| Author |

Topic Search Topic Search  Topic Options Topic Options

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Apr 2014 at 9:33am Posted: 04 Apr 2014 at 9:33am |

|

did not know that Ed. always thought it was an advance. i know our 6610 and tw5 start 100 times better when using in it the cold

|

|

|

Sponsored Links

|

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 6:26am Posted: 16 Apr 2014 at 6:26am |

|

finaly got it in the barn monday and pulled the gas engine out. yesterday i pulled the torque tube off and took the power director apart. the front half is fine( the low side i believe) but the rear side was completely destroyed. all the friction disks came out in multiply pieces. the rear half of the housing has a bunch of grooves in it and the inner hub is pretty much shot. also, the pto shaft, the shaft that is below the power director in the rear housing. is that the one with the seal that allows oil to leak between the compartments. it leaked oil the whole time i worked on it yesterday. gonna start pricing parts out today. the 301 came last week. i got a heavy duty clutch from rick, some exhaust gaskets and the intake pipe from the air filter to the turbo. i hope to have it together and running by the end of next week

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 9:40am Posted: 16 Apr 2014 at 9:40am |

Comon Screwylouie, you might be maken progress, but wheres the pics?

Glad to hear your getting your project started, and have such high hopes in getting it finished so soon. "running by the end of next week"

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 12:28pm Posted: 16 Apr 2014 at 12:28pm |

Edited by screwylouie010 - 16 Apr 2014 at 12:34pm

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 12:35pm Posted: 16 Apr 2014 at 12:35pm |

|

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 12:36pm Posted: 16 Apr 2014 at 12:36pm |

|

i will get some pictures of the power director and the new engine after lunch. waiting for a quote on parts from sandy lake right now. yea i know its pretty high hopes, but the plan is to be polishing the mold boards up by next weekend

Edited by screwylouie010 - 16 Apr 2014 at 12:36pm

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 12:46pm Posted: 16 Apr 2014 at 12:46pm |

|

when polishing up the moldboards, take into consideration the small rear axles and light differential carrier of that 190 gas. The turbo 301 diesel will be stout no doubt! lol! Keep weights off of it, and just let the tires spin a little, and you may be ok. Cool project, but isn't it a little cold yet to be wrenching in an open sided barn? brrr!

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 1:55pm Posted: 16 Apr 2014 at 1:55pm |

Good eye there Ed, small axels... My 190 gas has the small axels in it yet too... My XT diesel has the harden small axels because casting wouldn't accept the large axels...... Maybe his has been converted to the harden axel?

Yea, don't weight it down if its the origional axels.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 2:07pm Posted: 16 Apr 2014 at 2:07pm |

|

I don't think this one would have had any updates, it's a 190 gas, not an XT.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 7:49pm Posted: 16 Apr 2014 at 7:49pm |

|

it does have the small axles. i dont know how to tell if they have been hardened, but i doubt that they are. i wish it had the upgraded axles, but i got the tractor cheap enough($1200) with near new loaded rear tires, that i will upgrade to the larger axles and better differential when i pull the rear apart to fix 3rd gear. hopefully do that this fall or winter. as far as the pole barn, it been chilly in the mornings but it been as high as 75 the last 2 weeks here. except for this morning, we got 2" of snow and it was about 30 degrees. i work out of the barn pretty much year rough though. few other pictures coming in a few minutes here

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 8:38pm Posted: 16 Apr 2014 at 8:38pm |

|

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 8:40pm Posted: 16 Apr 2014 at 8:40pm |

|

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 8:42pm Posted: 16 Apr 2014 at 8:42pm |

|

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2014 at 8:47pm Posted: 16 Apr 2014 at 8:47pm |

|

so all the high side plates came out in pieces. they wore into the housing but didnt ruin it. but they did wear on the hub, but that is also still usable. i have to get a new front side housing because where the piston fits in is scored badly. the piston, i was told will clean up and work ok. bill from sandy lake called me back this afternoon. they have a good used housing and will take my old as a core, but he still had to finish the quote for the rest of the parts.

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Apr 2014 at 7:13pm Posted: 20 Apr 2014 at 7:13pm |

|

Well as usual, nothing goes as planned. The rear main seal in our tw went out. It got oil into the clutch and started slipping the first day I started chiseling. Also broke an axle or something in the rear of my dump truck hauling gravel. Ended up pulling the 5x16s with our 6610 to try to at least get something accomplished. Fan belt blew on that 4 hours in. Got a new 1 yesterday and finished the field I was in. Got the tw split to day and had to fix the fence that the cows ran throug. But on a better note, bill from sandy lake called back. He has all the parts I need except a seal or 2. Total would be around $1300. So hopefully order that stuff when I get paid next week. O and can't for get, put my knee through the side of one of the seed boxes on the planter, trying to change a hydraulic line. So yea, hopefully this week goes smoother and I can get back to work on the 190 next weekend.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Apr 2014 at 10:46pm Posted: 20 Apr 2014 at 10:46pm |

frusturating ain't it...Theres days like that...

Lou, the early 190 tractors had a rear end that you cannot put larger axels in... should be able to tell that by the A series stamped on them as I recall... B series can be changed. C had the large axels.

Just tried to find that info and did not run across it but should be the transmission serial number and dimensions lower right from lift arm housing... and the letter should be there designating which rear housing you have.

Hope some one can confirm or embelish on this.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2014 at 1:53pm Posted: 21 Apr 2014 at 1:53pm |

|

I did not even think about that. So I would have to find a whole rear assembly then. If I found a set up cheap enough,minus paintI still would only be into the tractor for about the amount of buying a nice xt III then

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 May 2014 at 7:44pm Posted: 02 May 2014 at 7:44pm |

so after all the rain lately, i got a few hours to work on the 190, i do have a good flywheel coming from rick, since some measurements where a little funky on my. will be ordering all the parts from sandy lake when the milk check comes next week. well anyways, i took the combine fan off and put the 190 gas fan on. it sits 3/4" further forward from the valve cover than on the gas engine and about an inch and a quarter or so further up. this should not be a problem, just a little fitting of the fan shroud. also got the front pulley off so i can take it too the machine shop to be shortened. the rubber is a little dried up, does anyone know if i can get it rebuilt with new rubber? then on to the oil fill, since i have the inline pump on this engine, i have a block off plate where the fuel pump would go on the side of the block. i will use this plate and fabricate an oil fill so i dont have to cut a hole in the hood or take it off every time i wanna put oil in it since the fill is currently in the valve cover. i took the turbine outlet off the turbo, cleaned it up, put a new gasket in and reinstalled it but with the outlet pointing up. still have to take the manifold off and install new gaskets. as far as the starter and rear plate, i will have to reuse the rear plate from the tractor as the one from the combine is slightly different. i think this will also cause me to have to use the gas engine starter. the alternator is the same on both engines, just one has a single groove pulley and the other a double. then comes the radiator. the bottom outlet of the radiator is on the wrong side for this engine. my radiator is in good shape, well the core is anyways, the ends need some work. i am thinking i can take it to a radiator shop and have then fix it up and sides of the outlet and the drain petcock. it may cost a little more but will be a lot easier and cleaner. i started my hunt for a intercooler from a 7020 or possibly 1 from a 426. now my other thoughts or dreams rather, lol, how do i got about converting from 540 pto to the 540/1000 pto setup? would really like to have 1000 pto for running the generator when i have to. might even be picking up a 1000 pto discbine. also picked up a set, well 3, 9 bolt 34"duals at an auction the other day. have a set of hubs in the works. then got a decent set of firestone SAT 23* for 50 bucks to put on the duals. one needs a boot, no big deal. ok ill shut up now, here a crappy picture of what i got done today

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 May 2014 at 11:25pm Posted: 02 May 2014 at 11:25pm |

As for the oil filler, just use the filler off the gas motor.

The oil cooler definately is different... see if it can remain there, if not, you will have to modify. 426 cooler is worlds different...

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2014 at 8:02am Posted: 03 May 2014 at 8:02am |

|

already tried the oil fill from the gas engine. not even close to fitting. i will be keeping the big oil cooler. im not even considering taking it of.as far as the 426 intercooler, im just going off what other guys have said to use, on here. said it will fit with some work and flows much better

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2014 at 8:23am Posted: 03 May 2014 at 8:23am |

Do you have a picture of the left side of your engine? even the combine engine I have here has a place for the oil filler pipe and it is identical (as in intake manifold and accessibility..) to the XTDiesel engine and the filler between the gas and the diesel are identical too.... Just like the one on your gas motor.

What causes the filler not to be even close?

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2014 at 9:06am Posted: 03 May 2014 at 9:06am |

|

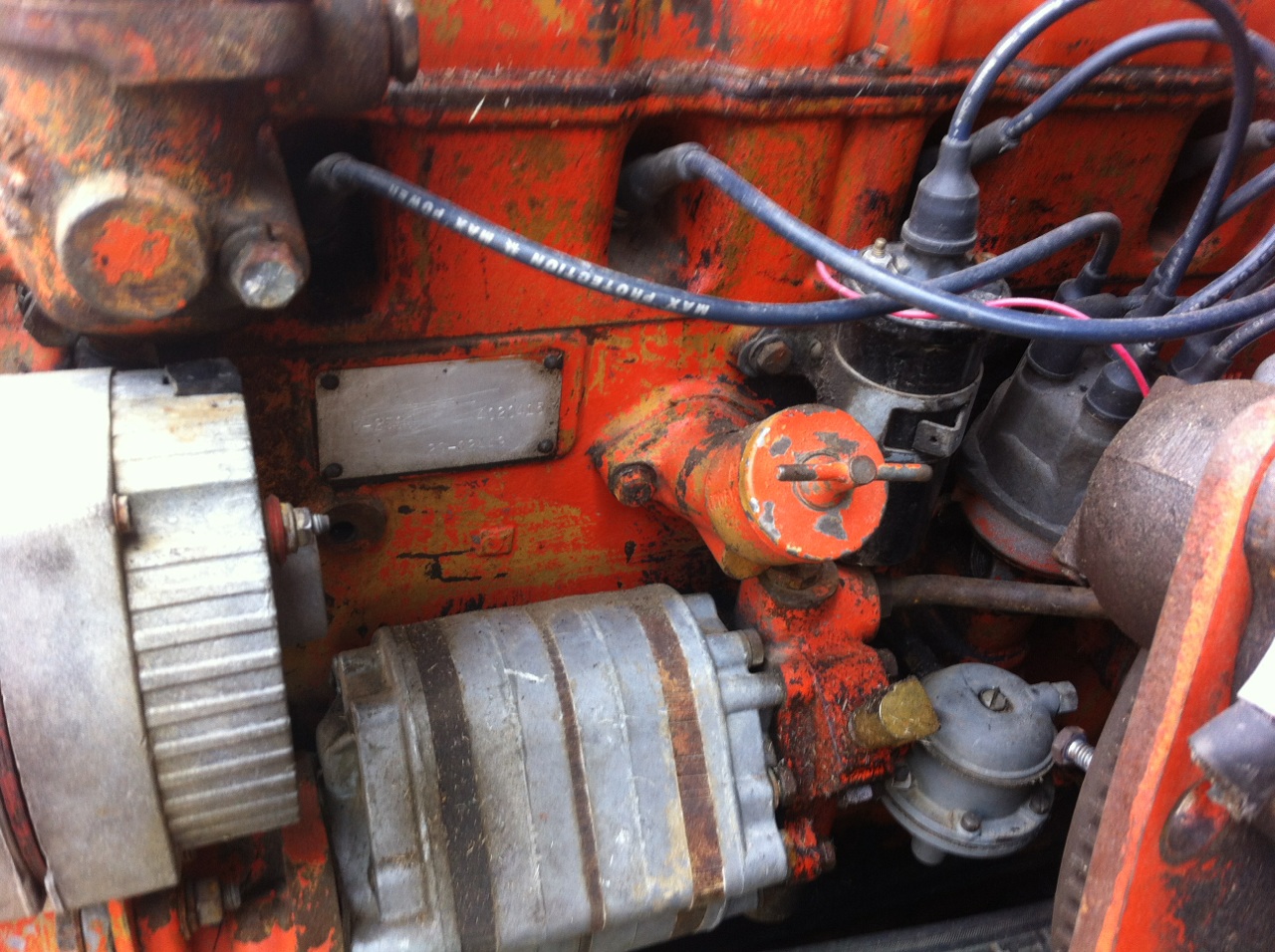

I can never get pictures to upload from my phone. Will post them later. But gas engine oil fill is a completely different size and shape where it bolts to the block. The gas engine is a round hole with 2 3/8 bolts, one on each side. The 301 has the shape and bolt pattern of a mechanical fuel pump. It is a kind of elongated hole, with a 5/16 bolt on each side. Also the bolt hole a much closer together than on the gas engine

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2014 at 9:08am Posted: 03 May 2014 at 9:08am |

|

They are located at relatively the same spot on the blocks though

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2014 at 7:38am Posted: 07 May 2014 at 7:38am |

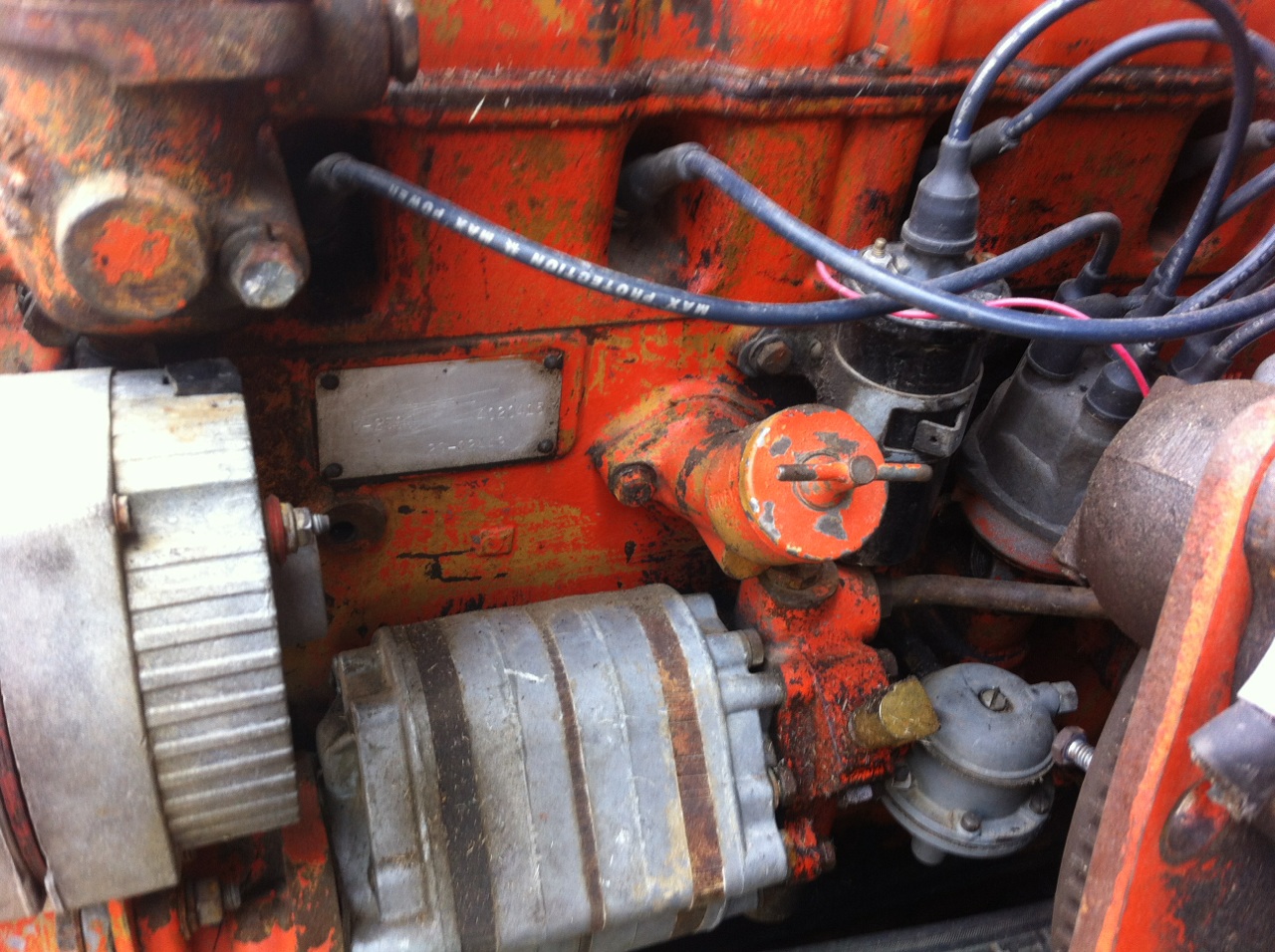

sorry it took so long, but here are the pictures. first one is the oil fill on the gas engine. second pictures is of the fuel pump block off plate on the 301 which i make into the oil fill

Edited by screwylouie010 - 07 May 2014 at 7:40am

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2014 at 7:39am Posted: 07 May 2014 at 7:39am |

Edited by screwylouie010 - 07 May 2014 at 7:40am

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2014 at 9:45am Posted: 07 May 2014 at 9:45am |

Lou, that is a fuel pump mount..., just like in the pic of your gasoline engine. Doesn't the block have a plate bolted over a hole higher up?

Trying to fill through fuel pump hole is going to be slow pour maybe.

mmm Thought those blocks were almost all identical between the gas and diesl, the 2500, 2800, and 2900... must be the Simms pump engine blocks were different?

Just looked at the first vid, that pipe for the oil cooler system must be covering up the oil filler hole , thus making it inaccessible. the coolers on XT tractors ran forward on right hand side of block to the volute on the water pump... your volute is on the left side.

Yea, looks like fuel pump port is the only choice to go unless you cut a hole in the side of the oil pan and bring up an oil filler tube from there... maybe weld a plate on inside and thread it to strengthen and bolt to it if there is room.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2014 at 8:12pm Posted: 07 May 2014 at 8:12pm |

|

The fuel pump hole is pretty open to the crank case. The blocks are fairly similar but different. You can see the fuel pump on the gas engine is, lower and to the right of where the oil fill is.

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2014 at 4:51pm Posted: 08 May 2014 at 4:51pm |

|

I took a closer look at the 301 today. The oil fill hole is hidden behind the oil cooler

|

|

Peterson

Orange Level

Joined: 05 Mar 2011

Location: Westboro, Wi

Points: 866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 May 2014 at 7:01pm Posted: 08 May 2014 at 7:01pm |

|

If I was doing this swap, I'd scrap the combine oil cooler, water pump and water pump backing plate and get the oil cooler, water pump and backing plate from a 7010 or 7020. Much easier to make stuff fit. But you will need to move your bottom radiator outlet to the other side. Then you could also run the factory 7020 intercooler.

|

|

7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2

|

|

screwylouie010

Silver Level

Joined: 02 Jul 2013

Location: Salt Point, ny

Points: 261

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2014 at 12:45pm Posted: 09 May 2014 at 12:45pm |

|

I should be able to run the 7020 intercooler either way, no?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)