| Author |

Topic Search Topic Search  Topic Options Topic Options

|

AC7040

Bronze Level

Joined: 17 Feb 2015

Location: Indiana

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Big Ten Motor and Tracker 8 Motor Help Topic: Big Ten Motor and Tracker 8 Motor Help

Posted: 02 Sep 2020 at 10:02pm |

|

Hello All.

I have a Big Ten Garden Tractor and a Tracker 8 Snow blower that both need some motor work. The Big Ten is hard to get started, once its running it runs out decent. Guessing carb work? I've used what little knowledge I have to attempt to fix it but to no avail. The Tracker 8 I can not get to run at all. I'm 99% its a spark problem. I've taken the snow blower to a couple local small engine shops with no luck from them either. One shop said they wouldn't work on that old of a motor and the other stuck some electrical parts in it but don't make it run. Info on the Snow Blower Motor: 8 HP Briggs, Model 190412 Type 0695-02. I don't have the info on the Big Ten handy at the moment. Both machines look great for their age. My hope is to find someone on here that would be interested in working on these machines or know of someone I can contact. I'm not apposed to driving a decent distance or spending decent money on both machines as I'd rather have someone work on the machines that is used to the older Briggs motors and/or also shares my love of Allis Chalmers equipment. Any/All help appreciated. Thanks and God Bless

Ryan

|

|

1953-WD45, 1949-G, 1950s Snap-Coupler All-Crop Drill, 1956 Roto-Baler, 1945 All Crop 60, Snap Coupler Subsoiler, Plow, Gleaner F, 505 wagon

|

|

|

Sponsored Links

|

|

|

oldfords

Bronze Level Access

Joined: 31 Mar 2020

Location: South Dakota

Points: 52

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2020 at 9:09am Posted: 03 Sep 2020 at 9:09am |

Just a couple of thoughts about the Big Ten. When I used to work on them and they were hard to start I would start with the points and clean them and adjust. Another way I used to get them to start was to hold the throttle shaft closed on the carb while starting. The throttle shaft and the carb housing will get worn and get to much air for the amount of starting fuel. I don't know if they still make throttle shafts and bushings for the carb. Just something to try. I don't know if your Tracker 8 is old enough to have points under the flywheel. They used to make a kit to switch these old Briggs form points to electronic ignition. Just a thought

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3949

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2020 at 9:16am Posted: 03 Sep 2020 at 9:16am |

|

on the modall 19 remove the flywheel and replace the points and condenser also this engine can have the pionts eliminated and use the new magneto i dont have the part # but your local mower shop should be able to call their briggs distributer and get the # from technial services the 10 hp will need the points and condensor done and also the valves should be lapped and the lash checked i have a good runnining 10hp out of my 101 same tractor i put a model 32 in so the 10 with starter generator regulator and complete wire harnass is just sitting needs to go to agoog home

|

|

AC7040

Bronze Level

Joined: 17 Feb 2015

Location: Indiana

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Sep 2020 at 10:07pm Posted: 03 Sep 2020 at 10:07pm |

Thank you both for the wealth of information! I will begin to see about preforming the task on both units as described and see what I come up with. If you don't mind, I will continue to update my progress/findings and post some more questions if/as needed.

|

|

1953-WD45, 1949-G, 1950s Snap-Coupler All-Crop Drill, 1956 Roto-Baler, 1945 All Crop 60, Snap Coupler Subsoiler, Plow, Gleaner F, 505 wagon

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Sep 2020 at 9:29pm Posted: 06 Sep 2020 at 9:29pm |

|

I bought a SnoBee 7 hp a few years ago. Broken rope so I had no idea if it would run even though the fella said it did. So I took him at his word, sure enough after I installed a new rope it did run but was rough. Pulled the flywheel which obviously had never been off. Installed new points, condenser. New plug, cleaned the carb and she runs wonderful. A compression test tells how healthy an engine is. That’s always my first test before pouring a lot of $ into it. If it’s in specs, then I will replace what it needs to make it run. Less than $30 to get my SnoBee in tip top shape.

My 5hp tiller the same way, points, condenser, carb kit, and a coil due to no spark after the points, condenser replacement. Less than $75 to get a great condition tiller ready for work.

They are not difficult to work on. Not much of a repair shop if they can’t repair an older B&S. A shop should understand how an engine works, be able to diagnose it’s issue, and repair it. JMO, I’m not a certified mechanic, just a fella that tinkers on old AC stuff and gets the satisfaction of fixing it myself. If you was closer I would be glad to look at it for ya.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC7040

Bronze Level

Joined: 17 Feb 2015

Location: Indiana

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Sep 2020 at 9:23pm Posted: 07 Sep 2020 at 9:23pm |

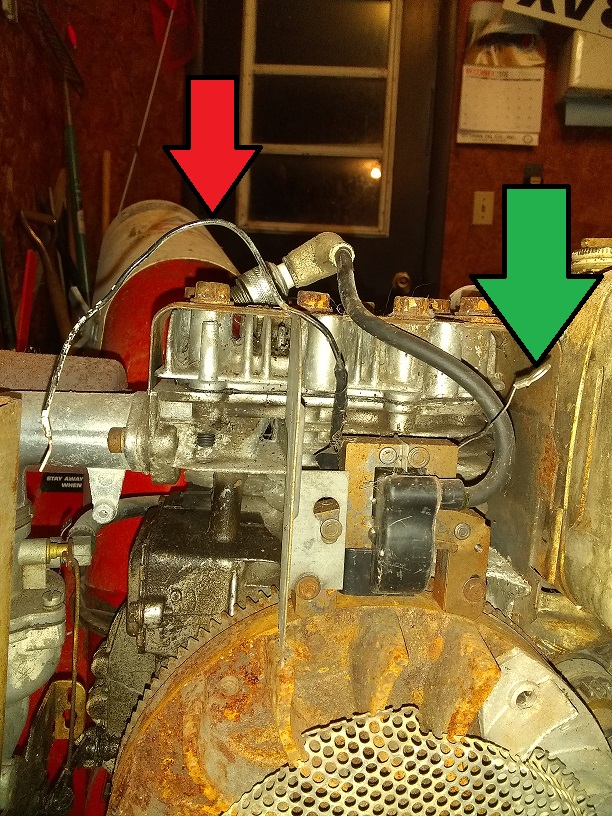

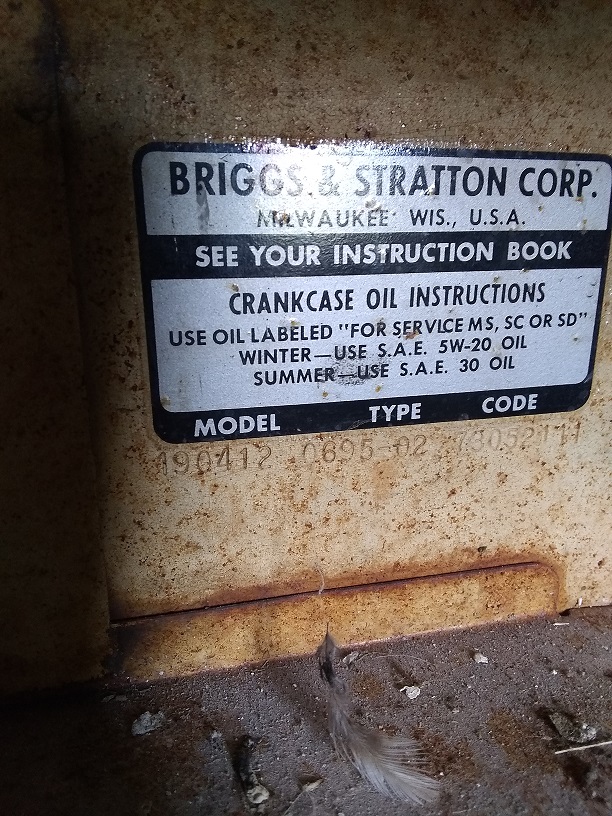

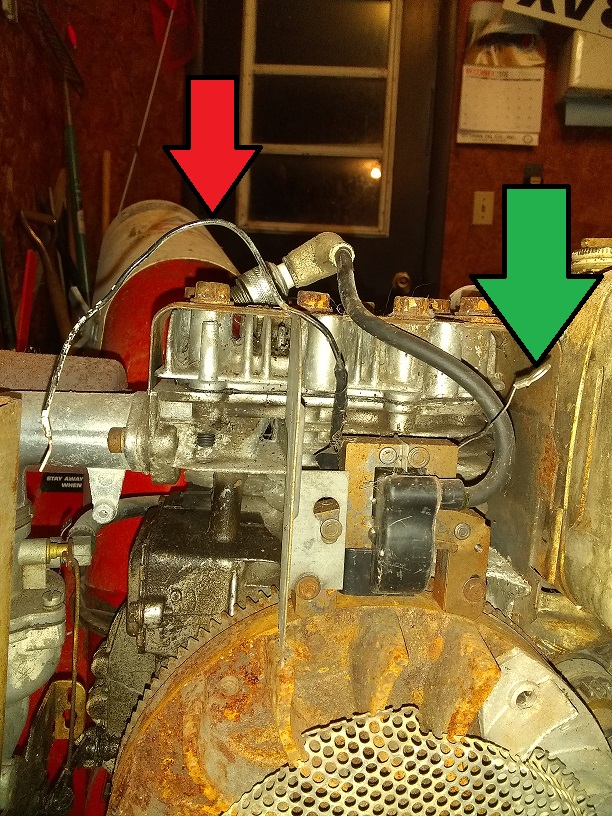

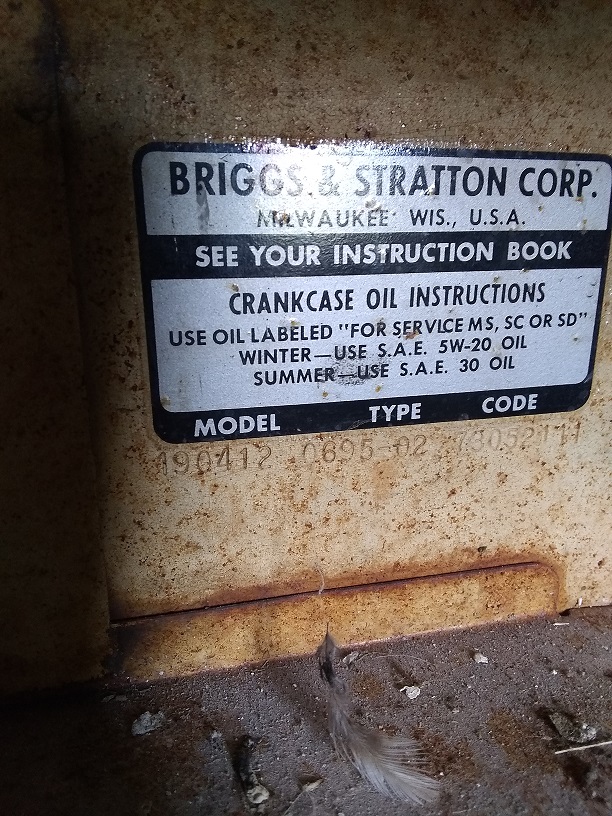

Thanks for the info AC720Man! Hopefully my engines don't need a lot of work like you described with yours. I pulled the Tracker 8 into the garage and started checking things out. My compression test showed 62psi. I don't have any spark. The spark plug is a Champion J19LM. The paper work for the last engine place that looked at it said they replaced the breaker and condenser. I've included a picture of what else I've found when I pulled the flywheel cover off. I have a wire (Green Arrow) that comes off the mag that is not attached to anything. I also have a wire (Red Arrow) that comes out from behind the flywheel not attached to anything. I believe the wire with the "Red Arrow" goes into the crank case...? Would have to pull the flywheel to verify. I'm lost on what both wires should be attached too. If anyone has a manual for the Tracker 8 snow blower or the manual for the Biggs engine I would be interested in purchasing one.  As always thanks a bunch for your help!

|

|

1953-WD45, 1949-G, 1950s Snap-Coupler All-Crop Drill, 1956 Roto-Baler, 1945 All Crop 60, Snap Coupler Subsoiler, Plow, Gleaner F, 505 wagon

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Sep 2020 at 9:09pm Posted: 08 Sep 2020 at 9:09pm |

|

The wire under the red arrow goes to the kill switch on the throttle plate. As you move the throttle to idle, you should see a male spade connector that the female connector should slide on. As you move the throttle more it will eventually touch the metal of the spade connector which grounds the coil to kill the engine.

The green arrow wire goes under one of the coil mounting bolts.

Of course this is based on if this is the correct coil for this engine....if it has the throttle plate that I described.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Sep 2020 at 9:14pm Posted: 08 Sep 2020 at 9:14pm |

|

The kill wire replaced the old flip top onto the spark plug that could give you a heck of a jolt or burn from a hot plug if you kept your finger on it. Lol....yeah ask me how I know?

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC7040

Bronze Level

Joined: 17 Feb 2015

Location: Indiana

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Sep 2020 at 9:33pm Posted: 08 Sep 2020 at 9:33pm |

|

Haha I been there before! Old 2 cycle Echo trimmer gave me quite a jolt! K, I'll go ahead and connect the wires as you described. I know it's not saying much but the mag looks very similar to the mag I removed because of the mouse chewed wire. Thanks for the help!

|

|

1953-WD45, 1949-G, 1950s Snap-Coupler All-Crop Drill, 1956 Roto-Baler, 1945 All Crop 60, Snap Coupler Subsoiler, Plow, Gleaner F, 505 wagon

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Sep 2020 at 8:44pm Posted: 09 Sep 2020 at 8:44pm |

My SnoBee has the kill wire attached by a spring clip which is the other way it can be attached.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Sep 2020 at 9:32pm Posted: 09 Sep 2020 at 9:32pm |

|

Did you find those wires not connected when it came back from the shop? If so, I would ask for my money to be refunded! Best thing to start with is get the model number, type, serial number from your engine. It’s stamped on the engine cowl or on the engine tin. With those numbers you can order the parts you need. Like any other engine, coils, points, condensers come in different types. The correct ones are required to make it run. Looking at your picture, there appears to be a lot of rust around the flywheel. Since you need to remove the coil anyway to place the wire under a mounting bolt, lets clean it up. If they did in fact replace the points and condenser then the flywheel will pop off easily. Loosen the center nut that holds the flywheel onto the crankshaft. Back it off until its flush withe end of the crankshaft. A few taps with a small hammer on the nut should pop the flywheel loose. If it doesn’t pop loose, my guess would be that they didn’t replace your parts. It takes a while for the flywheel to reseat onto the crankshaft after one has been removed. Anyway, if it doesn’t come loose then you will need a 2 jaw flywheel puller. Very inexpensive at a parts store or Harbor freight. If you haven’t used one before let me know. Once its off, use fine sand paper to clean up the magnetic pickup on the flywheel facing the coil. It should shine up pretty well when your done. Take the coil and clean up all 3 pickup points on it as well. Now that the flywheel is off, remove the cover that is covering the points, does it appear that you have new points and condenser? If so, check the gap between the points and the condenser. To make it easier, spin the nut back on the crank and use it to turn the engine clockwise slowly until you see the points open up the their widest point. A match book is the correct thickness and works well. Or if you have a .016-.020 inch feeler gauge then that will be fine. Loosen the bolt holding condenser to slide it in or out to obtain the correct gap. Once you have it set, turn the engine a time or 2 and check it again. If it is still correct, put the cover back on as well as line up the key way for the flywheel and slip it back onto the crankshaft. Tighten the nut. I use a piece of card stock, post card will work also, to set the gap for the coil because it can be wrapped around the flywheel. You only need it to go a inch beyond the magnetic area of the flywheel. Turn the flywheel so the magnetic area is at the top where the coil will be mounted. Lay the card stock on top of the magnetic area, place the coil in its mounted position. It will pull itself towards the magnet of the flywheel. Insert the attaching bolts on the coil along with the wire under the green arrow from your previous picture. Tighten bolts. Turn the flywheel clockwise and the card stock should come out as you turn the flywheel. If it doesn’t just pull it out.

Now your gaps should be correct, connect the kill wire and if the coil, points, condenser are good you should have spark at your plug.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC7040

Bronze Level

Joined: 17 Feb 2015

Location: Indiana

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Sep 2020 at 9:02pm Posted: 10 Sep 2020 at 9:02pm |

Thanks AC720Man! I did find the wires unhooked, however the shop never charged me any labor since they couldn't get it running. They did give me a bag with the old parts (Points and Condenser). I was able to get the flywheel off relatively easy so it was defiantly apart at one time. There was not a gap between the points and condenser. I rotated the engine to the point that the points opened the widest. I used a feeler gauge and set the point to .018. I rotated the engine and checked a couple times. All looked good. Used a business card to set the gap on the coil. Rotated the engine and checked my gap a couple times. Removed the spark plug and grounded it on the head, FINALLY seen some spark. Not as bright/hot as I think it needs to be but thought I was getting somewhere. Screwed the spark plug in the head to see if she would fire and I got nothing... Removed the plug and attempted to ground the plug on the head again, nothing this time. So I feel I'm closer but not there yet. Wondering if I have the correct spark plug. Currently using a Champion RJ19LM. From my understanding the "R" means it has an internal resistor? Any recommendations on a different brand of plug? I've posted a picture of the engine cover with the Model, Type, Code. Thinking I need to stop by a local Briggs dealer and check on the coil to make sure it is the correct one.

|

|

1953-WD45, 1949-G, 1950s Snap-Coupler All-Crop Drill, 1956 Roto-Baler, 1945 All Crop 60, Snap Coupler Subsoiler, Plow, Gleaner F, 505 wagon

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5249

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Sep 2020 at 10:33am Posted: 11 Sep 2020 at 10:33am |

|

According to the ole Internet a Champion RC12YC or equivalent. Was you able to get the flywheel cleaned up? Your on the right track, after a new plug, I would be suspecting the coil.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

LionelinKY

Orange Level

Joined: 12 Sep 2009

Location: Radcliff,KY

Points: 695

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Sep 2020 at 2:16am Posted: 12 Sep 2020 at 2:16am |

|

Whereabouts in IN are you? I'm in KY not quite an hour south of Louisville. I'm no expert but I have a B110 along with some other old ACs and I do my own maintenance and repairs whenever possible as well as willing to help out a fellow AC guy anytime.

|

|

"My name is Lionel and I'm an Allisoholic"

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Oct 2020 at 4:18pm Posted: 07 Oct 2020 at 4:18pm |

I recommend Bobs Small Engine Repair for parts and help, he is a older guy who has been around these old Briggs for a long time. He might be a help. Here is a link to his web site: https://www.bser.com/

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)