| Author |

Topic Search Topic Search  Topic Options Topic Options

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 5:32pm Posted: 26 Jun 2025 at 5:32pm |

|

Per the user manual it is the coil ht. I'll see if it has a low voltage option...I might need the accessory kit for that. I think i got the missed fields all mowed. I may have some more time tomorrow. I usually spend the last day of the trip putting things back in their place but not as much to do this time. It also has a spark burn time test.

|

|

1952 CA13092

|

|

|

Sponsored Links

|

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 9:28pm Posted: 26 Jun 2025 at 9:28pm |

dfwallis wrote: dfwallis wrote:

Per the user manual it is the coil ht. I'll see if it has a low voltage option... |

Ahhh... generally when I think of 'dwell' it is in reference to the amount of time (actually rotational degrees) that the points are closed; in which case if there was a double dwell period it would mean that the points didn't open that time around.

I would be greatly curious to see whether that anomaly occurred at the exact moment when a blip in the vacuum signal happened.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 9:29pm Posted: 26 Jun 2025 at 9:29pm |

ACinSC wrote: ACinSC wrote:

Thanks for the explanation Les. |

You are most welcome!

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2025 at 10:20am Posted: 28 Jun 2025 at 10:20am |

|

Additional info Compression 1 - 4 130, 129, 132, 129

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2025 at 10:45am Posted: 28 Jun 2025 at 10:45am |

|

When idling very slow it sounds almost like the key was switched off momentarily, but the voltage to the coil or signal to/from the points never shows any hint of a dropout on a voltmeter. Wish I had an oscope to look closer. Oh boy, a new toy...hard to get my tek 536 on the plane.

Edited by dfwallis - 28 Jun 2025 at 12:04pm

|

|

1952 CA13092

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2025 at 8:52pm Posted: 28 Jun 2025 at 8:52pm |

dfwallis wrote: dfwallis wrote:

When idling very slow it sounds almost like the key was switched off momentarily... |

I have actually had this happen with poor contacts inside the switch

dfwallis wrote: dfwallis wrote:

...but the voltage to the coil or signal to/from the points never shows any hint of a dropout on a voltmeter. Wish I had an oscope to look closer. Oh boy, a new toy...hard to get my tek 536 on the plane. |

My Fluke 88 meter will record Min/Max readings and would pick up a momentary disconnect; just watching the meter probably would not be noticeable though. I do have an oscilloscope too

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11974

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2025 at 11:45pm Posted: 28 Jun 2025 at 11:45pm |

Hi Guys! Just getting on here this evening. Haven't been on in a while. Been pretty busy in the shop. Gary, if your still having problems with that Tractor, I can tell ya it ain't the Distributor that's fir' sure! That unit didn't miss a beat on the last run test on the 504. I ironed the couple issues out with that. You have another problem there. Maybe a sticky valve when running. Higher rpms the valve may not stick. Lower rpms it starts to hang up and cause a dead miss. Gotta' be something with the Tractor. Possibly a fuel issue. A lean condition off idle till you get into the enrichment circuit, then it runs better and the miss is gone because it has a fatter mix and runs good under load. It's gotta' be somethin' like that.

Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 11:35am Posted: 29 Jun 2025 at 11:35am |

Steve in NJ wrote: Steve in NJ wrote:

Hi Guys! Just getting on here this evening. Haven't been on in a while. Been pretty busy in the shop. Gary, if your still having problems with that Tractor, I can tell ya it ain't the Distributor that's fir' sure! That unit didn't miss a beat on the last run test on the 504. I ironed the couple issues out with that. You have another problem there. Maybe a sticky valve when running. Higher rpms the valve may not stick. Lower rpms it starts to hang up and cause a dead miss. Gotta' be something with the Tractor. Possibly a fuel issue. A lean condition off idle till you get into the enrichment circuit, then it runs better and the miss is gone because it has a fatter mix and runs good under load. It's gotta' be somethin' like that.

Steve@B&B

|

Seems doubtful that it would be valves. It had a complete, professional shop valve job. Compression seems reasonably good. The operating symptoms date back to the 80s or 90s (per my brother). It isn't something new. In the 80s, it had an automotive style toggle switch for ignition. Same symptoms. The key switch is new, the wiring hardness is 100% new. It is burning very rich at all RPMs, but not enough for visible black smoke except under load. It was burning leaner when I had installed the incorrect venturi (smaller diameter) in the carb last month. When I installed the new, correct venturi, it is again blowing black specks of carbon onto the hood. So, about the only thing left in common that hasn't been changed is the carburetor itself. It has been thoroughly cleaned and all jets verified open, but the main jet was not changed because the screw driver slot was severely damaged and I didn't have a super tiny easy out (plus it's at a weird angle and not sure I can get to it). I wanted to keep a TSX 486 carb on it and not switch to a Zenith, but I didn't find a source that I trusted so far. I'll perform a few more ignition checks in July (e.g. direct wiring battery to coil, direct ground wire distributor to chassis, perhaps oscope some signals). The GTC 505 provides oscope features but only for the high voltage signals. Seems like slightly short sighted design.

Anyway, I've been wanting to get a small portable oscope for some time (they're pretty cheap now). My Tektronix 536 weighs about 500lbs and is a pain in the butt to move around. I should have done some of that low voltage signal testing this last trip but I wanted to get it out in the field and use it some (the fun stuff) :) The main glitches with that was the PTO shaft guard kept pulling too hard and stretching the chain clips (brand new it was very hard to turn in spots because it was severely warped), and on one occasion, the hydraulics would not go down (perhaps the hold valve stuck). The rest of the trip was spent raising the tree canopy around the yard to make it easier to mow. ~1 acre, 39 acres to go...I lost 6 pounds :)

Edited by dfwallis - 29 Jun 2025 at 1:28pm

|

|

1952 CA13092

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 1:51pm Posted: 29 Jun 2025 at 1:51pm |

dfwallis wrote: dfwallis wrote:

...Seems doubtful that it would be valves. It had a complete, professional shop valve job. Compression seems reasonably good... |

dfwallis wrote: dfwallis wrote:

Additional info Compression 1 - 4 130, 129, 132, 129 ... |

Those are excellent compression numbers; this does not eliminate the possibility of sticky valve guides though, or too tight valve lash, thus the recommendation for vacuum gauge testing.

dfwallis wrote: dfwallis wrote:

The operating symptoms date back to the 80s or 90s ... it is again blowing black specks of carbon onto the hood... |

Assuming the correct size of jet(s) then the fuel level in the float bowl must be too high; perhaps the float isn't floating?  A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere  |

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 7:28pm Posted: 29 Jun 2025 at 7:28pm |

Les Kerf wrote: Les Kerf wrote:

dfwallis wrote: dfwallis wrote:

...Seems doubtful that it would be valves. It had a complete, professional shop valve job. Compression seems reasonably good... |

dfwallis wrote: dfwallis wrote:

Additional info Compression 1 - 4 130, 129, 132, 129 ... |

Those are excellent compression numbers; this does not eliminate the possibility of sticky valve guides though, or too tight valve lash, thus the recommendation for vacuum gauge testing.

dfwallis wrote: dfwallis wrote:

The operating symptoms date back to the 80s or 90s ... it is again blowing black specks of carbon onto the hood... |

Assuming the correct size of jet(s) then the fuel level in the float bowl must be too high; perhaps the float isn't floating?  A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere  |

We set valve clearance at .012. Doesn't mean it stayed at .012. We had plans to recheck it at some point. Maybe when it cools down a bit in the fall. Needs to be done, regardless. I don't know that it was blowing carbon specks in the 80s. He only said it was misfiring similarly. It did not misfire the last I used it before then, but started at some point and continues to this day, regardless of nearly everything being overhauled to spec to the best of our and the machine shops ability. I checked float level this week. It was as close to 9/32s as I could measure. The float does not leak. It is dry as a bone. I've checked it a dozen times. I inspected the carburetor pretty carefully. I saw no obvious cracks or leaks beside the one I sealed that was leaking fuel from the bowl at a very slow rate (the screw (plug) at the bottom front of the bowl). I've ordered some tiny easy outs to try to fix it correctly. All jets were replaced except the one at the bottom rear of the bowl. There was no screwdriver slot material left to latch on to.

But, just because I express doubts about a particular cause, it does not mean that I've ruled ANYTHING out. Until it's resolved, everything is suspect.

I've ordered a new portable oscope that should allow me to actually correlate the points signal with the resulting spark of the secondary, Ch1 vs Ch2 (10000x reduction probe).

Edited by dfwallis - 29 Jun 2025 at 8:56pm

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 8:30pm Posted: 29 Jun 2025 at 8:30pm |

New manifold looks like it has a flat that could be drilled/tapped to provide a vacuum gauge attachment point. Don't think I want to do that. Not finding a good attachment option.

Edit: I found a pic of an original manifold and it appears to have a pipe plug at that same flat spot. If I were to drill and tap it I'd want to take it off so that I could clamp it to the drill press to drill a nice straight hole. Not ready to do that at this point.

Edited by dfwallis - 29 Jun 2025 at 10:22pm

|

|

1952 CA13092

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 10:08pm Posted: 29 Jun 2025 at 10:08pm |

dfwallis wrote: dfwallis wrote:

New manifold looks like it has a flat that could be drilled/tapped to provide a vacuum gauge attachment point. Don't think I want to do that. Not finding a good attachment option. |

Bummer. A vacuum gauge is a valuable troubleshooting tool.

I put a new manifold on my Model C a couple years ago and it had a small pipe plug that we pulled out to run the old Surge milking machine.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 11:52pm Posted: 29 Jun 2025 at 11:52pm |

dfwallis wrote: dfwallis wrote:

...We set valve clearance at .012. Doesn't mean it stayed at .012. We had plans to recheck it at some point. Maybe when it cools down a bit in the fall. Needs to be done, regardless... |

I just re-read this whole thread to try to cipher out what we have all missed

dfwallis wrote: dfwallis wrote:

... the engine probably hasn't run more than 4 hours since rebuild...

dfwallis - 14 Jun 2025 at 1:53pm |

I found no mention in this thread of re-torquing the head, re-setting the valves, replacing spark plugs, or re-tightening the manifold bolts since the rebuild; you have added a few hours since that post

dfwallis wrote: dfwallis wrote:

...The timing mark was also bouncing around quite a lot, completely out of the viewing window...

dfwallis - 22 Jun 2025 at 12:06pm |

This one is somewhat puzzling. At what RPM was this noted? At low idle there should be no advance, and at high idle it should be at full advance. I can see it bouncing around at mid-range while it is still partway advanced though.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11974

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2025 at 12:49am Posted: 30 Jun 2025 at 12:49am |

That wouldn't have Champion Spark Plugs in it would it? I've seen and heard of so many goofy issues with them things. Screw in a real set of plugs like NGK's or Autolites and all the Gremlins go away..... Black carbon specs on the hood? Hmmmm.... Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

jvin248

Silver Level

Joined: 17 Jan 2022

Location: Detroit

Points: 438

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2025 at 6:03am Posted: 30 Jun 2025 at 6:03am |

|

.

Leaks at the manifold to motor interface can cause fuel to air mixture leaks.

My WD ran better after I replaced the factory manifold it came to me with with a new one plus new seals as two exhaust leaked and I think one intake with a slight leak.

I bought one of the small harbor freight ultrasonic cleaners and have run at least four antique carbs through it for much improved operation. Split the carb and open sides down. That may be better than the easy out game.

Verify the coil you have uses an internal resistor not external block and is the correct coil for the voltage you are set at. External resistor blocks and wiring makes for more connections that can go bad/corrode.

Are you getting intermittent shorts in wiring?

Are the misses frequent enough you can pull a plug wire and isolate the cylinder it happens to?

.

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2025 at 4:26pm Posted: 30 Jun 2025 at 4:26pm |

Six videos have been uploaded to https://www.youtube.com/@OrangeAcres-h2k

These are under the playlist "misfire analysis". They will go public around midnight 1 July (CST).

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2025 at 4:33pm Posted: 30 Jun 2025 at 4:33pm |

jvin248 wrote: jvin248 wrote:

.

Leaks at the manifold to motor interface can cause fuel to air mixture leaks.

My WD ran better after I replaced the factory manifold it came to me with with a new one plus new seals as two exhaust leaked and I think one intake with a slight leak.

I bought one of the small harbor freight ultrasonic cleaners and have run at least four antique carbs through it for much improved operation. Split the carb and open sides down. That may be better than the easy out game.

Verify the coil you have uses an internal resistor not external block and is the correct coil for the voltage you are set at. External resistor blocks and wiring makes for more connections that can go bad/corrode.

Are you getting intermittent shorts in wiring?

Are the misses frequent enough you can pull a plug wire and isolate the cylinder it happens to?

. |

It isn't a single cylinder misfiring. It is all of them at different times. I've searched for intermittent shorts, intermittent opens, gremlins...The new 6V coil has no external resistor. I switched it out and it made no difference. I've switched everything out related to the distributor, wires, plugs, points, rotor (3 different ones), cap (3 different ones), distributor partial rebuild (not the dust cap). No manifold leaks (and brand new).

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2025 at 4:41pm Posted: 30 Jun 2025 at 4:41pm |

Steve in NJ wrote: Steve in NJ wrote:

That wouldn't have Champion Spark Plugs in it would it? I've seen and heard of so many goofy issues with them things. Screw in a real set of plugs like NGK's or Autolites and all the Gremlins go away..... Black carbon specs on the hood? Hmmmm.... Steve@B&B

|

Theyre autolite. I know there is a carburetor issue. GTC 505 was showing electrical issues, that's where I started first. I still haven't ruled electrical out. GTC 505 and timing light still show electrical dropouts. You can see them better on the long duration recording than on the single trigger waveform. But they happen at all 4 cylinders, not just one. But the analyzer is easily confused by proximity of other HV wires so I'm not 100% confident in my interpretation. I plan to try to find some high impedance tubing to wrap the wires in to improve it a bit. It says you need 2 inches of clearance, but that's hard to do coming right out of the distributor.

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 hours 30 minutes ago at 9:39am Posted: 16 hours 30 minutes ago at 9:39am |

The videos are now live. I need to search for one more that shows the long duration recording better. I changed one of the settings and never got it back to the same view :(

I also found some fire resistant fiberglass braid tubing that should help me better isolate the spark plug wires and eliminate the interference between plug wires. 25KV breakdown voltage. Hopefully it will allow a more accurate view of what's happening. I received my new oscope/dmm/signal generator and ignition probe. It's quite nice for the price.

Edit: I only find stills of the long duration recording showing the apparent dropouts, no video.

Edited by dfwallis - 15 hours 48 minutes ago at 10:21am

|

|

1952 CA13092

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 86834

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 hours 19 minutes ago at 9:50am Posted: 16 hours 19 minutes ago at 9:50am |

.The new 6V coil has no external resistor. I switched it out and it made no difference. I've switched everything out related to the distributor, wires, plugs, points, rotor (3 different ones), cap (3 different ones), distributor partial rebuild (not the dust cap).

so this is the original 6v system... I guess i assumed you had updated to 12v... Dont see a problem, but im not a fan of the 6v coils..

|

|

Like them all, but love the "B"s.

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 hours 57 minutes ago at 10:12am Posted: 15 hours 57 minutes ago at 10:12am |

steve(ill) wrote: steve(ill) wrote:

.The new 6V coil has no external resistor. I switched it out and it made no difference. I've switched everything out related to the distributor, wires, plugs, points, rotor (3 different ones), cap (3 different ones), distributor partial rebuild (not the dust cap).

so this is the original 6v system... I guess i assumed you had updated to 12v... Dont see a problem, but im not a fan of the 6v coils.. |

I'm keeping it as original as I can stand. I did add a regulator to the generator. I had to drill one hole in the drawbar to attach my new bail. I bought a new PTO guard off ebay and modified it (original straightened and stored away) to clear the rockshaft mounted top link bracket. I used the second light switch detent to turn on the rear spotlight. Everything else is bolt on additions using existing mounting points. I'm not a fan of 12V conversions. 6V works great if you have good wiring/connections and the engine timed.

It draws 195 amps when cranking. Is that about right?

Edited by dfwallis - 15 hours 46 minutes ago at 10:23am

|

|

1952 CA13092

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 hours 51 minutes ago at 12:18pm Posted: 13 hours 51 minutes ago at 12:18pm |

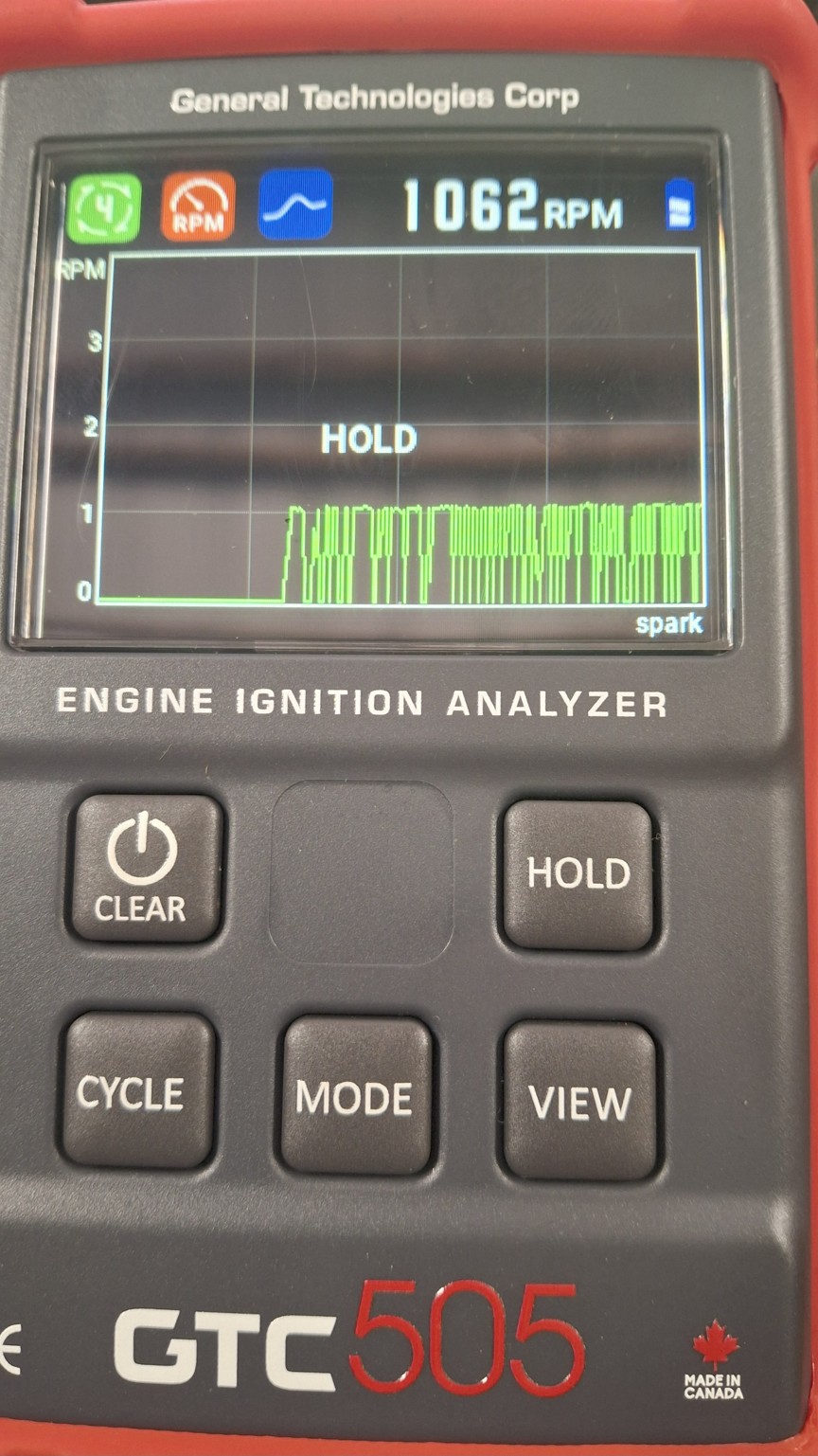

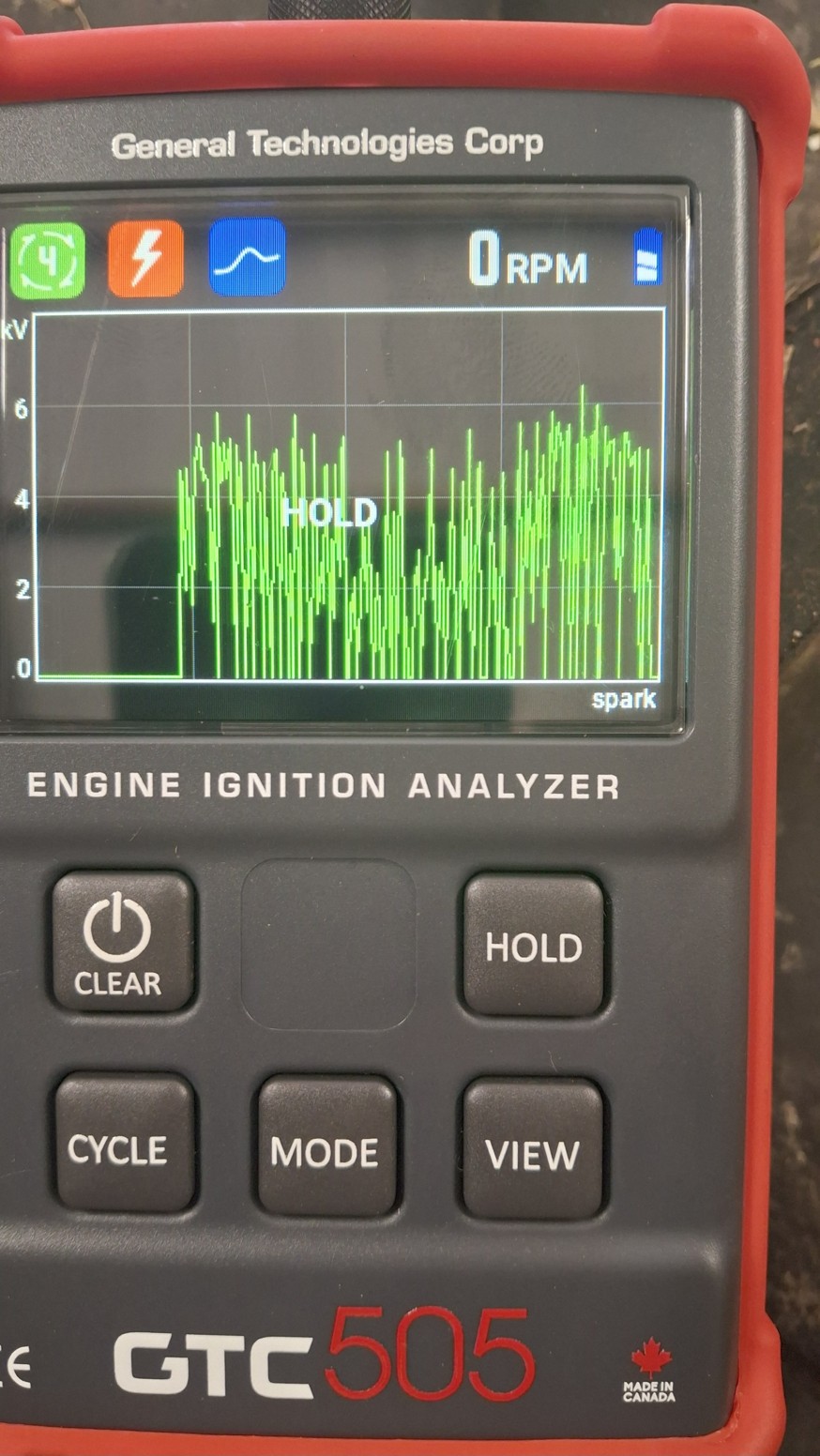

I've not found many good clean signal views due to wire proximity interference. These two images are the best I could locate. Unfortunately they are before the distributor rebuild:

Both cylinder 4. These are both before the distributor rebuild, the signals are now much more consistent, but still show these "apparent" dropouts. All cylinders look similar to each other if you get rid of the proximity interference:

RPM (pulse count):

Every one of those "wide" pulses seems to correlate with a misfire. These appear on all 4 cylinders. It also correlates with the meter having difficulty reading the correct RPM rate (cause or symptom of the instrumentation??).

Voltage (Again, before the dist rebuild, it's now much more consistently around 6KV):

I selected "hold" during a period when it couldn't read the RPM rate.

|

|

1952 CA13092

|

|

jvin248

Silver Level

Joined: 17 Jan 2022

Location: Detroit

Points: 438

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 59 minutes ago at 7:10pm Posted: 6 hours 59 minutes ago at 7:10pm |

|

.

If everything but the distributor cap (and likely the rotator), I'd really check that out for carbon buildup or cracks/shorts.

My WD had a wrong sized cap when it came to me, and the rotator had spots it hit the pole flanges. Ran a lot better after replacing the pair with correct parts, and uncracked.

.

Edited by jvin248 - 6 hours 58 minutes ago at 7:11pm

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 14 minutes ago at 7:55pm Posted: 6 hours 14 minutes ago at 7:55pm |

jvin248 wrote: jvin248 wrote:

.

If everything but the distributor cap (and likely the rotator), I'd really check that out for carbon buildup or cracks/shorts.

My WD had a wrong sized cap when it came to me, and the rotator had spots it hit the pole flanges. Ran a lot better after replacing the pair with correct parts, and uncracked.

. |

I'm also thinking there must be something amiss in that area as well. It is the only place that affects the high-tension delivery to all four cylinders.

I would start by measuring the length of the rotor to see if there is excessive gap to the terminals, and then I would sacrifice a distributor cap by drilling holes in it to see if the phasing is off (i.e. is the rotor actually pointing at the terminal when it fires).

I watched those videos several times and I am not quite ready to run out and buy one of those gadgets just yet  |

|

CA13414

Silver Level

Joined: 25 Feb 2024

Location: Nebraska

Points: 314

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 7 minutes ago at 8:02pm Posted: 6 hours 7 minutes ago at 8:02pm |

|

This has been a great discussion. Very much appreciate everyone's insights and ideas and has been fun to read, as much as it has been a thorn your the side trying to solve the problem.

Dan

|

|

Helping the aged survive and thrive! 1953 CA

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 7 minutes ago at 8:02pm Posted: 6 hours 7 minutes ago at 8:02pm |

dfwallis wrote: dfwallis wrote:

...It draws 195 amps when cranking. Is that about right?

|

That's plenty high but if it gets the job done it's ok; does it seem to drag?

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 37 minutes ago at 8:32pm Posted: 5 hours 37 minutes ago at 8:32pm |

Les Kerf wrote: Les Kerf wrote:

jvin248 wrote: jvin248 wrote:

.

If everything but the distributor cap (and likely the rotator), I'd really check that out for carbon buildup or cracks/shorts.

My WD had a wrong sized cap when it came to me, and the rotator had spots it hit the pole flanges. Ran a lot better after replacing the pair with correct parts, and uncracked.

. |

I'm also thinking there must be something amiss in that area as well. It is the only place that affects the high-tension delivery to all four cylinders.

I would start by measuring the length of the rotor to see if there is excessive gap to the terminals, and then I would sacrifice a distributor cap by drilling holes in it to see if the phasing is off (i.e. is the rotor actually pointing at the terminal when it fires).

I watched those videos several times and I am not quite ready to run out and buy one of those gadgets just yet  |

I tried 3 different distributor caps and 3 different rotors. Two were new and one each of the old (delco branded) ones. The delco rotor has a very long curved section trailing the front edge. From the spark wear, it looks like it has been firing very close to the leading edge where I would expect it to be. I have considered sacrificing one of the caps to instrument it.

I also added a thin gasket under the dust cap to get the distributor cap up just a hair higher since the old rubber seal is crunchy and I had to grind it in spots to get the cap to sit perfectly flat. The caliper shows it now spaces 5/16 inch consistently all around but I don't know what it should be. The dust cap does behave as a spacer, but adding the thin gasket made no difference.

Yes, it is difficult to tell if the signal dropouts are just because it lost sync or if the signal really went away. There is no trigger level adjustment. However, the timing light appears to miss signals in the same pattern as the GTC505 (when it shows one miss, the timing light shows one miss, two, timing light shows two misses (roughly)). The RPM view with pulse count view shows this correlation best. The long duration voltage recording charts are difficult to interpret without a timescale and knowing where one sequence begins and ends. The instantaneous voltage chart shows the signal missing periodically, but again, it's hard to tell if it's just a sync issue.

I'm hoping that the new scope will allow me to trigger on the points signal and more unambiguously show the spark pulse in relation to it.

I'm trying to work up the strength to recheck the valves next month. But if it's 100+f again in the barn, it'll be mighty difficult to make myself do it. I spent thousands to have the head professionally rebuilt (among other things). I'll be extremely upset if that turns out to be a problem (other than gap setting, which we did)...:(

I'll give the carburetor one last hurrah with the screw extractors and replacing the last jet, but I have doubts that will help...unless someone had bored (gouged) the jet out or something. I guess I could figure out the spec and check the size. I might also try lowering the float even though it shows to be in spec at 9/32 inch. I was going to try some things like that last trip, but it was 100+f and 65% and I was loosing mojo. :(

Edited by dfwallis - 5 hours 29 minutes ago at 8:40pm

|

|

1952 CA13092

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 53741

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 31 minutes ago at 8:38pm Posted: 5 hours 31 minutes ago at 8:38pm |

This thread reminds me of about 30 some years ago, was working on a turf farm, and they needed a big Ford truck started, sounded to me like it wasn't getting any spark, big gas 4V V8, had a (then) newfangled ignition on it, had a rotor that the business end was made outta a loop of wire, instead of a solid piece, like AC's had. The wire had broken so insteada a loop, there were 2 stubs sticking out, arcing all over the place... Took a copper penny, cut it half and soldered, and melted it into the plastic, and that's the rotor it had, when I stopped working there...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

dfwallis wrote:

dfwallis wrote:

A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere

A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere