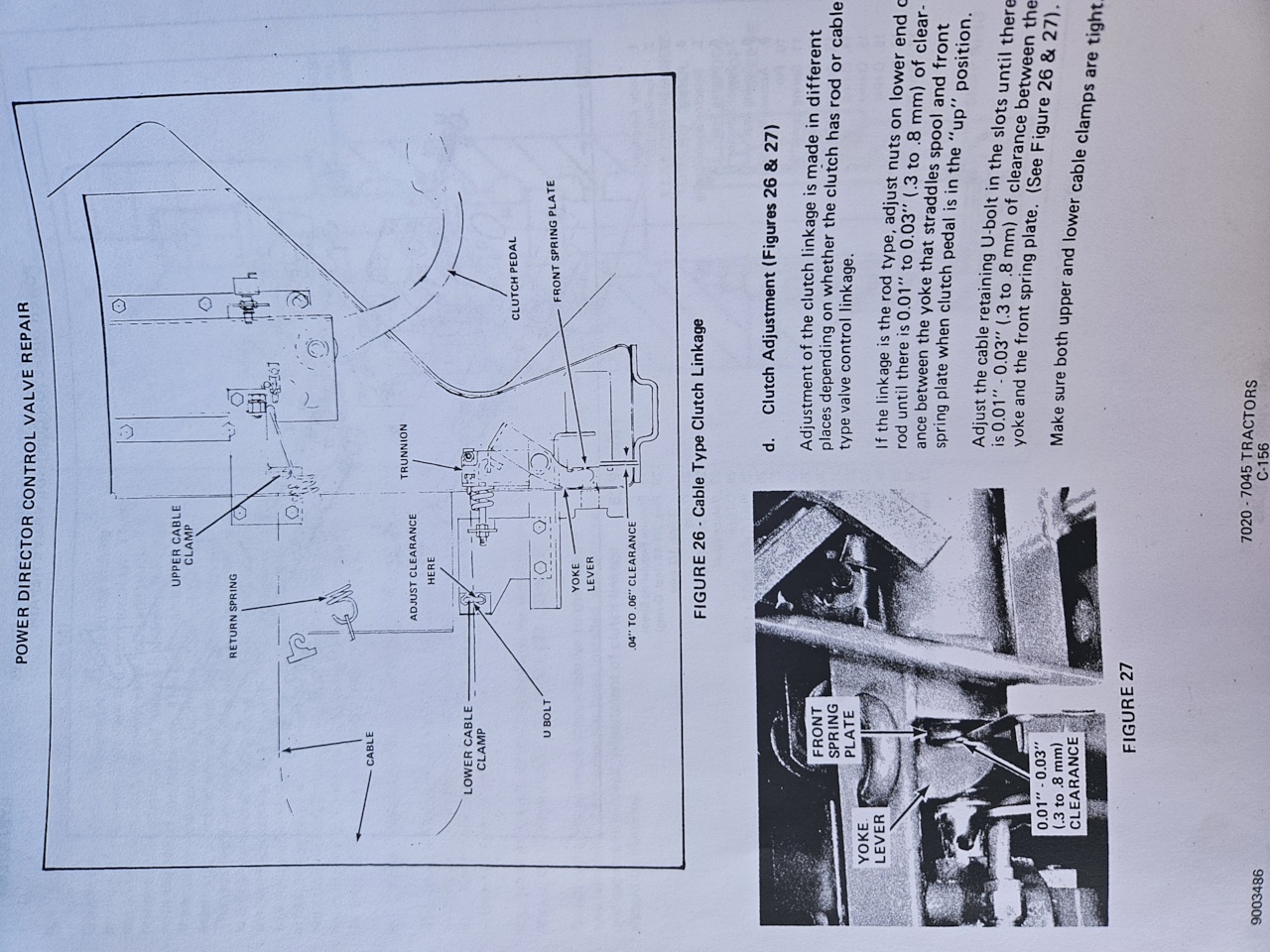

I read the manual and it only has one sentence about adjusting the cable in an obscure place. It shows doing that on the lower cable clamp and mentions a clearance of .01 inches - .03 inches. That's not very much clearance. I am going to play around with the lower cable clamp and see if I can get anything to change. Doesn't mention adjusting either the upper or the lower eyebolt lengths which surprised me. However, the adjustment I made on the upper eyebolt didn't change anything. Nothing has changed on this over the years other than this bolt breaking as far as I know. Is it possible that the cable is bad? How common is that? I can remove both ends of the cable and see if it moves back and forth freely to see if the cable is sticking as another test.

Anyone have experience adjusting the clutch pedal? Any help is appreciated.

Here is the page I found. Is there a reference somewhere else?

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: