301 from gleaner M into 190

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=86142

Printed Date: 21 Oct 2025 at 1:44pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 301 from gleaner M into 190

Posted By: screwylouie010

Subject: 301 from gleaner M into 190

Date Posted: 10 Mar 2014 at 9:41am

|

so i found a 301 on ebay from a gleaner M. it comes with the turbo, radiator, engine mount and the air cleaner. it has the inline injection pump on it. says it runs good with little blow by, but has a miss at hiring rpm. my experience with those minnimec pumps is that it either is getting air or possibly the governor is messed up. but im wondering what you guys think of putting this in my 190 which currently has the gas engine, it runs great but would rather have the diesel. far as i can tell i will have to open up the front plate for the hydraulic pump. also i have to replace 3rd gear as it pops out and rebuild the power director, looking for any guidance of what parts i will need or where to get them. i know already to get the pd plates for the 200/7000 tractors. thanks guys |

Replies:

Posted By: BPM75

Date Posted: 10 Mar 2014 at 12:47pm

|

I don't know about the M but the one I have out of a G does not have any way to mount the pump on the frt plate, you may have to find a plate for a tractor. ------------- 59 D17 gas nf, 66 XT 190, 69 220. |

Posted By: 2wise4agm

Date Posted: 10 Mar 2014 at 12:56pm

| Seems like the oil pan will have interference problems with the front axle also. ( If I remember correctly ) |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 1:18pm

|

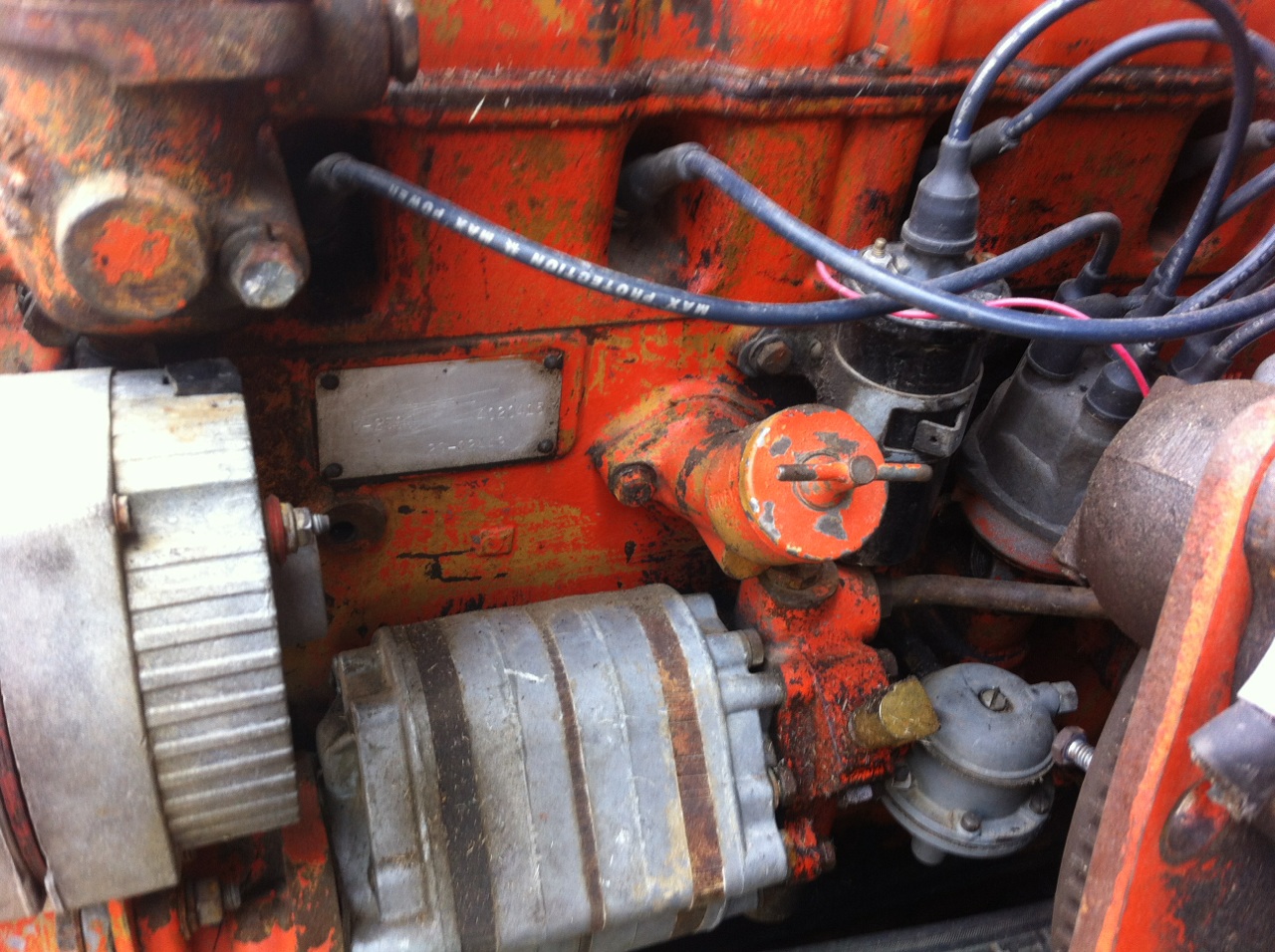

here are the pictures he sent me of the fron cover where my hyd pump is. the plate with 2 bolts on the front side looks identical to my 190. the back side looks bare , but with 4 bolts in about the same location as the mounting bolts of my pump. i am not to worried about the oil pan clearance. i can modify this 1 or fabricate my own, or if it is easy enough and cheap i would get the correct one. thanks for the input guys |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 1:20pm

|

uploads/9698/allis_301_front_cover.jpg" rel="nofollow - uploads/9698/allis_301_front_cover.jpg uploads/9698/allis_301_front_cover_1.jpg" rel="nofollow - uploads/9698/allis_301_front_cover_1.jpg uploads/9698/allis_301_front_cover_2.jpg" rel="nofollow - uploads/9698/allis_301_front_cover_2.jpg |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 1:20pm

|

ok, i kinda got it now |

Posted By: JC-WI

Date Posted: 10 Mar 2014 at 3:21pm

|

Looked at the engine on Ebay and I guess I never have seen an M gleaner engine befre... this one has the water /oil cooler line on the intake side of engine with the volute from water pump also on intake side. I have always seen them on the exhaust side.... that normal for the minnimec pump engines? Will there be room under the tube for the hyd. pump?

------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: DON G

Date Posted: 10 Mar 2014 at 3:44pm

WE PUT M ENGINE INTO 7000. WE PUT M ENGINE INTO 7000.yOU WILL NEED SOME GOOD PULLERS TO CHANGE FRONT PARTS. |

Posted By: pohlman249

Date Posted: 10 Mar 2014 at 3:55pm

| Eather pull the cam gear or the cam and swap the covers.... I'd 're torque the head too. |

Posted By: Peterson

Date Posted: 10 Mar 2014 at 5:24pm

|

Minnimec pumps use the same front plate as the later roosamaster like whats on the 7000 series. Get a front plate from a "7000" and put in on the front and she will bolt right in. ------------- 7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2 |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 7:08pm

|

yea looks like there should be room for the pump. so i just need the

front plate from a 7000 and the pump should bolt right on. thanks for

all the info guys. here is a video of the engine running. it does need

an exhaust manifold gasket. on edit, guess i cant get the video to load |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 7:12pm

|

here it is [TUBE]6t3RRFpJVNs&feature=youtu.be[/TUBE] |

Posted By: Lynn Marshall

Date Posted: 10 Mar 2014 at 7:20pm

| There were several versions of the M diesel engine. Early ones used a DB style roosamaster I think. They were very much like a 200 engine. I don't remember any of the M's using the SIMMs (Minnemac) style pump. I do know that the L's did use it for awhile. The later M's used a DM style pump like a 7000 if I remember correctly. If the 190 uses an engine oil pump driven tachometer drive, you're going to have to stick with a cam and cam driven oil pump system. Otherwise you could go with an alternator driven tachometer, but I think that uses a different tachometer head. There's a lot more to these projects than what you might think. |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 7:42pm

| right now the tach is driven off the distributor, or is atleast supposed to be. now on the minnmec, if it is like the 1 on our ford tw 5, the tach is driven off of the end of the pump. i did ask the seller if and where the cable hooks to |

Posted By: Lynn Marshall

Date Posted: 10 Mar 2014 at 8:34pm

| No tach cable on the combines. They used a magnetic impulse pickup on the rear PTO pulley. |

Posted By: tbran

Date Posted: 10 Mar 2014 at 8:49pm

|

I did this. It is a lot of work but doable. 1 front pulley will have to be 190xt - combine will hit front cast iron. 2 pan will hit axle - have to lower the axle. 3. oil cooler will hit rear firewall - it will have to go. 3 Frame will have to be cut on RH side for fuel pump and left hand side for oil filters. 4 Radiator will have to be raised 2.5" approx. Lots of flex hoses as radiator outlets not the same. (I spaced up the front side sheets leaving a gap between the bottom and the cast iron front ) 5 id did not change front cover drilled with holesaw opening for pump drive and used existing bolts and then fabricated clamp for rest of attaching drive parts. 6 clutch linkage will have to be modified. 7 front plates have to have mounting flanges welded to them for front attachment points. 8 starter drive change. 9 tach fits right into back of simms minn inline pump. 10 have to fab bracket for throttle and fuel shut off cables. (someone had maxed out the fuel screw on the simms pump. I dyno'd and clutch slipped at approx. 165 hp)

just use it fro cruzin and pulling a grain buggy.

|

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 8:51pm

| ah i see, thank you. well ill figure something out, still waiting to hear from the seller if there is a provision for one on the engine |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 8:54pm

| thank you tbran. that is a lot of useful info. but what do you mean you fabricated clamp for attaching rest of the drive parts |

Posted By: screwylouie010

Date Posted: 10 Mar 2014 at 9:04pm

| also will my flywheel and clutch bolt to the 301? i dont know what the engine will come with in that department. but i believe it will come with the starter. |

Posted By: screwylouie010

Date Posted: 11 Mar 2014 at 7:58am

| also, tbran, do you have any pictures, that would be great |

Posted By: screwylouie010

Date Posted: 30 Mar 2014 at 9:55pm

| well i bit the bullet and bought it tonight. cant wait for it to get here. now i just gotta get a hold of new power director plates and all the seals plus what ever i need to fix third gear. hope i can have it running to disc and plant with |

Posted By: GM Guy

Date Posted: 02 Apr 2014 at 6:09pm

|

the Simms pump was more common in the L, but we do have a few M's with the Simms pump as well one of which is a hydrostat bean special machine. I personally am not a fan of it. hard starting is the main downpoint. the roosa is a much better unit IMO. ------------- Gleaner: the properly engineered and built combine. If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help. |

Posted By: Jwmac7060

Date Posted: 02 Apr 2014 at 6:43pm

| My Gleaner M had a 426 in it not a 301 |

Posted By: screwylouie010

Date Posted: 02 Apr 2014 at 8:33pm

|

it could have come from an L, was told it was pulled from and m. thought i remember when i was flipping through my Shoup catalog that the M had the 301 and M2 had the 426. as far as the hard starting, ill be advancing the timing anyways. i dont if the simms pumps on the Allis engines have it but on our fords we a have cold starting timing advance button on the pump. it makes a big difference when starting in the winter |

Posted By: JC-WI

Date Posted: 02 Apr 2014 at 9:33pm

|

This is not a simms pump engine but one that came from a combine... Not mine. But one of the fellers on here ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 03 Apr 2014 at 9:46pm

| Think I saw the pictures from that build. Looks good. Engine should be here soon and have some parts on the way. Does anyone know what flywheel I will need? Ill put a fresh clutch in too. Would also like to find an intake stack like that one. |

Posted By: JC-WI

Date Posted: 03 Apr 2014 at 10:09pm

|

My suggestion, don't bother unless you really intend to use it in a real dust storm... I wanted one on mine then bought one with one and the dust bowl never got much in it during the year, but I made sure I kept the main filter clean.... That one stuck up in my vision and the bowl was at eyelevel too... And if the ground was rough, it shook too. After I experianced the precleaner, I was not interested in looking at one on my other 190's....

------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: DSeries4

Date Posted: 03 Apr 2014 at 10:10pm

|

I think Ms (1,2, and 3) used the 301 while the Ls had the 301 as standard engine with the 426 as an option.

------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: screwylouie010

Date Posted: 04 Apr 2014 at 6:26am

|

thank you for your input JC. i will reconsider getting one now.i mean it looks cool and i dont think i will ever seriously farm with this tractor, its more of just a toy. |

Posted By: injpumpEd

Date Posted: 04 Apr 2014 at 7:26am

The start button on a ford simms is not to advance the timing. But it does allow the rack to go into start fuel, which also retards the timing. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: screwylouie010

Date Posted: 04 Apr 2014 at 9:33am

| did not know that Ed. always thought it was an advance. i know our 6610 and tw5 start 100 times better when using in it the cold |

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 6:26am

|

finaly got it in the barn monday and pulled the gas engine out. yesterday i pulled the torque tube off and took the power director apart. the front half is fine( the low side i believe) but the rear side was completely destroyed. all the friction disks came out in multiply pieces. the rear half of the housing has a bunch of grooves in it and the inner hub is pretty much shot. also, the pto shaft, the shaft that is below the power director in the rear housing. is that the one with the seal that allows oil to leak between the compartments. it leaked oil the whole time i worked on it yesterday. gonna start pricing parts out today. the 301 came last week. i got a heavy duty clutch from rick, some exhaust gaskets and the intake pipe from the air filter to the turbo. i hope to have it together and running by the end of next week |

Posted By: JC-WI

Date Posted: 16 Apr 2014 at 9:40am

|

Comon Screwylouie, you might be maken progress, but wheres the pics?

Glad to hear your getting your project started, and have such high hopes in getting it finished so soon. "running by the end of next week" ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 12:28pm

|

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 12:35pm

|

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 12:36pm

| i will get some pictures of the power director and the new engine after lunch. waiting for a quote on parts from sandy lake right now. yea i know its pretty high hopes, but the plan is to be polishing the mold boards up by next weekend |

Posted By: injpumpEd

Date Posted: 16 Apr 2014 at 12:46pm

|

when polishing up the moldboards, take into consideration the small rear axles and light differential carrier of that 190 gas. The turbo 301 diesel will be stout no doubt! lol! Keep weights off of it, and just let the tires spin a little, and you may be ok. Cool project, but isn't it a little cold yet to be wrenching in an open sided barn? brrr! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: JC-WI

Date Posted: 16 Apr 2014 at 1:55pm

|

Good eye there Ed, small axels... My 190 gas has the small axels in it yet too... My XT diesel has the harden small axels because casting wouldn't accept the large axels...... Maybe his has been converted to the harden axel?

Yea, don't weight it down if its the origional axels. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: injpumpEd

Date Posted: 16 Apr 2014 at 2:07pm

|

I don't think this one would have had any updates, it's a 190 gas, not an XT. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 7:49pm

|

it does have the small axles. i dont know how to tell if they have been hardened, but i doubt that they are. i wish it had the upgraded axles, but i got the tractor cheap enough($1200) with near new loaded rear tires, that i will upgrade to the larger axles and better differential when i pull the rear apart to fix 3rd gear. hopefully do that this fall or winter. as far as the pole barn, it been chilly in the mornings but it been as high as 75 the last 2 weeks here. except for this morning, we got 2" of snow and it was about 30 degrees. i work out of the barn pretty much year rough though. few other pictures coming in a few minutes here |

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 8:38pm

|

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 8:40pm

|

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 8:42pm

|

Posted By: screwylouie010

Date Posted: 16 Apr 2014 at 8:47pm

| so all the high side plates came out in pieces. they wore into the housing but didnt ruin it. but they did wear on the hub, but that is also still usable. i have to get a new front side housing because where the piston fits in is scored badly. the piston, i was told will clean up and work ok. bill from sandy lake called me back this afternoon. they have a good used housing and will take my old as a core, but he still had to finish the quote for the rest of the parts. |

Posted By: screwylouie010

Date Posted: 20 Apr 2014 at 7:13pm

| Well as usual, nothing goes as planned. The rear main seal in our tw went out. It got oil into the clutch and started slipping the first day I started chiseling. Also broke an axle or something in the rear of my dump truck hauling gravel. Ended up pulling the 5x16s with our 6610 to try to at least get something accomplished. Fan belt blew on that 4 hours in. Got a new 1 yesterday and finished the field I was in. Got the tw split to day and had to fix the fence that the cows ran throug. But on a better note, bill from sandy lake called back. He has all the parts I need except a seal or 2. Total would be around $1300. So hopefully order that stuff when I get paid next week. O and can't for get, put my knee through the side of one of the seed boxes on the planter, trying to change a hydraulic line. So yea, hopefully this week goes smoother and I can get back to work on the 190 next weekend. |

Posted By: JC-WI

Date Posted: 20 Apr 2014 at 10:46pm

frusturating ain't it...Theres days like that...

Lou, the early 190 tractors had a rear end that you cannot put larger axels in... should be able to tell that by the A series stamped on them as I recall... B series can be changed. C had the large axels.

Just tried to find that info and did not run across it but should be the transmission serial number and dimensions lower right from lift arm housing... and the letter should be there designating which rear housing you have.

Hope some one can confirm or embelish on this. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 21 Apr 2014 at 1:53pm

| I did not even think about that. So I would have to find a whole rear assembly then. If I found a set up cheap enough,minus paintI still would only be into the tractor for about the amount of buying a nice xt III then |

Posted By: screwylouie010

Date Posted: 02 May 2014 at 7:44pm

so after all the rain lately, i got a few hours to work on the 190, i do have a good flywheel coming from rick, since some measurements where a little funky on my. will be ordering all the parts from sandy lake when the milk check comes next week. well anyways, i took the combine fan off and put the 190 gas fan on. it sits 3/4" further forward from the valve cover than on the gas engine and about an inch and a quarter or so further up. this should not be a problem, just a little fitting of the fan shroud. also got the front pulley off so i can take it too the machine shop to be shortened. the rubber is a little dried up, does anyone know if i can get it rebuilt with new rubber? then on to the oil fill, since i have the inline pump on this engine, i have a block off plate where the fuel pump would go on the side of the block. i will use this plate and fabricate an oil fill so i dont have to cut a hole in the hood or take it off every time i wanna put oil in it since the fill is currently in the valve cover. i took the turbine outlet off the turbo, cleaned it up, put a new gasket in and reinstalled it but with the outlet pointing up. still have to take the manifold off and install new gaskets. as far as the starter and rear plate, i will have to reuse the rear plate from the tractor as the one from the combine is slightly different. i think this will also cause me to have to use the gas engine starter. the alternator is the same on both engines, just one has a single groove pulley and the other a double. then comes the radiator. the bottom outlet of the radiator is on the wrong side for this engine. my radiator is in good shape, well the core is anyways, the ends need some work. i am thinking i can take it to a radiator shop and have then fix it up and sides of the outlet and the drain petcock. it may cost a little more but will be a lot easier and cleaner. i started my hunt for a intercooler from a 7020 or possibly 1 from a 426. now my other thoughts or dreams rather, lol, how do i got about converting from 540 pto to the 540/1000 pto setup? would really like to have 1000 pto for running the generator when i have to. might even be picking up a 1000 pto discbine. also picked up a set, well 3, 9 bolt 34"duals at an auction the other day. have a set of hubs in the works. then got a decent set of firestone SAT 23* for 50 bucks to put on the duals. one needs a boot, no big deal. ok ill shut up now, here a crappy picture of what i got done today |

Posted By: JC-WI

Date Posted: 02 May 2014 at 11:25pm

|

As for the oil filler, just use the filler off the gas motor.

The oil cooler definately is different... see if it can remain there, if not, you will have to modify. 426 cooler is worlds different... ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 03 May 2014 at 8:02am

| already tried the oil fill from the gas engine. not even close to fitting. i will be keeping the big oil cooler. im not even considering taking it of.as far as the 426 intercooler, im just going off what other guys have said to use, on here. said it will fit with some work and flows much better |

Posted By: JC-WI

Date Posted: 03 May 2014 at 8:23am

|

Do you have a picture of the left side of your engine? even the combine engine I have here has a place for the oil filler pipe and it is identical (as in intake manifold and accessibility..) to the XTDiesel engine and the filler between the gas and the diesel are identical too.... Just like the one on your gas motor.

What causes the filler not to be even close?

------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 03 May 2014 at 9:06am

| I can never get pictures to upload from my phone. Will post them later. But gas engine oil fill is a completely different size and shape where it bolts to the block. The gas engine is a round hole with 2 3/8 bolts, one on each side. The 301 has the shape and bolt pattern of a mechanical fuel pump. It is a kind of elongated hole, with a 5/16 bolt on each side. Also the bolt hole a much closer together than on the gas engine |

Posted By: screwylouie010

Date Posted: 03 May 2014 at 9:08am

| They are located at relatively the same spot on the blocks though |

Posted By: screwylouie010

Date Posted: 07 May 2014 at 7:38am

sorry it took so long, but here are the pictures. first one is the oil fill on the gas engine. second pictures is of the fuel pump block off plate on the 301 which i make into the oil fill

|

Posted By: screwylouie010

Date Posted: 07 May 2014 at 7:39am

|

Posted By: JC-WI

Date Posted: 07 May 2014 at 9:45am

|

Lou, that is a fuel pump mount..., just like in the pic of your gasoline engine. Doesn't the block have a plate bolted over a hole higher up?

Trying to fill through fuel pump hole is going to be slow pour maybe.

mmm Thought those blocks were almost all identical between the gas and diesl, the 2500, 2800, and 2900... must be the Simms pump engine blocks were different?

Just looked at the first vid, that pipe for the oil cooler system must be covering up the oil filler hole , thus making it inaccessible. the coolers on XT tractors ran forward on right hand side of block to the volute on the water pump... your volute is on the left side.

Yea, looks like fuel pump port is the only choice to go unless you cut a hole in the side of the oil pan and bring up an oil filler tube from there... maybe weld a plate on inside and thread it to strengthen and bolt to it if there is room. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 07 May 2014 at 8:12pm

| The fuel pump hole is pretty open to the crank case. The blocks are fairly similar but different. You can see the fuel pump on the gas engine is, lower and to the right of where the oil fill is. |

Posted By: screwylouie010

Date Posted: 08 May 2014 at 4:51pm

| I took a closer look at the 301 today. The oil fill hole is hidden behind the oil cooler |

Posted By: Peterson

Date Posted: 08 May 2014 at 7:01pm

|

If I was doing this swap, I'd scrap the combine oil cooler, water pump and water pump backing plate and get the oil cooler, water pump and backing plate from a 7010 or 7020. Much easier to make stuff fit. But you will need to move your bottom radiator outlet to the other side. Then you could also run the factory 7020 intercooler. ------------- 7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2 |

Posted By: screwylouie010

Date Posted: 09 May 2014 at 12:45pm

| I should be able to run the 7020 intercooler either way, no? |

Posted By: JC-WI

Date Posted: 09 May 2014 at 12:50pm

|

Peterson, you got Lou thinking now... He might have to change so he can use the oil filler hole. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: screwylouie010

Date Posted: 09 May 2014 at 1:12pm

| I've seen the intercooler on a 301 with the combine cooler before. The intercooler wouldn't go on before I got the tractor running anyways so, the oil cooler will be staying for now |

Posted By: screwylouie010

Date Posted: 10 May 2014 at 11:00am

| Well finaly got all the power director parts ordered from sandy lake. Most new and a few used. Want to thank bill and Betty for all the help. Does anybody know of a 7020 front plate cheap? Will be dropping the front pulley off at the machine shop on Monday |

Posted By: screwylouie010

Date Posted: 10 May 2014 at 8:07pm

| got a 7020 front plate cheap. should be here mid next week. there's a 7000 "parts tractor" at an auction im going to next weekend. im gonna try to pick it up if it goes cheap enough, especially if it has a cab. there is no pictures on the listing and preview is the morning of the auction only. since all the corn is planted and its raining every day, looks like i have a few days to work on the 190, just hope the parts come in time |

Posted By: Peterson

Date Posted: 10 May 2014 at 8:09pm

|

You don't want.a 7020 front plate. It don't have the hydro pump hole. You need a "7000" plate. ------------- 7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2 |

Posted By: screwylouie010

Date Posted: 10 May 2014 at 8:29pm

| i realized that earlier, but i bought it anyways so i dont have to make brackets to attach to the frame rails. unless i got a 7000 plate i would be cutting the hole for the pump anyways. i got the plate cheap enough, so |

Posted By: Peterson

Date Posted: 10 May 2014 at 8:31pm

|

It still wont work. There's not even a spot to put the pump. Also 7010 and 7020 plates are wider for.the frame rails. ------------- 7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2 |

Posted By: screwylouie010

Date Posted: 10 May 2014 at 8:33pm

| damn, thought i was getting out easy. o well, it was cheap enough |

Posted By: screwylouie010

Date Posted: 10 May 2014 at 8:35pm

| guess ill be modifying the combine plate to work anyways |

Posted By: screwylouie010

Date Posted: 22 May 2014 at 3:25pm

| Just a little update. I ended picking up a 7000 front plate. Received it this am along with getting the dampner pulley back from the machine shop. Also had them enlarge the alignment dowl holes on the fly so that the bolts for snug to still all for alignment. Still waiting for some gaskets and the bushing for the power director that got crushed during shipping. O and the 7000 at the auction last weekend. It was a power shift open station. They tranny was out. Was missing deck plate and left fender along with some other small parts. Sold for $650. I would have boughten if I didn't just order the power director parts last week or had gotten paid for a side job, I did, as promised. I'm getting pretty antsy, hope the rest of the parts are here Monday |

Posted By: screwylouie010

Date Posted: 13 Jun 2014 at 7:30pm

well between doing hay, fixing broken equipment, side work, and waiting

for parts i did manage to get get some things done on the 190. i got the

power director rebuilt and installed, changed the pto seals in the

trans housing. also changed the seal behind the pd. i got the new(better

used) fly wheel installed with the 190 rear plate and new rear main

seal and wear sleeve. then i got the engine bolted to the torque tube.

then i began to mount the the engine and to th trans. i had it to the

point of lineing up the shafts and the oil line. when i grabbed one to

put it in place, the brass fitting broke where it mounts into the pd

manifold. so it came back apart and is just sitting there. then the

other day i picked up a set of goodyear 11l-15 triple ribs, 8 ply on

craigs list and the local NH dealership had a good deal on a set of 15x8

heavy duty titan rims, so i got a set and got those mounted. so today

it rained most of the day, i pulled the front cover off the engine and

swapped the front plate. re installed with new gaskets and front main

seal. i do have to drill 1 hole for the alternator mount in the plate

and there is 1 less hole for and injection pump bolt. then i got the

front pulley on and bolted on the right side frame rail. i still have to

remove the pd and manifold so i can remove the broken fitting from the

manifold and put it back together. also had a few other set backs, but its going good. heres some pictures i took of my progress

|

Posted By: screwylouie010

Date Posted: 13 Jun 2014 at 7:32pm

| also, i need to firgure out what starter i am going to use. the 190 starter hit the oil cooler but the combine started is a larger bolt patter and larger pilot than the 190. thought i read somewhere of someone using a 6080 gear reduction starter |

Posted By: hillmonkey

Date Posted: 13 Jun 2014 at 8:31pm

|

nice.cant wait to see it all together with those tall front 3ribs. are they 10:00 or 11:00x16 ?? |

Posted By: screwylouie010

Date Posted: 14 Jun 2014 at 10:14am

|

They are actually 11l-15 but do seem Pretty tall |

Posted By: screwylouie010

Date Posted: 18 Jun 2014 at 8:52pm

|

well got some time and help today to get the engine/torques tube mounted to the trans. 3 hours later, fighting it the whole way. it refuses to go the last 3/4 of an inch. i have 2 long bolts in for alignment, tilted it up,down, pushed it sideways both ways, turned the engine over about 100 times. tried holding the pg housing while the other guy turned the engine, that worked for a while then i could no longer hold it. it sitting on blocks and jack stands now. may pull it back a part a little bit in the am and try again |

Posted By: Peterson

Date Posted: 23 Jun 2014 at 9:18pm

|

Get it together yet? Also with your crank driven oil pump motor, your goin to have to mount the front axle down farther to clear the oil pan. ------------- 7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2 |

Posted By: screwylouie010

Date Posted: 23 Jun 2014 at 9:42pm

| no, not together yet. been busy doing hay here then, going and helping my buddy do his hay. should be back on it Wednesday. yea, the front axle pivot bushing is shot and the rear cross member of the axle assembly has been broken out and welded back in crooked, so that and welding on extensions for the drop will be the next step |

Posted By: screwylouie010

Date Posted: 18 Aug 2014 at 6:17pm

|

well, ITS ALIVE!. haha. been working on it in the little spare time that i have and finally got the torque to the trans. i fired it up this afternoon, but i put it in reverse and and the power director in neutral and let the clutch out, it backed up like it was in low. and when i leave the trans in neutral with the clutch out and put the pd in neutral the engine bogs down a bit. i have 0 psi with the pd selector lever in neutral at idle and 50 psi in low and high at idle, but i only checked low at mid rpm and got almost 200psi.now i did have a really hard time getting the torque tube onto the trans. it went easy to about the last inch, then i fought it the rest of the way for for about 5 hours, maybe 6. still had to use like 4 bolts to pull it together. not cranking on them, but snugging them up good and working around it. o, also i dont have any steering, the wheel turns hard but the wheels do turn. when i turn the steering wheel, the psi at the pd valve drops. steering does get a little easier when you rev it up though. any help appreciated and i will post a few pictures and the first start video later. thank you |

Posted By: screwylouie010

Date Posted: 18 Aug 2014 at 9:40pm

|

http://www.youtube.com/watch?v=k9fe4VeY1gI&feature=youtu.be" rel="nofollow - http://www.youtube.com/watch?v=k9fe4VeY1gI&feature=youtu.be heres the video. not sure what happened to the quality of it. also. went back and messed with it more tonight and found something that made me feel real stupid. i put a block under the drawbar after i took the thing apart to keep the rear from flopping over backwards. the back of the tractor is up against a wall so to speak and completely for got about/ didnt really think it was causing problem. well the draw bar had decent weight on it, had to pound the block out from under the drawbar. im guessing thats why i had a hard time getting it back together. i just hope i didnt mess anything up |

Posted By: screwylouie010

Date Posted: 19 Aug 2014 at 10:35am

| This morning I got the book out and located the relieve valve for the steering and pd circuit. The valve was stuck open and pull of crap. I freed it up and cleaned. Put it back together. I now have steering and about 300psi at the pd valve in low at idle. But when I put it in low. At idle it bogs down and reads about 150 psi. I took it on a short 30 drive. It goes the same speed in neutral, low or high. It can't stop it with the brakes in any position and it bogs Down and feels as of it slows down in high. I really hope I didn't mess something up and have to pull it back apart. |

Posted By: screwylouie010

Date Posted: 20 Aug 2014 at 9:01am

|

Anyone have any ideas before I pull this thing back apart? Also is there supposed to spacers or something under the play form to hold it up off the rear end. Mine sits about 3/4 of and inch to low and cause problems with the power director linkage where it goes into the side of the torque tube On edit, I also figured out that an oil pan from a 200/7020 will allow me to use this engine with put modifying the front axle. I do have 1 on the way |

Posted By: Tanman_2006

Date Posted: 20 Aug 2014 at 2:41pm

|

I'm not any help but good info since I'm looking at a 190xt series 3 for a chore tractor. ------------- CIH 8930 MFWD Duals 205hp 9635 Massey Ferguson By Hesston Disk windrower 2856 Massey Ferguson By Hesston Round Baler 7050 AC PD Other tractors and GM Diesels |

Posted By: Sandknob

Date Posted: 01 Sep 2017 at 7:54am

| Curious if you have any updates on this project. |

Posted By: screwylouie010

Date Posted: 08 Sep 2017 at 1:42pm

| I haven't made much progress on the 190. I don't have a shop to work in so I was doing it in the pole barn but need the space to put hay so it is outside now. Right now the major hold up is a radiator. I am going to go with a custom radiator with the inlet/outlet swapped sides to match the engine. I need to plumb the fuel lines and at some point do the hydro lines better. Still have to swap oil pans and figure out the front axle. Pretty sure I had it figured out with out modifying to much but don't remember now. Someday I'll get back into it. I did have it running and driving and drove it around for a few mins. It sounded good |

Posted By: screwylouie010

Date Posted: 09 Sep 2017 at 9:03am

| I also bought a white 2-135 out of a field since I started this project. I needed a bigger tractor so it got priority over the 190. it had been sitting about 10 years but took minimal work to get it running. but this fall it lost compression on cylinder #4. so now that is getting an 8.3 cummins swapped in so that's where all my money is going now. so far its nickel and diming me to death. hopefully over the winter maybe I can get back onto the 190 |

screwylouie010 wrote:

screwylouie010 wrote: