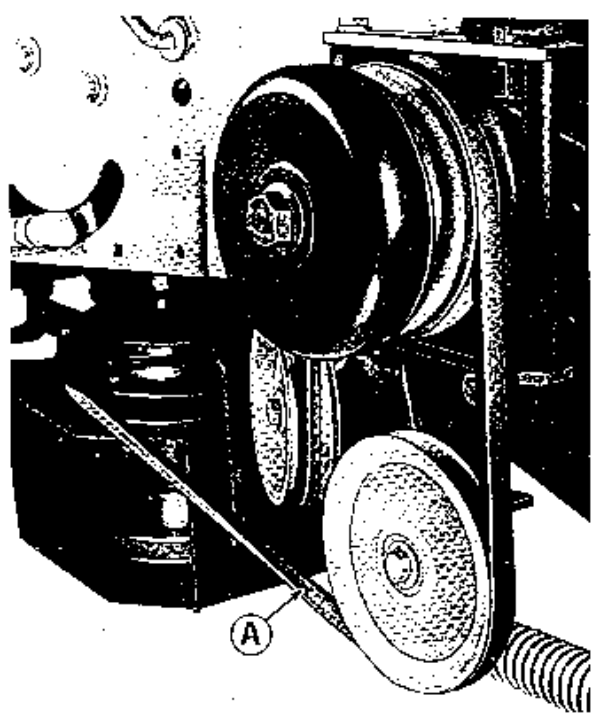

Generally it was in good shape, the major loss was the Drive pulley, which was a stamped steel original, it had rusted out

I found a replacement pulley on Amazon of all places: https://www.amazon.com/dp/B0032KM34Q which is an exact fit.

The bugaboo was getting the old pulley off the shaft, since the hub was seized on the shaft. First I had to use an angle grinder and cut up what was left of the old pulley’s hub. There is a woodruff key in the ‘crank’ shaft so you can’t pull the shaft OUT until you get the woodruff key out, and to get the key out you have to get the pulley hub OFF the shaft.

Plus, the hinge shaft has to be removed to make the space needed to get the drive pulley’s hub on/off of the end of the shaft.

The hinge itself was not seized up. But, I could not pull or drive the pin out due to the corrosion on it. (and actually you can’t drive the hinge pin out unless the Crank shaft, ala the drive pulley and all of that is removed first) I wound up using strips of sand paper to clean the rust off the hidden – back side of the pin, so I could finally pull it out.

With the hinge shaft out then you can remove and re-install the drive pulley.

Generally I disassembled, cleaned and re-greased everything that moved on the mower, Simplicity did a amazing job of building this thing. There are grease fitting everywhere and they used needle – roller bearings instead of brass bushing all over the place. In spite of the mowers lack of care, the mechanics, except for the one pulley were in good shape.

All of the sickle guards are in place as well as the sickle sections.. When I disassembled the bar to see what was what, I found that the wear plates that are behind and under the sickle bar itself were VERY pitted on the front edge, so much so that I figured they would act like rasps and wear down the sickle bar.

Being that I am a bit of a tight wad, and I also am a hobby machinist, I opted to modify ‘universal’ wear plates to fit, instead of putting my money into exact replacement parts. Hey I only paid $100 for the entire mower..

I was able to get 5 ‘MC468 Universal Sickle Bar Wear Plates’ for less than $30 to my door. Since I have the machinery, I modified them to fit the simplicity bar.

The hole spacing on the ‘785 – 46 inch sickle bar is 2 inches on center. The standard for other bars is 3 inches on center. Which means the hole spacing of the ‘Universal’ wear plates won’t fit. And, wear plates are hardened steel, not something you cut and drill with hand tools.

On the right side is an unmodified MC468 Wear plate, in the center is the original Simplicity 8161136 part, you can see the level of pitting on the top, the front edge is even worse. On the left is a MC468 part after I modified it.

Since these are hardened steel I used a cutting wheel in an angle grinder to reduce the length of them, which lead to that weird notch on the bottom. That’s where the original 3 inch spacing hole was. Next I set these up in my milling machine and used a carbide drill to make new slots spaced at 2 inches to fit the Simplicity bar.

If you want to do this, you could use an angle grinder and cutting wheel and just make a slot at 2” on center, by cutting in from the back. I don’t think that kind of a slot would effect the strength, based on how these are mounted:

Yes, I smeared grease all over the bar as a way to get it lubricated until it was running and I could coat it with oil.

With the sickle mower back together and working, I could start work on mounting it.. I don’t have Simplicity or Allis Chalmers tractors. I run OLD JI Case tractors, In particular I have a 1973 model 646 loader tractor that has 3 point and a hydraulic ‘pto’ for rear mounted attachments.

I didn’t want to belly mount the mower, because I have no way to drive it there, other than hydraulically, and for me 3 point mounted implements can be swapped much faster. I started on a 3 point mount design along with converting the mower to hydraulic drive. I also did not want to ‘hack’ the Simplicity mower, if I sold it or something.

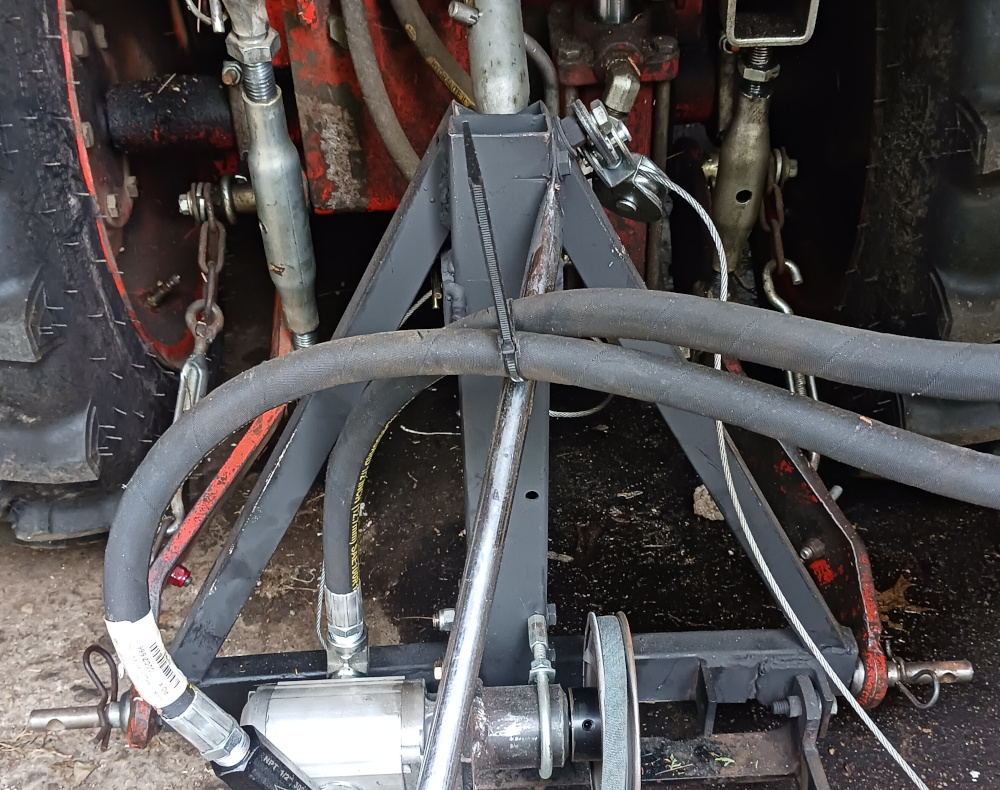

Which actually worked out quite well. I custom made a 3 point “A frame” so that it would bolt to the front mounting holes of the sickle mowers exiting frame assembly.

Eventually I wound up connecting the top of the “A” frame to what the parts list describes as the “stop” ?

A fair amount of my time getting this up and running was spent working out how to drive the mower with a hydraulic drive motor. Based on the planetary gear drive that sits above the drive pulley there was no way to just couple the drive motor to the shaft or anything like that.

Also, I knew I was not putting the drive motor behind the mower like the simplicity mowers drive belt attaches.

That did mean I had to remove the bracket that attaches to the rear shield – cover, that keeps the planetary gear case from turning. I had to create new bracket on the front side of the shroud assembly that keeps the gear case from turning.

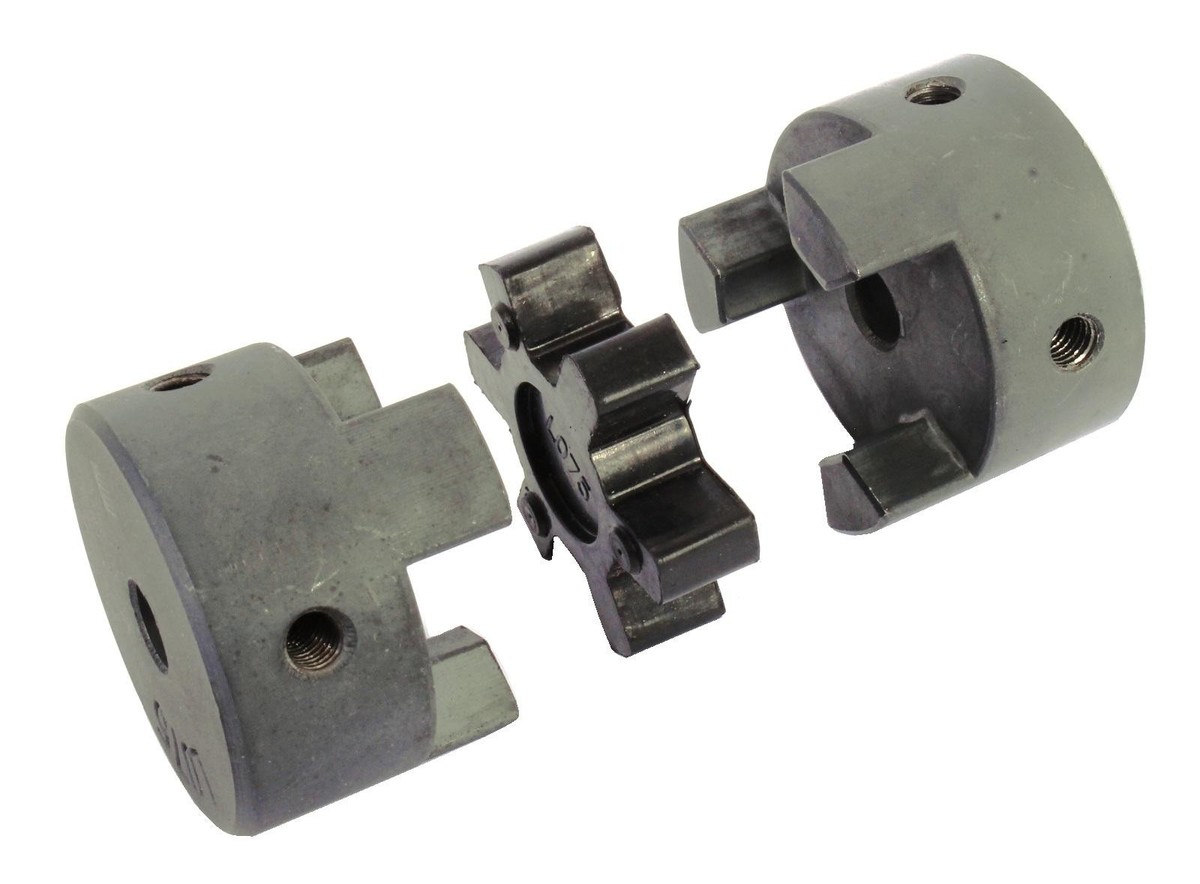

Once I started mocking up the drive motor, and bearing assembly. (most hydraulic pumps and motors are not designed for any kind of side load on the bearings, that is why you most often see them connected by “lovejoy” couplers)

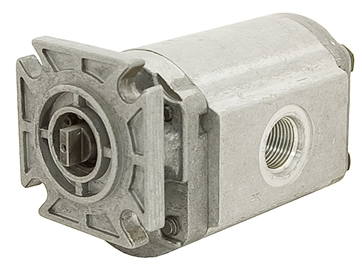

The drive motor I sourced for this project also has a “tang” drive output

Hey, it was CHEAP, like $30 and rated for 1800 RPM, so I figured that should not over speed the sickle.

I created a bearing assembly and mount for the drive motor that connected to the tang drive and has 2 ball bearings to handle the side load of the belt pulley.

The “mocking up” got real interesting when I figured out that based on where the mower drive pulley was, plus the length of the bearing assembly and the hydraulic motor, if I mounted it vertically the motor would have been in the dirt. The assembly is too long to mount vertically. Well how do we solve that?

The twisted belt also allowed me to attach the drive motor to my 3 point A-frame instead of having to clamp it to the mower frame some how, and it actually was easier to work out a belt tightening scheme, since I wasn’t going to use an idler in this setup. The location also made the hydraulic hose routing and setup much cleaner. (Since the drive motor is spec’d for only turn counterclockwise, I put a check valve inline so we always made sure it turns the right way. (Case garden tractor hydraulic ‘PTO’ can run the oil flow either direction, which is handy for my garden tiller. )

The other fun part of designing – building this was, how do I lift the sickle BAR when I want to transport or go around something?

I actually don’t have any more hydraulic circuits on my tractor to drive something like a hydraulic cylinder on the mower to lift the bar. And, for some reason what I saw in my mind was whenever I raised the 3 point to pick the mower up off the ground the bar should also some up. Soooo…

Since Simplicity used a pulley and cable system to lift the bar.... I also have a cable attached at the standard bar lift point, the cable then runs up and over a pulley at the top of the 3-point A frame, then back down to the ‘tongue’ on the rear of my tractor. Actually any fixed point on the tractor will work, the point is to tighten the cable when the 3 point lift arms come up. Now, when I raise the 3 point it tightens the cable you see in the 3 point A frame picture and it lifts the sickle bar up very similar to how the Simplicity tractors do..

Short video of the setup and process.

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)