| Author |

Topic Search Topic Search  Topic Options Topic Options

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Topic: D19 energy cell replacement Topic: D19 energy cell replacement

Posted: 11 May 2024 at 9:47pm |

|

About a month ago I asked about energy cell repair as I have a neighbor that had recently purchased a D19 diesel. As he looked over the tractor before the purchase he thought it was just a manifold leak. The previous owner had completed a restoration of the tractor including a out frame engine rebuild. The tractor has about 9 hours on it since the rebuild. It was obvious that he had been fighting several energy cell leaks after I removed the intake and exhaust manifolds. Attempts to stop the leaks included a copper crush washer under 2 of the 3 energy cell caps. Anyway, there is no information on the internet for this repair. After some discussion on the forum, I want to thank AC-Mike for some advice he gave me as well as some pictures of the tool he made to lap the cap. In the end I made a change to the lapping tool to match the new caps I ordered. I want to emphasize that this was a totally new experience for me, I may have not done everything correctly or as others have done but the end result was a good running tractor with no energy cell or manifold leaks. The tractor now has a few hours on it and all is well so my neighbor is happy as well as I. The purpose of the video is to show everyone what a energy cell and cap are, how to remove them, how to install them, the lapping procedure, and just to see what I did to solve his issue. Unfortunately, we began to get a hard rain during the video so the noise in the background is the rain hitting our tin roof on the farm shop. I’ve never made a video before and was quite nervous. I also cleaned up all the original air cleaner parts and painted them PO#2. The previous owner had installed a aftermarket air cleaner. I want thank my brother Charlie for shooting the video. Also need to thank AC-Mutt and brother Jim for helping me get the manifolds and original air filter system back on the tractor. Much easier to do with a extra set of hands.

Edited by AC720Man - 12 May 2024 at 9:07pm

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

|

Sponsored Links

|

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(2) Thanks(2)

Quote Quote  Reply Reply

Posted: 11 May 2024 at 9:47pm Posted: 11 May 2024 at 9:47pm |

|

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3952

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2024 at 10:30am Posted: 12 May 2024 at 10:30am |

|

good how to video , my question is if the energy cellwas cracked or had a hole insidebut did not leak outside where would combustion gasses go to cooling system or crankcase or back to the cylinder ?

|

|

Straanger

Bronze Level

Joined: 10 Dec 2019

Location: Michigan

Points: 62

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2024 at 11:17am Posted: 12 May 2024 at 11:17am |

|

Good video and well explained

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2024 at 3:15pm Posted: 12 May 2024 at 3:15pm |

|

There would be no where for it to go. The head area where the energy cell is, is solid casting.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 May 2024 at 9:17pm Posted: 12 May 2024 at 9:17pm |

|

So I guess I should have said combustion chamber.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

ac-mike

Silver Level

Joined: 14 Sep 2009

Location: Kentucky

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 7:50am Posted: 13 May 2024 at 7:50am |

|

You did a great job.

|

|

D-12III, 200D, 170G, HD-3, D19D 3pt, D17D High Crop, WD45G p/s, D15IID, D15IIG, D15G IND, 655, (3)WD45D p/s, 700, 816

|

|

KP4620

Bronze Level

Joined: 06 Apr 2020

Location: Greensburg, IN

Points: 92

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 8:38am Posted: 13 May 2024 at 8:38am |

|

Very interesting and very informative. Please excuse my ignorance, what is the purpose of the energy cell?

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 9:01am Posted: 13 May 2024 at 9:01am |

|

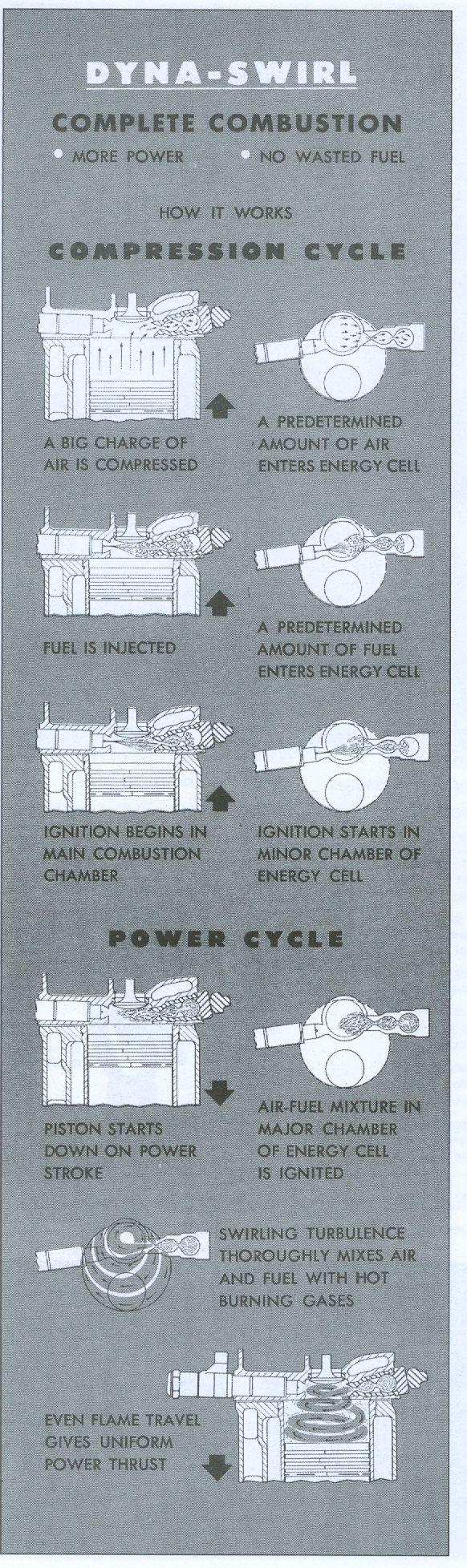

Thanks Mike, that means a lot coming from you sir. I really appreciate your advice. Correct me if I’m wrong Mike, but it is a indirect injection system. Fuel is shot through a head passage from the injector on the opposite side of the head. The fuel enters the energy cell and is repelled by the concave in the cap, pre ignited and then sucked into the combustion chamber to combust. My understanding was a cleaner burn of the fuel and was more efficient. It must work well because my D17 is very fuel efficient.

Edited by AC720Man - 13 May 2024 at 9:53am

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

ac-mike

Silver Level

Joined: 14 Sep 2009

Location: Kentucky

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 11:51am Posted: 13 May 2024 at 11:51am |

|

I have heard some descriptions of the process, they all come down to giving the engine a more even and complete combustion. I am trying to remember what it was named, but not right now.

|

|

D-12III, 200D, 170G, HD-3, D19D 3pt, D17D High Crop, WD45G p/s, D15IID, D15IIG, D15G IND, 655, (3)WD45D p/s, 700, 816

|

|

RedHeeler79

Silver Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 204

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 12:05pm Posted: 13 May 2024 at 12:05pm |

|

Lanova cylinder head design

|

|

ac45dave

Orange Level Access

Joined: 23 May 2015

Location: SE(IN)

Points: 1346

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 13 May 2024 at 8:45pm Posted: 13 May 2024 at 8:45pm |

|

|

|

54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12027

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2024 at 10:02am Posted: 14 May 2024 at 10:02am |

I'm wit' Mike! Ya did a great job Rob!! That's a great video man. Charlie did a great job with the Camera too!! Hey, you guys should do more vids. You're good at it.

Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2024 at 7:02pm Posted: 14 May 2024 at 7:02pm |

|

Thanks Steve, it’s nerve racking making one. So worried I was gonna leave something out which I did. I meant to say torque the retainer nuts evenly at 17 ft lbs. Also forgot to video the owner leaving our shop on his nice D19 and driving home. Engine had a real nice sound through the chrome straight pipe, you could hear the turbo spool up as he went up the hill. Oh well, main thing is that it’s fixed. It was a interesting project. Appreciate the compliment.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(1)

Thanks(1)

KP4620 wrote:

KP4620 wrote: