Starting reassembly of my G engine

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=44968

Printed Date: 11 Sep 2025 at 5:17pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Starting reassembly of my G engine

Posted By: Warren(Oh)

Subject: Starting reassembly of my G engine

Date Posted: 04 Feb 2012 at 8:00am

|

Figure I might as well start another thread for putting it together. Crank ground, bearings in hand, need to go to post office and then get some STP to put it together with.

I just pulled the oil pump off to make sure there wasn't a bunch of gunk in it. No gunk, it's nice and clean BUT the gears are grooved about like the # 1 rod journal was. .025 feeler gauge fits between the gear teeth ! It had good pressure when it ran last summer, granted the gauge needle was waving from high to low like a fan, bearing gap opening and closing. I can't believe whatever got in and did the damage was done while I owned it, so it should be long gone.

Understandably, for what I just put in bearings, putting it together with this pump would not be wise unless, someone that knows, says that gap is acceptable. Pumps on ebay ain't cheap, either, for no more than they amount to ! Have to see what dealers have for prices.

Off to the PO !

|

Replies:

Posted By: SteveM C/IL

Date Posted: 04 Feb 2012 at 9:43am

| I's not the clearence between gears.It's the clearence between the gear and the housing that counts as well as end play. Can't make pressure when it can leak around end or sides. |

Posted By: Warren(Oh)

Date Posted: 04 Feb 2012 at 10:29am

|

Thanks, Steve, There is no clearence between the gears and housing. I doubt I could poke the smallest feeler gauge in there, so I'm gonna say it'll work fine. Everything else is tight, putting it back together !

Well, maybe not that tight but it's plenty tight ! Oh, STP is like really slick honey and it stinks ! but it certainly ought to do a good job.

|

Posted By: CTuckerNWIL

Date Posted: 04 Feb 2012 at 11:19am

|

There has to be clearance between the gears and the end plate, maybe .002-.003. If you replace the gasket, make sure you use the proper thickness.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Warren(Oh)

Date Posted: 04 Feb 2012 at 12:23pm

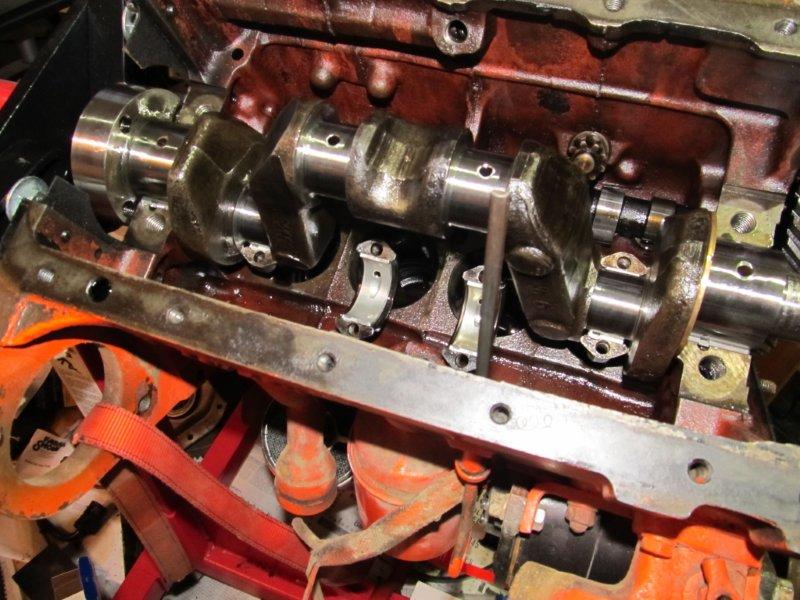

Figure I'd better get a picture before I forget. Just set the crank in place, in #1 and #4 rod, still got to rotate it to catch 2 and 3. Sure moves slick now ! Probably ought to get the other thrust bearing on, I guess...

Infernal thrust bearings and shims ! Still might not be right...

|

Posted By: Tracy Martin TN

Date Posted: 04 Feb 2012 at 5:24pm

| Warren, the thrust washer clearance is pretty time consuming to say the least. If you measure the shoulder on crankshaft from end to thrust surface. Note this dimension. Measure the main journal on block, and the cap thickness. They should be close to the same. Add this average highest reading to the thrust washers. Subract the crankshaft shoulder length from the caps and washers dimension, add a minimum of .003 to that. That will be the minimum thickness of shim or shim pack for correct clearance. Since everything won't be perfectly square and flat, you will probably have to add mor shim to allow for proper fit. I made me a spacer that takes the place of crankshaft gear and pulley hub. These press directlly on steel thrust plate that rides against fixed thrust washer. Makes it easier to get fit and quicker not having to press or pull pulley off each time if not correct. If you go around washers try to get a minimum clearance of .003. It will vary up from there. Once you start this it will be clearer to understand. Not saying you don't know how, but this works pretty well for me. Let us know how it goes. Tracy Martin |

Posted By: Warren(Oh)

Date Posted: 04 Feb 2012 at 5:40pm

|

"Not saying you don't know how"

No, I don't know how ! Basically winging it here ! It can't be far from right, I had everything tight and could turn it with the hand crank. Stiff but turnable. It turned so easy before, I don't know how hard it should be to turn ! If not for the compression it would likely turn quite easy. Guess I should pull the plugs, huh...

|

Posted By: Ted in NE-OH

Date Posted: 04 Feb 2012 at 5:59pm

|

For the oil guage , if you have an OEM guage with the small orfice it won't jump around. ------------- CA, WD, C, 3 Bs, 2 Gs, WC, I-400, 914 |

Posted By: Tracy Martin TN

Date Posted: 04 Feb 2012 at 6:04pm

| Warren, did you put new pistons and rings in it? They certainly will cause some drag. Your bearings will roll pretty smoothly if correct. I use assembly lube on everything. Be clean an be patient. HTH Tracy Martin |

Posted By: Warren(Oh)

Date Posted: 04 Feb 2012 at 6:19pm

|

Only doing the bottom end, plenty of compression. STP for assembly lube. Roll of paper towels later, it better be clean !

With the gap that was in the rod bearings, I figured that was the reason behind the erratic gauge.

|

Posted By: Gordy

Date Posted: 04 Feb 2012 at 8:05pm

|

I really like the

assembly lube from NAPA for new bearings and also use it on the cylinder walls cranks much easier than with anything else I have used for starting first time. |

Posted By: Warren(Oh)

Date Posted: 09 Feb 2012 at 7:34am

|

Got the day off so back to the N62. Cleaned the oil pan and bolts. Found something neat in the bolts ! Looks like someone had the forethought to cut slots in the heads of the 3 front pan bolts. 3 longer regular bolts must have been in the rear three holes. The rest must be original bolts as the washer won't come off, easily anyway.  |

Posted By: Warren(Oh)

Date Posted: 10 Feb 2012 at 9:29am

|

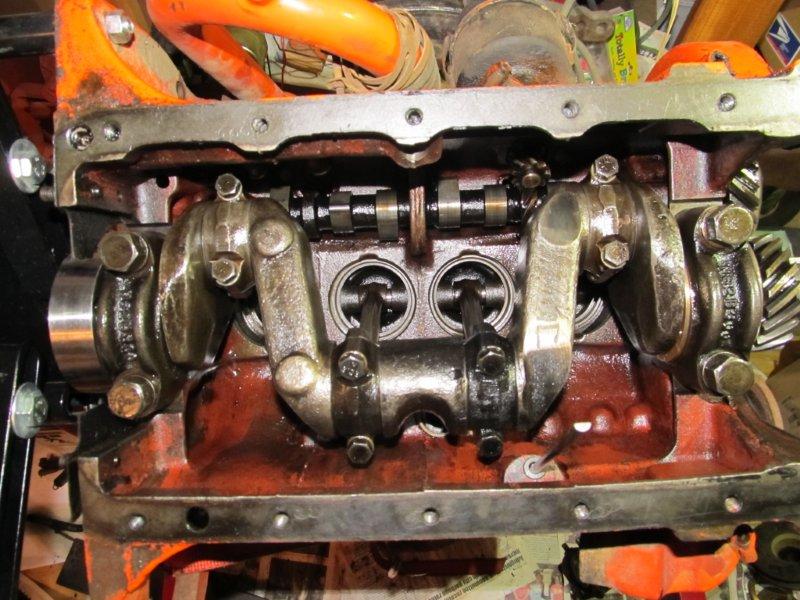

Third times a charm, maybe.

Well, it's ready to move out.  Just hanging loose

Anyone know if there is a particular torgue for the flywheel bolts ?

|

Posted By: Warren(Oh)

Date Posted: 10 Feb 2012 at 11:16am

On a good note, I now know I can lift and set down a complete G engine....

|

Posted By: Warren(Oh)

Date Posted: 10 Feb 2012 at 12:31pm

Back where it belongs. I did bend the throttle rod but that shouldn't be to bad to fix.

|

Posted By: Chalmersbob

Date Posted: 10 Feb 2012 at 10:16pm

|

Warren

lOOKIN GOOD.

I didn't get the head on mine yet.

Had to do brakes and some other repairs and a little paint.

I'm still not happy with the way it shifts, but there isn't any fluid in it yet.

Maybe it will shift better once I fill the tranny. I drained it 8 years ago, right after I bought it. It's been sitting since then. I have the engine rebored and a valve job done on it. Bob

|

Posted By: Warren(Oh)

Date Posted: 11 Feb 2012 at 6:51am

|

You get some oil in the tranny and it should shift better but they don't shift all that great anyway, I don't think. I have trouble with mine occassionally and I remember Grandpa did. Just don't force it.

I should pull the axles off mine and check the seals. Actually, when I had them off, I didn't there were any seals but after seeing the thread here on the forum, I guess they do. When I park on a hillside, oil leaks out !

I don't think I'll be doing much on it today, see picture (reason 1). 18 degrees (reason 2). After picking the engine up twice yesterday, I'm in pain ! (reason 3!)

|