| Author |

Topic Search Topic Search  Topic Options Topic Options

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Ambac 100 pump Topic: Ambac 100 pump

Posted: 10 Nov 2018 at 9:15am |

HagerAC wrote: HagerAC wrote:

7/16 probably works. Its actually an 11 mm. Same size as the bolts for the top cover |

Actually, it is 7/16", those are American Bosch pumps, and all fasteners are standard, most are 1/4" coarse, some 1/4" fine.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

|

Sponsored Links

|

|

|

soggybottomboy

Bronze Level Access

Joined: 20 Feb 2018

Location: Iowa

Points: 197

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2018 at 8:50am Posted: 10 Nov 2018 at 8:50am |

|

If a person had unlimited funding(which i don't),what would be the best pump that a person could install on an 8000 series tractor?

|

|

GM Guy

Orange Level

Joined: 31 Jul 2012

Location: NW KS / S.C. ID

Points: 1973

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Nov 2018 at 10:55pm Posted: 09 Nov 2018 at 10:55pm |

RelianceWorks wrote: RelianceWorks wrote:

we offer a complete kit to switch it to an A pump if you like |

Got a link? Have an L3 with a dying pump.

|

|

Gleaner: the properly engineered and built combine.

If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help.

|

|

Ron(AB)

Orange Level

Joined: 27 Dec 2009

Location: Alberta

Points: 943

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2018 at 12:49pm Posted: 08 Nov 2018 at 12:49pm |

|

Most of us with these tractors just want to know:

1. Is it possible?

2. What is the cost?

3. How great (if any) are the benefits?

4. What is involved? (if we can do it ourselves... being farmer mechanics)

5. Is there any options or alternate choices that may be better/worse?

Hopefully, with all of those facts we can decide how to proceed.

We all love our tractors. Compared to the new ones they still are great!

We just want them to be a bit more responsive and maybe better starting.

|

|

Kevin in WA

Orange Level Access

Joined: 08 Feb 2010

Location: Lynden, WA

Points: 607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2018 at 10:08am Posted: 08 Nov 2018 at 10:08am |

|

I have had an A pump with a Relianceworks adapter running on one of my 8070s for 12 years now, no problem with the mounting. Governor action is far superior to the rattletrap AMBAC M100 pumps.

|

|

RelianceWorks

Bronze Level

Joined: 13 May 2015

Location: Shiocton, Wi

Points: 31

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2018 at 10:02am Posted: 08 Nov 2018 at 10:02am |

No, your completely wrong about friction. Many people have mounted an A pump directly, but they didn't contact me to help them make it work afterwards. If you have it all figured out, then you spend the time and money and figure it out for yourself. Your the one that got upset because I wouldn't help you.

Your statement was the PROPER way to mount is to bolt to the front plate, and that you tried the adapter and didn't like it, and will be converting it back. Your alluding that there is a problem mounting the pump with adapters. Anybody is free to mount a pump anyway they chose but to mount on the front plate you have to take the plate off the tractor and have a machine shop locate and redrill and rebore the holes to make an A pump fit. To get the front plate off any 7/8000 series you have to take the cam out, which means you either have to get lucky enough to hold the lifters in place as you pull the cam, or remove the engine and flip it upside down to pull the cam remove the plate etc. I have met few machine shops that drop everything to locate and remount pumps, so your talking weeks at the quickest. The adapters on 7000 series just unbolt old rosa master pump, bolt on adapter bolt on pump, attatch new lines and your going. On 8000 series you have to remove the front cover and change the idler gear, then the process is the same as a 7000 series. Solid steel adapters, oring grooved so they dont leak, machine fit morris taper for the drive gear, timing pin is in the same spot. We made it as simple as possible. Many engines run adapters right form the factory to mount pumps, the 11000 series engine comes to mind. Our kit allows the tractor to be converted in hours,direct mounting would be weeks waiting for the machine shop, unless your going to go buy another front plate, which is more expense, and machine shops charge by the hour, all the time they burn up trying to locate that pump your paying for. Have a great day my friend

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2018 at 7:20am Posted: 08 Nov 2018 at 7:20am |

|

7/16 probably works. Its actually an 11 mm. Same size as the bolts for the top cover

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19592

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2018 at 7:11am Posted: 08 Nov 2018 at 7:11am |

|

Takes a 7/16" wrench if I remember right.

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 8:44pm Posted: 07 Nov 2018 at 8:44pm |

|

Yes I know how you feel. I had another forum member inform me on it and he actually came to our farm and helped me with mine. We tried to loctite the nut in place that time but it never held. Being its been too wet to do much here the last few days I took the time and tried to loctite it again. Hoping it will hold this time.

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

ACFarmer

Orange Level Access

Joined: 13 Sep 2009

Location: Ohio

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 7:17pm Posted: 07 Nov 2018 at 7:17pm |

|

Thanks. Gives me an idea on where to head with it. The flutter makes it annoying to run. And it is a powershift as well.

|

|

Making A living everyday farming with and working on Allis Equipment

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 6:08pm Posted: 07 Nov 2018 at 6:08pm |

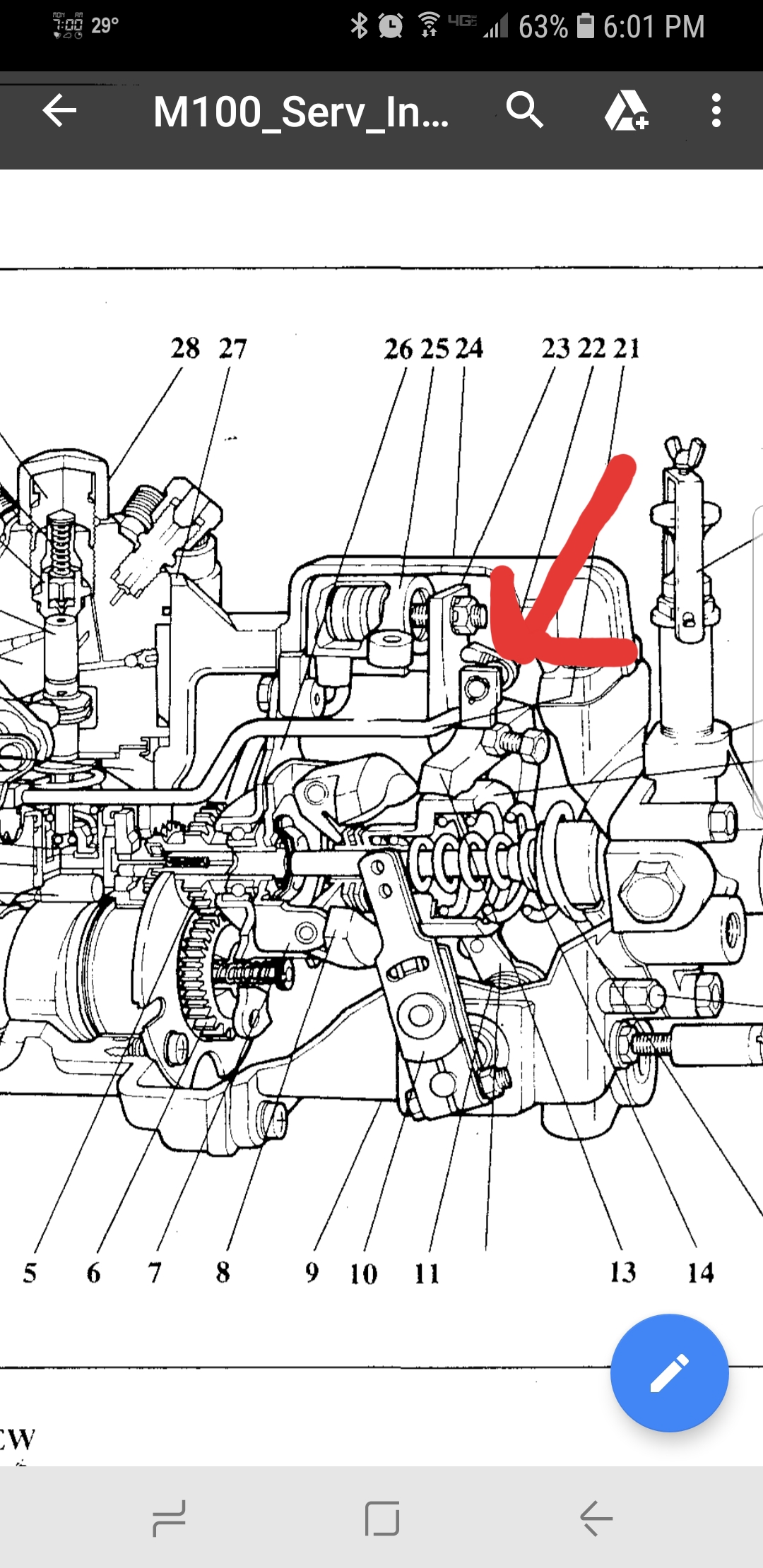

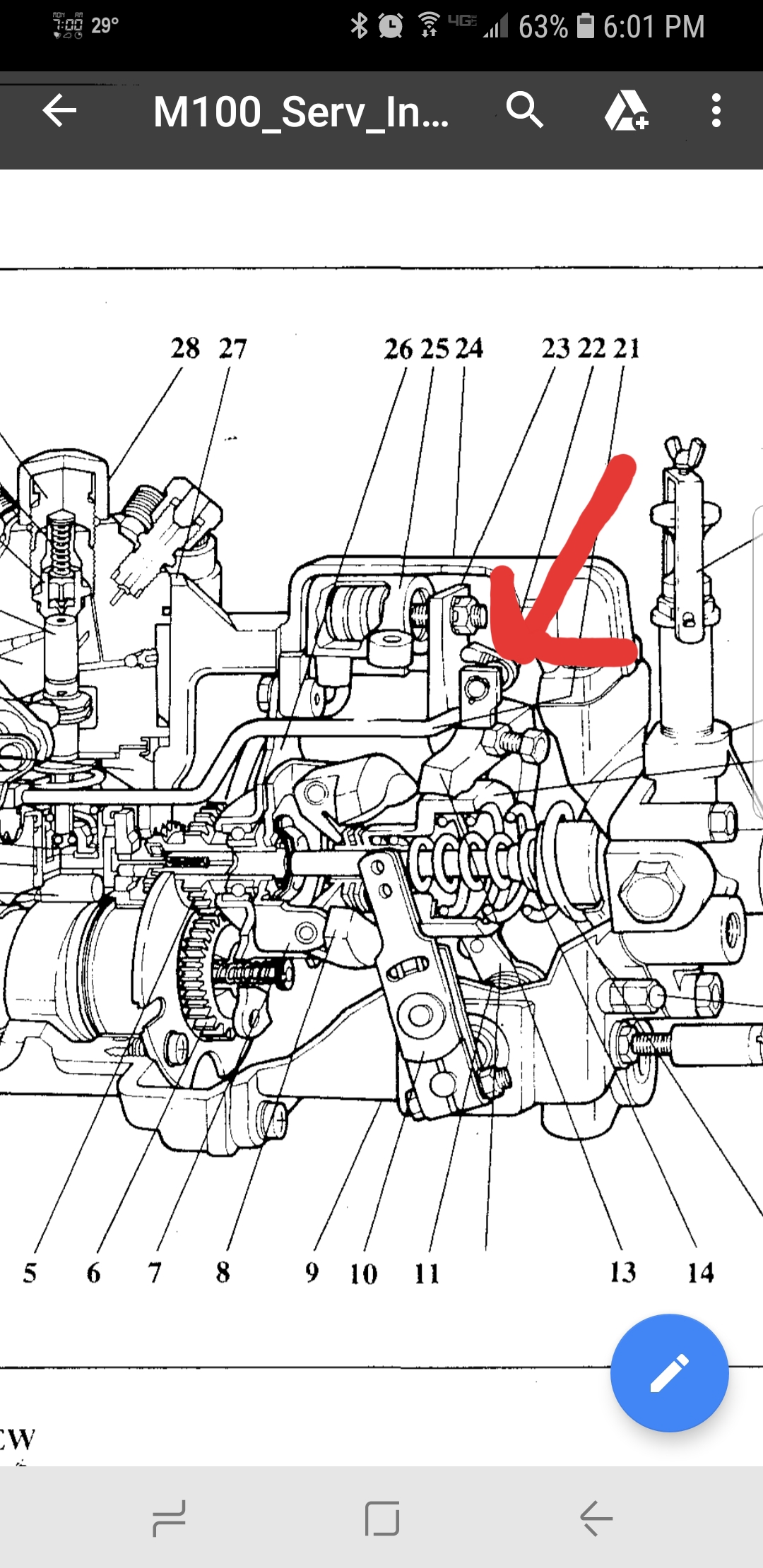

ACFarmer here's a pic of the pump schematic. The nut is located where the arrow is pointing. There is a nut on the opposite side holding a cam looking piece. Don't do anything with that nut, just tighten the one next to the governor arm. Tighten it enough to take care of the flutter but make sure the fulcrum lever still moves freely. If it's too tight it'll really make the governor lazy. This schematic must be from a pump used on an IH because everything is on the opposite side of the ones used on the ac's. I've changed the fuel line on mine but it did not cure the flutter in mine. Hope this helps

Edited by HagerAC - 07 Nov 2018 at 6:12pm

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 5:53pm Posted: 07 Nov 2018 at 5:53pm |

|

If you take the top cover of the pump with the 4 bolts there is the fulcrum lever that attaches to the governor lever. It's kinda hard to explain without a picture but there is a nut next you where the governor arm attaches that is towards the outside of the pump housing. There is a spring between the governor arm and the nut. I've had to tighten this nut periodically to keep the flutter out. From what I've been told there are different governor springs that are down in the pump that are supposed to cure this problem. I guess it is more of a problem in the powershift tractors.

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

Lonn

Orange Level

Joined: 16 Sep 2009

Location: Назарово,Russia

Points: 29773

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 3:26pm Posted: 07 Nov 2018 at 3:26pm |

I detect a little friction

|

|

-- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... -

Wink

I am a Russian Bot

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19592

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 2:31pm Posted: 07 Nov 2018 at 2:31pm |

|

Well, every engineer has reasons for doing something the way they did it. Ease of installation might be one reason. Cost may be another reason. Reliability should be a reason. And a combination of these 3 and more reasons could have something to do with it. You like your way, and that's great. But, it doesn't mean it is thee best and only way to do it.

|

|

Peterson

Orange Level

Joined: 05 Mar 2011

Location: Westboro, Wi

Points: 862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 2:15pm Posted: 07 Nov 2018 at 2:15pm |

Never said that it didn't work, it just isn't the best way to mount the pump. The proper way is to mount it directly on the front plate. Seems to me your still mad at me for having my 8050 engine build posted on here "showing" how to A pump these engines  . Have a great day!

|

|

7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2

|

|

RelianceWorks

Bronze Level

Joined: 13 May 2015

Location: Shiocton, Wi

Points: 31

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 1:59pm Posted: 07 Nov 2018 at 1:59pm |

|

Odd out of the 100+ 8000/7000 series tractors and Gleaner combines running with adapters not one has failed or had a complaint, yet the 1 adapter you bought has been plagued with problems? What exactly is not working PROPERLY on those adapters?

|

|

Peterson

Orange Level

Joined: 05 Mar 2011

Location: Westboro, Wi

Points: 862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 1:05pm Posted: 07 Nov 2018 at 1:05pm |

Had this same trouble with our couple 8000 series. Have you ever replaced the fuel hose that goes from the fuel filter to the head of the pump? Not the hoses on the back of the pump, the one that goes to the front of the pump on the side.

ACFarmer wrote: ACFarmer wrote:

sWhich spring are you guys talking about to help the flutter? Our 8030 has had the pump sent off to fix a flutter issue. Got it back and it was good for 20 hours maybe and its back to doing the same thing. Tractor has good power, starts great, just has a real bad flutter when not under a hard pull. |

|

|

7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2

|

|

ACFarmer

Orange Level Access

Joined: 13 Sep 2009

Location: Ohio

Points: 736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 12:49pm Posted: 07 Nov 2018 at 12:49pm |

|

sWhich spring are you guys talking about to help the flutter? Our 8030 has had the pump sent off to fix a flutter issue. Got it back and it was good for 20 hours maybe and its back to doing the same thing. Tractor has good power, starts great, just has a real bad flutter when not under a hard pull.

|

|

Making A living everyday farming with and working on Allis Equipment

|

|

Peterson

Orange Level

Joined: 05 Mar 2011

Location: Westboro, Wi

Points: 862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Nov 2018 at 8:19am Posted: 07 Nov 2018 at 8:19am |

|

You would think they would, but have a deere pump with them on our 220. When its above 40* it starts great. Below that, it just BELCHES smoke and coughs on fuel. Now the 8050 with the deutz pump, it has no trouble at all. I've tried high timing and low timing. Dont know why the allis's dont like the retarding plungers.

|

|

7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8033

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 8:01pm Posted: 06 Nov 2018 at 8:01pm |

|

I thought the retarding plungers would aid starting? Couldn't tell you whats in mine.Just know it starts on the first turn.

|

|

Peterson

Orange Level

Joined: 05 Mar 2011

Location: Westboro, Wi

Points: 862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 7:52pm Posted: 06 Nov 2018 at 7:52pm |

Tenn allis wrote: Tenn allis wrote:

I have an 8070 it seems really lazy with the throttle response. I also have some a pumps what is involved with the conversion any idea of cost . Can this be done at a reasonable cost |

To do the swap PROPERLY, you need to change out the front engine plate. I have tried the "adapter" from kcgrain. Dont like it at all. I've done both and will be converting the adapter tractor one over soon. And one needs a injection pump without the retarding plungers. Bending injection lines is the next fun part. It's a damn good swap to do, but I'm going to try a roosamaster on our 8030 soon. And putting together a roosa pumped n6 engine for our new 8050.

|

|

7095-685I at 255hp, 8070-225HP,8050-210Hp,8030 with 155HP,220 with 670T engine with A-pump, 7580, 185 with 140HP, 2-6080's,6070, S4 D17,wd45,CA,st34 agco, S1 D17 with 3500MK2

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 7:51pm Posted: 06 Nov 2018 at 7:51pm |

|

Ok. Kinda what I figured. I did look under the cover again tonight and the droop screw is already gone.

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 5:10pm Posted: 06 Nov 2018 at 5:10pm |

|

whole pump

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 4:57pm Posted: 06 Nov 2018 at 4:57pm |

|

Ed, wondering if it would be possible to pull the governor housing of the pump off and send it to you this winter and have you go thru and set it up to the latest specs. Or would you need the whole pump. Was thinking if I could leave pump on tractor and just send governor section to you. Thanks

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8033

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 11:25am Posted: 06 Nov 2018 at 11:25am |

Tenn allis wrote: Tenn allis wrote:

I have an 8070 it seems really lazy with the throttle response. I also have some a pumps what is involved with the conversion any idea of cost . Can this be done at a reasonable cost |

send Reliance PM

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 10:23am Posted: 06 Nov 2018 at 10:23am |

|

The last revision for all the AC tractor M100 pumps called for different governor springs and shimming specs to correct the fluttering issue, without having to tighten the spring so much!

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 9:49am Posted: 06 Nov 2018 at 9:49am |

|

Ok ed, I appreciate the insight. Thanks much

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 8:54am Posted: 06 Nov 2018 at 8:54am |

|

droop screw can be taken out if you want. The latest revision of 8070 spec calls for removal of the droop screw.

Edited by injpumpEd - 06 Nov 2018 at 8:55am

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

HagerAC

Orange Level

Joined: 14 Sep 2010

Location: SE MN

Points: 1184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 7:36am Posted: 06 Nov 2018 at 7:36am |

|

I understand that ed, that's why I'm real cautious and only tighten it enough to take the flutter out. Would I be ok if I backed to droop screw out a few turns?

|

|

30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4786

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2018 at 7:34am Posted: 06 Nov 2018 at 7:34am |

|

part of the lazy governor response problem on M100 pumps comes from having to tighten the friction spring on the governor rod to keep the flutter out.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

HagerAC wrote:

HagerAC wrote:

. Have a great day!

. Have a great day!