| Author |

Topic Search Topic Search  Topic Options Topic Options

|

brkfldj

Bronze Level

Joined: 13 May 2010

Location: Sharpsburg, MD

Points: 168

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Welding question Topic: Welding question

Posted: 20 May 2023 at 9:03pm |

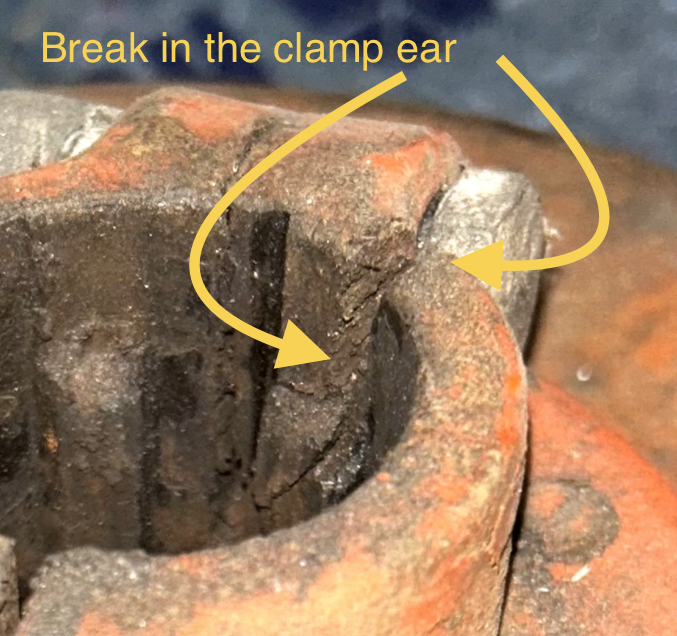

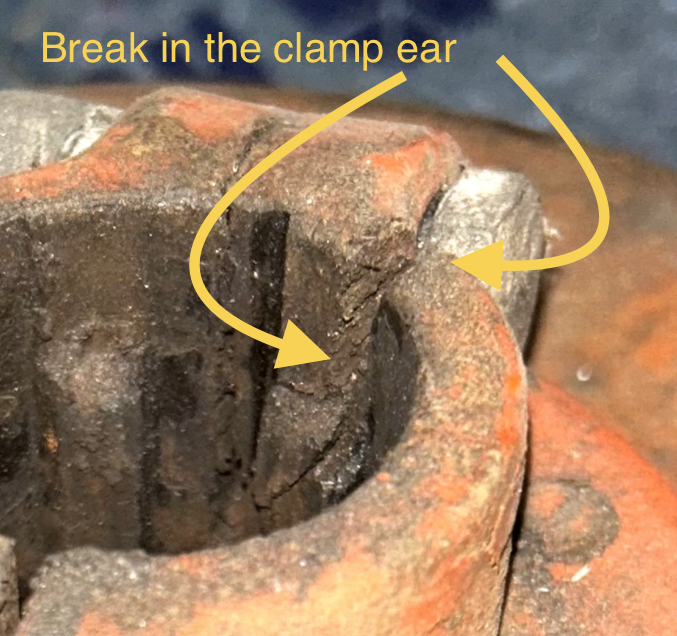

I bought my CA with a belly mount sickle bar mower installed. After successfully testing the mower for maybe 15 minutes, I removed the drive pulley so the tractor could be used with my pull behind brush hog. The drive pulley was held in place on the pto shaft with bolts though clamp ears. One of the ears is broken. I am not a welder. Can the ear be welded back in place?

|

|

Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin

|

|

|

Sponsored Links

|

|

|

Tbone95

Orange Level Access

Joined: 31 Aug 2012

Location: Michigan

Points: 12256

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2023 at 9:09pm Posted: 20 May 2023 at 9:09pm |

|

Looks like cast iron. If you’re not a welder, cast isn’t the easiest way to start, but yes it came be done. How about a flame, are you any good with that? Brazing it might work?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88672

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2023 at 9:17pm Posted: 20 May 2023 at 9:17pm |

as Tbone said, there are a couple ways to weld it...

another option.... the SPLINES do all the work. All the bolt does is stop the pulley from moving in or out.. Not a lot of load on it.. Maybe a steel strap an inch wide and 4 inches long with a 1/2 inch hole in each end... lay the plate under the head of the bolts, then tighten and PINCH the clamp into place.... it dont do much..

|

|

Like them all, but love the "B"s.

|

|

brkfldj

Bronze Level

Joined: 13 May 2010

Location: Sharpsburg, MD

Points: 168

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2023 at 9:19pm Posted: 20 May 2023 at 9:19pm |

|

Tbone95, my very limited welding experience was in the 70’s. I don’t have welding or brazing equipment. But your basic answer is that the ear can be reattached. I’ll seek a shop that can do the job.

Thanks.

Jim

|

|

Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2023 at 6:06am Posted: 21 May 2023 at 6:06am |

|

Surplus Center ( not afiliated) sells steel couplers with 1 3/8 x 6 splines would be a simple machine shop job to shorten up and turn a locating step then make a new flange with 4 bolt holes and weld the two together. Also they sell snap hitch pump adapters with spring loaded retention pin would work but they may be made from cast, The firs choice would need some way to keep it on the shaft, does your CA have a small hole thru pto shaft ?

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3956

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2023 at 9:47am Posted: 21 May 2023 at 9:47am |

|

i just looked at my pulley, mine lookes more like cast iron than cast steel. without doing a spark test , you can try some 7018 , one small bead you know before you weld a 1/4 inch other wise i would pick brass over nickle that will be atough piece to beval and weld with out re machining , maybe you can put all most all of your beval on te broken ear the goal is 100 % penetration put the part in your barbque grill when everthing is fitted up and start getting it heated up you may need help with the torch weld it up with the grill going when done leave grill on for a while then let cool in grill for the rest of the day

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3956

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2023 at 9:50am Posted: 21 May 2023 at 9:50am |

|

it lookes tlike the first half inch f those splines are gone it may be better off looking for anouther one

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2023 at 12:51pm Posted: 21 May 2023 at 12:51pm |

|

I've been in contact with Jim to sell him a NOS one

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

brkfldj

Bronze Level

Joined: 13 May 2010

Location: Sharpsburg, MD

Points: 168

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2023 at 2:43pm Posted: 21 May 2023 at 2:43pm |

|

Thank you, Paul. I now have the “new” hub. My intention is to get the pulley back on the tractor, make a video of the mower in operation and then post the mower for sale in the classifieds.

Thanks for the repair suggestions. The NOS hub sure beats me trying to locate someone able and willing to take on the hub weld repair.

Jim

|

|

Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)