Later d17 saved from fence row

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=208294

Printed Date: 10 Feb 2026 at 7:35pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Later d17 saved from fence row

Posted By: 55allis

Subject: Later d17 saved from fence row

Date Posted: 23 Sep 2025 at 11:49pm

|

I did it again, bought another tractor out of a fence row… Looks to be a series 3 d17 gas with a serial number of 66169, correct me if I’m wrong because I have been before. Haven’t picked it up yet to mess with it but hoping to get it this week before harvest stuff get crazy but I figured I’d post it now to start from the beginning. The front end is only sitting on it due to some one swapping the original narrow front to a wide front and not taking the time to do it properly.  ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Replies:

Posted By: Hubert (Ga)engine7

Date Posted: 24 Sep 2025 at 5:06am

|

Congratulations, nice find. Looks like a good winter project. ------------- Just an old country boy saved by the grace of God. |

Posted By: ACinSC

Date Posted: 24 Sep 2025 at 5:38am

| D series are my favorite. Please post pics of the process if you can. Good luck! |

Posted By: 55allis

Date Posted: 24 Sep 2025 at 9:02am

|

The guy who owed it is a John Deere guy so he was really excited to have this one gone, he has another one that’s in better shape he’s trying to get rid of too but it’s a series 1 I think. Don’t think this one will be a throw a battery in and go type…. What size of front tires are the series 3 supposed to have? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 24 Sep 2025 at 9:53am

| 6:00 or 6:50 x 16's. Some later ones may have had 7:50's but on a wider rim. |

Posted By: Alberta Phil

Date Posted: 24 Sep 2025 at 9:57am

| Standard size was 6.00 X 16 |

Posted By: Dan Hauter

Date Posted: 24 Sep 2025 at 11:32am

| Good luck with the restoration! I love to see AC's saved. |

Posted By: AC7060IL

Date Posted: 24 Sep 2025 at 12:12pm

|

55allis, Congrats on rescuing it. Serial number 66169 would make it a 1963. So its got the dry engine air filter. Assuming since its muffler is busted over, engine may be frozen?? One good thing, is that you won't have to remove old tires from rims.... :) |

Posted By: wjohn

Date Posted: 24 Sep 2025 at 10:50pm

|

Good save. Yes we are all curious if there is any chance the engine isn't stuck. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: 55allis

Date Posted: 24 Sep 2025 at 11:04pm

|

Not sure yet, previous owner was thinking it wasn’t stuck when he got it… but he wasn’t sure how long he had it… Was told the muffler got broke off in the year before storms… Not sure how good the muffler kept the moisture out but it does look like it has a good rain cap. Really hoping it didn’t fill with water and freeze…. I know from experience what that could do… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Phil48ACWC

Date Posted: 25 Sep 2025 at 5:58am

| Good fixable tractor. Go slow and easy on the bent up sheet metal. |

Posted By: Sugarmaker

Date Posted: 25 Sep 2025 at 6:30am

|

55allis, That is a project for sure. Looking forward to seeing your progress. I like our early D17! Regards, Chris and Cheryl ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: 55allis

Date Posted: 27 Sep 2025 at 11:51am

|

I got it to its new home!! It’s missing the starter, waterpump and both snap coupler latches. The engine is stuck but I got all the controls to move freely. The gear shifter is stiff but it will shift in all the gears. The gas tank is mostly shiny in the bottom as I can see. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 27 Sep 2025 at 1:53pm

|

Ok so the front end is off an early d17 and so the bolts are 1/2” instead of 5/8”… Would it be save to drill the bolster holes out to 5/8”? It looks like there’s enough cast there to handle it but I wanted to make sure… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: dfwallis

Date Posted: 27 Sep 2025 at 3:15pm

|

Good save. There's a WD45 near me sitting along the road almost like a lawn ornament. Doesn't look to be in bad shape. Wish I could afford another one :( ------------- 1952 CA13092 |

Posted By: 55allis

Date Posted: 27 Sep 2025 at 11:13pm

|

Well I came to the conclusion that I possibly could do some modifications to the front end to make it work… So I could cut the rear pin mount off the axle and weld it on the front side of and drill the 1/2” holes on the bolster to 5/8”… For the engine, it’s still stuck but looking through the spark plug holes it doesn’t seem to look too bad. I think I’m going to pull the head just to check things out to be safe. It’s going to need a water pump and starter due to them missing. What other machines have the same starter? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 28 Sep 2025 at 3:06am

| That is a legit series 3 tractor. That front axle is from the first gen D-17 series and it ain't quite the same at that rear pivot pin area. |

Posted By: 55allis

Date Posted: 28 Sep 2025 at 10:56am

|

Wonder if anyone would want to trade? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 28 Sep 2025 at 12:48pm

| I'm not saying you can't salvage the axle you have with some welding, torching, and fabrication. You should seek out a tractor with the correct axle and make a plan. Any D-17 from 1960 and up and a first generation One-Seventy are good to look at. This must be the missing info to the story. They bought a D-17 WF axle and it cannot work as-is. So, the tractor was abandoned. |

Posted By: 55allis

Date Posted: 28 Sep 2025 at 2:12pm

|

It was swap because someone bought this tractor for the narrow front to put on their picker d17, apparently an earlier d17. So they must had figured out that the original 5/8” bolts wouldn’t go back in due to it having 1/2” and just left it. I posted a trade in the classified in hopes of maybe correcting it. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 28 Sep 2025 at 5:34pm

| Well, not too hard to drill out the four 1/2" bolts to 5/8" on that bathtub piece. The difficult part is shortening the wishbone 3 inches and making the pivot plate to bolt to the bellhousing adapter. |

Posted By: 55allis

Date Posted: 28 Sep 2025 at 10:54pm

|

I got the head off and as I figured the 2 middle pistons are stuck and sleeves are rusted badly, no cracks visible yet and the valves all are free. One valve was a bit sticky but came loose pretty quickly. The two outside pistons and sleeves look fairly good.. would it be worth looking into getting good used sleeves for the two middles? Or is that just a cheap thought… I’d put new rings at least and maybe O-rings on the sleeve. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 03 Oct 2025 at 8:19am

|

After doing some research I'm wondering about doing a rebuild kit on the engine.. The hour meter reads right close to 2900 hours. The 2 good cylinders don't look to bad but the other two have rust pits. I kinda would like to make it mechanically in perfect working order but on a budget. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 03 Oct 2025 at 6:05pm

|

A lot depends on what you are planning to do with the tractor. None of these old tractors are going to be expected to do what they were expected to do when they were new. A lot of us have cobbled engines together with used sleeves and pistons. If I was going to do something like that (again!), I would hone all the sleeves, pull all the sleeves and install new O rings, make sure all the pistons are identical, weigh all the pistons on a mail scale and get them all as close to the same weight, install all new piston rings (make sure to check the end gap), install all new rod and main bearings and new seals. By the time you buy bearings, gaskets, seals, rings, O rings, etc., you don't really save a lot over buying a rebuild kit with new sleeves and pistons.

|

Posted By: 55allis

Date Posted: 03 Oct 2025 at 7:19pm

What will I be doing with the tractor? It probably won’t be much due to me having way too many of them..   It’s not that I needed it, I just couldn’t see it be a goner. That’s what I was thinking about cost.. Maybe I’ll wait a bit for the hobby fund to build up a bit and fully redo the engine. What are some common problems/ weaknesses past the engine? If I go that route, what should I be looking for and or replace in the back end? I know to replace the throw out bearing, and the one in the flywheel. I’m still new with the d series… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 03 Oct 2025 at 10:24pm

| I always assume the engine will need a complete overhaul. After that, if the gearshift boot is junk, you can surely assume the transmission/differential has rain water in it. Draining the oil out (and a new boot first) can determine how much water, which (if enough) can ruin the countershaft bearings. The same could be said for the hydraulic dipstick and the power steering. Final drives are usually always OK but need an oil change anyway after 60 years. |

Posted By: 55allis

Date Posted: 03 Oct 2025 at 11:02pm

|

The shifter boot is junk but long long time ago someone patched it with some kind of tape.. It still has oil in all the compartments, and they are low but I’m changing everything just because. Will also put plugs on the bottoms of the final drive pans, found that a lot easier. Does the power steering supposed to have its own oil tank? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 03 Oct 2025 at 11:32pm

|

Looking more closely at the overhaul kits and most are 4 1/8” over bore, is that a good upgrade? And what should a standard crank bearings and rod bearings measure? Was thinking maybe I should measure those before ordering anything. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 04 Oct 2025 at 5:37am

I (probably wrongly) figure that if the original gear oil in the final drives lasted this long, after changing to new gear oil, it will probably outlast anyone on this forum. When these tractors were new, they were the workhorse. Now, most have a pretty easy life. I change the gear oil and check it periodically (not as often as I should) and don't go to the hassle of adding drain plugs. The power steering on the older D-17's fills in front of the radiator, after you remove the grill.

|

Posted By: WF owner

Date Posted: 04 Oct 2025 at 5:52am

I doubt that you will be able to find a rebuild kit that is not 4.125. Good? it gives you more cubic inches, but you have to be real careful what the compression ration of the pistons. If I'm not mistaken, compression ratios ranged from 5.5/1 to 8.25/1 for the 226 engines. Main and rod journals need to be measured before ordering a rebuild kit. When you disassemble, the old bearings should have a number. If they have .010, .020, .030 or .040, the bearings have been changed at some point and replaced with undersized bearings. This usually happens when the crankshaft has been reground. When the engine runs, the crankshaft journals tend to get (VERY SLIGHTLY) egg shaped. (The only way to determine this is by measuring in several different locations with a micrometer). Regrinding or "turning" the crankshaft machines these journals back to perfectly round.

|

Posted By: DrAllis

Date Posted: 04 Oct 2025 at 7:02am

| You absolutely want 8 to 1 compression for the best power and best fuel economy. When you get a 6.5 to 1 kit (which most of them are) there is less HP and they use more gas. There is a reason there aren't drain plugs on the final drives. It is because rocks can roll in between the rim and the final drive pan and over time break off the drain plug that shouldn't be there. One quart of oil disappears quickly and then a perfectly good final drive is now toast. You will change the oil one time. It will be the last time. No drain plug needed. |

Posted By: 55allis

Date Posted: 04 Oct 2025 at 12:13pm

|

Does this look like the right one for the money? https://www.agkits.com/Allis-Chalmers-226-Engine-Rebuild-Kit.aspx" rel="nofollow - https://www.agkits.com/Allis-Chalmers-226-Engine-Rebuild-Kit.aspx It says they have free shipping on this kit. I was going to go with the major kit to get all the gaskets. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 04 Oct 2025 at 1:08pm

| I don't see a C/R listed. |

Posted By: 55allis

Date Posted: 04 Oct 2025 at 1:30pm

|

I emailed them on that but they are closed today, so I probably won’t hear from them until Monday. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WD45

Date Posted: 07 Oct 2025 at 2:13pm

|

Replace this engine from one from a Gleaner E that is running. ------------- Fred Dunlop, G,B,CA, WC,WF, 3 WD45`s,gas, diesel and LP,U,D10 series III, D12,D14,D15 SERIES II,D17 Series IV in Gas and Diesel ,D19 GAS and D21,170 185,210 ,220 an I-600 8070 fwd, 716H and 1920H |

Posted By: WF owner

Date Posted: 07 Oct 2025 at 7:09pm

| I guess what scares me about buying this, or any tractor that isn't running, is why it was parked years ago. After spending a lot of money getting it running, other unknown problems could surface. |

Posted By: jvin248

Date Posted: 07 Oct 2025 at 7:37pm

Like cars, the tractors had a few things wrong like wiring and such that were annoyances but not fatal. Many things naturally fixed as a part of getting the tractor in shape to run again, like replacing wires. . |

Posted By: WF owner

Date Posted: 07 Oct 2025 at 7:54pm

Replacing wires and things like that usually didn't result in tractors being parked. Transmission, differential, final drive, hydraulic, PTO and a whole long list of other MAJOR problems often led to them being abandoned.

|

Posted By: 55allis

Date Posted: 08 Oct 2025 at 12:31am

If the rest is junk there might be a rebuilt engine for sale…. I don’t think the back end is bad. Pulled the carb apart today and it’s very clean, even the needle wasn’t even sticky! I got a plan for tires now, going to pull the 16.9s off my wd, put them on the d17 and put my new set of 13.6R28 deep tread Firestones on the wd. Last year about this time I got one heck of a deal on a set of brand new Firestones and boy they got tread!   ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 08 Oct 2025 at 12:29pm

|

Measured the sleeves today and found they are 4 and 1/8” bore sleeves in it. Are they original with the 1/8th” overbore? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 08 Oct 2025 at 12:49pm

| NO. A-C never used anything but 4 inch bore in that series of engine. They had four different compression ratios (6.5 to 1.....7.25 to 1......8.0 to 1.....8.25 to 1) but never were 4 1/8" bore. |

Posted By: dfwallis

Date Posted: 08 Oct 2025 at 1:06pm

|

Common rebuild kits were 1/8 inch "overbore". Stock was 4.0 inches. ------------- 1952 CA13092 |

Posted By: 55allis

Date Posted: 08 Oct 2025 at 1:38pm

|

I wonder if it was rebuilt not long before it got parked? Maybe I could do it right with putting new rings on all of them and put 2 new sleeves. I think I will pull the pan and check out underneath before anything is set in stone. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 08 Oct 2025 at 1:39pm

| An A-C 4 inch bore kit at 8.0 to 1 compression has more HP than a 4 1/8" does at 6.5 to 1 compression. AND uses less fuel. |

Posted By: DrAllis

Date Posted: 08 Oct 2025 at 1:44pm

| 6.5 to 1 compression ratio makes 125 psi cranking compression........7.25 to 1 makes 145 psi.........8.0 to 1 makes 165 psi.......8.25 to 1 makes 170 psi. |

Posted By: 55allis

Date Posted: 08 Oct 2025 at 5:08pm

|

How do you tell what pistons are what? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 08 Oct 2025 at 6:49pm

| Farm Equipment Knowledge section....page one.....near the bottom..... "Compression ratios for 226 engines". These are for A-C pistons only. After-market manufacturers has to make their own claims, which many are very low. |

Posted By: dfwallis

Date Posted: 08 Oct 2025 at 7:00pm

|

Cool, now google thinks I want to see ads for 4 and 1/8 pistons on every possible social media outlet :( ------------- 1952 CA13092 |

Posted By: 55allis

Date Posted: 08 Oct 2025 at 10:11pm

|

Thanks Doc I did find it, looks like I have to pull a piston and measure to find out. I did some calculations and came up that with 4.125” bore would make it a 254 cubic inch engine, no clue if that right but I thought that was interesting. Looks like to get the highest compression ratio possible would be to get piston for a 175 or d17 lp ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 08 Oct 2025 at 10:52pm

| 240 cubes and you can pull a piston and measure all you want, but the compression ratio specs are for 4 inch bore Allis pistons only. NOT any 4 1/8" pistons. |

Posted By: Allis dave

Date Posted: 09 Oct 2025 at 6:46am

|

It's fairly difficult to calculate your compression ratio. I did it a few years ago. You have to get the pison to the top of it's stroke and measure to the top of the stroke and calculate that volumn. You have to know the thickness of your head gasket and calculate that. Then you also have to calculate the volumn of the dish in the piston. Dr helped me wiht this. You need to get a piece of cut glass and drill a small hole in it. Put some grease on the piston edges to seal it. Then take a suringe and fill the dish through the hole. There other things I"m missing, but even after all this it's easy to be off a little bit. |

Posted By: 55allis

Date Posted: 09 Oct 2025 at 1:00pm

|

I wonder if you’d set the head gasket on the block with grease sealing the one that is getting tested. If you guys are willing to help me I will attempt to test. I’m sure everyone is curious what the 4.125” overbore compression ratio is. I wonder if plexiglass would work? I have some pieces of plexiglass laying around I could use. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 09 Oct 2025 at 1:03pm

|

First I need to get the engine to come completely loose (I got it to wiggle a bit) and that might involve the two new sleeves+rings. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 09 Oct 2025 at 1:56pm

| I have internet surfed around and found a piston/sleeve kit with a p/n of SK156 that is 4 1/8" bore and has flat top pistons. I need to do some more calculations at home, but this could be the 8.0 to 1 compression ratio kit that has been talked about before. While I prefer a bowl (power crater) the higher compression is more important for making HP. Will report back with calculations. |

Posted By: 55allis

Date Posted: 09 Oct 2025 at 2:40pm

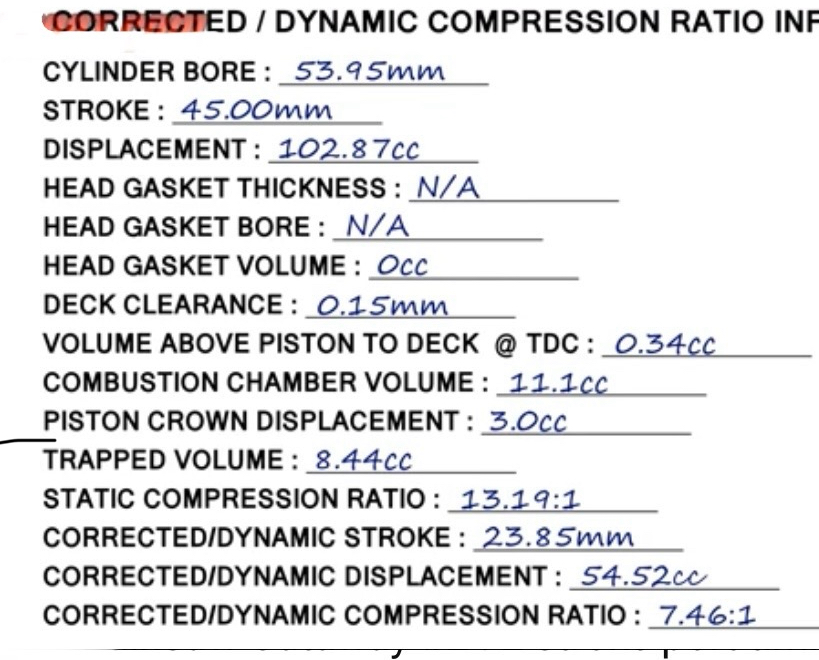

Here’s a picture of the piston in it.  Also surfed the web and found this chart for a single cylinder. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Les Kerf

Date Posted: 09 Oct 2025 at 3:02pm

|

That piston looks just like the hoof on my Norwegian Fjord Horse's foot!  Head gasket thickness and bore N/A? (Not Applicable/Not Available?) It is a pretty important factor there methinks  |

Posted By: 55allis

Date Posted: 09 Oct 2025 at 3:20pm

|

It’s just an example, not for this engine. I was going to erase what is written on it and change it to the 226 engine. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 09 Oct 2025 at 7:57pm

| That is an M & W piston. SP-48 was the kit p/n. Compression ratio was 7.5 to 1, just a little more than a std D-17 at 7.25 to 1. They were a 4 HP gain in a D-17 tractor. My research on the SK156 flat top kit makes me call it maybe almost 10 to 1 compression. A call to someone who sells them could give you the correct compression ratio number. 10 to 1 (210 psi cranking compression) will require 93 octane gas at a minimum and you wouldn't farm with it. |

Posted By: DrAllis

Date Posted: 09 Oct 2025 at 8:33pm

| TO THE TOP |

Posted By: 55allis

Date Posted: 09 Oct 2025 at 10:21pm

|

I’m not planning on pulling with it.. I want it able to pull a plow again and do it good!! ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 09 Oct 2025 at 11:14pm

|

I got on A and I parts and search that number (SK156) and they have an overhaul kit for $918 or $131 for the sleeve, piston, and rings per cylinder. And it says it’s a high compression kit and 4.125” overbore. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 10 Oct 2025 at 2:24pm

|

Would anyone know of a ring kit for the sp-48 m and w piston? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 10 Oct 2025 at 3:40pm

|

They are available from some of the aftermarket companies. If I remember correctly, I got a set from Perfect Circle several years ago. You need to measure the size of the rings. All M&W pistons (for the 201/226) are 4.125" (oversize).

|

Posted By: evan austin

Date Posted: 11 Oct 2025 at 7:48pm

| Steiner lists a piston and sleeve kit P/N ACS3056, 4 1/8" bore, they claim 7.25:1 compression, for $439.99 plus shipping. This is the first time that I have seen the compression ratio listed on one of their kits, maybe it was always there and I didn't notice it before... |

Posted By: 55allis

Date Posted: 12 Oct 2025 at 4:11pm

|

Think I’m going good used on the two sleeves due to it being decently low houred and the two good sleeves are very good. Will put rings and O rings on all the sleeves to prevent problems. Think I will rebuild the head because of a lot of pits in the valves. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 14 Oct 2025 at 12:02pm

Got the oil pan off today and figured out why it was parked, it had spun a rod bearing…  ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: scott

Date Posted: 15 Oct 2025 at 9:30am

|

Is the spun rod bearing on one of the good cylinders? |

Posted By: 55allis

Date Posted: 15 Oct 2025 at 9:40am

|

Yes, it was number 4. 1 and 4 has good sleeves but 2 and 3 sleeves are junk. Got all the pistons and sleeves out and the pistons look all good. Even the rings don’t look too bad. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 16 Oct 2025 at 6:11pm

|

Found Abilene machine has the overhaul kit for $500 and that comes with everything including shipping. Only thing is that it’s the original 7.25:1 compression ratio. But it is 4.125 overbore. Also found a guy who might be able to fix my crank shaft quite a bit cheaper. Question: how would I test the oil pump before I put it together? I want to be sure that it has good oil pressure before I put it together to be safe. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 16 Oct 2025 at 8:33pm

|

The doctor can correct me, but I believe only the (gas) 175 had the 8.25/1 compression ratio pistons (maybe some propane engines, too) and they are very hard (almost impossible) to find. |

Posted By: 55allis

Date Posted: 16 Oct 2025 at 9:34pm

|

Here’s a link to an A and I high compression kit.. https://www.allpartsstore.com/ItemDetl.htm?ResultsList=251016376624998&CategorySeq=&SelcBrand=&SelcMachn=&SelcModel=&SelcSectn=&SelcSubsc=&SearchDesc=1&TextSearch=ALLIS%20CHALMERS%20D17%20OVERHAUL%20KIT&ItemNumber=IK405" rel="nofollow - https://www.allpartsstore.com/ItemDetl.htm?ResultsList=251016376624998&CategorySeq=&SelcBrand=&SelcMachn=&SelcModel=&SelcSectn=&SelcSubsc=&SearchDesc=1&TextSearch=ALLIS%20CHALMERS%20D17%20OVERHAUL%20KIT&ItemNumber=IK405 It’s $918 bucks but according to Doc it’s 10:1 compression. I wasn’t wanting to spend that much on it though. Would be curious if anyone on here has done that kit and dynoed it? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 16 Oct 2025 at 10:58pm

| 175 gas engine is 4 inch bore @ 8.25 to 1 compression. D-17 LPgas is also 8.25 to 1 with 4 inch bore. |

Posted By: HudCo

Date Posted: 17 Oct 2025 at 8:41am

| no cumbustion chamber with flat tops |

Posted By: 55allis

Date Posted: 17 Oct 2025 at 9:03am

|

Found a 8.25:1 kit but I’m NOT going to give $2400. So I guess it’s going to go to stock. https://www.jensales.com/products/ep-915144-allis-buda-out-of-frame-overhaul-kit-allis-chalmers-g226.html" rel="nofollow - https://www.jensales.com/products/ep-915144-allis-buda-out-of-frame-overhaul-kit-allis-chalmers-g226.html ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: wjohn

Date Posted: 17 Oct 2025 at 8:06pm

|

I think I'd go with the lower CR kit at that price too! ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: ACinSC

Date Posted: 18 Oct 2025 at 7:03am

| Dumb question probably, but what is the reason for overbore? Why can't you just replace the liners and put new rings on the pistons? Thanks |

Posted By: WF owner

Date Posted: 18 Oct 2025 at 9:09am

|

You can just replace rings. Sleeves should be honed before doing that. M&W made pistons that were supposed to add power. The were introduced more for the WD45 that had the lower compression ratio. In addition to higher compression than stock, going from 4" bore to 4.125" added 14 more cubic inches to the engine. I suspect that other manufacturers followed M&W for more cubic inches. Other than through AC (AGCO now), I don't remember any aftermarket rebuild kit that was not the 4.125". Sleeves are usually replaced when rebuilding for a number of reasons. These engines usually have lots of hours of run time, when they are rebuilt. Like engines that have dry (pressed in) sleeves or have no sleeves, there is usually some damage and/or wear to the bore. Sleeveless engines have to be bored by a machinist to get a perfect bore. Wet sleeves (like most AC or Buda engines) are relatively easy to replace, so rebuilding is easier (and usually less expensive) than a dry sleeved or an engine without sleeves. In addition, wet sleeves have O rings on the outside to seal them, and the O rings deteriorate over time, so the sleeves have to be removed to replace the O rings. The wet sleeves also corrode over time and it's not unusual to have an old engine that develops pin holes in a sleeve. New sleeves on rebuilding usually eliminates the possibility of leaks.

|

Posted By: 55allis

Date Posted: 18 Oct 2025 at 11:05am

|

Would it be safe to sandblast the block? Was thinking about the different panels not matching so eventually I will paint the rest of the tractor. If I could go ahead and sandblast, prime , and paint the block while it’s all apart it would be one less thing to pull apart later. Plus a brand new engine needs brand new paint. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 18 Oct 2025 at 12:40pm

|

Personally, I would never sandblast an engine, especially one that is tore down. I doubt you could ever get all the sand out it. I would rather pay someone to "hot tank" it. It will also do a better job cleaning the inside of the engine block.

|

Posted By: 55allis

Date Posted: 19 Oct 2025 at 10:34pm

|

Would hot water power washing be a crime? I’m just going through and checking cheap, safe options. Got the crank off completely and the main bearings look good. Found this number on the back of the rod bearings.  [IMG] [IMG]Edit: doubled the pictures. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 19 Oct 2025 at 11:37pm

| Federal Mogule brg and probably their part #. Heard of using easy off oven cleaner where grimy. |

Posted By: ACinSC

Date Posted: 20 Oct 2025 at 5:41am

| Thanks for the explanation Curt, and good luck Gavin. |

Posted By: WF owner

Date Posted: 20 Oct 2025 at 6:45am

|

I use a regular pressure washer and elbow grease. Lots of spraying (solvent), scraping, brushing, then hitting it with the pressure washer. My pressure washer is 3000 psi and I use a turbo nozzle (stay away from wires and small lines). I would use a hot water pressure washer in a minute, if I had one. I think the SB on your bearing is probably standard bore or standard bearing.

|

Posted By: 55allis

Date Posted: 21 Oct 2025 at 10:02am

|

Thanks Curt!! My Dads hot water power washer seems to take anything off, including paint. I have used it before to clean gear cases with old grease and it removed all of it till clean. Is there a way to test the oil pump while it’s apart? Maybe rebuild the pump too? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 22 Oct 2025 at 8:24am

| There is no such thing as a rebuild kit for the oil pump. There are no new parts available that I know of. A good used pump is all you have to work with. I always disassemble the oil pump and inspect the main wear areas. Having a running engine before you tear one down gives you a chance to know what the oil pressure was like. Drive out the roll pin on the top drive gear that mates with the camshaft. Remove the six screws on the bottom and carefully remove the end plate to avoid tearing the gasket (which you don't have). Loosening the screws first and tapping on the plates sides may help loosen up the gasket fit. Remove the idler gear and inspect. Drive downward on the long shaft to free it from the camshaft drive gear. Inspect the bottom gear and especially inspect the long driveshaft for serious wear near the top. If it's worn, it will be noticeable. Remove the pressure regulator spool, spring guide spacer and spring and make sure everything is free to slide. Clean it up and reassemble if the parts all look decent. Pour some oil down the oil tube. Use a rubber tipped blow gun and gently blow thru this tube to 'motor" the pump. DON"T overspeed it. Remove the suction screen baffle (carefully unbend tabs), clean the screen really well and reassemble. Two new bolts and washers to hold the oil pump in place to the block. |

Posted By: 55allis

Date Posted: 22 Oct 2025 at 2:36pm

|

Thanks Doc, Never tore into one of those this far. Figured I’d better check everything being it spun that rod bearing. Been busy with harvest work so haven’t had time to work on the tractor much. I have been calling around for local people with possible parts, so far I possibly have found a hood side and a source for a crank if this one is shot (still haven’t got it into the machining shop). Only time I have is while I’m waiting on a dump. I did get the crank out and the head is almost ready for the rebuild. This thing should run awesome!! Really hoping everything behind the engine works as it should.. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 22 Oct 2025 at 9:35pm

The main bearings have been turned once I think. But they don’t look bad.. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 28 Oct 2025 at 6:02pm

|

Got a few hours to work on it again so I pulled the oil pump apart. The shaft looks almost perfect other than a few scuffs, everything else looks fine to me. Is the suction screen supposed to float in the oil pan? It seems to leak oil out of a crack in it. The screen cover had lots of metal pieces in it but I was figuring that since it spun that bearing. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 28 Oct 2025 at 8:40pm

| The D17 screen does float. |

Posted By: 55allis

Date Posted: 28 Oct 2025 at 8:53pm

|

Could that be possibly be a reason for it to spin a bearing? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 28 Oct 2025 at 8:57pm

| Not logically. All the other bearings look fine. An oil pump failure (there is none) would have ALL bearings damaged, not one. |

Posted By: SteveM C/IL

Date Posted: 28 Oct 2025 at 9:11pm

| It doesn't float on top of the oil. It's submerged. Been too long....I think it has an air pocket to keep it raised but it can sink if oil is low or steep hill etc... Either way it's always in the oil so that's not what ruined your bearing. |

Posted By: 55allis

Date Posted: 28 Oct 2025 at 10:35pm

|

That was what I was thinking but I wanted to make sure. I will see if I can get it to drain and get it patched up. Probably with have to have it soldered (looks like a visit to the local blacksmith). ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: AC7060IL

Date Posted: 27 Dec 2025 at 9:27am

| 55Allis, how is this fence row D17 patient? Did you locate some good used sleeves/pistons/rings/etc? Or did you go with a new rebuild kit? |

Posted By: 55allis

Date Posted: 27 Dec 2025 at 10:36pm

|

I’m planning on a complete new rebuild, figured by the time I’m done anyway it won’t cost much more. The crank is the problem right now, it’s possibly gone too far to have it ground but the guy doing it could possibly get it built up again. Currently waiting for a phone call from him next week (possibly and hopefully) for a definite answer. I did get the head fully rebuilt (new valves, guides, and freshened up seats). Also got the rims for the WD primed and painted so I can put the 16.9s on the D17, at least then I can say it’s on the start to go together..  ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 27 Dec 2025 at 11:56pm

| There is zero reason for him to "build up" a crank journal when there are hundreds of used cranks laying around in salvage yards. Bearings of minus .040" should be available for that crank. |

Posted By: WF owner

Date Posted: 28 Dec 2025 at 6:05am

Things like this happen when you have a mechanic that really isn't familiar with Allis Chalmers engines. Unnecessary expensive repairs get done without anyone realizing there is a lot less expensive fix. A friend of mine has a construction business. His screening plant had an AC 125 (B, C, CA) engine on it. It started putting coolant in the oil. His mechanic, who is a very good heavy equipment mechanic, told him to get another head because the head was cracked. He gave me the old head. I took the core plugs out of it and they were rusted out (not unusual). There was nothing else wrong with the head. Sometimes paying a mechanic that is familiar with the brand you are working on is worth the extra cost.

|

Posted By: 55allis

Date Posted: 29 Dec 2025 at 1:26pm

|

Not going to build up, just confirmed that the rod bearings are std and the crank was turned .020 under… Bet that really hammered/knocked when it did run!! Guy can get me a .020/.020 under crank for $700. Is there any known cheaper options? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: WF owner

Date Posted: 29 Dec 2025 at 3:37pm

Has the crank been newly machined to .020/.020 ? If it has, the price is in the ballpark Make sure it is a crankshaft for a G-226 and not a W-226. When I look at replacement crankshafts, some say their crankshaft fits a WD45, D-17, 170 and 175. The G-226 were in the D-17, 170 and 175, but not in the WD45 (which was a W-226). They use different size bearings. |

Posted By: 55allis

Date Posted: 29 Dec 2025 at 9:02pm

|

Thanks for the warning!! Yes pretty sure it was freshly done. Sure don’t take long to fill it with green paper …  I was really hoping this one would be saveable but we win some and lose some. I had a slight hope of finding a junk gleaner around here but I guess the scrap price is too good for that. I have been going off the casting number (229022) on the crank so hopefully I get the right one. The spun rod is bad too so I’m wondering if it’s the same as a wd/wd45? I think I have some of those on hand… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

55allis wrote:

55allis wrote: