| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Topic: WD and WD45 Electronic Power steering conversion Topic: WD and WD45 Electronic Power steering conversion

Posted: 16 Mar 2022 at 10:51am |

Hello All,

I thought it would be easiest to start a new thread on my electronic power steering conversion for the WD and WD45 Tractors. I am currently restoring my 1953 WD in this thread:

the thought was to keep this separated for future use and general info for the modification.

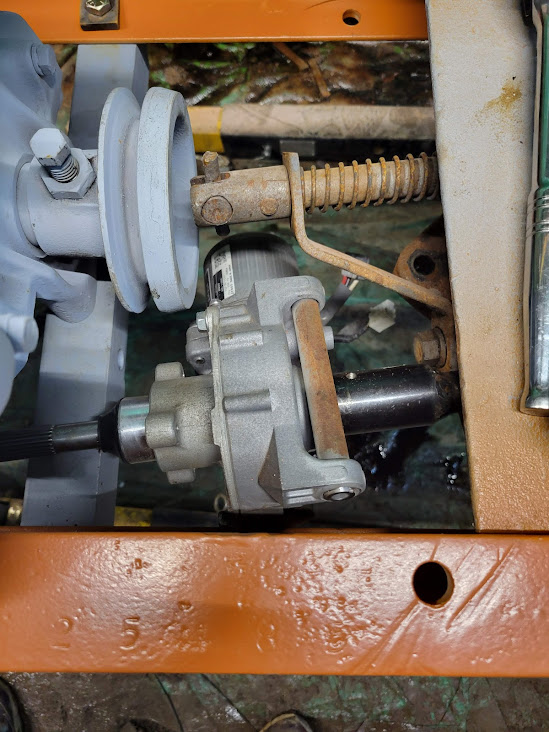

The unit I will be using is as shown below. this one is particularly from a 2005 Chevrolet Equinox. this is not an electronic unit that makes a certain amount of turns before locking but rather a 12V torque generator that assists a worm gear internal to the unit once the torque sensors see shaft movement. it has unlimited turns left and right. perfect for these types of projects.

This is the EPS Journey. Stay tuned for updates.

Edited by Jtaylor - 20 Apr 2022 at 6:58am

|

|

|

Sponsored Links

|

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2022 at 10:52am Posted: 16 Mar 2022 at 10:52am |

The trouble spots to overcome to fit into these tractors:

- splines on EPS is 16.5MM - 36 spline. (larger than 5/8" but smaller than 3/4")

- steering shaft is 7/8" in diameter from the steering wheel to u-joint and 1" after that.

- it draws A LOT of power. 12V 60A

- it fits in the frame below the front crank pulley (gas models) but needs custom brackets to work. = fabrication required.

I have purchased the following components:

5/8" coupler ( one needed, I bought 2 for trials) 3/4" keyed steering u-joint Go Kart Axle - Steps down from 1" to 7/8" to 3/4" keyed. tie rod boot for water seal on input to unit. 50A circuit breaker 10AWG wire (enough to go back to the battery box) Bruno Steering EPS controller (to trick the ECU into providing feedback)

You will also need 3/16" (roughly 6"x6") plate steel and 2x2 or 1x1 angle iron (1 ft) to complete the fabrication.

Since i am changing U-joint sizes, I had to adapt the steering shaft to 3/4" which involved shortening the original shaft by about 5.625" to fit this adapter. I Used the Go-Kart axle for this, Cut the threads off the end and cut the correct length off the shaft. Next will be to weld it to the steering shaft for a perfect fit length wise, and a nice tapered step down to 3/4" for the new u-joint.

Edited by Jtaylor - 20 Apr 2022 at 7:02am

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2022 at 10:52am Posted: 16 Mar 2022 at 10:52am |

|

Saved for future posts

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2022 at 10:54am Posted: 16 Mar 2022 at 10:54am |

|

#3 Saved for future posts

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2022 at 11:45am Posted: 16 Mar 2022 at 11:45am |

|

Seems like the way to go, I have seen a unit like that installed on a tractor over on the Red Power site.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2022 at 6:44am Posted: 19 Mar 2022 at 6:44am |

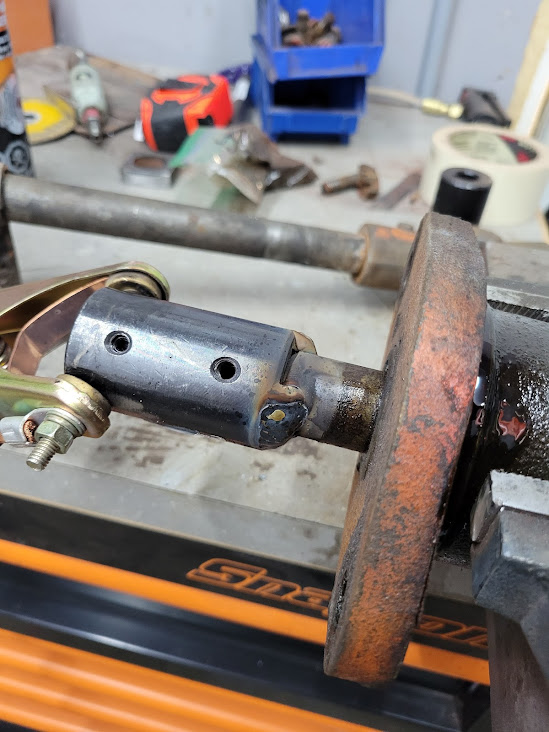

I was able to get the keyed shaft welded to the new steering shaft. cleaned the welds up and test fit the u-joint.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13729

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2022 at 8:38am Posted: 19 Mar 2022 at 8:38am |

Hey JTaylor,,,this sounds like a great project that many will look into,,,,including ME,!!! I been dreading having to dismante the PS system on my D14 to repair it,,,IF the parts can even be found,,! I'll be following your project, so, keep the info and pics coming,,,,

Hey B26240 ,,what is the address of the "red Power" tractor site you refer to,,? TIA.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2022 at 8:45am Posted: 19 Mar 2022 at 8:45am |

Great site! Similar expertise as here for all things Red.

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2022 at 4:00pm Posted: 19 Mar 2022 at 4:00pm |

|

Joe The article was in the Red Power bi-monthly magazine, There is articles by the "Tractor Doctor" there version of our Dr. Allis. He installed it on if I remember correctly a Farmall A or 100 with a mower deck that his wife cuts grass with. Article included pictures, he mounted unit about where the PS unit mounts on a WD45. Mark

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2022 at 8:22pm Posted: 19 Mar 2022 at 8:22pm |

B26240 wrote: B26240 wrote:

Joe The article was in the Red Power bi-monthly magazine, There is articles by the "Tractor Doctor" there version of our Dr. Allis. He installed it on if I remember correctly a Farmall A or 100 with a mower deck that his wife cuts grass with. Article included pictures, he mounted unit about where the PS unit mounts on a WD45. Mark |

I remember that article, it was awhile back. Probably more than a year? "Tractor Doctor" is my favorite part of the magazine!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 6:24am Posted: 23 Mar 2022 at 6:24am |

I removed the original steering shaft from the front bolster. I previously marked the shaft in a rough spot to cut. double measured and cut the original steering shaft to make fit! no turning back now..

I ended up with 1 3/16" shaft protruding from the bolster bolt plate.

I took my coupler adapter and welded it onto the stub shaft. I have yet to find a smaller coupler to allow the bolster plate to be removed once this shaft is welded. so, in that case (and so it was in my case) replace the bearings on the worm gear or make sure they are good prior to welding this on.

Once welded into place, I was able to grease the bearings and reinstall the worm gear into the bolster. the worm gear is much easier to fit in once its 2 feet shorter!

I slid the power steering unit onto the coupler for a test fit. It fit rather well with some minor adjustments. It has roughly 1/4-3/8" between itself and the front crank pulley.

I used a rubber tie rod boot (part number from DJS Tractor) to keep water away from the torque sensors on the unit.

Here is the unit placement in the frame rails. More space then you think but at the same time less space than you think!

Steering shaft comes through the original area under the engine. tight space but no different than the original. I do still have an extension I need to make to mate to the u-joint that will be 3.25" long and made out of the remaining stepped portion of the go kart shaft.

Edited by Jtaylor - 20 Apr 2022 at 7:04am

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5055

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 6:38am Posted: 23 Mar 2022 at 6:38am |

Very interested.

I assume the unit was from a scrapped Saturn that you had access to. Are there any other vehicles (that you know of) that have a similar setup for parts?

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 6:45am Posted: 23 Mar 2022 at 6:45am |

WF owner wrote: WF owner wrote:

Very interested.

I assume the unit was from a scrapped Saturn that you had access to. Are there any other vehicles (that you know of) that have a similar setup for parts? |

My specific unit came from a 2007 chevrolet equinox. but, saturn vue and ion do work as long as it is a metal (grey) box for the ECU. if it is the black box, it will not work with any controller correctly due to a computer issue inside the unit.

There is a few other units that do the same purpose (toyota prius, nissan cube, kia soul etc) but none that were as tightly compacted as this setup.

I picked my power steering motor and ECU up for the tune of $60 at the local auto wreckers.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 8:31am Posted: 23 Mar 2022 at 8:31am |

|

Very nice! $60 for the unit is great. Know you have $$ in other things but should be cheap power steering!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 9:21am Posted: 23 Mar 2022 at 9:21am |

IBWD MIke wrote: IBWD MIke wrote:

Very nice! $60 for the unit is great. Know you have $$ in other things but should be cheap power steering!

|

Honestly,

I think i currently have about $175 into the conversion as it sits. Including the odds and ends that i thought i would need that i never used. i should be right around the $250 mark when completed.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13729

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 9:28am Posted: 23 Mar 2022 at 9:28am |

Well,, a lot more and more of us Have to go this route due to these very rare parts no longer available and if you do find the parts,,they are super expensive!! Most owners would like to keep their tractors original,,AND their cars, trks,,just bout everything any more and eventually we all wind up like ole JTaylor and look for other ways to get our work done. Great job, JTaylor,,,keep up the great work and keep them pics coming,,,,

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88584

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 9:29am Posted: 23 Mar 2022 at 9:29am |

Justin, can you break it down into several steps of "what is happening".... Start with "turn the steering wheel" .... "the sensor sees movement"... etc ??

engine speed, ground speed, wheel effort have no input to "the box"..?

Edited by steve(ill) - 23 Mar 2022 at 9:32am

|

|

Like them all, but love the "B"s.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13729

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 9:31am Posted: 23 Mar 2022 at 9:31am |

Hey JTaylor,,did you consider getting the worm gear shaft and the coupler machined for a keyway,,thereby making it removable for later repairs,.,?? Just thinking,,,,,,,

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 12:04pm Posted: 23 Mar 2022 at 12:04pm |

steve(ill) wrote: steve(ill) wrote:

Justin, can you break it down into several steps of "what is happening".... Start with "turn the steering wheel" .... "the sensor sees movement"... etc ??

engine speed, ground speed, wheel effort have no input to "the box"..? |

I will definitely be breaking it down once i figure it all out for myself!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 12:09pm Posted: 23 Mar 2022 at 12:09pm |

desertjoe wrote: desertjoe wrote:

Hey JTaylor,,did you consider getting the worm gear shaft and the coupler machined for a keyway,,thereby making it removable for later repairs,.,?? Just thinking,,,,,,,

|

I did have this thought, And There could be some improvements in other versions. with the proper access to a good machine shop would yield a better, removable coupler on the steering box side. I verified all my bearings were good and did not think we would run into any issues over the next 50 years so i was not overly concerned for my tractor. I would think someone who had the perfect resources and could spend a few bucks could make it happen.. although i wanted to keep within a certain budget and the local machine shop wanted $310 for the custom coupler and keyed shaft. that was my reasoning for the way i did it..

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13729

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2022 at 7:14pm Posted: 23 Mar 2022 at 7:14pm |

WHOA,,,$310,,,!!! OK, I see your point now and prolly what I would of done myself,,,,  you know ole Shameless don't call me cheep for nuttin,,,,,,

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 6:22am Posted: 24 Mar 2022 at 6:22am |

I was able to get the steering shaft extended last night by the 3.25" it needed.

here is the 3/4" section of go kart shaft i cut out to fit.

Welded onto the original shaft without cutting

Total length of the shaft now is as followed:

I put the assembly into the frame once again to double check. it looks like it lines up perfect! I will very likely be re-using the original shaft support as well with a 1" to 3.4" bushing.

Edited by Jtaylor - 24 Mar 2022 at 8:19am

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3074

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 8:13am Posted: 24 Mar 2022 at 8:13am |

|

That looks like a neat way to get power steering without all the pulleys and oil. It'll be fin to see how it works in the end

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13729

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 9:19am Posted: 24 Mar 2022 at 9:19am |

Looking Good, Justin,,Looking good,,!! Beautiful weld too,,,,,mig or tig,,?

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 10:03am Posted: 24 Mar 2022 at 10:03am |

desertjoe wrote: desertjoe wrote:

Looking Good, Justin,,Looking good,,!! Beautiful weld too,,,,,mig or tig,,?

|

thanks! That shaft was MIG welded.

|

|

Stan R

Orange Level Access

Joined: 03 Dec 2009

Location: MA

Points: 994

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 10:59am Posted: 24 Mar 2022 at 10:59am |

|

12V/ 60A: is that true? If so, what are your plans for that load? Or is that load peak and normal load is a lot less?

Thanks

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2022 at 2:00pm Posted: 24 Mar 2022 at 2:00pm |

Stan R wrote: Stan R wrote:

12V/ 60A: is that true? If so, what are your plans for that load? Or is that load peak and normal load is a lot less?

Thanks |

That load is peak, it is roughly 30-40 amps while assisting, less if idling. your standard GM one wire alternator will handle this load just fine. You could also convert a ford 3G to one wire and get just over 120amps.

this is the info pulled from some EPS enthusiests sites;

"The EPS motor is a 12 volt brushed DC reversible motor with a 65 amp rating"

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2022 at 6:42am Posted: 25 Mar 2022 at 6:42am |

Installed the steering u-joint as a test fit. Fits very well! I still have a couple lock screws to make for the correct clearance in the u-joint. working on the mounting bracket next. this should be pretty straight forward.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2022 at 7:38am Posted: 25 Mar 2022 at 7:38am |

|

My engineering question would be......how many ft lbs of torque is this device capable of ?? The front wheels on a small car surely would be lighter than front wheels on a farm tractor, right ??

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2022 at 8:30am Posted: 25 Mar 2022 at 8:30am |

DrAllis wrote: DrAllis wrote:

My engineering question would be......how many ft lbs of torque is this device capable of ?? The front wheels on a small car surely would be lighter than front wheels on a farm tractor, right ?? |

From all the sources i have read, 80 ft lbs is the norm... the saturn vue weighs in at 4894 lbs gross weight. with 60% of the weight being at the front of the car, you have 2936lbs roughly over the front wheels that the EPS needs to overcome.

the WD45 weight varies but consider 4000lbs as a rough number. exclude rear wheel weight and maybe 40% of overall tractor weight on the rear tires? you would have a front axle weight of roughly 2400lbs. about 500 lbs less than the saturn car.

I would think we would be okay from a simple math standpoint.. only time will tell!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(1)

Thanks(1)

B26240 wrote:

B26240 wrote: