Need advice on tire spoons, for changing rears

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=24792

Printed Date: 26 Jan 2025 at 10:30pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Need advice on tire spoons, for changing rears

Posted By: RyanTN

Subject: Need advice on tire spoons, for changing rears

Date Posted: 27 Jan 2011 at 6:30pm

|

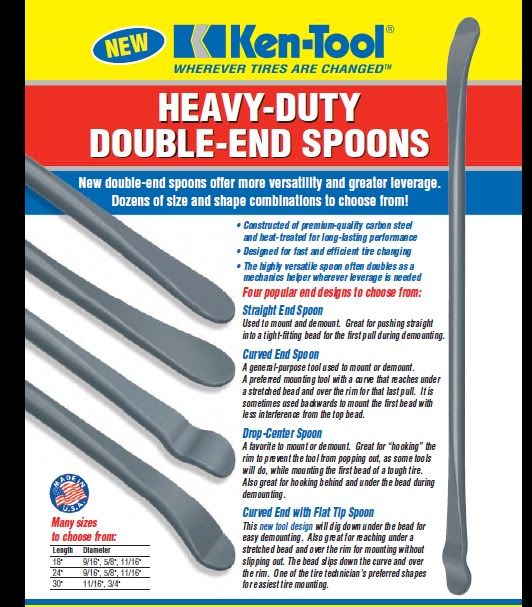

I would like to get your opinion on what kind of round stock I should use to make some tire spoons like these:  As we were discussing in another post, I want to try to change some rear tires myself. I was going to order some from Northern Tool, but they were made from 11/16th stock and were very cheap. The reviews were also poor, they said they were soft and bent easily. I found these Ken ones, and they look good, but were much, much more money--it got me thinking.

I have a good friend who is an amateur blacksmith. He said we could easily turn some round stock into some heavy duty spoons like these. Here's my question, what kind of metal do you think I should get to make some 30" and 18" spoons? I was thinking 7/8" cold rolled, but i don't do much metal work.

Thanks in advance, I appreciate all comments and thoughts.

|

Replies:

Posted By: R.W

Date Posted: 27 Jan 2011 at 6:33pm

|

I have no idea what to make them out of. But i would sujest to have a tire shop to change them for you way less agravation. ------------- In Search Of: 1958 Allis Chalmers D17 Diesel serial #9643D |

Posted By: Thad in AR.

Date Posted: 27 Jan 2011 at 6:35pm

| Ryan I've been thinking the same. I just bought 10' of 5/8 cold rolled to make a WC clutch rod and I think I will use the rest to make spoons. Our tractor club has a good blacksmith shop and I thought I would take the round stock to them. I don't know if 5/8 cold rolled is good for this or not. I plan to make a forge someday. |

Posted By: RyanTN

Date Posted: 27 Jan 2011 at 6:36pm

| Okay, thanks Randy- I almost put that in my post. This is a hobby for me...I'm not a farmer and I'm not in a hurry. I could pay someone to restore the whole tractor for me if i wanted to save aggravation, but what fun would that be? LOL |

Posted By: Nathan (SD)

Date Posted: 27 Jan 2011 at 6:37pm

| Be sure to harden them when you are done or you will be wasting your time. |

Posted By: D-17_Dave

Date Posted: 27 Jan 2011 at 6:49pm

| I can say I've used several of the Ken-Tool brand tire tools and they are very good stuff. But to make your own, your just asking for trouble. As Nathan said they need to be real hard. As a matter of fact they make the best work pry bar I've ever used, BAR NONE...Parden the pun there. I'm not goingto say you can't make them but you'll be much happier if you buy it and move on. |

Posted By: Coke-in-MN

Date Posted: 27 Jan 2011 at 6:54pm

|

I bought some Ken-Tool bars for tubeless 22.5 truck tires and now find i use them for many things also, have had them for over 15 years and no problems. Also bought one of their tire malls with the duck spoon bill for breaking truck beads . Quality tools aren't expensive they pay to own them.

If you want to try making some, look for some old crow bars at auctions or garage sales and reforge and harden and temper them after working , least you will be starting with good steel if the bars were good to start with and not cheap imports.

I use a old 20 # propane tank with a 3/4 full flow ball valve and flattened pipe as a cheetah for inflating tubeless tires to get them to bead. Works most of the time to give them that extra shot of air while adding air through stem. ------------- Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something. "Challenges are what make life interesting; overcoming them is what makes life meaningful." |

Posted By: FredinInd

Date Posted: 27 Jan 2011 at 6:54pm

|

I agree about having a tractor shop strip them off, but mounting the new ones back on is not to bad. Son and I can mount tire and tube on a rim in about 10 mins. We use 2 flat spoons, vice grips, soapy water and rubber mallet. When you put air to the tube to seat bead, make sure you have the valve core out of the tube. You will need a bigger volume air supply to seat them. Don't worry if you have to go 10 or 15 lbs above recommendation psi for tire...... ------------- Oh well, I won't do that again! |

Posted By: RyanTN

Date Posted: 27 Jan 2011 at 7:00pm

| Yeah, the price to buy theses wasn't totally out of line, in fact it was very reasonable for a quality tool. But my friend also didn't seem to be put off by the hardening process either. In fact, he said we would just have to "be careful to harden it right". He is a bright guy--college professor, ordained minister, published author and holds a PhD as well as common sense (a RARE combination in my opinion). I really enjoy watching him blacksmith, he makes it look easy and fun. I thought it may be fun way to spend a evening with him. I may press him further to see if he thinks we'll be successful. |

Posted By: Denis in MI

Date Posted: 27 Jan 2011 at 7:01pm

|

Go to tractor supply and buy a 48" alltrade brand "Trades Pro" "The Enforcer" prybar and grind the ends down to get rid of the sharp edge. I bought on last week and it works great. Unfortunately they are made in india but they are pretty heavy duty and only $20.00 I coldn't buy a used spoon or steel to make one for that price. Plus it says it has a lifetime warranty.

Just my opinion,

Denis ------------- 1938 B, 1945 B, 1941 IB, 1949 C, 2 1938 WCs, 3 1950 WDs, 1951 WD, 2 1955 WD45, 1957 D-14 |

Posted By: Denis in MI

Date Posted: 27 Jan 2011 at 7:08pm

|

Here it is,

http://www.tractorsupply.com/tools/hand-tools/pry-bars/trades-pro-48-in-enforcer-pry-bar-4044111 - http://www.tractorsupply.com/tools/hand-tools/pry-bars/trades-pro-48-in-enforcer-pry-bar-4044111

The ends are real sharp So I ground them smooth and it works great. Changing tires is the main reason I bought it. I have found that it is well worth my time to change them myself, I can save money and time. By the time I haul it 20 mile to the tire store, I can have it off and the new tire on. The main thing is breaking the bead I use my Hi-Lift jack and a heavy tractor that is near by to break the bead or drive another tractor on the tire.

Just my 2 cents,

Denis ------------- 1938 B, 1945 B, 1941 IB, 1949 C, 2 1938 WCs, 3 1950 WDs, 1951 WD, 2 1955 WD45, 1957 D-14 |

Posted By: CTuckerNWIL

Date Posted: 27 Jan 2011 at 7:10pm

|

Cold rolled steel doesn't tell you what it is made out of. If it isn't a high enough carbon content, you will not be able to harden it(maybe case harden if you knew how). If you take on a tire change job with soft steel you might as well use a q-tip.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: RyanTN

Date Posted: 27 Jan 2011 at 7:27pm

|

Lots of good comments! Thanks!

Charlie your comment is kind of what I was looking for--IF we decide to try and make my own, what type of metal do you suggest? I think I may try to time my visit the steel yard for when they are not busy. I guess I can explain what I am wanting to do, and ask their opinion. It sounds like most here don't think this sounds too feasible. I'll talk it over some more with my buddy and mention some of the concerns, especially the tempering. Again, I'm not too familiar with working with metal; but he is. I may decide to just buy a quality set if we don't think it will turn out.

Great forum with a wealth of knowledge-keep it coming! Thanks, Ryan

|

Posted By: jrjuday

Date Posted: 27 Jan 2011 at 7:46pm

| 4140 or 5160 steel, and quench in oil after forming. If I buy tires from my local shop, they come out and mount and fill with ballast so cheap I would be stupid to do it myself. |

Posted By: CTuckerNWIL

Date Posted: 27 Jan 2011 at 7:49pm

|

Ryan, here is a chart and some reading material. Maybe you have some old leaf springs laying around? http://tidewaterblacksmiths.net/1.html - http://tidewaterblacksmiths.net/1.html

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: monitordoc

Date Posted: 27 Jan 2011 at 7:50pm

|

I MADE MY SPOONS FROM OLD TRUCK SPRINGS. ------------- WD,D17-S4,180,D21 |

Posted By: Chris/CT

Date Posted: 27 Jan 2011 at 7:54pm

| IF you can find some old boat shafts [ inboard type, thru hull] They have made nice bars for me in the past. I have the Napa brand and they are well made. |

Posted By: Leon B MO

Date Posted: 27 Jan 2011 at 8:02pm

|

If your going to make them, go ahead and make 3 of them. You really need all three to dismount a large tire. Two to hold what you have and the 3rd to get the next bite.

Leon B MO ------------- Uncle always said "Fill the back of the shovel and the front will take care of itself". |

Posted By: Richardmo

Date Posted: 27 Jan 2011 at 8:03pm

|

I use both lengths and plus a think it is a 4' bead breaker slide hammer had alot of good luck with.

pick it up at a farm and home i am in the boat that i way to many to fix to hire some one and i agree need to be carefull when using them.

|

Posted By: Thad in AR.

Date Posted: 27 Jan 2011 at 8:16pm

| I just went on the kentool web site and they have a dealer 10 miles from here in golden mo. one rear tire change will pay for one spoon. I worked in a tire shop as a kid and have changed many tractor tires. I have a homemade bead breaker that works great. I don't want some tire guy draggin my purdy painted wheel across the concrete. Now what to do with old tires? |

Posted By: wfmurray

Date Posted: 27 Jan 2011 at 8:20pm

| If you want to remove an old tire that is no good take a coarse tooth saber saw and saw out a good size hole down to the rim , then use thin cold chisel to cut wire.Then just peel it off. |

Posted By: CTuckerNWIL

Date Posted: 27 Jan 2011 at 8:24pm

|

Now what to do with old tires? That's what brush fires and real foggy days are for. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Stan IL&TN

Date Posted: 27 Jan 2011 at 8:33pm

|

Build a nice wood pile. Place wheel with old tire on top of pile. Do it at night. Don't tell anyone. It will also remove all the old paint too. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: GlenninPA

Date Posted: 27 Jan 2011 at 8:44pm

|

I thought you put the wood/brush over top of the tire..........

+1 on the foggy day...

|

Posted By: Thad in AR.

Date Posted: 27 Jan 2011 at 8:52pm

| I have wore out 14x24 grader tires on my wc. They should be easy to break down and remove shouldnt they????? I thought they would make beautiful blueberry planters near the garden but my wife says NO. |

Posted By: CTuckerNWIL

Date Posted: 27 Jan 2011 at 9:00pm

|

Save em for sandboxes for your grandchildren. Then figure they are too hard to move so they become planters. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Jacob (WI,ND)

Date Posted: 27 Jan 2011 at 9:26pm

NO, No, NO..... You get black butted pants that way! LOL! I had one of these when I was little, I can just remember it. Mom got tired of black pants, so away went the tire (it even had a fancy custom made wood cover to keep the cat crap out...) , and Dad had to make a wooden sandbox for me..... ------------- Jacob Swanson 1920 6-12; 1925,1926 20-35 longfenders; 1925,1926 15-25's; 1927,1929 20-35 shortfenders; C; B's; IB; WC's; WD; WD45 |

Posted By: Dakota Dave

Date Posted: 27 Jan 2011 at 10:28pm

| If you cut the bead out of one side you can turn the tire inside out. makes a nice strawberry garden. I just use an 18" prybar and a 24" crowbar. My grandfather made a real nice pair of spoons when He was a boilermaker for burlington Northern. My Brother has one and I can't find the other one. So you can make them. Old car axles are a good quqliaty steel and almost free. |

Posted By: Amos

Date Posted: 27 Jan 2011 at 10:39pm

|

I bought the set of three bars in 30" at an auction for $42. I was walking back to the truck to leave as what I went for was sold and I had a few other items bought but didn't see anything else. Looked over the crowd at the auctioneer's helper holding up the bars and he was saying going once at $21. I started yelling to get a bid in and pushed my way to the front of the crowd. When I bought them I thought I paid that price for each not all three but not so. The auctioneer said to the fellow who almost bought them for $21 "that really hurt didn't it". I laughed about it all the way home that afternoon.

The bars more than pay for themselves. If I have a tire shop come out to change a loaded tire it is min $200, usually more like $300. I have been changing truck tires since 10.00-20's were the main tires used on all trucks, thanks to the designer of the tubeless tire of today. One day I changed all 8 20.8 x 38 on my Steiger. It was a long day but was well worth it what I saved by buying the tires loose and mounting myself.

|

Posted By: Wendell(OK/TX)

Date Posted: 28 Jan 2011 at 12:12am

| I still have the ones my Dad used, all made from leaf springs and they work great. I'm not a big fan of dismounting tires myself, the mounting part usually goes ok. The big problem around here is that if there is or has been fluid in the tire then no one in town will touch it, they also will not touch a rim that has been repaired. Have to call the guys that actually come out to your place to handle the ones with fluid and that ain't cheap! So being the frugal person that I am, I have to do my own part of the time. Just remember when you are sticking those spoons in there and prying on the tire, whichever one you are not watching closely will fly up and pop you in the head! At that point the type of steel doesn't matter, it just hurts. |

Posted By: JW in MO

Date Posted: 28 Jan 2011 at 8:44am

|

I like the their "NEW" double ended spoons, maybe new to them, I too have one of Dad's old double ended tire spoons that I use but I have been looking for others at sales only to find short ones. After the first couple you learn real quick especially when I had to dismount a rear tractor tire on the shop floor. I think if I can't do it on the tractor I'll haul it to town next time. ------------- Maximum use of available resources! |

Posted By: BobHnwO

Date Posted: 28 Jan 2011 at 8:47am

|

I got mine at TSC,2 short and 1 long,good quality.

------------- Why do today what you can put off til tomorrow. |

Posted By: Brian G. NY

Date Posted: 28 Jan 2011 at 8:52am

|

Wendell and others have mentioned car springs. Many old time garages had tire "irons" made from car springs and they work really well. The older cars had narrow springs which worked best. They are already flat so they just need a little "dressing up" on the ends and they are not likely to break. I have picked up three really good tire "spoons" at garage sales over the years but the longest one I have is only about 2 feet. Once I got the bead broken, I was able to change the rear tires on my Allis WD using just the regular tire spoons. |

Posted By: HD6GTOM

Date Posted: 28 Jan 2011 at 9:42am

| Ryan I spent 22years owinng and operating a tire shop. Go to a farm supply store near you and buy the KenTool bars. Buy a wooden handle duckbill tire hammer. Get yourself some professional tire lube, it is much slicker than soapy water. If you do not have a bead breaker, Leave the rim on the tractor, break the outside bead first, pull the outside bead off the rim, then break the inside bead, pull the tube and take the last bead off the rim. You will need 2 irons to remove remove the tire. you will need 2 irons and sometimes a pair of vicegrips to reinstall the tire, it depends on the tire ply. Most new 4 ply tires sidewalls are so flimsey you can put the inside bead on the rim without irons, just falls on. Good luck |

Posted By: Dick L

Date Posted: 28 Jan 2011 at 2:47pm

| I have one tire spoon and use it some times if I can find it. If you have the tire broke down and push the opposite side bead down to the center of the old style rims you can use a coupla big screwdrivers to pry the bead over the top. Been taking tem off with screwdrivers for over 50 years. |

Posted By: RyanTN

Date Posted: 25 Mar 2011 at 5:08pm

Well I went ahead with this project. My blacksmith friend, Stephen, and I spent a weekend modifying some crowbars into tire spoons. We quenched and tempered each one and tested the hardness when we were finished. Again, we did this for fun, as part of our hobbies. I realize I could have bought some tools for much less effort.

Here they are all painted up. The bottom two items in the picture are a duckbill bead breaker and a little tire spoon/ split ring tool I found at a local junk tool store with the initals "HF". I didn't end up using them this time.

For my first test, I decided to use an old rusty B rim with a dry rotted tire. Here is my bead breaker, a farm jack and chain. It worked like a charm:

I got a gallon of tire mounting lube and a swab applicator at the local wholesale tool store. I had the first lip of the tire over the rim in about five minutes.

I flipped it over and was done in about ten to fifteen minutes. I didn't think that was bad for my first attempt!

Thanks for the encouragement, I had a lot of fun making the tools and trying this for myself. I encourage anyone else who is on the fence to jump right in and give it a shot.

|

Posted By: DMiller

Date Posted: 25 Mar 2011 at 5:44pm

| I bought my Ken-Tools irons years ago at a truck tire supply shop, work you hard to use them but well worth the money I spent on them so long ago. I too have the bead hammer(8#) and four bead irons as well the irons for split rims though I do not ever intend to work split rims again. |

Posted By: Ted J

Date Posted: 12 Feb 2017 at 9:15pm

|

Split rims...........safest way is to take them to a tire shop and let them do it. If YOU have to,,,,,,,,,,,,,,,, Step 1 - Get the tire and tube on the rim. Step 2 - put the ring on the rim Step 3 - lay the tire, ring side DOWN on the ground Step 4 - have the air hose shut off Step 5 - put one of those self locking chucks in the air hose and onto the valve stem. With NO valve core in the stem Step 6 - turn on the air and fill the tire Step 7 - insert the valve core into the stem and fill the tire again WITH the ring side DOWN against the ground Step 8 - check for correct pressure in tire Step 9 - lift tire off ground and drop two or three times onto the side with the ring on it. Step 10 - If the ring didn't go BOING during the dropping and come off, mount tire onto vehicle (check the ring first to see it is set correctly first) I did it that way for years and never had a problem. Had a few go BOING but as I wasn't even close it didn't even scare me. When you're 50 feet away, it's pretty safe that way. ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: shameless (ne)

Date Posted: 13 Feb 2017 at 1:59am

| now you need to buy yer buddy sum knee patches! |

Posted By: DiyDave

Date Posted: 13 Feb 2017 at 5:10am

| Y'all know this is a 6 year old post, doncha? Anyway, all the tire Irons I gots came from various auctions. Most came in a $45 bucket lot, split it with a neighbor, he wanted the short ones, I got the long stuff. |

Posted By: LeonR2013

Date Posted: 13 Feb 2017 at 6:10am

| Right Dave, it is an old post but I would like to add something. This is the way I seated the bead. After mounting the tire and getting the ring in place, I'd put 10 lbs of air in it, or just enough to bead it up. Then with the ring still up I would go around the wheel lightly tapping the ring inward starting across from the ends working both directions. These wheels can be bent by someone beating to hard on them to break the bead. So in the spot they are bent take your tire hammer and drive outward on the wheel until it fits the ring in the bent area. If I don't like the looks of it I'll add just a little air then mount on the vehicle and finish airing it up. Make sure you get the rust out of the lip of the wheel and any rust off the wheel (scale). If it's getting thin, throw the dang thing away! I was breaking one down one time and when I hit it that one last time to break the bead, the tire hammer went through the wheel. So if you don't get the scale off you don't what you've got. Leon |

Posted By: Ed (Ont)

Date Posted: 13 Feb 2017 at 9:19am

What size tires are you mounting? I mounted 14.9 x 28's myself. Very easy - I just used some medium sized prybars. Worked on a 4 x 8 ft sheet of plywood on front lawn. 1 beer per side. LOL. Now in fairness everything was new. New tires, tubes and new 13" rims. Old stuff is harder. Tires are stiffer etc.

|

CTuckerNWIL wrote:

CTuckerNWIL wrote: