Building a Stroker Crank on YT

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=66245

Printed Date: 28 Feb 2026 at 5:10am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Building a Stroker Crank on YT

Posted By: Larry(OH)

Subject: Building a Stroker Crank on YT

Date Posted: 02 Mar 2013 at 8:08pm

|

Not mine, but is this what they all look like while being made? http://www.ytmag.com/cgi-bin/viewit.cgi?bd=pulling&th=179012

------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Replies:

Posted By: wi50

Date Posted: 02 Mar 2013 at 8:27pm

|

Some get welded the other direction, meaning around the crankpin rather than across it as in those pictures. But yes, they are not pretty during the process. Some cranks will have a small pit left in the crankpin where the weld meets the parent material. Doesn't hurt anything. By welding a little further around the crankpin, those bottom welds are gone as it's offset ground in "deeper" during the offset grinding. I'l give a little explanation of the process. Lots of welding, straightning, and more welding and straightnong involved. Typical on a 4 cyl they may weld 1, 2 or 3 crankpins. Straighten and then index off the original un welded crankpin and grind the welded ones oversize, say .100" from finished diameter. Then the last crankpin or crankpins are welded, straighten and index off one of the prior ground pins. Straighten again after roughing in and then ready for the final grind. Carbon plugs are used to fill the oil passage during welding. My sd card isn't working on my phone so I can't take pics right now but when I get it fixed I'll post some pictures for you. I like to see some welding on the bottom of the crankpin blending it into the throw. It's extra work but most of the strength in the crank is in that area. By filling it and tapering it to the crankpin the crank is much stronger when done. In the first pic there you see that welding done so after roughing in they can taper the throw to the crankpin. It's more work but makes for a better product when done. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Larry(OH)

Date Posted: 03 Mar 2013 at 6:06am

|

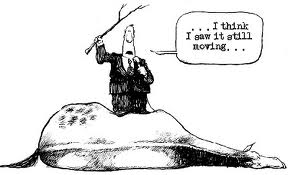

I guess just never seeing the process, it looked like Ray Charles was welding on it. I'd like to see the finished product for sure. THanks for the info ------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Posted By: DougG

Date Posted: 03 Mar 2013 at 6:12am

| How do they stay straight??? Thats looks like a very rough process! |

Posted By: wi50

Date Posted: 03 Mar 2013 at 6:57am

|

There's prettier ways to do it. They don't stay straight. They get straightened several times, after first welding before rough grinding. After second welding before rough grinding. That's why through the process the crankpins are roughtd in to say .100" over finished size. The crank will get bent straight before grinding but sometimes move around during the grinding also and get straightened again. Heating the crank will hrlp to "normalize" after welding. The crank press and cold chisel are never far away. Each time the crank is straightened, it's placed on V blocks and beat or pressed straight with a dial indicator on the mains. That's also why the whole welding process isn't done at once, to keep say the rear and center main straight to refrence off from to straighten the front. Grind then do thr rear. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 03 Mar 2013 at 7:06am

|

That's why it's about $200 per cylinder typically to weld and offset a crank. It really doesn't matter if they weld a little or a lot. The welding isn't that much work difference from a little welding to a lot, but the rest of it is the same. Then let it chung away offset in the grinder doing an interrupted cut and it's hard on grinder ways and stones compared to grinding concentric. With the time and materials involved, welding and strokeing cranks is about the least profitable jobs for a machine shop. Don't complain about the price. Of they were reconditioning heads or boreing blocks they'd make 4x the money at the end of the day. One thing I should add is that I say "index" off from a crankpin. Sometimes the stroke gets moved far enough that thr oil passage can be exposed on the bottom side of a crankpin. To avoide this, the welding is done to a different angle, or "clocked" differently on the crankpin meaning that rather thAn going straight "up" it may be moved to the side just a bit. Index, change rotation a bit and then grind. Then grind other crankpins according to the first one. The timeing marks on the crank gear will have no value once this is done. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Rod B

Date Posted: 03 Mar 2013 at 8:36am

|

http://ytforums.ytmag.com/viewtopic.php?t=701577&start=0&postdays=0&postorder=asc&highlight=stroker+crank" rel="nofollow - http://ytforums.ytmag.com/viewtopic.php?t=701577&start=0&postdays=0&postorder=asc&highlight=stroker+crank Also on YT and might help prevent a future outburst from the most quoted forum member and his storybook shop. ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: Mrgoodwrench

Date Posted: 03 Mar 2013 at 8:42am

|

i've been waiting for the "keyboard commando" to tell us it is ugly because they used the wrong kind of welder ------------- There are 3 ways to do job GOOD, FAST, CHEAP. YOU MAY CHOOSE 2. If its FAST & CHEAP it won't be GOOD, if it's GOOD & CHEAP it won't be FAST, and if its GOOD & FAST it won't be CHEAP!!!! |

Posted By: Larry(OH)

Date Posted: 03 Mar 2013 at 8:50am

|

I didnt post this for all that BS........

------------- '40 WC puller, '65 770 Ollie *ALLIS EXPRESS contact* I can explain it to you, BUT I cannot understand it for you!! |

Posted By: Gary in da UP

Date Posted: 03 Mar 2013 at 9:20am

| Not exactly on topic, but my question for Marty is, is there ever a need to weld up the crank nose and install a harmoic balancer rather than using the stock front pulley? would this ease some stressess , or contribute anything to smoother rotation, better balance? thanks, Gary |

Posted By: wi50

Date Posted: 03 Mar 2013 at 9:36am

|

Of course it would help. But will it help enough at say 2000 rpm to be worth the effort? A dampner would help, but verry little. I turned the nose down and cut a keyway on my cranks to run a fluid damper from a SBC for my high rpm Allis engines but never worry about it on a low speed stroker. Not relevant to the topic much but look at just about all modern diesels have a damper. Ones modified to run high rpm run verry largr fluid dampers. Diesel ignition is brutal on crankshafts. Then look at the ones like in our alky superstock with counterweights added, less impact from the ignition and we don't have to run any damper at all, just drive pulleys for fuel and oil system and ignition trigger. Even a stock diesel will break the crank nose off if the dampner fails or is removed. I used a JD 4450 for one of the bailers and the air cond belt went out, the damper had slid apart seperating at the rubber ring. I had to go in a hurry with the tractor so I idled it to the shop, cut the outer ring off and see. By 1800 rpm I thought the crank was going to come apart so needless to say I switched tractors for a day untill I had time to put a new dampner on. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: AC200Puller

Date Posted: 03 Mar 2013 at 7:28pm

| Excellent information guys! really enjoy reading these and trying to learn a few pointers. Keep up the good work! |

Posted By: cms

Date Posted: 03 Mar 2013 at 7:47pm

| I never straighten a crankshaft cold it will create cracks and break. I always weld up the mains and grind straight and weld all rods to tie the weld meat and crank metal together. |

Posted By: wi50

Date Posted: 03 Mar 2013 at 8:44pm

|

Just curious if you grind the mains undersize before welding them? I've heard various opinions on welding them. I've heard of some roughing the crankpins in undersize and then welding all the way around them before a final grid, but that seams like a lot more work for no reason, other than if the forging has some issues in the first place. Some guys want heat on the crank, to straighten and I've heard some guys don't want to press them but cold hammer them. I just had a Leroi crank done and that crank had some pits in the parent metal, no welding on the mains but grinding exposed some in the thrust surface as well as a few other areas so it took a bit of tig welding to fix. The forging just wasn't the nicest one. What do you think of welding a crack in the front main of a 226 Allis crank where it meets the throw? I've had a few of them cracked there and I just welded one for a low hp engine.......we'll see if it works out. Everyone I asked for more opinions said the same thing. It'll work. A friend broke a MM crank in the front main, welded with a draw bolt through and never failed after that, it was one of those deals where there was to much in it to throw awayand he wasn't out much to try it. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 04 Mar 2013 at 7:47am

|

submerged arc is alot better .gleason two wire welders the best .weld the mains grind them down to size a press will get them somewhat straight but the crank grinder gets them true . when putting a balancer on the snout the weight of the balancer and distance (raidus) can put alot of extra weight on the snout at rpm. I submitted the formula and said one should add it to their notebook back a few posts ago. A harmonic dampner if used should be as small a diameter as it can and the lightest possible. The reason they are cracking wi is your using a welding rod with to hard a rockwell rating . go to a 40 rockwell so the crank can flex and use the 56 rockwell on the journal itself. Then balance the crank and the main caps well love you and stay in it without breaking from a crank thats trying to jump out of them from being imbalance. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Glockhead SWMI

Date Posted: 04 Mar 2013 at 8:05am

| here we go.... |

Posted By: wi50

Date Posted: 04 Mar 2013 at 8:10am

I didn't know that bone stock take out cranks from a WD-45 were welded with to hard of wire from Allis? Did any of you know that?.......

Mine have not been welded, just take out ones. I've been unlucky and have had 3 cracked ones over the years on parts engines. 2 of them were junk, but I welded one to revive it for a restoration project.

As far as the broken MM crank example above, it broke in the front main when it suffered an impact from another (unrelated) failure. Several cranks and crank cases had failed untill it got counterweighted and the problems dissapeared (immagine that) Then it reved hard enough to make some other problems. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 04 Mar 2013 at 8:13am

Nah, he didn't have any idea what he was trying to talk about anyway... stock take out cranks with cracked front throw. Same as anyone elses.

At least this week he doesn't claim to be a crank welder, have a Gleason. Rod's link pretty well should keep the BS out. There's more links from Speedtalk also where he uses a crank shop that has a bad reputation and went out of business......

Behave spankey and save the BS and the drama. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 04 Mar 2013 at 8:56am

|

they are the ones who taught me the ins and outs of crankshafts. Also his reputatio on his work was good but he was alot like you and lies . Well he just lies about turnaround time you on the other hand lie about everything that pertains to me. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 04 Mar 2013 at 8:58am

|

Now we also see why wi has been going through the deal to add counterweights by his own admission of having crank problems he is looking for answeres . ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ihateillinoisnazis

Date Posted: 04 Mar 2013 at 10:11am

| Spunky, for once I thought this was going to be a good post WITHOUT your drama. You don't know anything, you bring no added value to the forum, stfu and go elsewhere. |

Posted By: Ihateillinoisnazis

Date Posted: 04 Mar 2013 at 10:14am

Where did Wi say he had crank problems?? He said he REPAIRED a MM crank. The definition of repaired is: to fix or mend. Reading comprehension, try it sometime. |

Posted By: WildBill

Date Posted: 04 Mar 2013 at 1:51pm

|

Panky its called sharing ideas ! not Looking for answers ? in a (team) members share ideas to complete a task. TRY IT SOMETIME !! ------------- Allis fan for life ! B,C,2-WC'S,WD45G,D19G,190xt ,LLSS 8010, terra tiger refurbished |

Posted By: WildBill

Date Posted: 04 Mar 2013 at 1:52pm

|

LARRY GREAT POST AND GOOD TOPIC OF IDEAS .. THANKS ------------- Allis fan for life ! B,C,2-WC'S,WD45G,D19G,190xt ,LLSS 8010, terra tiger refurbished |

Posted By: mlpankey

Date Posted: 04 Mar 2013 at 2:47pm

|

[QUOTE=WildBill] <FONT style=": #000000">Panky its called sharing ideas ! not Looking for answers ? in a (team) members share ideas to complete a task. TRY IT SOMETIME !! [/QUOTEi shared info with allis team as why members crank is breaking] l------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 04 Mar 2013 at 8:42pm

|

How would cracked core engine cranks have anything to do with someone's skills as an engine builder? Why is pankey a crank expert when he's looking for someone to do his crank work for him after breaking a few? The timeline of events and his story do not add up. Lies never make sense. http://speedtalk.com/forum/viewtopic.php?f=1&t=22323&start=15" rel="nofollow - http://speedtalk.com/forum/viewtopic.php?f=1&t=22323&start=15 ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 1:20pm

|

look at the date of post look at the date i posted last crank breaking . It is still flattering that you and wi follow me on all the forums it is a good way for you two to pickup your knowledge in building engines but if one cant seam to find the finer details like dates of post i really think clearance and other fine points would blow right by them in a build also. if you look at yt pulling forum you will see where i purchased one of the shops in july of 11 i believe may be 12 either way post was july 2010 ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 05 Mar 2013 at 4:11pm

|

In this age of modern technology why don't you set up a video camera and make us a short condensed video of you welding and grinding crankshafts in your shop? ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: Ihateillinoisnazis

Date Posted: 05 Mar 2013 at 5:19pm

If his video skills are anything like his welding skills, or typing skills, or being able to remember last weeks lie..... Oh My.

|

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 5:56pm

|

I have some video from the balancing class you guys missed. I will try to post them soon. I know some will be mad rhey didnt come to it and some will come just watching the video ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 6:15pm

|

http://s738.beta.photobucket.com/user/pankeyc/media/2013-03-05_17-59-36_317_zps27bed708.mp4.html" rel="nofollow - http://s738.beta.photobucket.com/user/pankeyc/media/2013-03-05_17-59-36_317_zps27bed708.mp4.html

http://i738.photobucket.com/albums/xx26/pankeyc/2013-03-05_17-59-36_317_zps27bed708.mp4" rel="nofollow">  ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 6:17pm

http://i738.photobucket.com/albums/xx26/pankeyc/2013-03-05_17-48-34_811_zps5d9df3aa.mp4" rel="nofollow"> ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 6:50pm

|

you guys wishing you had payed to attend class yet . i have seen ole butchy and nazi viewing they must be speechless from swalling their tongue . ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 05 Mar 2013 at 7:07pm

|

Actually I was viewing this pic on your album and having a chuckle. How anyone could post this mess of a cooler install and actually be proud of it was when I decided you would never touch anything I own and also when I started to really pay attention to your posts and found out your not half FOS,,,, your are totally FOS.

A two year old can push a switch and spin a crank, Your engine lasted 5 runs and was 100 feet behind the winners. Quite the expert you are. Pankys plumbing for hire, cal BR 549  |

Posted By: JayIN

Date Posted: 05 Mar 2013 at 7:07pm

|

Swalling their tongue! !!!! Har har ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 7:11pm

|

Butchy it was a mockup installation to see if it would work. It did bradded lines and fittings followed. Some of you guys wouldnt know why the in and outlets are oriented to the top. Theres a reason. Lets here it.maybe someone can impress me if they can give the correct answer. Butch you impreased so mutch you checking them all out. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 05 Mar 2013 at 7:31pm

|

Oh Mitchy, you are so FOS, here is the link to the original thread on this site for all to see.

http://www.allischalmers.com/forum/forum_posts.asp?TID=15031&KW=oil+cooler&title=ugly-but-oil-cooler-is-functional" rel="nofollow - http://www.allischalmers.com/forum/forum_posts.asp?TID=15031&KW=oil+cooler&title=ugly-but-oil-cooler-is-functional Next time here are some hints.

We use line benders in our shop instead of rocks, then you can get close bends without kinks Oh and listen there are also fittings that have bends in them for differant angles but they take wrenches, do you own any or just Vise Grips?

Looks like chit, turned out was chit, ran 5 times, finished middle of pak and blew up and now you are keyboard commando expert who follows WI50 around like a window peekiing wierdo. And now you also sit and watch who looks at the threads you post on? Like good grief, you really need a life Pank.

|

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 7:39pm

|

Long radius bends have less friction loss. If i remember right you were one od the experts that said the oil filter wouls blow ocf of it with the series one oil pump in a series two block.i am sure you can find it i fhink it was titlex it aint pretty but its functional. It would have been around 2010. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 7:41pm

|

Lets stay with cranks after all thats the topic. I know you all like to change the topic when. You fealizae your wrong but we shoild stay on topic so i cans scotchbrite your rears some ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 05 Mar 2013 at 7:44pm

No reply intended, just saved before he edits for all to get a giggle. Lets do stay with cranks, that can be agreed upon.

|

Posted By: Ihateillinoisnazis

Date Posted: 05 Mar 2013 at 7:46pm

|

LOL Spunky went out of his way to PM me this " a video of us in action ihas been posted on the stroker crank yt topic . i know it will make you come all over your shoes" No Spunky, I was looking at your collection of  chain saws and admired the blue homelite. I remember throwing one of them away as fast as the neighbor gave it to me haha. chain saws and admired the blue homelite. I remember throwing one of them away as fast as the neighbor gave it to me haha. As for the crank balancing video... Yeah you spun up a crank... whoopdeefuggingdoo!! And I couldn't get over your "Purosity" test <<-- I know Spunky spelling. We yall spell like we talllk. Slow and STOOPID never won the race spunk.

|

Posted By: Hoss

Date Posted: 05 Mar 2013 at 7:47pm

------------- I got both ends meetin in the middle but I can't seem to get em tied. |

Posted By: mlpankey

Date Posted: 05 Mar 2013 at 8:03pm

|

See now changing subject to spelling. Scotchbrites working .chafing well. If you had pajd and attended skool you woulx have been told hos machine worx but you didnt so you lost ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Glockhead SWMI

Date Posted: 05 Mar 2013 at 8:33pm

| Geesh. Spanks must be drunk. fealizae? shoiled? You edit every post anyway. Spell check! Punctuation. You think your smarter than everyone and can't even spell. That is just icing on the cake for why nobody takes you serious. Get to the shop, build something, have fun. That's what its about. |

Posted By: patrickmull

Date Posted: 05 Mar 2013 at 8:38pm

| dufe doo |

Posted By: Rod B

Date Posted: 06 Mar 2013 at 7:49am

|

I'm still laughin. I asked for a video of you crank welding and grinding. The kind of stuff that happens on precision machines. A monkey can hit a crank with a hammer and flip a switch on and off on someone's balancer. ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 8:05am

|

The balance video was for the school you missed and if you had attended you would know that the video shows the exact heavy spot that is causing the imbalance.Rod i laugh at you cause you cant even produce a video of anything meaning you dont even have access to let alone own.. it takes more than a socket rachet and plastigauge to be a engine builder. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 8:13am

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 06 Mar 2013 at 8:22am

|

You picked the crank up behind the front main. Wouldn't matter if it was cracked by the way you were holding it. A little education would do you good. ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 8:31am

|

For thw ignorant like rod the cra.k ringing through like atuning fork shows two things one its not crackes two ita not got bad qelds full of purosity. When either occurs the crank will thud.and not eing through.this is even a good technique to use when buying forged cores from a junkyard. You walk away knowing wither they are cracked..your free lesson for the month It takes more than plastigauge and wrencbes in a outbuilding for me to considee one a engine builder. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 06 Mar 2013 at 8:34am

So you're sore you bought a bad crank. You should be ashamed that you sold it to Kendak. Ashamed for lying claiming you had a Gleason and crank grinder. ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 8:59am

|

I never bought a bad crank I am trying to tell the monkeys how to tell. I know its a stride but i think the monkeys will know the difference in a crank and a banana but the verdict isnt in on rod yet. I would bet on the monkey before i would rod. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 9:06am

|

Larry in ohio knows more about cranks than several of the posters crom wisconsin. He picked it right. His gut told him the crank weld from yt was junk from the start.one thing you learn from this site is which experts to trust and to walk away from all experts lo ated in wisconsin and promote themshelves on this site. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ihateillinoisnazis

Date Posted: 06 Mar 2013 at 9:07am

This, this is why you're an idiot. Can anyone understand this jibberish? |

Posted By: Rod B

Date Posted: 06 Mar 2013 at 9:08am

Says right here it was full of cracks. Cracks aren't bad? Or you made it yourself? I know you don't do well with multipal choice. But this one's easy. http://ytforums.ytmag.com/viewtopic.php?t=388223&start=0&postdays=0&postorder=asc&highlight=used+lessons" rel="nofollow - http://ytforums.ytmag.com/viewtopic.php?t=388223&start=0&postdays=0&postorder=asc&highlight=used+lessons ------------- for the money there is nothing better than provoking idiots and posers |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 9:18am

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Glockhead SWMI

Date Posted: 06 Mar 2013 at 10:00am

| Gibberish. |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 10:11am

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: unstylish_

Date Posted: 06 Mar 2013 at 10:17am

|

Is that y you ran the guy down on yt that you bought it from ? Cause it was blown? When you just said you knew it was blown? Again, you are a liar. You didn't couldn't post anything till just now, and with no verification. You didn't have anything they entire time you ran your mouth. You are nothing more than a chicken $ hit poster who only plays a sure thing because you are lacking so badly ------------- Arguing with mlpankey is very much like arguing with a woman. Only you can teach a woman after a while. |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 10:29am

|

I knew he was lucky just needed to buy his engjne to prove it. When i purchased his junk all doubt of it being anything but luck was removed.the only chicken poster on here is pictured on this site showing everyone he is number one but confused on where his index finger is located . ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Glockhead SWMI

Date Posted: 06 Mar 2013 at 11:53am

| The language you speak is five year old. My daughter spells better. Post any videos yet of you at a pull? Your so successful but you have no proof? Sounds fishy. |

Posted By: mlpankey

Date Posted: 06 Mar 2013 at 11:58am

|

Even rod has posted my finishes.be post some of the worst but that pretty well makes the only thing fishy being your crotch. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Ihateillinoisnazis

Date Posted: 06 Mar 2013 at 12:03pm

Lol you bought his engine to prove he was lucky.... Lol what a fairy tale! |

Posted By: Glockhead SWMI

Date Posted: 06 Mar 2013 at 12:07pm

| Good one Spanks, fishy crotch. This reminds me of the saying about arguing on the internet.... How did I get here anyway? |

Posted By: unstylish_

Date Posted: 06 Mar 2013 at 12:25pm

|

What am I chicken of? I work on my own stuff, post photos, actually pull, help others, work on alot of other peoples stuff ( up here ) , provide dyno time, oh and get along with just about everyone. You can't even come UP with someone on here or yt that WONT just laugh and roll their eyes at you. Again, i don't pull much at the natpa events, but I attend. There, and at pulls all thru Michigan i go to, you are regarded as a complete f@cktard amongst the pullers. Its your own fault no one likes you..... ------------- Arguing with mlpankey is very much like arguing with a woman. Only you can teach a woman after a while. |

mlpankey wrote:

mlpankey wrote: