| Author |

Topic Search Topic Search  Topic Options Topic Options

|

ac fleet

Orange Level

Joined: 12 Jan 2014

Location: Arrowsmith, ILL

Points: 2337

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: continuing saga of the D grader Topic: continuing saga of the D grader

Posted: 14 Jun 2022 at 12:13pm |

Well, ------ the starter was NOT the problem as to why the motor wouldnt turn over! The a-holes that barrowed the grader let it set outside and it filled up with water and stuck the pistons tight. They were sposed to keep it in a shed for me in exchange for using it BUT it never saw a shed I guess! Anyway when I went to bring it home cause I have a urgent project to use it on, --- well it wouldnt turn over! So we had to push it up on the trailer.

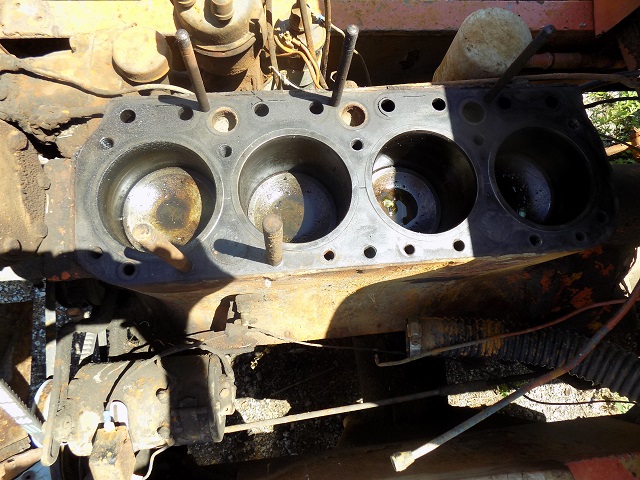

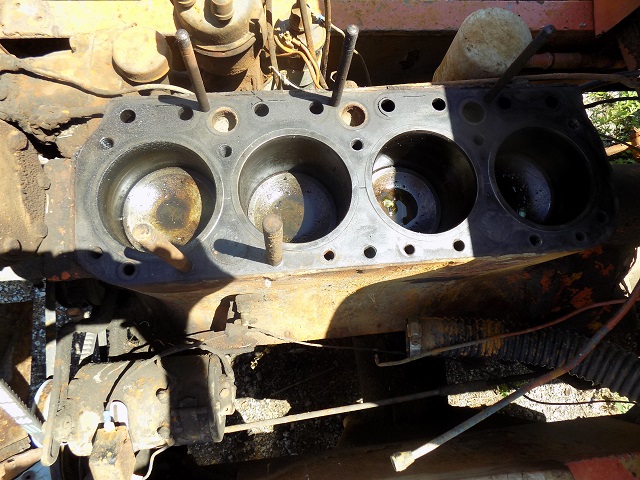

Finally got the head off and we got a mess in there. water everywhere, -- took the oil plug out to drain the oil,---yup 2 or 3 gallons of water in there too! Guess its going to turn into a major job that I dont have time for! The motor block # is W84723G which I assume is a special grader block so I s'pose a tractor motor is out. Didnt want to take the motor out if it can be avoided since I am not really able to do that with my current health problems.

Question is will the oil pan come off with the motor in the grader, or does motor have to come out?--anybody know? Cylinder walls dont look good at all, ---- worn real bad, also cracks on top of block between all cylinder sleeves.

the holes look to be 4 and 1/8"? as near as I can measure. I dont have sleeve pullers, boring bars, or other needed tools to work on it. I do have a set of m & w I think 4 and 1/4" sleeves and pistons,--but no rings or sleeve O rings in the box.

I hate to go this radical if I can just get the motor loose again and slap new rings in and go for now and do the serious work later.

I need the grader like NOW! LOL! Opinions please!!! THANKS!!!

|

|

http://machinebuildersnetwork.com/

|

|

|

Sponsored Links

|

|

|

DonBC

Orange Level Access

Joined: 12 Sep 2009

Location: Courtenay, BC,

Points: 947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 1:03pm Posted: 14 Jun 2022 at 1:03pm |

|

No, the D grader used the same 226 cu in that was used in the tractors. A very common engine. The cracks between the sleeves was fairly common. I never took the pan off my D grader so I have no information there. My D grader would barely run when I bought it. I immediately took the head off and had it rebuilt and put it back on. The sleeves had a fair ridge at the top but I chose not to rebuild that part. The engine ran smooth and good power but did burn a little oil. Number 4 plug would foul as that was the worst sleeve. I installed electronic ignition and that reduced the plug fouling.

|

|

Jack of all trades, master of none

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 1:31pm Posted: 14 Jun 2022 at 1:31pm |

|

Some of the early D gas graders used the 201 engine. The one our tractor club has is one of them. If you have any running 201-226 engine I'd swap it in and get it going again.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

DonBC

Orange Level Access

Joined: 12 Sep 2009

Location: Courtenay, BC,

Points: 947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 4:16pm Posted: 14 Jun 2022 at 4:16pm |

|

I made many modifications to my D grader to make it a more convenient to run. Example: left blade/left hand, right blade/right hand, steering/left hand/right hand ?, throttle/right hand, shift right hand. NOT ENOUGH HANDS. Solution: Left and right hydraulic blade controls moved to side by side for one hand use leaving the other hand free for steering. Foot controlled throttle. I moved the hydraulic pump to direct drive off the crankshaft. No more slipping belt. Mounted a belt driven power steering pump from an old car in the old location of the hydraulic pump. Mounted the a power steering control and hydraulic cylinder from an old sp combine to complete the power steering. Could steer it with one finger. The modifications made it a treat to operate.

|

|

Jack of all trades, master of none

|

|

ac fleet

Orange Level

Joined: 12 Jan 2014

Location: Arrowsmith, ILL

Points: 2337

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 5:19pm Posted: 14 Jun 2022 at 5:19pm |

This one has an old car ps pump runnin into a BIG unit and wont keep up with the amount of oil flow needed to run it. --- it steers easier without the motor runnin that it did with it runnin, so that junk comes off!! --- OR tie it into the regular system! ---right now everything is located o.k. for me since I kinda grew up on heavy equipment and have run some real dogs in my time! lol! One thing I wonder about is the crankshaft pulley, --- is the crank the same length nose as tractor??

I could steal one of the wd 45's motors if they would fit! OR the one out of my runnin wd!--forgot about it being in the shed! lol!

|

|

http://machinebuildersnetwork.com/

|

|

Ross D.

Silver Level

Joined: 02 Sep 2013

Location: Erin, Ont.

Points: 339

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 5:50pm Posted: 14 Jun 2022 at 5:50pm |

|

Hi. From 1949 to 1953 - 201 engine as in a WD 35

From 1953 to 1957 - W226 engine as in a WD 45

From 1957 to ---- - G226 engine as in a D 17.

These engines can swap easily. I had a 1967 'D Special' for about 20 years.

Ross D.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89931

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2022 at 9:28pm Posted: 14 Jun 2022 at 9:28pm |

I believe the 201 (WD) and the 226 (WD45) motors both had 4 inch diameter pistons, so yours has been updated before if it is 4.125 inch bore...

If you can measure the STROKE of the piston, i think the 201 was 4 inch and the 226 was 4.5 inch ?

|

|

Like them all, but love the "B"s.

|

|

ac fleet

Orange Level

Joined: 12 Jan 2014

Location: Arrowsmith, ILL

Points: 2337

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2022 at 9:25am Posted: 08 Jul 2022 at 9:25am |

got rad off since pix. motor about ready to pull out, --- still stuck tight, beat on pistons to no avail so ya they junk anyway,---BIG ring grooves in the sleeves! Guess I will try to put my 4 1/4" set in it and grind the valves. Hate to have to go thru all that but lookin like the simplest rout to go.

|

|

http://machinebuildersnetwork.com/

|

|

DonBC

Orange Level Access

Joined: 12 Sep 2009

Location: Courtenay, BC,

Points: 947

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2022 at 12:29pm Posted: 08 Jul 2022 at 12:29pm |

|

Re your question about the crankshaft pulley, I don't think the crankshaft pulley is the same as a tractor.

|

|

Jack of all trades, master of none

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jul 2022 at 8:35am Posted: 12 Jul 2022 at 8:35am |

|

W-84723G is a WC/WD 201 cube tractor engine block. The right side will have a cover plate over the valve lifters and push rods. If it was a 226 cube WD45 engine the serial number would have been 45-84723G with no cover plate over the lifters/push rods.

|

|

Ages Cat

Orange Level

Joined: 12 Sep 2009

Location: Hutchinson, MN

Points: 700

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2022 at 4:47pm Posted: 13 Jul 2022 at 4:47pm |

|

The crankshaft is unique to the D grader as the external shaft is longer to accomodate the dual crankshaft pulley that drives the pump. A tractor engine is shorter. The 226 parts book calls out the -1 shaft as the correct crankshaft.

|

|

Curt Anderson

HD3, HD5B, HD6AG,HD6B dozer, I-400,615, 616,620,720,ACP25 lift truck, 1956 D Grader, AC 540 loader, AC #84 plow, Simplicity tractors, Agco MT225, Agco 2025,

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

got rad off since pix. motor about ready to pull out, --- still stuck tight, beat on pistons to no avail so ya they junk anyway,---BIG ring grooves in the sleeves! Guess I will try to put my 4 1/4" set in it and grind the valves.

got rad off since pix. motor about ready to pull out, --- still stuck tight, beat on pistons to no avail so ya they junk anyway,---BIG ring grooves in the sleeves! Guess I will try to put my 4 1/4" set in it and grind the valves.