cylinder sleeves

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=28832

Printed Date: 03 Mar 2025 at 10:33am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: cylinder sleeves

Posted By: LouSWPA

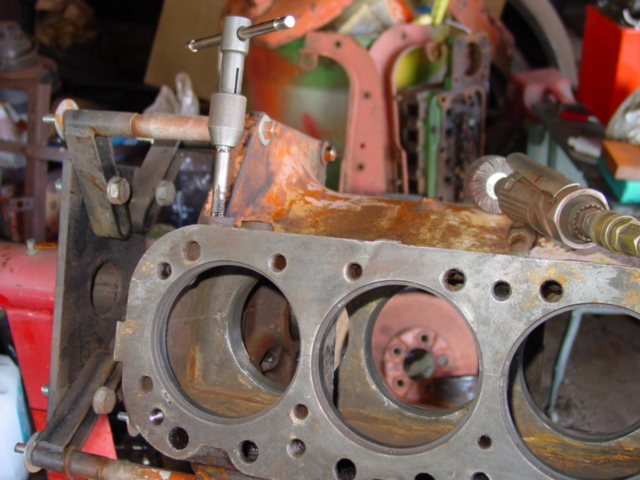

Subject: cylinder sleeves

Date Posted: 09 Apr 2011 at 3:51pm

Ok, new sleeve should spin easily w/o o rings. New sleeves are binding at the bottom, i believe resulting from rusty scale build up on upper part of area where rings will seat. My question is, how does one clean that up w/o scaring the surface to the point that the rings would snag and be damaged on it? ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Replies:

Posted By: DMiller

Date Posted: 09 Apr 2011 at 3:54pm

|

I have used what is called a 'Huckleburr' hone one of those with the wire supported balls of abrasives, if the bore gets too torn up or the rust too deep it may require a counterbore re-sleeve. One other note, use Crisco to lube the sleeve seal rings, they will not swell as they will with petroleum lubes. |

Posted By: Michael Crowe

Date Posted: 09 Apr 2011 at 7:12pm

|

It also helps to put the new sleeves in the freezer over night, and then only take them out one at a time as you install them. ------------- The 14th Annual Exclusive AC Swap Meet will be held in Boonville, MO, March 7-8, 2025. See the club website for details: http://www.moacclub.com/ |

Posted By: Brian Jasper co. Ia

Date Posted: 09 Apr 2011 at 7:26pm

|

I've heard the type of hone DMiller is talking about also called a "rabbit turd" hone. I had to run one in the sleeve seal areas on my CA block when I overhauled it. On mine, I honed it until I could shove them in with some effort. I didn't hone them to the point they could be turned easily w/o the o rings. It's been like 15 years now since I went through it. Just finally decided to run the rack (valve lash) a while back. Only thing it's needed other than a reman dist in all that time. ------------- "Any man who thinks he can be happy and prosperous by letting the government take care of him better take a closer look at the American Indian." Henry Ford |

Posted By: GregLawlerMinn

Date Posted: 09 Apr 2011 at 8:00pm

|

I use a dremel with small wire wheels and the sanding drum w/emory cylinders with good results. I also use olive oil to lube the O-rings. ------------- What this country needs is more unemployed politicians-and lawyers. Currently have: 1 D14 and a D15S2. With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC |

Posted By: Dick L

Date Posted: 09 Apr 2011 at 8:23pm

|

Thar she bee in a upper rite corner.

I also use a carbide burr for the tight spots where the flapper wheel seems to slow. You never hold it in one place. you rake around in a circle lightly. A flapper wheel will not scar.

I use a 1 1/4" wire wheel in the die grinder to clean the inside of the water jacket. One of them thar jobs that makes it hard to keep you nose hair clean.

|

Posted By: CTuckerNWIL

Date Posted: 09 Apr 2011 at 8:50pm

|

Lou, I did it the easy way. I put my block in a plastic 55 gallon barrel and cooked it with the battery charger for a week or 2. All the nasty rust is gone and a flapper wheel like Dick has will easily polish up the lead in. The next best thing, but costs money, is to have the block baked and shot blasted, or dipped and cleaned. Get rid of that flaky bubbly rust, then polish the chamfer.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: CTuckerNWIL

Date Posted: 09 Apr 2011 at 8:58pm

|

The chamfered area would need to be clean and smooth for assembly, to keep o-rings from being snagged, but shouldn't bother the sleeves. If you clean a bore up with sand paper, then put a sleeve in and turn it, you might be able to detect a high spot on the bore. Some high spot bluing would make the interference show up. Maybe your sleeves are a tad out of round?? I would polish the bore and get a Micrometer and an inside mic or telescoping gauge and check roundness of both the sleeves and the bore.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Steve M C/IL

Date Posted: 11 Apr 2011 at 10:46pm

| Little chunks of emery cloth,thumbs,fingers and a fair bit of elbow grease not to mention time. |

Posted By: Larry Miller

Date Posted: 11 Apr 2011 at 11:26pm

|

I use a piston ring groove cleaner to clean out the groove for the O rings. Just take off the little wheel for different width grooves and scrape away - not fun or easy but it gets er done. You can feel the crud and when it is gone too. ------------- I used to be young and stupid, now I am not young anymore. |