| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dave H

Orange Level

Joined: 11 Sep 2009

Location: Central IL

Points: 3583

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: V Belt pulley for my hand crank meat grinder? Topic: V Belt pulley for my hand crank meat grinder?

Posted: 28 Jan 2025 at 3:23pm |

My meat grinder is a Universal #333. Has made in America on the side of it. I been searching for a V belt pulley around 10 to 12 inches in diameter that would fit on the auger instead of the crank. Any experience or leads to a source for this model? thanx

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87651

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2025 at 3:35pm Posted: 28 Jan 2025 at 3:35pm |

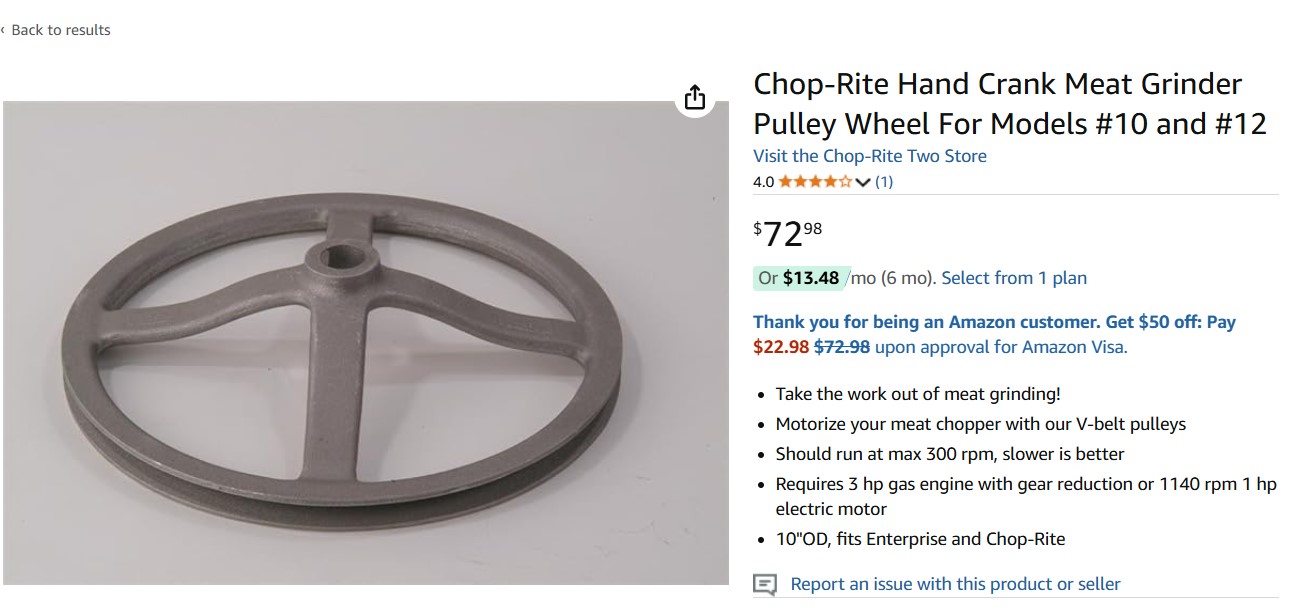

i am wondering if something like this might fit ? would have to know the shaft / bore size... might be worth calling them........... i suppose you could buy a generic pulley... but adapting to the shaft / machining the hole would be the big problem.

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24658

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2025 at 3:55pm Posted: 28 Jan 2025 at 3:55pm |

LOVE this disclaimer.... Designed for Chop-rite Brand but will fit other

grinders.*Potentially dangerous when added to Meat grinders. Can cause amputation,

possibly death!*

hay I was curious... 1st I'd buy 2 ,3 spare #333 units !!, seen some for $15 !

Use one of those cranks, and modify for a pulley, though I'd look into using a 'lovejoy' coupling and THEN the pulley reduction system. Big deal is to decide what RPM the crank needs to spin at THEN work backwards on the drivetrain.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Dave H

Orange Level

Joined: 11 Sep 2009

Location: Central IL

Points: 3583

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2025 at 4:04pm Posted: 28 Jan 2025 at 4:04pm |

|

I think Steve might have the answer. With some more checking I will probably order one foe the #10/12. My searching indicates the ideal grinder auger speed is 300. Am gonna install a jack shaft to help with the rpm.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24658

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2025 at 5:09pm Posted: 28 Jan 2025 at 5:09pm |

|

Using a 1725 RPM motor with a 1 3/4" pulley gets you 300 RPM !

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Thad in AR.

Orange Level Access

Joined: 12 Sep 2009

Location: Arkansas

Points: 9653

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jan 2025 at 11:49am Posted: 29 Jan 2025 at 11:49am |

|

I made one once. It had a triangle shaft where the crank handle hooked to it.

I cut the triangle part off the handle and turned it down to fit one of those weld in pulley hubs.

I never got the rpm quite right.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1264

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jan 2025 at 4:13pm Posted: 29 Jan 2025 at 4:13pm |

Dave H wrote: Dave H wrote:

I think Steve might have the answer. With some more checking I will probably order one foe the #10/12. My searching indicates the ideal grinder auger speed is 300. Am gonna install a jack shaft to help with the rpm.

|

I spent many, many hours on a hand-cranked meat grinder back in my youth. My Dad wasn't one to waste money on such frivolities as electric powered grinders when he had seven children to keep out of mischief.

Even at the peak of my manhood I never came even remotely close to 300 rpm though

I now own a Cabella's 1.5 HP grinder and love it!  |

|

Dave H

Orange Level

Joined: 11 Sep 2009

Location: Central IL

Points: 3583

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 29 Jan 2025 at 6:05pm Posted: 29 Jan 2025 at 6:05pm |

Les, when I was a youngster the grown ups mounted that grinder to a 2X6 and set that on two 5 gal buckets. They jacked one wheel of the family car off the ground and tied the handle to the wheel. It ran at idle in low gear. My job was to set in the car and push the clutch in if someone yelled. That ole flat head Plymouth could grind some meat at butchering time.  One grown up sat on each end of the 2X6 of course.

Edited by Dave H - 29 Jan 2025 at 6:07pm

|

|

FloydKS

Orange Level

Joined: 12 Sep 2009

Location: S E Kansas

Points: 8384

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 29 Jan 2025 at 6:32pm Posted: 29 Jan 2025 at 6:32pm |

|

Memories... ...yes we too had a grinder in the middle of a board, been to long to remember the size though... did a lot of meat through that grinder and it was all powered by arm-strong, course there were five of us guys and 3 younger sisters- - they did not turn much, if any. if I am remembering correctly we also ground the cranberries for the Thanksgiving salad... The "triple action" ice cream freezer was also powered by armstrong to get it good and solid. supposedly it was better that way. Yes, lots of memories...

|

|

Holding a grudge is like taking poison and expecting the other person to die

|

|

Lars(wi)

Orange Level Access

Joined: 14 Sep 2009

Location: Permian Basin

Points: 8037

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2025 at 11:07am Posted: 30 Jan 2025 at 11:07am |

|

Went to close-out/relocation sale for Wall Street Antiques, in Midland Texas a couple months ago. That weekend every item was $1.00, in the outside area there must have at least 200 hand crank meat and coffee grinders that obviously had been outside for decades.

|

|

I tried to follow the science, but it was not there. I then followed the money, and that’s where I found the science.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87651

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Jan 2025 at 1:26pm Posted: 30 Jan 2025 at 1:26pm |

I was a youngster the grown ups mounted that grinder to a 2X6 and set that on two 5 gal buckets. They jacked one wheel of the family car off the ground and tied the handle to the wheel. It ran at idle in low gear. My job was to set in the car and push the clutch in if someone yelled. That ole flat head Plymouth could grind some meat at butchering time.  One grown up sat on each end of the 2X6 of course. One grown up sat on each end of the 2X6 of course.

That should show up in the OSHA BOOK on "how to grind meat !!

|

|

Like them all, but love the "B"s.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54068

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2025 at 6:19pm Posted: 30 Jan 2025 at 6:19pm |

|

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2025 at 10:07pm Posted: 02 Feb 2025 at 10:07pm |

Well... about, six months ago, I bought an AC servo motor for my big Singer 111w155 industrial sewing machine... it had the common heavyweight continuous-speed clutched motor drive, I decided to take a leap of faith and swap it with these inexpensive kits, and it actually worked really well... so I bought two more for my two Necchi machines... then I bought one to replace the constant speed drive on my brake disc/drum turning lathe, and I picked up yet-another for a combination metal-munching profile cutting machine I'm building.

It would probably work really well on an auger-type food grinder.... with programmable minimum and maximum speed, it certainly won't be hard to match.

Do a search, they're on Slamazan for around eighty smacks... in sizes of 400, 600, and 1000w or so... (750w is around 1hp)... they're physically very compact.

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Dave H

Orange Level

Joined: 11 Sep 2009

Location: Central IL

Points: 3583

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2025 at 11:11am Posted: 05 Feb 2025 at 11:11am |

well Steve gets the gold star.  I ordered the one that he posted from amazon and it fit like a glove. Just goes to show you that a blind squirrel can always find an acorn,

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87651

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2025 at 3:46pm Posted: 05 Feb 2025 at 3:46pm |

so your "old American" unit was purchased and COPIED by China and now EVERY unit made uses the same part ??? NICE !

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Dave H wrote:

Dave H wrote:

One grown up sat on each end of the 2X6 of course.

One grown up sat on each end of the 2X6 of course.