CA erratic spark

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=206666

Printed Date: 04 Feb 2026 at 7:12pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: CA erratic spark

Posted By: dfwallis

Subject: CA erratic spark

Date Posted: 11 May 2025 at 3:33pm

|

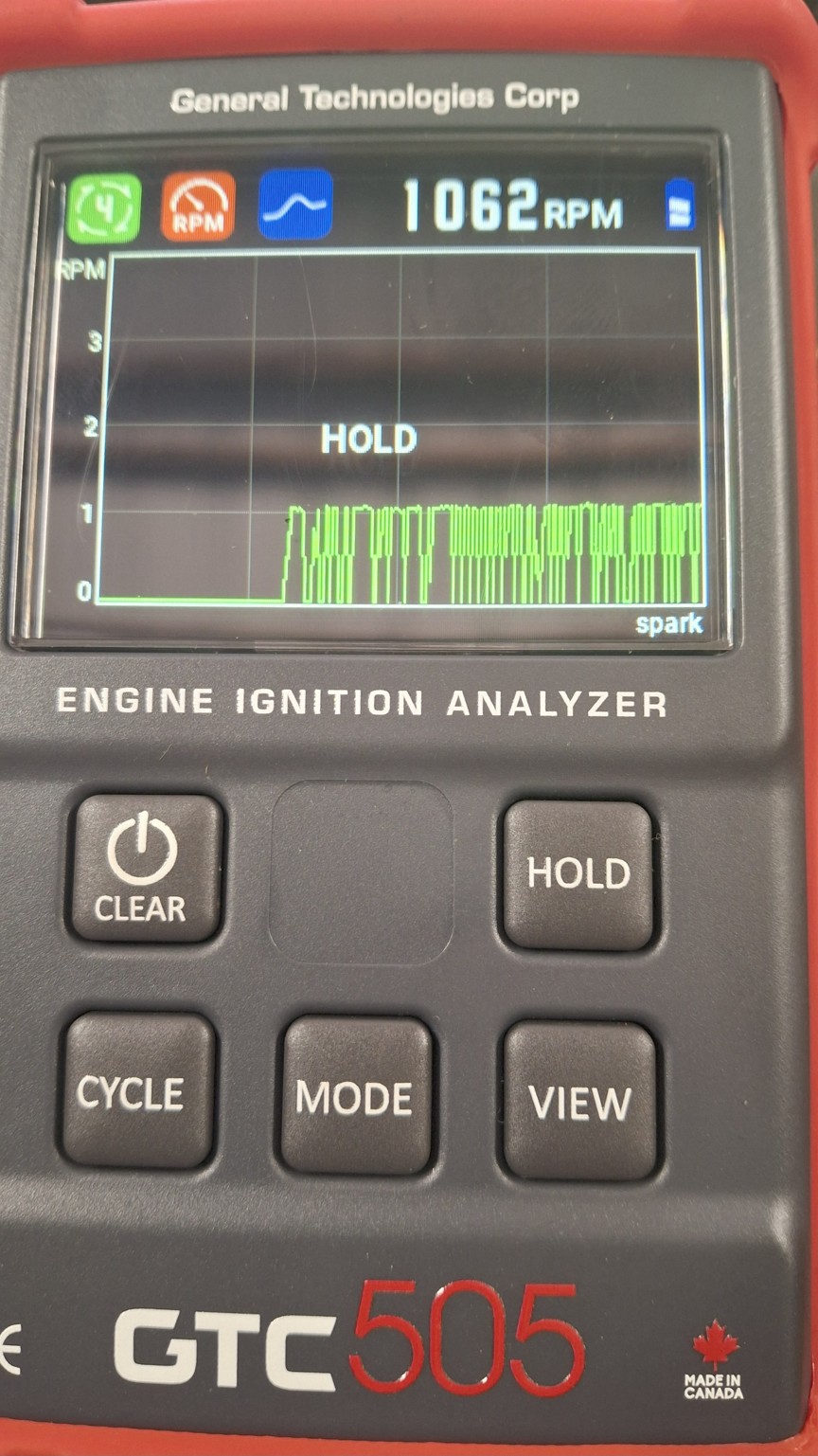

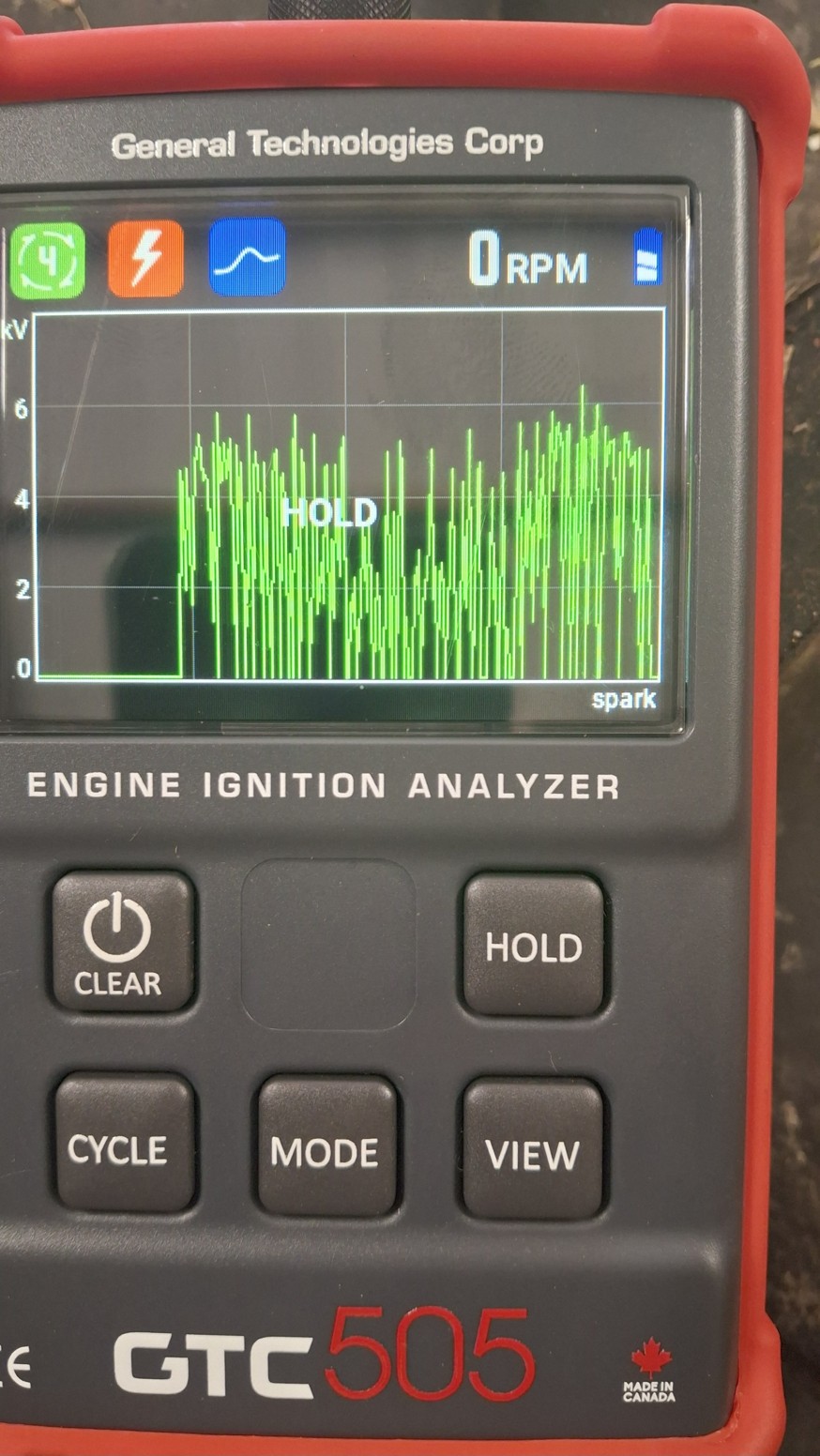

Analyzing spark via a gtc505 analyzer. All 4 cylinders look horrible. Cylinder 1 and 4 have the best signals but 2 and 3 are spiking randomly. All have a peak voltage of around 6kv, but 2 and 3 have extra random spikes to 9kv. Suspect random short circuit through cap or wires or other...all is new. My brother says it behaved the same in the 80s. It is running better with new venturi in carb, corrected spark plug gaps. I think to get higher spikes, the dwell time must randomly increase?? Does not seem to be any side to side distributor play, but there is up and down (in/out) play. Suggestions? ------------- 1952 CA13092 |

Replies:

Posted By: steve(ill)

Date Posted: 11 May 2025 at 3:36pm

|

i always suspect a weak condenser or coil when i have problems.. ------------- Like them all, but love the "B"s. |

Posted By: Stan R

Date Posted: 11 May 2025 at 3:52pm

| Last electrical tune-up was in the 80's? I'd throw in new points, condenser, wires, cap and rotor in it. And go from there if still problematic. I'm sure your time is worth more than the cost of these items. |

Posted By: jaybmiller

Date Posted: 11 May 2025 at 4:18pm

|

Distributor shaft float? Yep, I’ve seen that a dozen times on old CA tractors. That’s your gremlin right there. New cap, new wires won’t fix it till you take out the slack. Re-bush or swap that dizzy ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: dfwallis

Date Posted: 11 May 2025 at 4:48pm

|

Stanr...Those are all new...completeish rebuild...from the waveforms, I think the coil is fine. I think more likely erratic points...the analyzer also gets confused with lots of extra pulses, declaring rpm 5000 instead of 1040 momentarily...cylinder 2 and 3 mostly. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 11 May 2025 at 4:59pm

I am not familiar with that analyzer, is it an actual oscilloscope?

Please describe "horrible". Is this at idle?

Do you mean that there are additional spikes other than the one, correct voltage spike? When the points open, the electro-magnetic field in the coil collapses; the resulting 'flyback effect' induces a voltage in the secondary windings of the coil. This voltage increases until the spark is able to jump the gap. It is not unusual to have variations in the firing voltage as an engine runs; I would not be alarmed seeing 6-9kV ranges.

No. The required firing voltage was higher on that particular event. In order to fire at all, the dwell had to be at least 'adequate'. The first two things I would want to know is what each cylinder has for compression, and next would be to hook up a vacuum gauge and see what that looks like. Also, do you have any way to take analyzer readings under load? That would be most interesting.

|

Posted By: Les Kerf

Date Posted: 11 May 2025 at 5:04pm

You posted this while I was composing my previous answer. Your points might be bouncing around, also poor grounding can give fits. The breaker plate needs to be well-grounded to the outside.

|

Posted By: dfwallis

Date Posted: 11 May 2025 at 5:22pm

Cylinder 1 and 4 do not experience the additional spikes to 9k or more at all. Gtc505 is a scope of sorts. I have images but too painful to edit and upload on android. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 11 May 2025 at 8:43pm

After ponderizing about this for a while I believe jaybmiller is right. The vertical play in the distributor shaft can make the points chatter about due to the spiral gears causing the shaft to advance and return rapidly. |

Posted By: Trinity45

Date Posted: 11 May 2025 at 9:26pm

| I had problems with my B, thought it was points, then change the coil and the cap, lastly replaced the condenser and that fixed my problem. |

Posted By: DiyDave

Date Posted: 12 May 2025 at 4:43am

|

Check the insulator block that carries the points wire through the side of the distributor for cracks, and to see if the points wire has one ear grounding the points at that point... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: dfwallis

Date Posted: 12 May 2025 at 7:29am

I will check...there was a grounding issue that I fixed...got shocked adjusting timing while running, touching the housing, but did not change the behavior when I fixed the grounding (paint). I did check that the points plate is grounded. ------------- 1952 CA13092 |

Posted By: ekjdm14

Date Posted: 12 May 2025 at 8:54am

|

What are the run symptoms from this? Spluttering/missing randomly? I've not scoped the signal but believe I'm having a similar issue on the redneck B & (timing "fluttering" all over the place due to slack in it's ignition timing chain setup, needs a new bit of chain. So could be caused by the lash in your distributor in your case Also, if the condenser is new new & not NOS then perhaps switch back to the previous one/a known good one. Modern parts are/were trash last I checked.

------------- Stuck Farmer |

Posted By: dfwallis

Date Posted: 12 May 2025 at 9:24am

Sorry for posting inside the quote...android ui sucks

------------- 1952 CA13092 |

Posted By: ekjdm14

Date Posted: 12 May 2025 at 9:55am

|

Not a problem, posting from a 'phone must be a real PITA! This is kinda like mine now I think about it, acts like it was going to clear up and then back to misbehaving. thought I was losing fuel initially but pretty sure it's timing slop. Would certainly attend to the distributor on your tractor, especially as Jay has experience of this being a cause. ------------- Stuck Farmer |

Posted By: orangeman

Date Posted: 12 May 2025 at 2:42pm

| I would check the play or displacement in the distributor shaft, possibly worn main shaft bushings? ~ Orangeman |

Posted By: dfwallis

Date Posted: 13 May 2025 at 1:54pm

|

I took the distributor apart and gave it a thorough cleaning. I didn't have a rebushing kit so stopped there. There is some marginal improvement...the centrifugal mechanism was highly gunked up, but only improved the advance/retard process...cylinder 2 and 3 waveforms are also slightly improved, but could partially be from changing point gap from 22 to 20...one manual says 22, one says 20...I'm leaning towards getting one from bnb while I work on other stuff...I had made a slow moving vehicle bracket, but I'll have to mod it...too close to the rockshaft mounted top link bracket when raised...I swear I measured it:( ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 13 Jun 2025 at 10:02am

|

Sent the distributor to B&B. Sun 504 tests showed the misfire and erratic dwell issues and mods were made and its now on its way back home. It appears the main problem was worn/pitted CAM/lobes (not end play). Replaced and tested with good spark all the way to 3200RPM (~where points float started). It may have worn in part due to lack of lubrication. The lubrication "wick" was there, but not consistently working, so that was also fixed. It's doubtful anybody ever lubricated it in 72 years. ------------- 1952 CA13092 |

Posted By: steve(ill)

Date Posted: 13 Jun 2025 at 3:49pm

|

very interesting about the cam !!!.......... and have heard many say that STEVE does excellent work ! ------------- Like them all, but love the "B"s. |

Posted By: CA13414

Date Posted: 14 Jun 2025 at 6:54am

|

Very interesting with everything you’ve done! The trouble I’ve had with our CA is very much the same. Cylinders 2 and 3 quit working after the engine warms up. This was at an idle and full throttle. 2 was worse than 3, and there is no spark on #2 to the fingertip when touching the wire, my crude way vs your analyzer!! :-) In sequence, I replaced the spark plugs first, then wires, distributor, cap, rotor, and the other day the magneto coil and condenser. Replacing the magneto coil and condenser did the trick…… “thus far!!” Since it happened at an idle and full RPM didn’t seam to be floating and getting hot and cooling down was clearly causing the problem. My money was on the condenser but I can not explain why #2 and to a lesser extent #3 and not #1 or #4!? I’m putting our little “Orange Dude” to work next weekend. That’ll be the test! Dan ------------- Helping the aged survive and thrive! 1953 CA |

Posted By: dfwallis

Date Posted: 14 Jun 2025 at 10:51am

I just hope it's fixed. It's hard for me to imagine a CAM wear pattern happening that would give those results, unless it was pretty severely lop-sided. I polished up the CAM to try to improve it (pitting), but I did not check for roundness. When I set the points, I just picked one lobe and did not check if it had the same gap on other lobes. I'll try to be more thorough if there's a next time. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 14 Jun 2025 at 2:05pm

I can. It's called "bounce". The keyboards we use to type these messages have a built-in delay system known as "de-bounce" to help prevent multiple re-strikes; our mechanical distributor cam lobes have no such thing. Any roughness at the time of opening the points can easily cause this. |

Posted By: Steve in NJ

Date Posted: 14 Jun 2025 at 2:54pm

|

For those who were curious about this particular Distributor, here's the poop. It's very rare I change a cam. When I first ran that Distributor out of the box, the dwell was all over the place. First thing you think of is main shaft bushing. Not this time. Main shaft spun nice n' true. Up n' down, side to side all in spec. Looked good in the 504 too. Point Contacts were worn funny with a matching rub block which led me to a possible cam problem. Inspected the cam and one lobe looked almost round toward the middle. Installed a new NOS cam, ran it on the 504 again (same points) and the dwell straightened out quite a bit, but the misfire still was there. Put a new set of my points and condenser and ran it again. Misfire gone, dwell perfect, and full spark to all plugs. The ole' 504 said she was good ta' go! Should run pretty nice now. Let us know how she runs Gary. Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: dfwallis

Date Posted: 14 Jun 2025 at 3:50pm

Thanks, Steve! Kinda strange there was points wear. They were brand new and the engine probably hasn't run more than 4 hours since rebuild. I guess maybe they really WERE crappy quality.

------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 14 Jun 2025 at 8:30pm

And that's the difference between having the proper test equipment and merely stabbing around guessing!

|

Posted By: dfwallis

Date Posted: 14 Jun 2025 at 8:37pm

Yeah, I may get me one of those...only about $4k...but I may never need one again at my age...:( ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 14 Jun 2025 at 9:25pm

|

Should I get one of those super duper coils? I see a 40kv, a 55kv, and a 60kv option. Does that risk burning the points/plugs faster? ------------- 1952 CA13092 |

Posted By: wjohn

Date Posted: 14 Jun 2025 at 10:27pm

|

Thanks for following up and letting us know what the issue was, and thanks to Steve for even more details. This is why this forum is great. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Les Kerf

Date Posted: 14 Jun 2025 at 11:04pm

Complete waste of money. No, it won't hurt anything other than your bank account.

|

Posted By: Les Kerf

Date Posted: 14 Jun 2025 at 11:11pm

My last job before retiring was in the electronics engineering department at Encoder Products Company doing R&D work; we had lots of really cool test equipment that I sometimes wish I still had access to, but my pockets aren't deep enough and it is difficult to justify for a one-time use

|

Posted By: ACinSC

Date Posted: 15 Jun 2025 at 6:18am

| Thanks for the explanation Steve B !! |

Posted By: Steve in NJ

Date Posted: 16 Jun 2025 at 10:40am

|

No problem! I know a lot of us here are like me. Wondering what took place with stuff that doesn't work right and what the correction was. Sometimes we don't always hear the outcome of an issue. Makes ya wanna' know in case that particular issue happens to you. I've been doing this type of work for over 50 years, and every once in a while you come across something goofy and you say to yourself "what the h*ll?? Of all the Distributors I've done over the years, I've only changed a few cam assys. A couple were in Automobiles due to higher rpm ranges. Les is right. You don't need a 40K volt Coil. The standard Coils work fine unless you want to put one in. Not neccessary... BTW, I think the main reason why the one lobe wore out was lack of lubricant. The cam was dry as a bone, and the wick was there for the ride. Wasn't even touching the cam. Steve@B&B

------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: dfwallis

Date Posted: 22 Jun 2025 at 1:18pm

|

Well, there doesn't seem to be any change in behavior. The gtc505 waveforms are much more consistent and with improved characteristics, but the misfire is still there exactly the same. Timing light on cylinder 1 is very clearly missing it's going about 3 pops then misses. It could be that the voltage is a little below the timing light minimum, but I see misses on th gtc 505 also, just not as glaring as the timing light...timing light on 2 and 4 is much more consistent. Changed plug wire, new cap, bnb installed new points and condenser. I'll try a different rotor next, then see if I can scrounge up another coil. The timing mark was also bouncing around quite a lot, completely out of the viewing window. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 22 Jun 2025 at 2:04pm

|

Changed plug wires, coil to 72 yo original, rotor to possibly original, no difference...timing light agrees with gtc505...cylinder 3 is reading 3000+ rpm at 920rpm on other cylinders...timing light cylinder 3 is flashing 3 times faster than other cylinders. Sneak path somewhere? Cylinder 1 still shows clear dropouts, but when flashing is at correct rate per 2 and 4. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 22 Jun 2025 at 2:20pm

OK, solved one problem, the coil ht wire is inducing voltage on the plug wires/jacket and confusing the instruments...I'll completely isolate the wires and try again  ------------- 1952 CA13092 |

Posted By: steve(ill)

Date Posted: 22 Jun 2025 at 3:55pm

|

thats an odd one all right... since STEVE rebuilt the distributor you got a 99.999% chance that it is NOT the problem.. That dont leave much to look at but coil , plugs, wires and the motor itself ! ------------- Like them all, but love the "B"s. |

Posted By: WF owner

Date Posted: 22 Jun 2025 at 7:12pm

| Have you tried running it in the dark? I had a WD45 that looked almost like fireworks in the dark. |

Posted By: dfwallis

Date Posted: 22 Jun 2025 at 8:30pm

Worth a try...I ran out of gas, I'll resume tomorrow...does seem like it's arcing somewhere it shouldn't...I found the original dust cap wasn't sitting quite flat, but I think the rotor rides far above and wouldn't be rubbing on it. But I cleaned it up and will see if any effect. ------------- 1952 CA13092 |

Posted By: Wispitfiremike

Date Posted: 22 Jun 2025 at 8:48pm

| Is it possible you have a bad ground somewhere? Or a wire grounding from vibration? If tests ok but when on running engine its different sure seems possible. |

Posted By: Les Kerf

Date Posted: 22 Jun 2025 at 8:59pm

Great idea!

|

Posted By: HudCo

Date Posted: 22 Jun 2025 at 10:37pm

| i allways check more than one lobe with the feeler gauge , that will catch a wore lobe |

Posted By: dfwallis

Date Posted: 23 Jun 2025 at 11:59am

|

Interestingly, the timing light dropouts have all but stopped. Maybe the distributor cap simply was not sitting level enough. I improved the crunchy dust cap gasket. I'll look at that a bit more. It's still missing some. And every plug wire that runs close to the coil ht wire flashes the timing light much faster...I tried adding a rubber hose on the coil wire but didn't seem to dampen it much. Harder to diagnose with unreliable test equipment behavior:( ------------- 1952 CA13092 |

Posted By: DonBC

Date Posted: 23 Jun 2025 at 12:49pm

|

My experience with an engine that starts and runs for a few minutes and then starts to miss is a bad coil. When this happens, feel the coil and if it is very hot, it is a bad coil. ------------- Jack of all trades, master of none |

Posted By: dfwallis

Date Posted: 23 Jun 2025 at 2:38pm

It's immediate, no delay. Swapped coil with no difference in behavior. I've now swapped everything but dust cap and plug wires. I did find an old make your own plug set and made a new ht coil wire. Did not produce a noticeable difference in behavior. I did try a few plug wire switches from the H, but may not have been the right cylinders. I did ohm all the wires and checked for intermittent connections but they all tested ok...not a good test for hvhf tho. Taking a break to work some other cleanup items. The plug wires are brand new, i meant i didn't get another brand new set. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 23 Jun 2025 at 5:46pm

|

Just mowed another 2 ac field. It doesn't noticeably miss a lick when under load and at operating temp it only misses every now and then when not under load, several good seconds, roughly 1 miss. It may be a little improved from yesterday. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 24 Jun 2025 at 7:21am

|

Inspected for arcing in the dark. Did not see anything. ------------- 1952 CA13092 |

Posted By: steve(ill)

Date Posted: 24 Jun 2025 at 7:58am

|

it only misses every now and then when not under load DFW... you may skip a beat when you get to be 75 years old also...  ... I have seen that on more than one tractor... Have wondered if its electrical or gas flow thru carb.. Not really "common", but many have a similar effect... ... I have seen that on more than one tractor... Have wondered if its electrical or gas flow thru carb.. Not really "common", but many have a similar effect...------------- Like them all, but love the "B"s. |

Posted By: Les Kerf

Date Posted: 24 Jun 2025 at 1:22pm

Just for grins, try opening up the spark plug gap a whole bunch, like maybe double the normal amount. At some point this will likely cause a miss while under load, but it just may smooth out the no-load situation.

|

Posted By: dfwallis

Date Posted: 24 Jun 2025 at 8:30pm

I might try it. The gap recommended is from a time when octane was in the mid 70s and without alcohol... ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 25 Jun 2025 at 8:18am

These engines have a rather primitive combustion chamber; the spark plug location is way off to the side, the siamese intake ports will deliver different swirl patterns in all four cylinders, the squish patterns are haphazard, etc. Under load, when the air-fuel charge is approaching maximum density, there will be ample mixture present inside the spark plug gap where (obviously) the flame kernel is initiated and then spreads smoothly (we hope) across the combustion chamber. Under no-load conditions (even at high idle) the air-fuel density is significantly less which results in much less mixture being available at that spark plug hanging out way over there in the far corner of the chamber; if this mixture inside the gap happens to be too lean at the instant of sparking then a misfire is the result. A wider spark plug gap increases the probability of having adequate fuel being present at the instant of sparking; it also increases the voltage required to initiate the spark. At low compression pressures this is not a problem, but it can be a problem at higher pressures. At low idle speeds the compression pressures are quite low due to the throttle butterfly being nearly shut; the idle circuit in the carburetor throws in excess fuel in order to allow enough fuel for reliable ignition (idling results in very poor fuel economy). Under load at wider throttle opening there is ample mass airflow to provide a strong vacuum signal to pull in adequate fuel through the main fuel circuit. Since you are seeing smooth running under load it tells us that you have sufficient fuel and good spark energy for the conditions. Misfiring at no-load high idle may be a sign of inadequate fuel; the butterfly isn't shut but is open just far enough that the idle circuit is probably not delivering much (if any) fuel, yet isn't open enough to allow the mass airflow needed to pull enough fuel for steady ignition. If a wider plug gap helps the no-load condition it may be a clue as to what is happening. |

Posted By: steve(ill)

Date Posted: 25 Jun 2025 at 8:54am

|

that is a great explaination Les ...... I have SEEN it happen, but never thought of WHY... Engine design / combustion chamber size / air flow velocity is probably the answer.. THANKS ! ------------- Like them all, but love the "B"s. |

Posted By: dfwallis

Date Posted: 25 Jun 2025 at 9:47am

|

Changed to .041 and then to .055. If there was a difference in behavior it was too subtle for me to detect at either setting...although at .055, it did have very slightly less stable slow idle. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 25 Jun 2025 at 2:35pm

I think we have beat the ignition system plumb to death

At this point I would contrive some way of hooking up a vacuum gauge to see what it says under your operating conditions. At this point I would contrive some way of hooking up a vacuum gauge to see what it says under your operating conditions. |

Posted By: dfwallis

Date Posted: 25 Jun 2025 at 3:41pm

|

May have to wait until the next trip. I've cleaned up several items including the left side final drive oil pan and the sealant needs 72 hours to cure. I did also find a tiny leak at the carburetor main jet, but the fix is a kludge due to broken jet driver slots...don't have that small of an easy out. If the kludge helps (or even if not), I may either send the carburetor out for rebuild or break down and get the Zenith. Running out of things to change... ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 26 Jun 2025 at 10:43am

If ever there were an engine design just begging for an MSD-CDI ignition it is our beloved AC's  The triple-strike capacitor discharge can hide a multitude of sins inside that lousy combustion chamber; it is also by far the most expensive solution  An MSD setup firing some iridium tipped spark plugs would likely last much longer than I will be able to drive the tractor. Edit: This assumes proper carburetor function

|

Posted By: ACinSC

Date Posted: 26 Jun 2025 at 10:51am

| Les,is this the same as a pertronix ignition? Thanks |

Posted By: Les Kerf

Date Posted: 26 Jun 2025 at 1:22pm

No. The Pertronix is simply a solid-state triggering device that does nothing but replace the original breaker points and condenser. They are available in both 6 Volt and 12 Volt versions, and can use the original coil, wires, and plugs (although Pertronix recommends using resistor wires/plugs). The advantage of Pertronix is that you do not need to do periodic maintenance on the points, and performance does not deteriorate gradually like happens with points. If it fails, it tends to fail suddenly and all at once, and the points can be quickly and easily replaced if need be. Pertronix units have a pretty good reputation for reliability; I currently have one running in my Model C. Since it uses the same coil as the original breaker points, the ignition energy is no greater, and no less than, that which is delivered by the breaker point triggering. The MSD is a whole 'nuther animal. It uses Capacitor Discharge Ignition (CDI) whereby a special module charges a capacitor up to maybe 400 Volts, and then discharges the capacitor through a special coil. This results in a spark that has a VERY fast rise time and is well-known for its ability to fire a fouled spark plug. The MSD system produces three separate spark events in rapid succession, the theory being that if the first one doesn't light the fire then maybe the next two will. Better late than never. Due to the speeds involved, most MSD's only produce one spark at high RPM, say, above 4000 RPM. But then our tractors never come close that speed. There are CDI ignitions that are not MSD and only provide one spark per event. CDI is the main reason why your modern chain saws start so very much easier than the old magneto ignition McCulloch saws I grew up with. The MSD unit still requires something in the distributor to trigger it; this can actually be done with the original breaker points (which will now last practically forever) or I believe even a Pertronix can be used. |

Posted By: dfwallis

Date Posted: 26 Jun 2025 at 2:10pm

|

I have taken a video of dwell time %. Essentially every large spike in the dwell time is an engine miss. I'll upload next week. My nephew left me a little more work than planned. Also had to fix the brush hog pto shaft for my brother. Running out of time for this trip. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 26 Jun 2025 at 3:24pm

I am curious to see the video. Meanwhile, can you describe the aberration? Is this 'large spike in the dwell time' being measured on the primary (low voltage) side?

|

Posted By: ACinSC

Date Posted: 26 Jun 2025 at 3:27pm

| Thanks for the explanation Les. |

Posted By: dfwallis

Date Posted: 26 Jun 2025 at 5:32pm

|

Per the user manual it is the coil ht. I'll see if it has a low voltage option...I might need the accessory kit for that. I think i got the missed fields all mowed. I may have some more time tomorrow. I usually spend the last day of the trip putting things back in their place but not as much to do this time. It also has a spark burn time test. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 26 Jun 2025 at 9:28pm

Ahhh... generally when I think of 'dwell' it is in reference to the amount of time (actually rotational degrees) that the points are closed; in which case if there was a double dwell period it would mean that the points didn't open that time around. I would be greatly curious to see whether that anomaly occurred at the exact moment when a blip in the vacuum signal happened.

|

Posted By: Les Kerf

Date Posted: 26 Jun 2025 at 9:29pm

You are most welcome!

|

Posted By: dfwallis

Date Posted: 28 Jun 2025 at 10:20am

|

Additional info Compression 1 - 4 130, 129, 132, 129 ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 28 Jun 2025 at 10:45am

|

When idling very slow it sounds almost like the key was switched off momentarily, but the voltage to the coil or signal to/from the points never shows any hint of a dropout on a voltmeter. Wish I had an oscope to look closer. Oh boy, a new toy...hard to get my tek 536 on the plane. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 28 Jun 2025 at 8:52pm

I have actually had this happen with poor contacts inside the switch

My Fluke 88 meter will record Min/Max readings and would pick up a momentary disconnect; just watching the meter probably would not be noticeable though. I do have an oscilloscope too  |

Posted By: Steve in NJ

Date Posted: 28 Jun 2025 at 11:45pm

|

Hi Guys! Just getting on here this evening. Haven't been on in a while. Been pretty busy in the shop. Gary, if your still having problems with that Tractor, I can tell ya it ain't the Distributor that's fir' sure! That unit didn't miss a beat on the last run test on the 504. I ironed the couple issues out with that. You have another problem there. Maybe a sticky valve when running. Higher rpms the valve may not stick. Lower rpms it starts to hang up and cause a dead miss. Gotta' be something with the Tractor. Possibly a fuel issue. A lean condition off idle till you get into the enrichment circuit, then it runs better and the miss is gone because it has a fatter mix and runs good under load. It's gotta' be somethin' like that. Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: dfwallis

Date Posted: 29 Jun 2025 at 11:35am

Seems doubtful that it would be valves. It had a complete, professional shop valve job. Compression seems reasonably good. The operating symptoms date back to the 80s or 90s (per my brother). It isn't something new. In the 80s, it had an automotive style toggle switch for ignition. Same symptoms. The key switch is new, the wiring hardness is 100% new. It is burning very rich at all RPMs, but not enough for visible black smoke except under load. It was burning leaner when I had installed the incorrect venturi (smaller diameter) in the carb last month. When I installed the new, correct venturi, it is again blowing black specks of carbon onto the hood. So, about the only thing left in common that hasn't been changed is the carburetor itself. It has been thoroughly cleaned and all jets verified open, but the main jet was not changed because the screw driver slot was severely damaged and I didn't have a super tiny easy out (plus it's at a weird angle and not sure I can get to it). I wanted to keep a TSX 486 carb on it and not switch to a Zenith, but I didn't find a source that I trusted so far. I'll perform a few more ignition checks in July (e.g. direct wiring battery to coil, direct ground wire distributor to chassis, perhaps oscope some signals). The GTC 505 provides oscope features but only for the high voltage signals. Seems like slightly short sighted design. Anyway, I've been wanting to get a small portable oscope for some time (they're pretty cheap now). My Tektronix 516 weighs about 500lbs and is a pain in the butt to move around. I should have done some of that low voltage signal testing this last trip but I wanted to get it out in the field and use it some (the fun stuff) :) The main glitches with that was the PTO shaft guard kept pulling too hard and stretching the chain clips (brand new it was very hard to turn in spots because it was severely warped), and on one occasion, the hydraulics would not go down (perhaps the hold valve stuck). The rest of the trip was spent raising the tree canopy around the yard to make it easier to mow. ~1 acre, 39 acres to go...I lost 6 pounds :) Edit: My Tek Oscope is a 516, not a 536. 516 is 15Mhz, 536 is 11Mhz.

------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 29 Jun 2025 at 1:51pm

Those are excellent compression numbers; this does not eliminate the possibility of sticky valve guides though, or too tight valve lash, thus the recommendation for vacuum gauge testing.

Assuming the correct size of jet(s) then the fuel level in the float bowl must be too high; perhaps the float isn't floating?

A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere A crack somewhere inside the carburetor leaking excess fuel in where it shouldn't? I certainly dunno why, but if it has been blowing black specks onto the hood since the 1980's it must be getting too much fuel from somewhere |

Posted By: dfwallis

Date Posted: 29 Jun 2025 at 7:28pm

We set valve clearance at .012. Doesn't mean it stayed at .012. We had plans to recheck it at some point. Maybe when it cools down a bit in the fall. Needs to be done, regardless. I don't know that it was blowing carbon specks in the 80s. He only said it was misfiring similarly. It did not misfire the last I used it before then, but started at some point and continues to this day, regardless of nearly everything being overhauled to spec to the best of our and the machine shops ability. I checked float level this week. It was as close to 9/32s as I could measure. The float does not leak. It is dry as a bone. I've checked it a dozen times. I inspected the carburetor pretty carefully. I saw no obvious cracks or leaks beside the one I sealed that was leaking fuel from the bowl at a very slow rate (the screw (plug) at the bottom front of the bowl). I've ordered some tiny easy outs to try to fix it correctly. All jets were replaced except the one at the bottom rear of the bowl. There was no screwdriver slot material left to latch on to. But, just because I express doubts about a particular cause, it does not mean that I've ruled ANYTHING out. Until it's resolved, everything is suspect. I've ordered a new portable oscope that should allow me to actually correlate the points signal with the resulting spark of the secondary, Ch1 vs Ch2 (10000x reduction probe).

------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 29 Jun 2025 at 8:30pm

|

New manifold looks like it has a flat that could be drilled/tapped to provide a vacuum gauge attachment point. Don't think I want to do that. Not finding a good attachment option. Edit: I found a pic of an original manifold and it appears to have a pipe plug at that same flat spot. If I were to drill and tap it I'd want to take it off so that I could clamp it to the drill press to drill a nice straight hole. Not ready to do that at this point. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 29 Jun 2025 at 10:08pm

Bummer. A vacuum gauge is a valuable troubleshooting tool. I put a new manifold on my Model C a couple years ago and it had a small pipe plug that we pulled out to run the old Surge milking machine.

|

Posted By: Les Kerf

Date Posted: 29 Jun 2025 at 11:52pm

I just re-read this whole thread to try to cipher out what we have all missed

I found no mention in this thread of re-torquing the head, re-setting the valves, replacing spark plugs, or re-tightening the manifold bolts since the rebuild; you have added a few hours since that post

This one is somewhat puzzling. At what RPM was this noted? At low idle there should be no advance, and at high idle it should be at full advance. I can see it bouncing around at mid-range while it is still partway advanced though. |

Posted By: Steve in NJ

Date Posted: 30 Jun 2025 at 12:49am

|

That wouldn't have Champion Spark Plugs in it would it? I've seen and heard of so many goofy issues with them things. Screw in a real set of plugs like NGK's or Autolites and all the Gremlins go away..... Black carbon specs on the hood? Hmmmm.... Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: jvin248

Date Posted: 30 Jun 2025 at 6:03am

|

. Leaks at the manifold to motor interface can cause fuel to air mixture leaks. My WD ran better after I replaced the factory manifold it came to me with with a new one plus new seals as two exhaust leaked and I think one intake with a slight leak. I bought one of the small harbor freight ultrasonic cleaners and have run at least four antique carbs through it for much improved operation. Split the carb and open sides down. That may be better than the easy out game. Verify the coil you have uses an internal resistor not external block and is the correct coil for the voltage you are set at. External resistor blocks and wiring makes for more connections that can go bad/corrode. Are you getting intermittent shorts in wiring? Are the misses frequent enough you can pull a plug wire and isolate the cylinder it happens to? . |

Posted By: dfwallis

Date Posted: 30 Jun 2025 at 4:26pm

|

Six videos have been uploaded to https://www.youtube.com/@OrangeAcres-h2k" rel="nofollow - https://www.youtube.com/@OrangeAcres-h2k These are under the playlist "misfire analysis". They will go public around midnight 1 July (CST). ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 30 Jun 2025 at 4:33pm

It isn't a single cylinder misfiring. It is all of them at different times. I've searched for intermittent shorts, intermittent opens, gremlins...The new 6V coil has no external resistor. I switched it out and it made no difference. I've switched everything out related to the distributor, wires, plugs, points, rotor (3 different ones), cap (3 different ones), distributor partial rebuild (not the dust cap). No manifold leaks (and brand new). ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 30 Jun 2025 at 4:41pm

Theyre autolite. I know there is a carburetor issue. GTC 505 was showing electrical issues, that's where I started first. I still haven't ruled electrical out. GTC 505 and timing light still show electrical dropouts. You can see them better on the long duration recording than on the single trigger waveform. But they happen at all 4 cylinders, not just one. But the analyzer is easily confused by proximity of other HV wires so I'm not 100% confident in my interpretation. I plan to try to find some high impedance tubing to wrap the wires in to improve it a bit. It says you need 2 inches of clearance, but that's hard to do coming right out of the distributor. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 01 Jul 2025 at 9:39am

|

The videos are now live. I need to search for one more that shows the long duration recording better. I changed one of the settings and never got it back to the same view :( I also found some fire resistant fiberglass braid tubing that should help me better isolate the spark plug wires and eliminate the interference between plug wires. 25KV breakdown voltage. Hopefully it will allow a more accurate view of what's happening. I received my new oscope/dmm/signal generator and ignition probe. It's quite nice for the price. Edit: I only find stills of the long duration recording showing the apparent dropouts, no video.

------------- 1952 CA13092 |

Posted By: steve(ill)

Date Posted: 01 Jul 2025 at 9:50am

|

.The new 6V coil has no external resistor. I switched it out and it made no difference. I've switched everything out related to the distributor, wires, plugs, points, rotor (3 different ones), cap (3 different ones), distributor partial rebuild (not the dust cap). so this is the original 6v system... I guess i assumed you had updated to 12v... Dont see a problem, but im not a fan of the 6v coils.. ------------- Like them all, but love the "B"s. |

Posted By: dfwallis

Date Posted: 01 Jul 2025 at 10:12am

I'm keeping it as original as I can stand. I did add a regulator to the generator. I had to drill one hole in the drawbar to attach my new bail. I bought a new PTO guard off ebay and modified it (original straightened and stored away) to clear the rockshaft mounted top link bracket. I used the second light switch detent to turn on the rear spotlight. Everything else is bolt on additions using existing mounting points. I'm not a fan of 12V conversions. 6V works great if you have good wiring/connections and the engine timed. It draws 195 amps when cranking. Is that about right?

------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 01 Jul 2025 at 12:18pm

|

I've not found many good clean signal views due to wire proximity interference. These two images are the best I could locate. Unfortunately they are before the distributor rebuild: Both cylinder 4. These are both before the distributor rebuild, the signals are now much more consistent, but still show these "apparent" dropouts. All cylinders look similar to each other if you get rid of the proximity interference: RPM (pulse count): Every one of those "wide" pulses seems to correlate with a misfire. These appear on all 4 cylinders. It also correlates with the meter having difficulty reading the correct RPM rate (cause or symptom of the instrumentation??).  Voltage (Again, before the dist rebuild, it's now much more consistently around 6KV): I selected "hold" during a period when it couldn't read the RPM rate.  ------------- 1952 CA13092 |

Posted By: jvin248

Date Posted: 01 Jul 2025 at 7:10pm

|

. If everything but the distributor cap (and likely the rotator), I'd really check that out for carbon buildup or cracks/shorts. My WD had a wrong sized cap when it came to me, and the rotator had spots it hit the pole flanges. Ran a lot better after replacing the pair with correct parts, and uncracked. . |

Posted By: Les Kerf

Date Posted: 01 Jul 2025 at 7:55pm

I'm also thinking there must be something amiss in that area as well. It is the only place that affects the high-tension delivery to all four cylinders. I would start by measuring the length of the rotor to see if there is excessive gap to the terminals, and then I would sacrifice a distributor cap by drilling holes in it to see if the phasing is off (i.e. is the rotor actually pointing at the terminal when it fires). I watched those videos several times and I am not quite ready to run out and buy one of those gadgets just yet

|

Posted By: CA13414

Date Posted: 01 Jul 2025 at 8:02pm

|

This has been a great discussion. Very much appreciate everyone's insights and ideas and has been fun to read, as much as it has been a thorn your the side trying to solve the problem. Dan ------------- Helping the aged survive and thrive! 1953 CA |

Posted By: Les Kerf

Date Posted: 01 Jul 2025 at 8:02pm

That's plenty high but if it gets the job done it's ok; does it seem to drag?

|

Posted By: dfwallis

Date Posted: 01 Jul 2025 at 8:32pm

I tried 3 different distributor caps and 3 different rotors. Two were new and one each of the old (delco branded) ones. The delco rotor has a very long curved section trailing the front edge. From the spark wear, it looks like it has been firing very close to the leading edge where I would expect it to be. I have considered sacrificing one of the caps to instrument it. I also added a thin gasket under the dust cap to get the distributor cap up just a hair higher since the old rubber seal is crunchy and I had to grind it in spots to get the cap to sit perfectly flat. The caliper shows it now spaces 5/16 inch consistently all around but I don't know what it should be. The dust cap does behave as a spacer, but adding the thin gasket made no difference. Yes, it is difficult to tell if the signal dropouts are just because it lost sync or if the signal really went away. There is no trigger level adjustment. However, the timing light appears to miss signals in the same pattern as the GTC505 (when it shows one miss, the timing light shows one miss, two, timing light shows two misses (roughly)). The RPM view with pulse count view shows this correlation best. The long duration voltage recording charts are difficult to interpret without a timescale and knowing where one sequence begins and ends. The instantaneous voltage chart shows the signal missing periodically, but again, it's hard to tell if it's just a sync issue. I'm hoping that the new scope will allow me to trigger on the points signal and more unambiguously show the spark pulse in relation to it. I'm trying to work up the strength to recheck the valves next month. But if it's 100+f again in the barn, it'll be mighty difficult to make myself do it. I spent thousands to have the head professionally rebuilt (among other things). I'll be extremely upset if that turns out to be a problem (other than gap setting, which we did)...:( I'll give the carburetor one last hurrah with the screw extractors and replacing the last jet, but I have doubts that will help...unless someone had bored (gouged) the jet out or something. I guess I could figure out the spec and check the size. I might also try lowering the float even though it shows to be in spec at 9/32 inch. I was going to try some things like that last trip, but it was 100+f and 65% and I was loosing mojo. :( ------------- 1952 CA13092 |

Posted By: DiyDave

Date Posted: 01 Jul 2025 at 8:38pm

This thread reminds me of about 30 some years ago, was working on a turf farm, and they needed a big Ford truck started, sounded to me like it wasn't getting any spark, big gas 4V V8, had a (then) newfangled ignition on it, had a rotor that the business end was made outta a loop of wire, instead of a solid piece, like AC's had. The wire had broken so insteada a loop, there were 2 stubs sticking out, arcing all over the place... Took a copper penny, cut it half and soldered, and melted it into the plastic, and that's the rotor it had, when I stopped working there... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: dfwallis

Date Posted: 02 Jul 2025 at 10:46am

It spins quite fast when the engine is timed right. If not timed right though, it does struggle a bit (engine firing too soon). ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 02 Jul 2025 at 10:47am

Definitely been a thorn in my side :( ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 02 Jul 2025 at 3:47pm

It's a long shot for sure, but there is a slim possibility that there was a manufacturing defect affecting the rotor phasing that has plagued this since time immemorial.

Is it practicable to remove the dust cap as a test to minimize the rotor/terminal gap? Do you know how large that gap actually is?

This is the major flaw I see with this gadget

The high level of noise from the non-resistor wires/plugs seems to give this gadget fits

I am most curious to see what develops, please keep us posted

It's been mid-90's here in northern Idaho and less humidity than your area, and this old hillbilly pretty much shuts down above 80 degrees nowadays  |

Posted By: Straanger

Date Posted: 03 Jul 2025 at 1:48pm

| I’m more of a shade tree mechanic, so I’d be looking for a big shade tree with a cool breeze, and take a tool box with the tractor out there. I’m to lazy for that kind of heat. |

Posted By: dfwallis

Date Posted: 03 Jul 2025 at 3:15pm

I live in Texas. I'm mostly used to heat, but not usually that much humidity. Was more Houstonesque than Dallas. It's regularly > 105 in my TX workshop. I just keep a fan on me, drink water, go inside once in a while. ------------- 1952 CA13092 |

Posted By: dfwallis

Date Posted: 08 Jul 2025 at 6:31pm

|

Brother spoke with the guy that rebuilt the head. He bought a complete valve train kit for it. He checked all valves, seats, and guides and replaced anything that was not to spec. It was rebuilt several times before, so not everything was 72 years old. Does not mean that something wasn't missed, but if there's anything wrong in the valve train, it would most likely be that 0.012 was not maintained. The misfiring symptoms were immediate after the rebuild. It doesn't seem to have changed since then (and of course occurred before the rebuild). He also milled the head, cleaned and polished cam and installed new cam bearings, cleaned the block, ground crankshaft to spec (took several attempts to get the end play acceptable). I went ahead and bought a new knockoff zenith carburetor. That should help me quickly eliminate that as an issue. It didn't come with the adapter for the breather so I'll have to make one if I leave it installed :( That will leave me time to decide whether to follow up with a repair or replacement TSX 486 or attempt to locate a 670, 701, or 815. They all seem to be scarce as hens teeth. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 08 Jul 2025 at 8:28pm

We have all been doing a heap of guessing and spinning our wheels  There is something fundamentally wrong here, so it's time to get back to the basics. There is something fundamentally wrong here, so it's time to get back to the basics.If that were my engine, I would pull the valve cover, re-torque the head, and re-set the valves. Then, I would verify TDC by actually measuring it (not by merely assuming the marks to be correct). Next, with the valve cover still off, bring #1 to TDC on compression. Now observe the valves on #4, which will be at the tail end of the exhaust stroke and the beginning of the intake stroke. Both valves should be open the same amount at this point or at least almighty close to the same amount. If not, then rock the engine back and forth past TDC until they are open the same amount, and then decide if it is off far enough to matter, and why (or why not). Now check #1 the same way with #4 at TDC compression. If both #1 and #4 check good you can probably skip #2 and #3, but I would still put my dial indicator on the rocker arms and check the lift on all eight cam lobes. I have actually found incorrectly assembled engines that refused to behave using the above technique; it is also possible to have incorrectly manufactured components. This may seem like a lot of fiddling, but this is a long-standing problem with with this engine that dates back prior to the overhaul; something is clearly amiss, and none of the usual remedies has cured it. Have fun  |

Posted By: dfwallis

Date Posted: 08 Jul 2025 at 8:35pm

On the list. We did verify TDC matched valve position/state (I/E), piston at top, and rotor pointing in the correct direction. Doesn't hurt to look again. ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 08 Jul 2025 at 9:53pm

|

Posted By: dfwallis

Date Posted: 09 Jul 2025 at 3:56pm

|

The parts manual seems to show two NPT ports on the manifold. It shows 70912725 1/2 NPT at the left/front flat of the intake manifold and it shows 70901651 1/8 NPT at the flat just above the carburetor. I purchased a vacuum gauge. If I decide to modify the manifold, do I need both ports for a complete test? ------------- 1952 CA13092 |

Posted By: Les Kerf

Date Posted: 09 Jul 2025 at 4:22pm

No. A 1/8" NPT port at the flat above the carburetor is perfect. Bigger just means more drilling than necessary (unless you plan to run a milking machine like we do on occasion).

|

Posted By: dfwallis

Date Posted: 15 Jul 2025 at 11:26am

|

The GTC-505 vendor has agreed there could be a trigger level issue and has provided a firmware update that adjusts the algorithm for distributor systems. If the voltage is held high too long (e.g. coil hysteresis), the trigger may not reset properly ready for the next cycle. They are also working on an update to facilitate trigger level adjustment and will provide that update when ready. It isn't clear whether that will allow manual adjustment or whether it's just an update to the automatic internal adjustment process. ------------- 1952 CA13092 |

dfwallis wrote:

dfwallis wrote: