Long sitting Allis

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=35251

Printed Date: 27 Sep 2025 at 12:55am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Long sitting Allis

Posted By: soundman502

Subject: Long sitting Allis

Date Posted: 08 Aug 2011 at 10:19pm

|

I'm about to bring home my grandfather's old I'm familiar with soaking the cylinders in ATF and giving them time and nudges until they release, but I'm sure this can of worms still hasn't fully opened yet. My plans are to attempt to restore it for show and minor house work, and in doing so preserve a piece of my families history. Where can I find some documentation on what levers do what, and wiring diagrams and such? I'll have the serial number to run soon so I can get the year info, but I'm trying to study up before she gets here. Will post pictures soon. Thanks, Scott **Edited because I found the serial number on the back, and it shows as a WC.**

|

Replies:

Posted By: Bill_MN

Date Posted: 08 Aug 2011 at 10:27pm

|

Scott, check ebay for an operator's manual, many reprints and a few originals can be had for cheap. You might also want to get an I&T shop manual, available at many farm stores like Tractor Supply, Runnings, Mills, etc.- it has very good illustrations and instructions for disassembling and repairing anything on the tractor. ------------- 1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow |

Posted By: Pat the Plumber CIL

Date Posted: 08 Aug 2011 at 10:28pm

|

operator manual,believe vendors on here sell them.

Bill types faster than I do.Fat thick slow plumber fingers ------------- You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails 1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF. |

Posted By: CTuckerNWIL

Date Posted: 08 Aug 2011 at 10:34pm

|

Scott, go to the top of this page and click on Allis Store then click on manuals. Darin sells these and they are excellent quality reprints and you help support this site.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: soundman502

Date Posted: 08 Aug 2011 at 10:37pm

|

Awesome guys, I'll check into Darin's manuals and keep reading here. I've been waiting for years to finally get to bring this thing home, and I'm probably like a kid on Christmas Eve waiting to get it here. Just looking forward to getting to work on it. I get a strange kick out of getting down and dirty on old stuff.

|

Posted By: Steve in NJ

Date Posted: 09 Aug 2011 at 6:38am

|

Nothing like saving a family airloom, especially when its an Orange tractor that says Allis-Chalmers on it!! Darin's manuals are the way to go there. If you need any electrical diagrams, info, a wiring system, or any electrical parts for your "new" 45, we can help you out with anything needed on board that Tractor. Good Luck! They are a lot of fun to restore, and its a GREAT hobby!! The problem is, once you do one, the "Orange bug" bites you and you need another to restore for your "fix". And then other, and then another...Don't ask me how I know that!.... Hello, my name is Steve Barbato and I'm addicted to ORANGE.... LOL!

mailto:Steve@B&B - Steve@B&B

|

Posted By: DaveKamp

Date Posted: 09 Aug 2011 at 9:14am

|

Scott- whatever you do, keep us updated on the step-by-step, and post pictures frequently. Most of us are working on these buggers, but there's a few guys who, for some reason, can't... and we ALL live vicariously through our comrades challenges. Oh, and if you post pictures soon enough, we'll tell 'ya what NOT to do, before you do something we wished we wouldn't'a done ourselves. And give 'ya little tips like mixing up equal quantities of ATF, kerosene and acetone to make your own high-potency penetrating oil... and the fact that the pistons are usually 'dished' design, so it takes LOTS of penetrant, and if she's really stuck, you can bust the ceramic cores out of the spark plugs, weld on some 1/4" pipe, and thread on hoses to a regulator and put a little air pressure on the cylinders to help break her free. Most common spot to get a visual of a broken block, is on the left side, below the carbeurator. When they split, they'll typically SHOW it about 2" above the crank pan flange. IF they're cracked, you COULD fix it... oftentimes guys did by a variety of methods... brazing... arc/flame welding, silver-soldering, or in the case of my '50 WD, they drilled and tapped about loozanteen holes around the outside of the crack, covered a piece of tin plate with roofing tar, and screwed that sucker down. Of course, it would've worked, but when the block froze, it also cracked some of the internal webbing, so the cylinder sleeves wouldn't seal against the block, so it leaked internally... But no fear... decent running engines aren't hard to find, not incredibly expensive, and they're easy to change. These engines (and the tractors in which they lived and worked) were designed for in-frame rebuild... pop off the head and pan, break the rods loose, lift out the pistons and cylinder liners, drop in new stuff, new rod and main bearings, and button it up for another 40 years... Most expensive part of a home remodel, is the kitchen and bathroom. Likewise, most expensive part of a tractor revival is tires and engine. First thing I always look for, is a way to ROLL IT AROUND. If the rubber is good enough to hold air, then you've made it to the first step... working on flat-tired tractors SUCK, 'cause you can't jockey 'em in and out of the shop. I bought a set of old steel wheels, unbolted the cleats, and put 'em on my current project, just so I could wheel it in-and-out. Nice thing is, steel is really easy to work around- you can see through it, even get wrenches and arms around it. When I'm done with everything else, then I'll make a rubber investment and get it burblin' down the road. Then I'll move the steels to the next project, or clean 'em up and keep 'em on hand for someday when I wanna take an oldster to a show. I need to put a bumper sticker on my car that says "The more I work on modern cars, the more I love my Old Tractors!" |

Posted By: Kcgrain

Date Posted: 09 Aug 2011 at 10:45am

| If your going to buy a repair manual dont waste your money on an IT pay a little extra and get the one from Allis Chalmers you will be much happier, and it also has machine updates in it so if something changed internally it will tell you what. The IT is cheaper but the info is vague, and if your not a mechanic its sometimes hard to understand. |

Posted By: soundman502

Date Posted: 09 Aug 2011 at 12:27pm

|

The tires on this one are SHOT! I think when it was rolled into its current resting place, they were flat, and they are shredded now, front and back. But I don't have a shop to move it in and out of, so she'll sit in about the same spot for a while. DaveKamp - What kind of steel wheels can I put on this old girl? I thought about getting those since rubber is so stinking expensive. I'm new to tractors overall. I've run them, and helped work on a few, but it's been years ago. Thanks for all the input guys! I can't wait to get a full assessment of what I'm getting into.

|

Posted By: John WV

Date Posted: 09 Aug 2011 at 2:05pm

| soundman I brought a wd45 years ago. I don't know how long it set out side but the boot at the gear shifer was bad and had water in it . all the gears in tranny and rearend was shoot full of rust and bad pits .I wish you luck in getting her fired up |

Posted By: Dusty MI

Date Posted: 09 Aug 2011 at 6:28pm

|

You've got my curiosity going. Why do you say assumed cracked block? Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Dipstick In

Date Posted: 09 Aug 2011 at 8:39pm

|

I own some IT manuals and just love them. They take you step by step through all the easy stuff up to the point where you need to know something and just drop you FLAT! Just a little better than a comic book. ------------- You don't really have to be smart if you know who is! |

Posted By: soundman502

Date Posted: 09 Aug 2011 at 10:06pm

|

I was told that the block was cracked, but no one has been able to show me or tell me where, so until I see it, it's an unknown. I'll be bringing it home tomorrow hopefully if the weather holds out here, and I'll have tons of pictures to post then. My family farmed with this one until it was parked, so it was maintained in it's operational times, but I know no one has ever tried to fix it since, so it's just a bag of unknowns. I appreciate all the interest here, and the help so far!

|

Posted By: LouSWPA

Date Posted: 09 Aug 2011 at 10:13pm

|

I'd get a good woman for the housework! ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: soundman502

Date Posted: 09 Aug 2011 at 10:15pm

| I have one of those, but the WD is for the stuff she won't do ;) |

Posted By: Orange Tractors

Date Posted: 09 Aug 2011 at 10:32pm

|

Scott,

I have seen a tractor (MF-65) with a cracked block that would leak coolant when cold; but once the engine warmed up, the cracks quit leaking. Quite the pain to actually use because it always seemed to me that it was a fine line between getting the block warm enough to seal and getting it so hot that it would seize. Check the oil pan for water first.

My WD sat from a couple of years before Grandpa went into a nursing home until a couple of years after I retired from the Navy, about 16 years as close as I can figure it. I couldn't turn it over with the hand crank, the rod through the front pedestal was siezed, (the tractor had lived with a loader on it ever since Grandpa bought it when Dad and my other Grandpa quit farming in '65). It turned over fine with the starter though.

I had a little bit of water intrusion through the shifter boot, but the gear oil had left a thick enough film that none of the transmission gears were damaged. My only real problems were that someone had helped themselves to the generator, dash and the oil pressure guage. Don't you just hate thieves?

My magneto also wouldn't work, I used the distributor and a few other parts from the parts tractor I bought. It was cheaper to buy a ratty WD for the parts I needed than to buy some off brand and replace the implements I already had.

Good luck on the tires, hopefully your rims are salvagable.

Robert

|

Posted By: Dusty MI

Date Posted: 10 Aug 2011 at 6:45am

There are soft plugs it the head under the tappets cover. They often rust out/get pin holes in them, allowing coolant to get in the oil. It could be that is what happened, and someone thought there was a crack somewhere. Good Luck, Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Dave Richards (WV)

Date Posted: 10 Aug 2011 at 8:38am

|

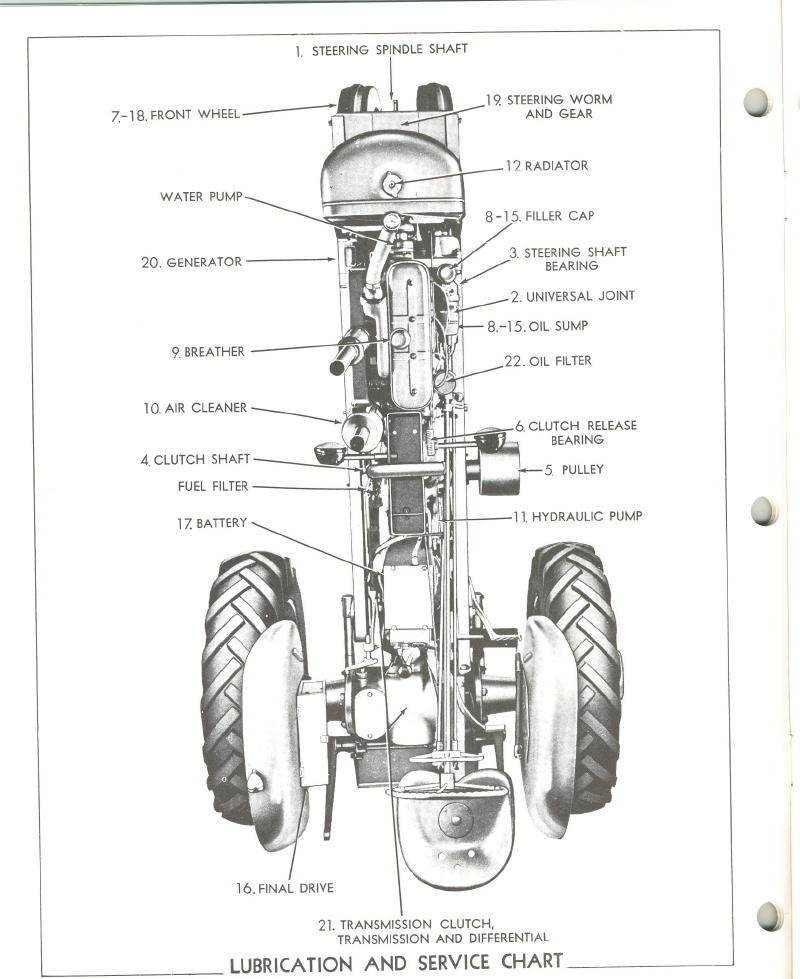

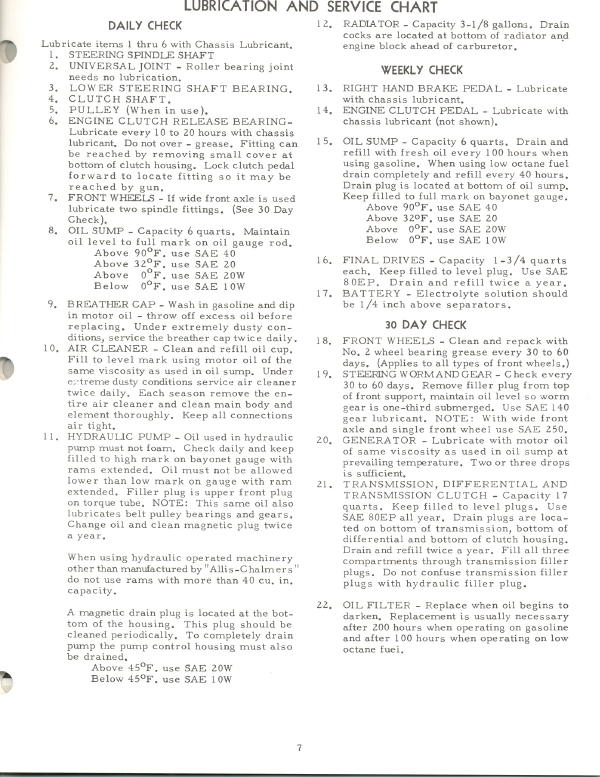

Tried to load these yesterday, but the picture loader was down. This should get you started Dave   |

Posted By: DaveKamp

Date Posted: 10 Aug 2011 at 9:26am

|

Scott- I don't know if there were any 'factory' steel wheels to fit the WD-45- it's standard wheels are spin-out rims with rubber tires, and the WD45 used a different bolt pattern (more bolts). The prior models (WC) STARTED with steel, and in the late '30's went to rubber (kinda a landmark thing that Allis Chalmers did). After rubber ag tires came out, many steel rims were torched off, and steel rims were welded on, then rubber tires and tubes mounted in their place. During WW2, steel came back a bit because of war material rationing... but after the war, rubber went back on. By the 45's time, everything was all rubber. The way you'll FIND steel, is just by coming across the unique situation of someone having a set that they made... mebbie some steel from another model where they drilled new holes or made some sort of adapter plate. Lemmie ponder that- mebbie I have enough materials and info here to make some adapters that'll put WC steel on a WD hub... If your rims are shot, a better method might just be to saw the bad rubber off, and set it down on the rims, and when you get back to it, put on a set of better wheels/tires on it later. |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 9:51am

| Thanks Dave. I don't know if the rims are shot the rubber is for sure, but who knows. There's a tractor bone yard about 30 miles from me that I'll be visiting soon. |

Posted By: Gerald J.

Date Posted: 10 Aug 2011 at 10:23am

|

Go gently with forcing a stuck engine to move by the crankshaft. That can take more force than the connecting rods can push and they will buckle and bend. That's not progress. Best to work with pan and head off and jack out piston and sleeve and maybe separate them with a hydraulic press pushing on the piston. You may save the rod that way, but once you have the head off you can see what the pistons have for crud above them to make them hard to move up. Its almost sure a couple valves have been open all the parking time and humidity as well as mouse urine has been able to circulate in those cylinders to leave significant rust. Stored inside there's a chance for much less rust. Gerald J. |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 9:38pm

|

Went out to retrieve Ole Red, and she won't come willingly. Went out with a trailer and a winch, but no budging. I'll have to take another tractor out there and see if I can coax her out. In doing so though, I have tons of pictures that I took of her, and my serial number info, which despite my previous information of it being a WD45, it is in fact a WC. SN# WC145071 I don't know what that means yet, but I'll soon find out. As for the "crack" in the block, it turns out to be a hole big enough for my to fit my fist into. I don't think it started that way, because I see remnants of JB Weld around the edges, but I can see clean into the cylinder wall. I'm wondering if this block is repairable at this point....

|

Posted By: soundman502

Date Posted: 10 Aug 2011 at 9:46pm

| If I've decoded the SN correctly, it would appear that I have a 1945 A.C. WC Can anyone confirm this based just on the SN? I'll have pictures up very shortly. |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 9:48pm

|

https://picasaweb.google.com/109604935659554672897/1945AllisChalmersWC145071?authuser=0&authkey=Gv1sRgCOjPw6uX7-D98gE&feat=directlink - https://picasaweb.google.com/109604935659554672897/1945AllisChalmersWC145071?authuser=0&authkey=Gv1sRgCOjPw6uX7-D98gE&feat=directlink |

Posted By: CTuckerNWIL

Date Posted: 10 Aug 2011 at 9:52pm

|

You have a 1945 WC. A decent block should not be hard to find. Depends where you are going with the tractor, you could buy a running engine and drop in it if you want it going to do some work or play. If you want to restore it later that might be the best choice, give you time to find other needs or wants for the finished product.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Rfdeere

Date Posted: 10 Aug 2011 at 9:54pm

|

That serial # would make it indeed a 1945. ------------- Randy Freshour,Member Indiana AC Partners, http://www.rumelyallis.com" rel="nofollow - http://www.rumelyallis.com |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 9:56pm

| For those that have looked at the images, #7 shows the hole I'm referring to in the block. Is that too much to fix? I would love to hear it run soon, but the main focus is restoration, so if possible, I'd like to keep her all original :/ |

Posted By: Pat the Plumber CIL

Date Posted: 10 Aug 2011 at 10:21pm

|

We had a 39 WC on our farm when I was younger.Raked and crimped a lot of hay on it back in the day.

Not too bad for sitting out so long,have seen a lot worse brought back to life. Mechanical lift is a plus. Whats the story on the planter in the weeds next to it? 4 row? snap coupler? Are both marker arms on it? ------------- You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails 1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF. |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 10:25pm

|

The planter is a 4 row with both arms. We have a harvester sitting right next to it. I figure if I can Red fired up, I might be able to pull those out too. I don't have the land to use them, but it's a shame to watch them decay in the fence line. I'm not sure about the coupler though. I think my grandfather bought them for use with the McCormick Farmall H that he bought after Red. It's sitting in a corn crib about 100 yards away, but I don't think I have a chance at getting that one. It still runs :)

|

Posted By: Pat the Plumber CIL

Date Posted: 10 Aug 2011 at 11:04pm

|

If you get a chance take some pics of the planter and harvestor.Love to see the stuff back in the weeds.

Thanks for posting pics,keep us informed of your progress. ------------- You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails 1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF. |

Posted By: soundman502

Date Posted: 10 Aug 2011 at 11:09pm

| I'll take the good camera with me next time and get some shots of the other equipment. There's also a disc out there that I may be able to grab as well. We'll see. I love old equipment as well. I was happy at the thought of getting a WD45, but getting this '45 WC tops that just a bit. It will look nice next to the '79 Bronco in the driveway :) |

Posted By: DaveKamp

Date Posted: 11 Aug 2011 at 2:18am

|

That is definately a '45 WC... 4spd transmission (shifter WILL be 'floppy', so you'll guess-your-gear, but hey- it's fun!)... there's a straight rod that points up at the family jewels, that's called a DRIVELINE DISCONNECT... that does just what it says- disconnects the rear axle just after the mechanical lift... so you can stop the tractor, flip the disconnect lever, release the clutch, and the mechanical lift will operate without the tractor having to move. Make sure it's in the disconnect position (I think that's DOWN) before you pull, so one less thing to worry about holdin' 'ya back. The brakes are hand-levers, make sure they're not locked on and held with the parking-brake cams... and make sure the lever IS in NEUTRAL... gonna be tricky to feel it, I'm betting. Sheetmetal looks to be in very good shape- won't take much to make that pretty... but I think you're gonna wanna pop that motor out and drop in a known-good-runner. It'll give you opportunity to 'work on' the clutch, too, as well as hand-spin the transmission shaft and make sure there's no serious problems there. While you have the engine out, it's an excellent time to clean up the bearing surfaces of the steering, blast the crud out of the insides of the frame rails, and if the tranny needs TLC, it's right there. But you CAN set this on WC steel (without the cleats on, of course) and it'll be easy to work on. Those rear rims might be good enough to blast, paint, and re-use. If the valve-stem holes are all rotted, but the metal is thick enough, grind the holes back 'till there's good metal, cut little disks and MIG'em into the holes, then polish it all smooth with a flapper-wheel, and drill new holes in another place on the rim. Git'r pulled out... stop at the car-wash, hose it down with degreaser, then blast as much crud off as you can, then roll it into the shop, where you can get a cherry-picker rolled under. Be gentle with the shroud, radiator, fuel tank, and tinwork, move it to safe storage location, then pull the carb, voltage regulator, generator, and put 'em in boxes for later. rig and lift the engine out, set it aside for now, then block up the rear axle and give the transmission and final drive an assessment. |

Posted By: Dusty MI

Date Posted: 11 Aug 2011 at 6:12am

|

It's had some up-dates, After market seat, battery ignition, voltage regulator. Plus what Dave Kemp talked about. And like he said try to get the transmission in neutral or the drive line disconnect. It could be the reason it didn't want to move is because it is in gear and the engine is stuck. Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Orange Blood

Date Posted: 11 Aug 2011 at 7:44am

|

To answer your question.

If you have the piece of the block that broke out, it is fixable, if you have a really good welding shop around. However as cheap as these blocks are, and as easy to find as they are, I would go get another one, as mentioned before.

As for running her with the hole, it can be done for around a minute is all no load, until she cools back down again, but yes it can be run without water for a very short time ------------- Still in use: HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060 Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7 |

Posted By: Sandknob

Date Posted: 11 Aug 2011 at 9:37am

|

Scott,

I have a WC tire and rim that you can have. It has a little rust around the valve stem, and the tire is an older recap, but I have no use for it. I would like the fluid out of it though. Tire shop said $25 to pump the fluid into another tire.

Let me know if your interested.

Located in Oblong, Illinois

Adam

|

Posted By: soundman502

Date Posted: 11 Aug 2011 at 9:40am

| Sandknob, I am interested, though it could be a bit before I could come after it. Thanks for the offer! |

Posted By: soundman502

Date Posted: 11 Aug 2011 at 12:47pm

| Well guys, I hate to do this, but apparently my plans are on hold for a while. Leave it to family squabbling to screw up perfectly good plans. Perhaps I can located another AC soon and just restore it. Thank you all for your help and wisdom, it won't go unused. |

Posted By: DaveKamp

Date Posted: 11 Aug 2011 at 4:24pm

|

Hmm... sounds like someone in the family thinks it's worth big, big money, and has no realistic understanding of what it will deteriorate into. Don't worry- they're around... we'll find 'ya something. |

Posted By: TedBuiskerN.IL.

Date Posted: 12 Aug 2011 at 8:26am

|

Most 1945 WC's I've seen have the steel rear end housing, I think the cast ones are unusual. ------------- Most problems can be solved with the proper application of high explosives. |

soundman502 wrote:

soundman502 wrote: