How to Make an AC Haybine Sickle

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=44916

Printed Date: 02 Mar 2026 at 9:03pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: How to Make an AC Haybine Sickle

Posted By: Michael (WI)

Subject: How to Make an AC Haybine Sickle

Date Posted: 02 Feb 2012 at 10:42pm

|

Last year while cleaning out the shed I came across some old JD 1209/1219 sickles and I had an idea. I already knew that JD sickle sections had the same key dimensions as AC sections. But, when I started looking at the backing bar on the old sickles it seemed similar as well. After some measuring I found it had the same cross sectional size. Furthermore AGCO seems to have recently discontinued sickle bars for the AC haybines so the idea was born to convert a JD sickle to an AC sickle. For my trial run I started with a near new Fleet Farm (JD) sickle that had a bad head, but all the pictures you will see are of the second bar I made with a brand new bar from JD. I would have liked to save the money and buy another Fleet Farm bar but Fleet Farm did not carry a riveted over-serrated bar. In case you are curious I ended up changing all the sections on the Fleet Farm bar to over-serrated after converting it. For those who know, or as the pictures show, JD bars have a 1 1/2 section on the end of the sickle while AC has a 1/2 section and the rivet holes do not line up between the two on the backing bar.  Also, the drive end on a JD sickle has a dummy 1/2 section which makes the rivet holes on that end not line up.

Thus if one started from either end on a JD sickle all the sections would become mis-aligned. Luckily, JD backing bars are several inches longer than an AC bar so with cutting the proper amount off of each end of the backing bar one is able to re-align the sections. I briefly entertained the idea of making a small side business of making bars but time is short and shipping on a 10' item is cost prohibitive so below is the procedure to convert the bars. Hopefully this will help some people like me keep these old machines running a bit longer.

First line up both bars so the first full section from the non-drive end line up, then flip the bars over and you will get an idea of what needs to be cut off the JD bars.    Next, remove the drive head from one end and the 1 1/2 secition from the other end of the JD bar. Re-aign the bars and mark both ends of the JD backing bar for cutting.

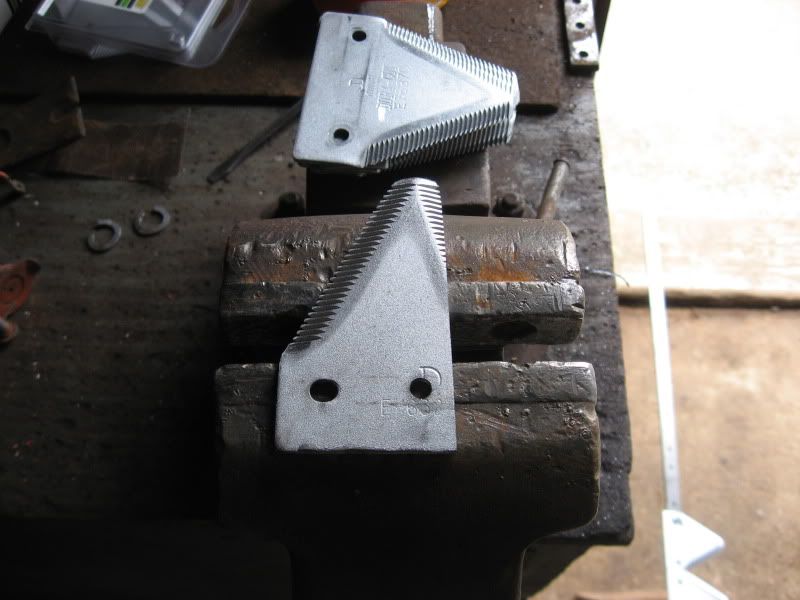

Then, take the JD 1 1/2 end section, place the AC 1/2 section on top and mark the JD section to cut it down. After doing this put the AC section back on top and mark the JD section for a new second rivet hole.   After cutting the non-drive end of the backer bar it will then have to be drilled for the corresponding second rivet hole.

The drive end of the backer bar needs to be simply cut to length and no more needs to be done. The last step is to rivet the 1/2 section on the non-drive end of the backer bar and rivet your salvaged AC drive head on the JD bar along with the sections removed while taking the JD head off.  Ignore the extra rivet hole in this AC head from the salvage yard as someone tried to scab it on a JD cutter bar already with out cutting off the end of the backer bar to re-align the sections. Because of this the rivet holes were not lining up do the 1/2 dummy section so they drilled an extra hole in the AC head, not properly centered to boot.

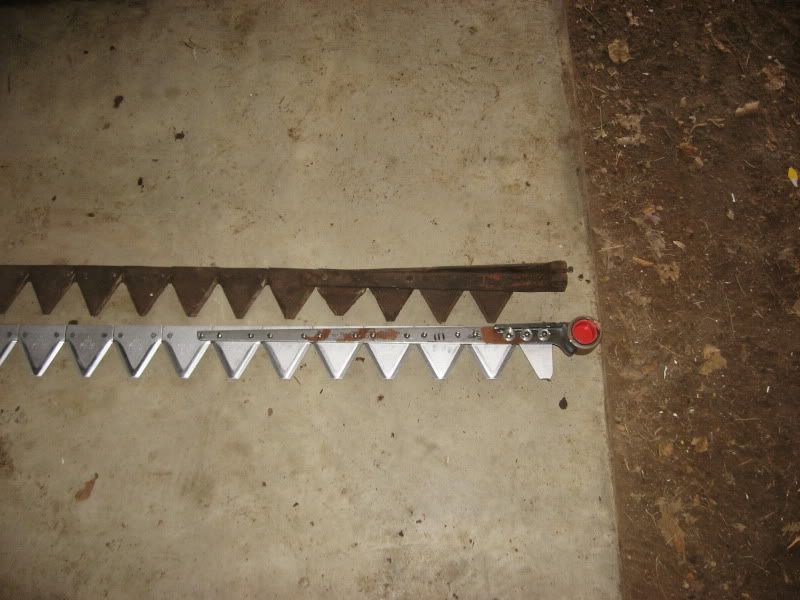

Below is the finished product.

In my case I simply wanted extra sickles on hand so if I break a section I can just switch bars in the field rather than try and replace the section with the bar in the machine or drive home and pull the bar. Because of this I needed extra AC heads. AGCO does still service that part but it is a bit pricey, I was able to get one from a salvage yard for half the price. I just blasted and repainted it before installing it in the sickle bar. Below should be the link to my album, to see all the pictures. Hopefully this will be of use to someone. http://s29.photobucket.com/albums/c261/pappathopoulosm/Haybine%20Sickle/" rel="nofollow - http://s29.photobucket.com/albums/c261/pappathopoulosm/Haybine%20Sickle/

|

Replies:

Posted By: HagerAC

Date Posted: 03 Feb 2012 at 2:14am

|

Our 5 foot on our AC C has a 1.5 section on the end. ------------- 30+ A-Cs ranging from a 1928 20-35, to a 1984 8070FWA, Gleaner R52 |

Posted By: old farmer

Date Posted: 03 Feb 2012 at 8:08am

|

If you want to make it easier yet, go to bolt on section knife. Makes it SO much easier to change section in field WITH OUT pulling knife from unit. Might have to lossen one or to guards or move knife one way or the other to make things a little handier. |

Posted By: SHAMELESS

Date Posted: 03 Feb 2012 at 12:31pm

| i have been trying to change heads on an old to new sickle for....well along time!! those are the hardest rivets i've ever come across!! grind the heads off, try to punch out the remainder, that didn't work, tried drilling them out, that ain't work'in either!! any ideas?? |

Posted By: Michael (WI)

Date Posted: 03 Feb 2012 at 1:49pm

|

I briefly entertained the idea of going to bolted sections but decided against for two reasons. First, I was unsure if the guard and hold-down clips had clearance for bolts. Secondly, I am what some call "old school" and take satisfaction in a job well done doing something with older tools and methods. Don't get me wrong, I have worked with bolts before on a 14' haybine and am glad I did not have to pull the 1/2 sickle out of that machine. Working with rivets just brings back memories of watching my uncle do it when I was younger.

When it comes to removing riveted sections I just place the backing bar on the long edge of the anvil with sections pointing down hanging over the long side of the anvil. Then just take a few good swings at the back edge of the section and shear the rivets right off, then punch what's left out of the backing bar. It does get a little more tricky by the drive head since not much of the section back sticks out past the head. About the best method I have found for removing the entire drive head is grinding the heads of the rivets flush on the bottom of the sickle. Then, drive a chisel or prybar in between the head and sections one at a time and it will pry apart. If you are just replacing one section held under the drive head sometimes the only way is to grind the rivet flush and drill just under the rivet size and drive out the remains.

|

Posted By: LionelinKY

Date Posted: 03 Feb 2012 at 2:03pm

|

Dad had a special tool for replacing riveted sections on the NH haybine. One end punched out the old rivets and the other end smashed the new rivet end. You used a socket wrench on both ends for power. It was designed to work with the sickle bar still in the haybine. No removing guards or anything. Worked very well-could change a broken knife out in minutes without pulling whole cutter bar out. The only time we had to pull cutter bar out was to replace bushing in the end when it failed. ------------- "My name is Lionel and I'm an Allisoholic" |

Posted By: SHAMELESS

Date Posted: 04 Feb 2012 at 3:15am

| Lionel...i have that tool you mentioned too...that won't even punch the old rivets outta my sicle!! i have used that tool 100's of times and it never failed me until now!! Michael...all you have to do is buy the higher guides for the bolt on sections...they sure are easier to replace, but you have to have just the right torque on them or they will either break or come loose! also some guards are to small or to short to use the bolt ons. but they can be changed to! alot of dealers will tell you that won't work...but they will sell you a high priced version of it! it will work...have done it for years! |

Posted By: GBACBFan

Date Posted: 04 Feb 2012 at 8:10am

|

Another excellent, detailed how-to post on keeping old orange equipment run better and longer. That's good stuff, Michael. ------------- "The trouble with quotes on the Internet is that you can never know if they are genuine." - Mark Twain |