Pics for Mitch

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=73093

Printed Date: 28 Feb 2026 at 5:10am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Pics for Mitch

Posted By: Ken(MI)

Subject: Pics for Mitch

Date Posted: 08 Jul 2013 at 8:43am

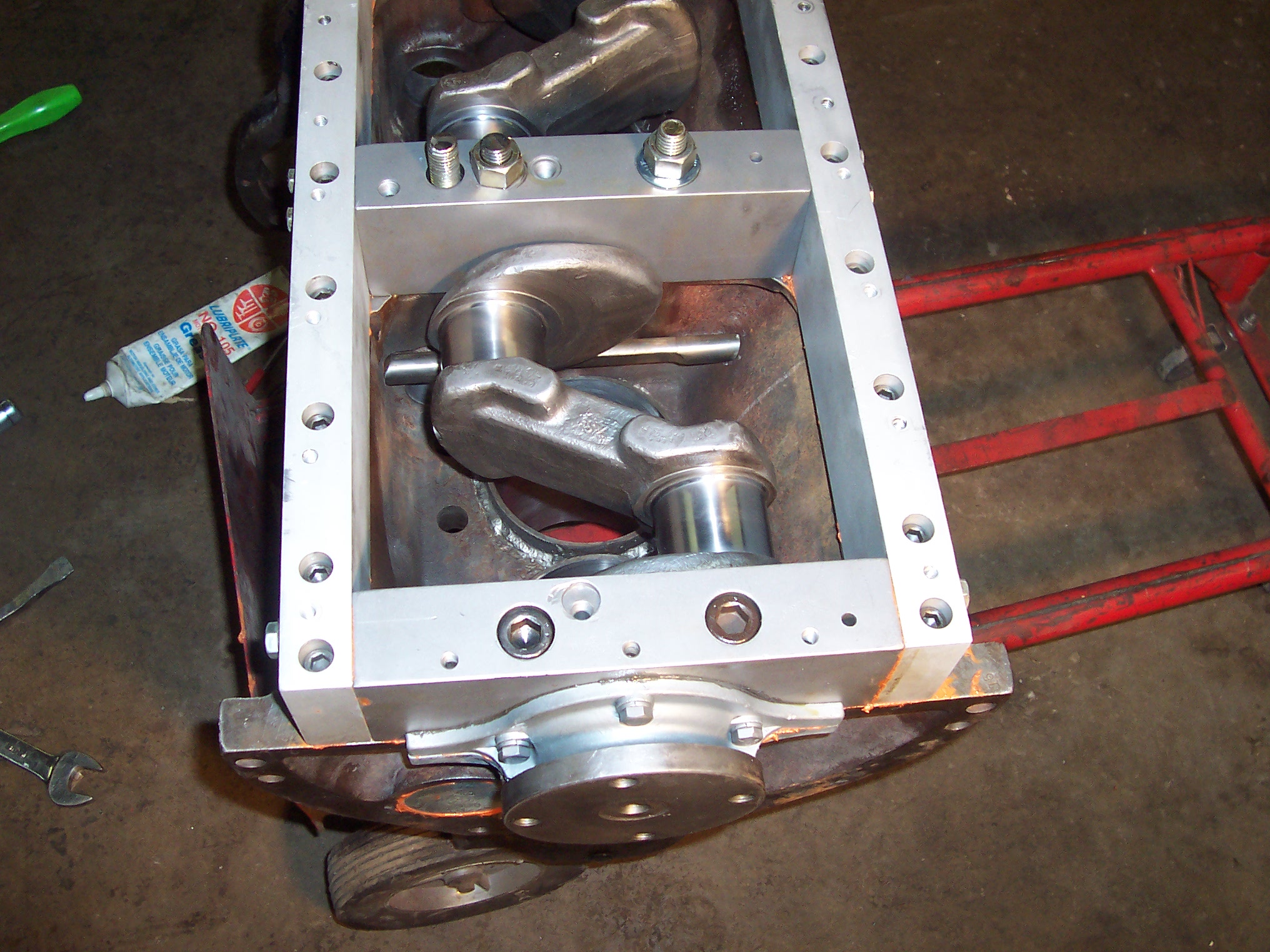

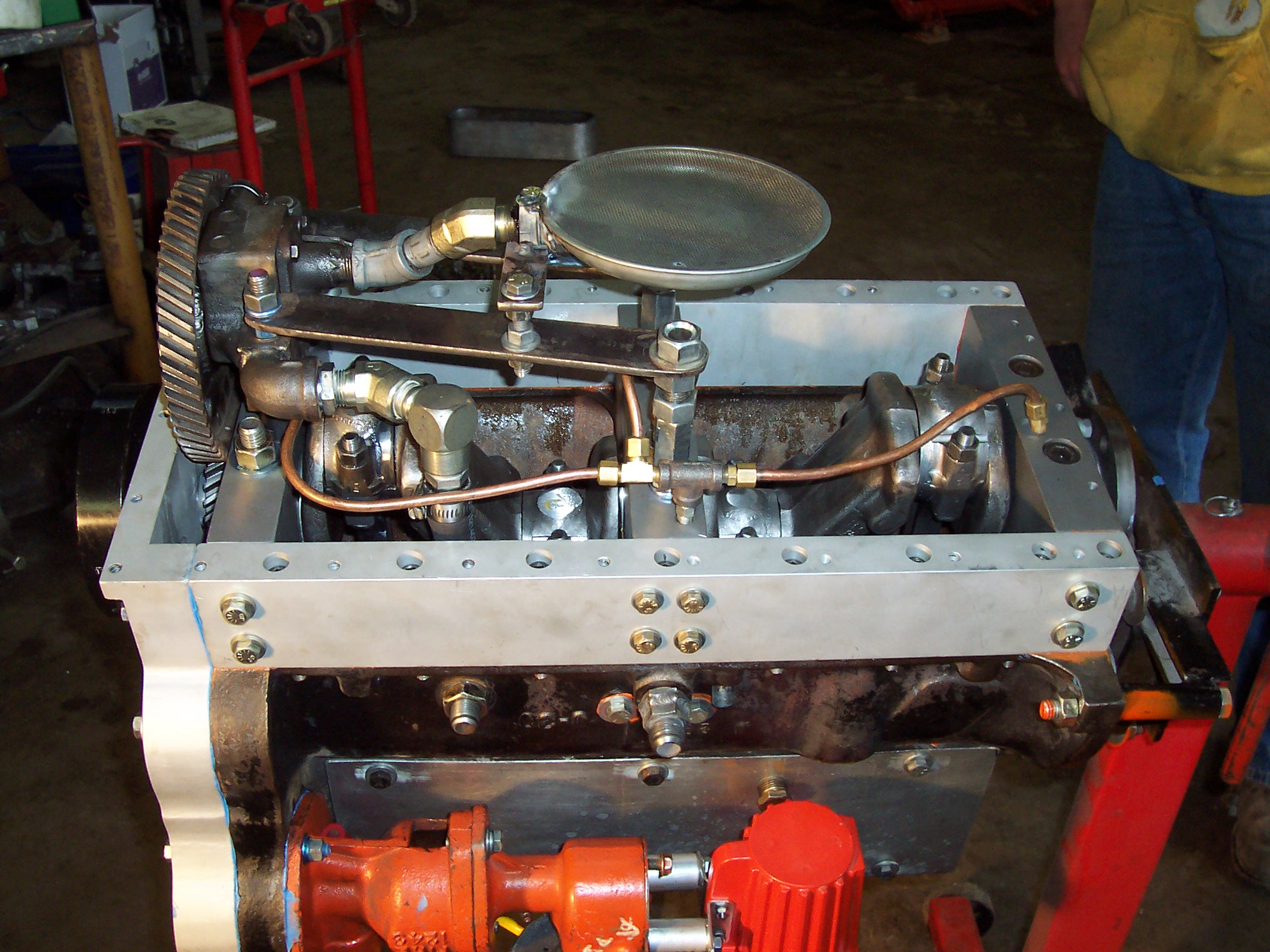

Wheelie bars, weight brackets, custom bull gears, hubs, brake rotors, axle shafts, light weight WC centers, aluminum transmission cover, Porsche rack and pinion aluminum front end including wheels, all made complete in house Pankey, including broaching, gear cutting, and heat treating, please keep in mind that this stuff is sideline work, not our main stream business, but I'm not going there because this is a tractor forum, not about race cars, chainsaws, minibikes, tonka trucks, or anything else you care to brag about. I really don't need to defend my position to a Clown like you, but here is a fair sample of my work, and from this point on, I'm done responding to your 3rd grade behavior. Wheelie bars, weight brackets, custom bull gears, hubs, brake rotors, axle shafts, light weight WC centers, aluminum transmission cover, Porsche rack and pinion aluminum front end including wheels, all made complete in house Pankey, including broaching, gear cutting, and heat treating, please keep in mind that this stuff is sideline work, not our main stream business, but I'm not going there because this is a tractor forum, not about race cars, chainsaws, minibikes, tonka trucks, or anything else you care to brag about. I really don't need to defend my position to a Clown like you, but here is a fair sample of my work, and from this point on, I'm done responding to your 3rd grade behavior. |

Replies:

Posted By: Larry(OH)

Date Posted: 08 Jul 2013 at 9:09am

|

Man, thats some nice looking stuff Ken.

------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Posted By: Butch(OH)

Date Posted: 08 Jul 2013 at 9:26am

|

That weird sound you are hearing is the VI loosing control of his bowels,,, |

Posted By: O.P.S. Heads

Date Posted: 08 Jul 2013 at 11:53am

|

Nice stuff there Ken. Good one Butch (on the noise I was hearing). Ken, Can you make transmission gears say for a model 180? I realize that's a tough questions without having a pattern or at least a picture. |

Posted By: WCCLASON

Date Posted: 08 Jul 2013 at 12:00pm

|

Looks good! I am thinking about trying to make a diffrent 1st gear in my WC to slow it down....Really dont want to do the rear end swaps becuase everything i hear is light duty and wont hold up.Do you have an opinion on this? Its just an idea i am throwing around. |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 12:42pm

| Looks great, if you post, he will come.....unfortunately |

Posted By: mlpankey

Date Posted: 08 Jul 2013 at 1:52pm

|

Looks good mig aluminum welds and stuff. Looks like you have given up on making a allis compete against olivers though. I am just to head strong to join them so i work to beat them. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 1:59pm

| Do you not see the orange tractor, there is no reason the man can't have two pullin tractors, guy round here comes with a big rightly of em and in all different colors |

Posted By: Ken(MI)

Date Posted: 08 Jul 2013 at 3:00pm

| Thanks for the compliments Guys. The Oliver was a customer job, we built the chassis and he put a Gingrich engine in it. As for the other questions, I would need to see the 180 gears in question before giving an answer, and about making another first gear for a WC/WD, I tried it, and felt it was a waste of time, easier and more versatile to play with final drive ratios and the ring and pinion, than to change on gear. The RC/High Crop conversion is the most bang for the buck, no durability problems if done correctly. |

Posted By: Butch(OH)

Date Posted: 08 Jul 2013 at 3:02pm

|

Plinky, hate to be the bearer of bad news but your amateur status is showing again, that is TIG weld not MIG as is obvious to anyone who has actually used the processes on aluminum. Just as we know that the process you used on the balancer was PAH (Poo Apllied by Hack) As for the Oliver real shops do work for others gesh! Not to worry Plink as you dont need to make a living welding, or figuring out simple things like the Oliver picture as the royalties from your Gleason cloaking devise should allow you to live high on the hog.

|

Posted By: Ihateillinoisnazis

Date Posted: 08 Jul 2013 at 3:16pm

Lol, you of all people to pick apart welds.  Spunk your weld jobs have been posted so many times I doubt there is a member on here who hasent whitnessed your work of art welds on that pulley. Spunk your weld jobs have been posted so many times I doubt there is a member on here who hasent whitnessed your work of art welds on that pulley. Nice tractors Ken, nice work on the internals too. Quality machine work is nice to see. I know spunk, you're going to say shiny parts please everyone but there's a difference here. Ken's parts work, and continue to work, your parts aren't even shiny, more less work lol. |

Posted By: Glockhead SWMI

Date Posted: 08 Jul 2013 at 3:19pm

| Nice! |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 3:45pm

|

Posted By: Butch(OH)

Date Posted: 08 Jul 2013 at 3:53pm

Yessir you can weld Alum with a correctly set up MIG, where did you see me say ya couldn't?

LOL. Point is/was the welds are clearly TIG, and the site's self proclaimed smartest person doesn't know the difference. LOL. Point is/was the welds are clearly TIG, and the site's self proclaimed smartest person doesn't know the difference. |

Posted By: wi50

Date Posted: 08 Jul 2013 at 4:04pm

I don't think the goon has a clue Butch. He (pank0) yeah thats not pank o that's pank0 as zero doesn't seam to want to take part in his challenge so I'll take the liberty to post some pics of our resident idiots workmanship in a bit. You guys beleve this idiot thinks you can make billet main caps and put them on without line boreing-honeing? He seams to make up BS about his cobble shop thinking you can. It has to be the anti rotation tabs. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 4:18pm

Ahh never done any tig work myself so I had no clue, than again I did claim it was and I was an expert on it like he did

|

Posted By: mlpankey

Date Posted: 08 Jul 2013 at 7:50pm

|

Butch if its tig must have either used floranted tungstien or argon or both together. To correctly tig aluminum under alcoa aluminum certification you use pure tugnstein and helium for sheild.its been a while since i had welding certs. I do keep medical gas cert still though. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 08 Jul 2013 at 8:05pm

I'm sorry plinko but I just gotta save this for future generations. You boys have fun explaining to him the difference between fluoride and throited tungston and why argon is used. Google it Mitch and edit your post...you're literally to stupid to try and argue with at this point. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 08 Jul 2013 at 8:13pm

|

To pass a aluminum certification helium is correct sheild gas and pure tungstein is used. Argon or tboranatedd florinated whatever other than pure tungstein will not pass certification tig test at alcoa aluminum ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wlenoir

Date Posted: 08 Jul 2013 at 8:16pm

Quality work. Some of the best wheelies I've seen in a long time. Do y'all sell custom R&Ps for WCs? Quality work. Some of the best wheelies I've seen in a long time. Do y'all sell custom R&Ps for WCs?I'm still figuring out why one would need a medical Gas cert to balance turbines and work on camaros?

|

Posted By: mlpankey

Date Posted: 08 Jul 2013 at 8:25pm

|

Nuclear maintenance. Ps thoranated tungstein when sharpened stuck into a nuke workers jacket will lock up the radiation portal monitors. At least the oliver guy knows that wheelie bars are for safety and modified engines and cut tires are for pulling ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 8:57pm

| Really it says here unless you eat it its fine http://www.pro-fusiononline.com/tungsten/radioactivity.htm |

Posted By: blue924.9

Date Posted: 08 Jul 2013 at 9:01pm

So you need medical Gas certification to do nuclear maintenance, are you an anostesiaoligst as well as a nuclear power plant builder

|

Posted By: patrickmull

Date Posted: 08 Jul 2013 at 9:18pm

|

i have my medical o2 certs but i am a commercial diver O yea nice parts

|

Posted By: Ken(MI)

Date Posted: 08 Jul 2013 at 9:19pm

OK, so it's incorrectly welded, and you know this how? First it was a MIG weld, now it's a TIG weld, but done incorrectly, Helium hasn't been used since the dark ages for most applications. What kind of cert is required for the welds shown in those pics of yours? We may be on to something here with the medical gas certs, there may have been a serious over application of NOS causing irreversible damage. Still waiting on your pics Mitch, and I think the Judges on here are too. |

Posted By: patrickmull

Date Posted: 08 Jul 2013 at 9:25pm

| is that a cast center and how did you cut it so nice |

Posted By: Butch(OH)

Date Posted: 08 Jul 2013 at 9:33pm

|

LOL, I figured when the VI came back it would be good for a laugh. This AM he didnt know MIG from TIG but this afternoon he is giving us carnal knowledge of the process. You may be right Ken, NOS? But he did post a picture of a car fender he painted, wonder if he wore a mask? ISO will cause brain fade. Around here every 1 stop light town has a shop that paints fenders, sometimes two or three. All in all I think Marty has had it right on his sig line since way back. AND where is the Gleason?? |

Posted By: Ken(MI)

Date Posted: 08 Jul 2013 at 9:47pm

| The cast centers are cut on our water jet machine, I think that Gleason is virtual, maybe part of some computer game like Farmville, Pank plays "Motorsports Mogul" complete with 3D glasses, joystick and secret decoder ring. |

Posted By: Butch(OH)

Date Posted: 08 Jul 2013 at 9:58pm

Whoa! Something else for Plinky to Google and play expert, Key word "water jet machine" Be careful Plink that you don't come up with soda fountain equipment! that could be embarrassing if you posted about making a rootbeer float. I don't blame ya for being totally jealous of Ken's work Plink but somes got it some dont. |

Posted By: steve(ill)

Date Posted: 08 Jul 2013 at 10:49pm

|

Ya know, you guys would be sad if spanky got mad and left ! You got to admitt, he makes a good straight man for a comedy act. ------------- Like them all, but love the "B"s. |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 7:30am

Ya Steve, your right. Plinky makes my day sometimes . . But I think he is more like a Parrot than a comedian.

|

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 8:19am

|

Ken you asked a question . I will give a answere. I thought it was mig due to the weld penetration. Then hou guys said it was tig ao i knew rhen it was either argon or tungstein that caused what i was seeing. Your post proves it was the argon use. Because you. dont know proper technique or to cheap to have helium for shield gas isn't a reason to say its a dark age technique . When its still known as the best way to get good penetration welds when welding aluminum. I was farm raised like alot on here. When I furtheded my education with trades and labor i found out alot of things taught on the farm were incorrect. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Glockhead SWMI

Date Posted: 09 Jul 2013 at 8:24am

| Right... you're educated... |

Posted By: firephight

Date Posted: 09 Jul 2013 at 8:44am

| I am taking up a collection so we all can rent a large bus and take a trip south to check out this incredable machine shop and unbeliveable pulling tractor of pankys |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 8:51am

|

Why travel to Tenn when all you have to do is go to your local junk yard and watch the goings on? Ken also asked another question and so have I ???WHERE IS THE GLEASON??? LIAR |

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 8:59am

|

Butch run over to another forum you may find it. Then again you have and havent ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 9:05am

What is that supposed to mean? Speak english! I want to know where YOUR Gleason is, The one YOU own and YOU operate. ??WHERE IS THE GLEASON??? LIAR |

Posted By: wi50

Date Posted: 09 Jul 2013 at 9:17am

|

Butch, he also claims to be doing all kinds of line boreing jobs on all those billet main caps that the ameturers are building on their Allis blocks....... anyone smart enough to build the main caps is smart enough to have them line bored though. Another lie he's posting.

I've logged a few thousand hours of helmet time and can just about tell you what machine Ken was useing.....nice design and fabrication work on the parts. It makes a difference when a professional builds things, the ameturers and apprentices really show their jealousy.

Ken issued the challenge to have pics by monday. All weekend to grind and shine plinko and you have avoided Ken's challenge. So I've decided to help my simple minded southern buddy meet Ken's demands.

Straight from plinko's shop, to your computer screen

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 09 Jul 2013 at 9:25am

|

Speaking of proper welding technique and for a guy with all his welding cirtification, another pic from plinko.  Though we've seen this pic before it illustrates what some feel is proper welding technique. Others feel it's "been victamized by a low flying flock of geese"

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 9:25am

You need to get control of your bowels Plinky. Ken has posted great quality machine and fab work while we have memories of your wheelie bars that look to have been chewed out by an alligator and chit on by a chicken to hold them together. Then the same (or another?) chicken dropped a load on your front pulley and you werent even ashamed to post a picture of it, was all that prior to your new found education? Just a question. Edit, Marty posted some pics while I was typen. Too bad we dont have a close up of that mounting Marty, LOL Of course it is hard to have good control of the weld bead when you cables are 2/3 chopped in two, LOL. |

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 9:48am

|

I could plug them with my thumbs as you do. But then i couldnt work my machinery ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 9:48am

Here is "my" Gleason Plinky only I am not going to tell tall stories like you. This Gleason is at Harts in Cecil and I hire John to use HIS Gleason to weld my cranks. Talk to John sometime about crank welding and you will at least be able to type about that subject without making a fool of yourself.  |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 9:56am

Which machine was it you used to make your lightweight WD wheel centers? Ken has posted that he used his CNC water jet table to build his. I posted that I guessed that you used a broad axe to make yours but you never responded. Could you take a close up of those for us and explain? |

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 9:57am

|

Then its not yours is it. So dont post pictures of other peoples stuff. Why would you spend that much time doing tbat much clean work on short wheels and leave lugs as tall as they are for pulling. It would have to be inexperience cause anyone who has been to two pulls that they participated in know tall tire lugs. Kills a pulling tractor and good cut tires makes a tractor ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 10:14am

|

Why would I own a Gleason to weld two cranks a year? Smart people hire out what they cannot economically do for themselves and hire good people to do it. Even you chose to purchase complete engines from Tarbil and Shippman. Too bad you didnt leave them alone or you could still be pulling instead of talking about it. Picture of John's machine was to show I am honest, and a joke,,,but then again I never claimed to own a Gleason,, you did,, where is it? So when you showed up at the pulls with Rice and Cane tires on your tractor that was prior to your 3rd hook I take it?

|

Posted By: Ken(MI)

Date Posted: 09 Jul 2013 at 10:14am

| Those are Wards Riverside tires I use for Dead weight at a pull where cut tires aren't allowed Pankey. Something I'm sure you can't fathom, but that tractor pulls on 28's, 36's, 38's, cut and uncut, and steel, deadweight and transfer, 2750# to 4500#, all gears from 1st to 4th, been doing it for ten years now, trophies to prove it and the engine has only been out once to change a clutch. Plenty of witness's also. I must admit that I've never tried rice and cane tires like someone on here posted pictures of. If you ever build anything that makes it one season, I'd be surprised by the looks of your work. Once again, why don't you just give it up and try to learn something here? |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 10:22am

|

Plinky, Read Ken's post very carefully, Hint, read what gears he uses. Ken, Spose plink would cough and spit when he seen you shove the shifter all the way to the right and pull down??? LOL

|

Posted By: Ken(MI)

Date Posted: 09 Jul 2013 at 10:34am

|

|

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 10:53am

|

Better height on tires no front weight rack . What you pull 2750and quit at 3000. Butch you can move shifter to road gear with my engines. I am sure its just not my talent around the entire usa. Last picture proves point looks dont make them pull ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 10:56am

|

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 11:00am

|

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 11:05am

|

Hitch has pulled more in 6000 lbs class than all the hecklers years of pulling combined. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 11:16am

| Someone give it a cookie, Mitch how long has that hitch lasted, cause mine has lasted 63 years pulling and doing field work combined, and I am pretty sure it has lived threw a lot more force than your cob job has in its maybe 5 years of pulling 6000 pound class. Not to mention that a sled gradually puts pressure on the hitch where as doing field works jerks it about with more force edit: I should mention I am second owner of it and knew the previous owner and it was his main tractor for 20 some years and a frequently used backup or secondary tractor when or if his main tractor had the loader on it |

Posted By: mattb

Date Posted: 09 Jul 2013 at 11:16am

| U haven't pulled it lately because all the sleds use the big hook now and theres no way u could get the big hook in there has to be 3 1/2 inch hole. |

Posted By: O.P.S. Heads

Date Posted: 09 Jul 2013 at 6:13pm

|

I don't care for the wheelie bar / drawbar set up in the above photos (not Ken's, the other ones) and here is why: 1 - It appears the wheelie bars and drawbar are tied together or connected in some way. They should be separate pieces. 2 - The third link or whatever was used for the drawbar height adjustment appears to be above the centerline of the rear axle. It should be well below it. There are safety reasons for both examples. Those of you with a little common sense will understand why. And then I'm sure there are those who will argue. This is the stuff that makes it on to You Tube when it fails and makes tractor pulling and those involved in it look bad - not to mention the possibility of someone getting hurt or killed. Use a little thought before building this stuff. Safety first boys. |

Posted By: Butch(OH)

Date Posted: 09 Jul 2013 at 8:24pm

| Nope the adjuster isn't legal for NAPTA and anyone who cant figure out why shouldn't be building hitches. They don't like the wheelie bars attached to the hitch but not strictly forbidden in NAPTA but I have seen it so other places. Just more non-engineered cobbling by the site's smartest person. |

Posted By: LeonR2013

Date Posted: 09 Jul 2013 at 8:54pm

| Dang, have I been doing it wrong all these years by using 100% Argon? Leon R |

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 9:32pm

|

Who pulls with natpa. Heck we want competition not oil and water blowers.yes you.could have better penetration if you use helium. Seen to many of the insides of them ntpa points winners engines no competition from engines with loose sleeves.and water in oil or blowing out stack. Ask larry edmonds about them natpa points winners he bought one hax it a week when be gave me a call wanting to know how to stop the water from getting into oil pan. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 9:36pm

|

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 9:40pm

| Ohh and pank just so you know you can tell a grade 8 bolt by its head and the markings it has, or at least you can if you buy them from a reputable place, you probably just make your own on a piece of equipment you don't actually have, kinda like the Gleason |

Posted By: mlpankey

Date Posted: 09 Jul 2013 at 9:42pm

|

It will hold more wheight hooked to it than kens wheels will. Pulled 6000 lbs alot with that hitch.hitch has ran many of years in kentucky alabama and tn ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 9:49pm

Yeah, 6000 pounds of slow gradually applied weight, that's a lot

|

Posted By: blue924.9

Date Posted: 09 Jul 2013 at 9:58pm

|

Posted By: O.P.S. Heads

Date Posted: 09 Jul 2013 at 10:01pm

|

I really doesn't have to do with the strength of the adjustable link. I'm sure it's strong enough as there is much less pull downward in comparison to the pull rearward. The problem has to do with the location of the top of the adjustable link. Anything above the centerline of the rear axle is incorrect and dangerous. Example #1: If the lower portion of the hitch fails or gets pulled loose from the tractor, then the adjustable link being higher than the axle centerline (still attached to the loose hitch which is still attached to the sled)could potentially pull the tractor over backwards. Then, in this case since the wheelie bars are attached to the broken lower hitch, there now is nothing to keep the tractor from going over backwards. Example #2 When a hitch fails it is typically at the beginning or even more likely at the end of a run just before it spins out. At the end of a run the front wheels are in the air so if a hitch would break at this point it is the equivalent of dumping the clutch heading up a steep hill at full power. Again, if the wheelie bars are attached to the hitch that has just left the scene, then there is nothing to keep the tractor from flipping over. Yes there are some that will say it would never happen, but what if it did. It is certainly two plausible scenarios. If we take time to think of what could happen when building things, then bad things are less likely to happen. |

Posted By: Butch(OH)

Date Posted: 10 Jul 2013 at 6:08am

Good grief slow down, take a deep breath and wipe the tears out of your eyes and the slobber off your mouth. Your like a toddler who just got told to put the cookies back in the cupboard as supper is in the oven. Wheneveryougetallworkedupthewordsallruntogetherlikethis. My post has nothing to do with NATPA other than I used their rule as an example. Other organisations use the same rule and it was formed with sound basis. The reason your hitch is not allowed is if it breaks loose at the bottom the adjusting link then becomes the pulling point and being above the center of the rear tires, or axle as they say it, this means instant back flip before the cutoff cable can work or you can get off the throttle. This is why NATPA and a whole host of other pulling organisations require the adjusting devise to be located BELOW the axle centerline. What this has to do with somebody who has water in the oil you need to further explain as you lost me somewhere? Where is the Gleason?. |

Posted By: wi50

Date Posted: 10 Jul 2013 at 7:45am

|

Usually whenever plink0 gets haggled these threads turn into a 5 gold star rateing. Whatever that means. I wish I had more time to pull up some old info, but plink0's reason for his oil cooler at one time was because he was oil cooling the block also. Seams he couldn't keep the water out of the oil pan. Then he posts using .002" press fit on sleeves, any of you care to guess what .002" press fit will do to a ribbon of material left after boreing the block? Plink0's not as bright as he thought. Not only is his lack of experience showing, but his lack of intelligence is showing. Trying to argue the same point from different angles every few days, not knowing if it's water, oil, what kind of system is used. Ken and Mike would know about gears and gear ratios. One of my favorite plink0 lies is when he was telling me he was running high gear, fast ring and pinion and pulling at 5500 or 6000 pounds. His governor broke and his engine went to 6000 RPM so fast he couldn't pull the throttle back. Do any of you know how fast high gear is in a WD? Well it's very close to 18 to 1, meaning 18 turns of the crankshaft turn the wheels 1 turn. I pull a NTPA Light Super Stock. Many of the tractors in this class also run a gear ratio real close to 18 to 1, some taller, some shorter. Just depends on turbos and how fast the engine is set up to run. But with and 18 to 1 gear ratio and big enough windmills up front, a pretty good cylinder head we can run in the 6000 RPM range also. It's just that we can prove it and have roughly 3000 HP under the hood. At 6200 pounds it takes about 2500 ft lbs of torque to pull it off and the engines may have to build more than 3000 ft lbs when the pan on the sled loads up. That's not even an impressive lie plink0, it's showing lack of intelligence even thinking you can lie like that. By the way, when the tires break and spin even the forced induction engines will climb fast, but usually only a few hundred RPM before the driver can pull the throttle. I love the external balance BS, his flywheel drilled full of holes, OEM CAST flywheel that is. Shoots the 6000RPM story full of holes now doesn't it. And last but not least, lets see some more pics of that oil cooler. I'd like to point out a few flaws in the way that ignition system is set up. Mounting the coil where it's placed is a no no. Running a coil wire that long is asking for trouble on such a "high performance application". The longer the wire, the more the resistance. Trust me, I have to pay attention to those things to keep all the cylinders fireing. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Ken(MI)

Date Posted: 10 Jul 2013 at 7:58am

| You are correct Mitch, helium shielding gas allows better penetration, but on material that is only 1/8" to 1/4" thick, it's really not an issue, especially if a square wave machine is used, and really not much of an issue with a sine wave machine if the operator is any good. I'm not a certified welder, never professed to be, but I 'm confident enough in my skills to not be ashamed either. As for the use of 4th gear, I 'm not sure what you meant about your talent and everyone else in the USA, but, by using 4th gear you remove a gear train from the equation, resulting in more power through the transmission, if a speed limit is not an issue, and you have the ponies to turn it, there is no down side. You should be thanking Marty for helping you out with the pics, these guys on here are really a good bunch if you would just back off and learn to not antagonize everyone with your critical remarks. |

Posted By: wi50

Date Posted: 10 Jul 2013 at 9:04am

|

I found myself a Lincoln square wave 355 machine, made in the mid to later 1990's it's 410 amps of pure power on a single phase line. I don't . I don't have3 phase in the shop but run a home made converter for the mill and lathe. Sure the new inverter machines are fancy and light, but the big Lincoln has the horsepower to do anything and more features than a guy needs or knows how to use. I do some tubeing fabrication. Again nothing fancy, $400 to Pro-tools in Florida for a bender, a few die sets that cost about as much as the bender itself and a notcher. I'll post some pics a bit later iI get a chance. is that AC or DC chicken poo in your pics there plank0? Relax, we don't really care. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Ihateillinoisnazis

Date Posted: 10 Jul 2013 at 9:29am

Haha, I was going to ask how that all aluminum intake was holding at 100 psi TIG welded with Argon... You must have done it wrong Marty :) |

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 10:33am

|

Your correct ken glad you researched helium is for material 3/8 thick. helium and aluminuim welding .now aluminum being a soft material compared to steel how thick is your bars. To address marty yes the post turn into several stars cause one has to weed him and his cheerleaders inexperience posts out. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 10 Jul 2013 at 10:46am

You forgot about the liars,, where is the Gleason??

|

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 10:53am

|

Butch the last aluminum chainsaw piston dome i welded on a 026 the one i traded for a wc on steel that the guy loves to run and cut with i stick welded. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 10 Jul 2013 at 10:55am

That I believe.

|

Posted By: Ihateillinoisnazis

Date Posted: 10 Jul 2013 at 11:04am

I know chineese people who speak better engrish. < intentionally spelled wrong.. than you do. Give up the lies, you are not a value added member to this forum. This thread proves yet again you are a fool with a keyboard. And to the fella who traded a WC for anything you worked on. Talk about no Vaseline, or he must have been dumber than you. I really like when you try to argue engineering with Ken about his wheelie bars... Have you looked at yours?? Classic. |

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 11:05am

|

Yeap pretty much what all thin aluminum tanks get welded with is stick rods ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ken(MI)

Date Posted: 10 Jul 2013 at 11:18am

| Mitch, what does it matter how thick the bars are? if I tell you, it won't be right, and my work will never compare to your wonderfully engineered and built masterpiece, will it? I didn't ahve to research anything, I've been welding since 1971, it may not look like it, but I do have a little knowledge on the subject, and to answer the earlier post, helium is expensive and usually not needed with proper joint design, I do this to earn a living, I don't get a Government paycheck to subsidize when I lose money on a job, and don't spend it when I don't have to. So where is the proof of the Gleason, if your camera is broken, just scan the copy of the invoice with your name on it, we will accept that and I will be the first to apologize. Being a certified welder, why would you weld a piston with a stick welder? just to stay sharp on your skills, so the next time a critical job comes up (say a leg breaks on the cream seperator, the wringer on the wash machine breaks, or a door hinge on your research library (outhouse) breaks, it won't be a problem? |

Posted By: Ken(MI)

Date Posted: 10 Jul 2013 at 11:24am

| I'm wrong again, darn it, I've built one or two oil tanks and TIG welded them, and used argon, but that was only for Indy cars and a couple Champ dirt cars, that must be why we got away with it, Those USAC guys aren't too bright, probably couldn't tell the difference. |

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 11:38am

|

Camera isnt broken i am in edinboro for two weeks. Shops are in tn where i live. One shop is at 727 REYNOLDS BRIDGE RD. The other is 184 STARLETT CIRCLE .but you guys dont believe that so why bother with showing the gleason or the crank grinder or crank press for that matter. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ken(MI)

Date Posted: 10 Jul 2013 at 11:40am

|

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 11:45am

|

Thats what i figured your shop would be. If you critique hard you expect to be critiqued hard. Its all a learning process it just hurts the ones who wears their feelings on their sleeves wich i find is common among the yankees. I guess thats why they curse in every sentence so they can feel big ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: blue924.9

Date Posted: 10 Jul 2013 at 12:09pm

I do believe someone asked for this I do believe someone asked for this

|

Posted By: Ihateillinoisnazis

Date Posted: 10 Jul 2013 at 12:11pm

If you had anything to show for all yur profound knowledge peoeple might believe a word that spews from your mouth. The only thing you have to show for it is p!ss poor workmanship ex: pulley welds, and wheelie bars, and oil cooler, and Blunt axed lightened rims, the list goes on. The other thing you have is a bucket of parts (scrap) that came out of your engine. Oh and that awesome points standing that you keep eluding too.. Did you manage to get those big pistons out through the bottom yet? Post more you our buddies addresses on the Internet to google up. Where's the Gleason..........? |

Posted By: Butch(OH)

Date Posted: 10 Jul 2013 at 12:18pm

|

You right for once Plinky, Its all laid out here over the years for all to see and critique. "You can fool a few people part of the time but you cant fool all of the people all of the time" unknown You have been judged F.O.S.,,,entertainment value only,, Where is the Gleason?? |

Posted By: blue924.9

Date Posted: 10 Jul 2013 at 12:31pm

| If you want to see his other work, including his wheel work check out the thread titled hi comp pistons |

Posted By: mlpankey

Date Posted: 10 Jul 2013 at 6:47pm

|

After i get off vacation i will be assembling a stroker 226 . Other than my friend kurt no one has shown one but me and no one is continuing to show them but me. Eat your heart out . Some play with wheels hitches and paint. Only the hitch has anything to do with pulling. Engine tire cutting and hitchez is what gets one down track. My pictures are out there for the ones who have nothing to sbow something. Thats obviously why so many post them ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ihateillinoisnazis

Date Posted: 10 Jul 2013 at 7:27pm

You pictures might not be but your record is... Remember buddy 100ft short of the competition is not "getting down the track" . That's just a display of what doesn't work. Where's the Gleason? |

Posted By: blue924.9

Date Posted: 10 Jul 2013 at 8:15pm

| You wait pank, my grandma took plenty of pics last sat. And ordered them today, in a weeks time or so I will be able to scan the pics and post them here, I will also be able to post. Videos at some point just haven't figured it out yet |

Posted By: CTuckerNWIL

Date Posted: 10 Jul 2013 at 9:36pm

Is that what they call it in Vols country. I just thought it was hot air or flatulence.  ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: THE-MAN

Date Posted: 10 Jul 2013 at 10:06pm

| Tn medical gas card is like a certif so one can smoke pot right? |

Posted By: blue924.9

Date Posted: 10 Jul 2013 at 10:35pm

|

Posted By: mlpankey

Date Posted: 11 Jul 2013 at 7:04am

|

Picture of the equipment insixe the starlet circle shop have been posted since 2010. The newest sbop i purchased 727 reynolds bridge road hasnt been. The starlet circle has more equipment for engine building than most who jab posts on here. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: TerryMtAuburnIA

Date Posted: 11 Jul 2013 at 8:04am

| bunch of kids playing with toy tracters. |

Posted By: wi50

Date Posted: 11 Jul 2013 at 3:14pm

I've posted all these pics before Ken, but I was in my real early 20's when I built this in the early 2000's. I didn't own a mill or lathe but for 3 hrs, one night a week the local vo tech had an "open shop" night where we could go play on the machines. When I got a little older I bought a lot of shop equipment as I could afford to from machining equipment to a flow bench for doing airflow work.

I knew there was no way stock main caps were going to stay on a block any length of time with a non weighted crank whipping around at high RPM.

I was pretty tight with the $$$ so I used a lot of what was laying around and free. Case oil pump with an Allis cam gear, pickup screen from a broken John Deere pump, GM HEI ignition. Oil filter base and regulater from the dumpster off a burned John Deere engine. Fluid dampner from a small block GM fit to the nose of a Leroi crank. Our rules at the time dictated that I couldn't use a later D-17 type block so I used a W201 block and welded the sleeves top and bottom to keep the deck intact for any of the "outlaw" stuff where a guy could shoot a dose of NOS at it.

I scrapped out a rear axil and used the spindles from a IH combine and built a wide front.

The block is filled, but I run some water in the cylinder head. There's 4 tubes threaded in by the exhaust ports and water fed in front and rear of head. I cut holes in the head where I could blast clean around the intake port and intake valve bowls and filled those areas and cut in a new larger port with a long radius rather than that sharp T shaped port and I built dividers in the intake to cancel out the overlap signals.

Built a twin disc clutch setup and a steel flywheel. A few times the engine would rev to about 6500 RPM mid track. Kept a dumb farm kid busy for a while and still makes a jealous old man out of plink0.

I'll post a few pictures of last winters work building a light super stock when I get more time.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 11 Jul 2013 at 5:08pm

|

Yeap that is the picture of the bottom end that so many are doing and send it to me to be align bored/ honed so the crank will turn in their new main cap s. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Larry W.

Date Posted: 11 Jul 2013 at 5:37pm

| Sure it is pank, what ever you say. |

Posted By: mlpankey

Date Posted: 11 Jul 2013 at 5:47pm

|

Yeap i know a fellow that cnc aluminum to drop the oil pan down so he could run 5 quarts of oil with the stroke he is running. With oil pan in stock location anything over two quarts was a hard ro do. He still uses stock timing gear cover and a stock cast oilpan. I just hang on to drysump stuff myshelf for a stroke as long as his of coarse we all know the 201 small main bearing journal size creates alot more problems with the crank than the d 17 journal size does. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 11 Jul 2013 at 5:52pm

|

You're so good at posting pictures of other peoples work you'll have no problem showing us all those other main setups that you're finishing with your line boreing machine. Make sure to show the Gleason to. ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 11 Jul 2013 at 5:54pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Mrgoodwrench

Date Posted: 11 Jul 2013 at 6:22pm

------------- There are 3 ways to do job GOOD, FAST, CHEAP. YOU MAY CHOOSE 2. If its FAST & CHEAP it won't be GOOD, if it's GOOD & CHEAP it won't be FAST, and if its GOOD & FAST it won't be CHEAP!!!! |

Posted By: Ihateillinoisnazis

Date Posted: 11 Jul 2013 at 8:09pm

|

My lord. WI posts pics of what he had built by hand, which looks really nice btw, and all we get is the village idiot jizzig himself. SpunkO has anyone ever told you to just shut the hell up? It was fun for a while, but now you have proved to everyone how dumb you are and it's just routine lies and b.s. from your keyboard. Oh yeah, where's the Gleason? |

mlpankey wrote:

mlpankey wrote: