D17 clutch rod falls out of bell housing

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=209601

Printed Date: 08 Jan 2026 at 3:23am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 clutch rod falls out of bell housing

Posted By: WD45 Aaron

Subject: D17 clutch rod falls out of bell housing

Date Posted: 05 Jan 2026 at 7:26am

|

Happy New Year all, I have newly acquired D17 gas. It's a franken tractor built from various parts. The operating rod from the clutch pedal falls out of the bell housing. What is supposed to retain it into the clutch fork? More importantly, can I fix it without splitting? Thanks! Aaron ------------- Machinery rescue for all things rusty or broken. Current residents include 2-1/2 WD45s, Oliver Row 77 gas, Farmall super C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota. |

Replies:

Posted By: only AC orange

Date Posted: 05 Jan 2026 at 7:57am

| The rod threads into end of clutch fork, if you're lucky, try lining it up and threading it in. No idea how many turns into fork - that is what controls clutch pedal travel. Good Luck! |

Posted By: WD45 Aaron

Date Posted: 05 Jan 2026 at 7:59am

|

Hmmmm. I wonder if the threads are stripped off the rod. I saw a hex, but when I quickly looked at it it appeared smooth. I am going to have to take a closer look. Hopefully the threads are good in the fork. Fingers crossed. ------------- Machinery rescue for all things rusty or broken. Current residents include 2-1/2 WD45s, Oliver Row 77 gas, Farmall super C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota. |

Posted By: Nathan (SD)

Date Posted: 05 Jan 2026 at 8:55am

| Or. The rod broke and the threads are in the fork yet. |

Posted By: DrAllis

Date Posted: 05 Jan 2026 at 12:47pm

| Seems as tho this happens once in a while. The threaded clutch rod is 1/2" NF thread. The nut inside the bellhousing surely has damaged/missing threads. To avoid having to split the tractor you need to make a smart repair. Whack off the end of the clutch rod approx 1 1/2" inches. Whack off the threaded end of a 1/2" NF bolt and weld it onto the whacked off clutch rod. Smear a bunch of red or green loctite on the threads and install into the bellhousing, making at least TEN good turns into the nut. Twenty turns is one inch. Let the Loctite cure overnite and you should be fixed until it's time for a clutch job. How far you screw the rod into the clutch yoke nut, only positions where the clutch pedal will wind up. It has NOTHING to do with actual clutch adjustment. So, with that in mind try and pre-figure where you'd like things to turn out when done. Cutting off the end of a bolt would give you 1 1/2" max threads. So, maybe you want to cut that much off the clutch rod itself ?? it's up to you. New threads on your clutch rod should help make up for rough threads inside. And loctite should lock them together for as long as they need to be. |

Posted By: WD45 Aaron

Date Posted: 05 Jan 2026 at 1:50pm

|

This is great info! Thank you! My next question was going to be what thread it is. I have a full machine shop at my disposal. With your description this should be an easy one. Fingers crossed. ------------- Machinery rescue for all things rusty or broken. Current residents include 2-1/2 WD45s, Oliver Row 77 gas, Farmall super C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota. |

Posted By: steve(ill)

Date Posted: 05 Jan 2026 at 1:51pm

|

the FURTHER it screws into the nut, the better... Chances are there are 3-4 damaged threads on the nut, and an inch inside the threads are OK... ------------- Like them all, but love the "B"s. |

Posted By: WD45 Aaron

Date Posted: 05 Jan 2026 at 7:44pm

Ok, we're getting somewhere. It appears that the threads on the rod are fine, just full of gunk and need to be cleaned. The nut on the fork appears stripped out. I might look at work and see if we have a helicoil kit for 1/2-20. Otherwise, I can make a threaded insert on a lathe and fit it into the nut.  ------------- Machinery rescue for all things rusty or broken. Current residents include 2-1/2 WD45s, Oliver Row 77 gas, Farmall super C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota. |

Posted By: DrAllis

Date Posted: 05 Jan 2026 at 8:38pm

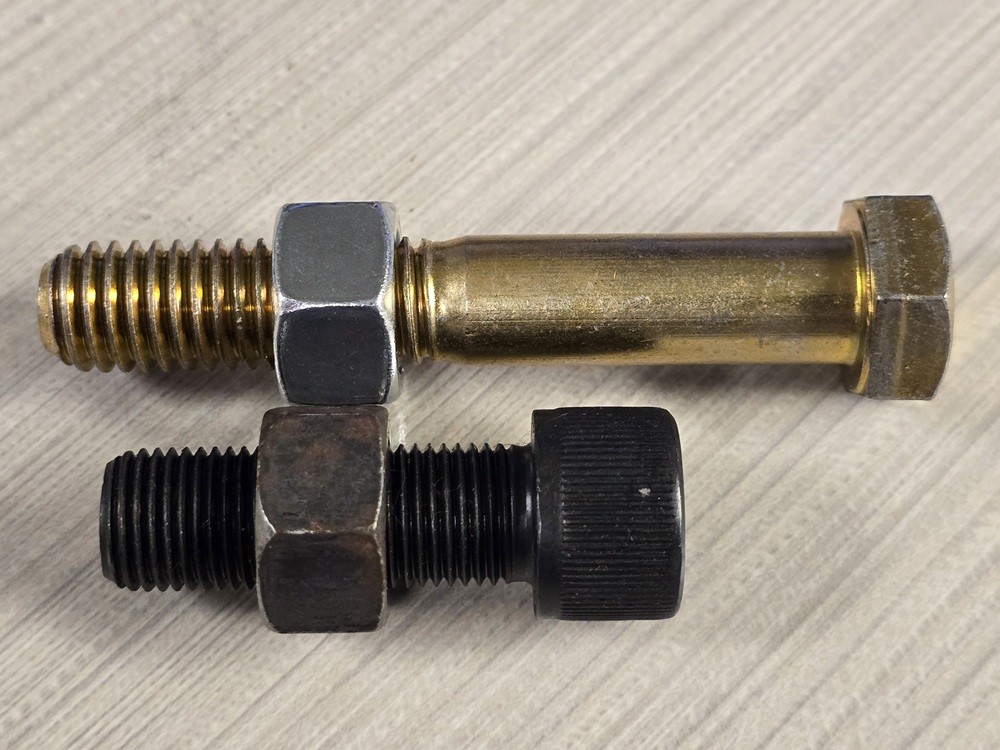

| There's been a problem going on there for a long time. First off, that looks like 1/2" NC threads not NF threads. Second, someone has put a stop nut on the rod to keep the rod from pushing thru the internal nut, which is worn out. Good luck with whatever you try. |

Posted By: DiyDave

Date Posted: 05 Jan 2026 at 8:55pm

Likely rethreaded the original fine threaded hole to coarse thread. starts you out at a disadvantage, as you get a sloppy mess, when you do it that way... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: Nathan (SD)

Date Posted: 06 Jan 2026 at 8:24am

| You got 10 threads on the roughly 1/2 inch sticking past the nut. That is fine thread on the rod. |

Posted By: WD45 Aaron

Date Posted: 06 Jan 2026 at 11:40am

I grabbed a coarse as well as fine thread bolt with nut from the shop. In my picture of the clutch rod I count 10 threads past the nut (not counting the chamfer lead). I threaded each nut out the same number of threads. I agree, it appears to be fine thread. ------------- Machinery rescue for all things rusty or broken. Current residents include 2-1/2 WD45s, Oliver Row 77 gas, Farmall super C, two Cat D2's, Clark C500-80 forklift, and a sick Kubota. |

Posted By: DrAllis

Date Posted: 07 Jan 2026 at 8:42pm

| So, are we fixed ??????? |