"Belly Filters"

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=205006

Printed Date: 05 Feb 2026 at 5:38am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: "Belly Filters"

Posted By: tbran

Subject: "Belly Filters"

Date Posted: 19 Jan 2025 at 8:36am

|

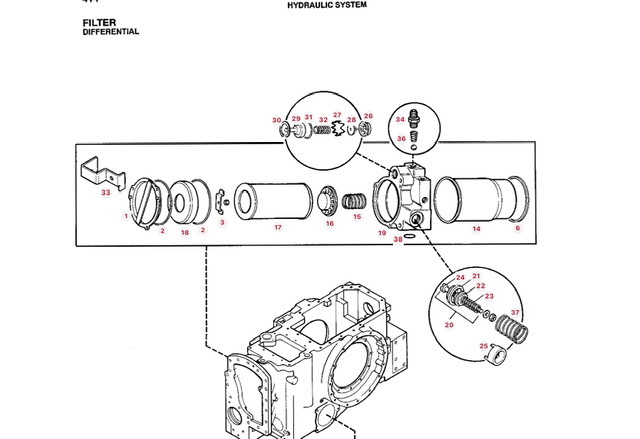

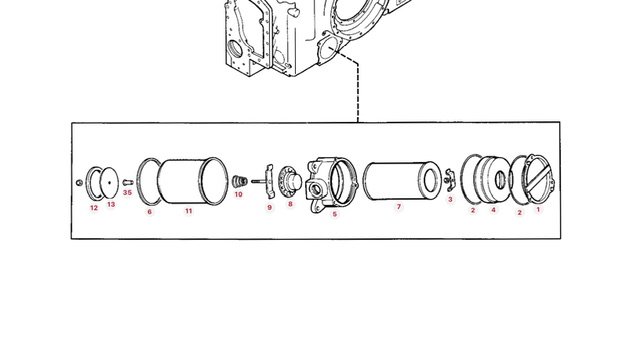

This is just a comment on several issues we have had in the past year. For some reason we are having problems after a filter change - with after market and OEM filters - with customers having a complaint of no hydraulic flow. About 10% of sales. The problem is either the filters are a very small degree shorter, or are 'crushing' a very small amount and not allowing the 'trap door' to fully open. What we are doing is removing the cork gasket from the old filter and glueing it to the new one. That is working. IF too thick a gasket is added it collapses the filter. IF the cork can't be removed a 'made' thin gasket will work. The symptoms are noisey cavitating remotes, especially when cold, and steering issues.

------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Replies:

Posted By: darrel in ND

Date Posted: 19 Jan 2025 at 8:41am

| That could be the answer to the issue I've been having with my 7060. Be a while before I can check it out, but it's a great place to start. Thanks Darrel |

Posted By: DougG

Date Posted: 19 Jan 2025 at 9:09am

| Thanks for that info- what kinda glue works for that? |

Posted By: tbran

Date Posted: 19 Jan 2025 at 10:28am

|

loc-tite products or just a 'thin' coat of silicone. Doesn't take much. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 19 Jan 2025 at 10:41am

| We always use to roll on an Oring of the right size diameter onto the screen and then place the screen in the end of the filter as usual. Oring fatness was approx 1/4" to be sure the door got opened plenty. Oring for reused for the next filter change. I'd been doing that for 40 years because we had some problems a long time ago, so it became just a standard practice for us. |

Posted By: 8070nc

Date Posted: 19 Jan 2025 at 1:42pm

|

Im glad to see this post because Ive got an 8070 that doesnt act just right ------------- 1984 80780 1957 D14 DES 300 with 25000 engine 616 tractor |

Posted By: CrestonM

Date Posted: 19 Jan 2025 at 2:40pm

| I've changed filters and fluid on a 7010 recently, and the remotes make that cavitating noise a lot, especially when cold. I'll look into adding an O-ring as doc suggested, since I've already discarded my filters. |

Posted By: DrAllis

Date Posted: 19 Jan 2025 at 3:28pm

| Everything hydraulic begins at the left-hand belly filter. If that spring loaded door isn't being pushed open enough, there will be nothing but trouble. Thee most common issue is the screen not being transferred over from the old filter to the filter. |

Posted By: SilverShoes

Date Posted: 20 Jan 2025 at 6:44am

| Are all OEM Agco filters being made correctly? |

Posted By: AC7060IL

Date Posted: 20 Jan 2025 at 3:09pm

| Tbran, thanks for sharing your knowledge. Would these filter issues have any influence to cause belly filter caps to leak constantly? |

Posted By: SilverShoes

Date Posted: 20 Jan 2025 at 4:01pm

| 7000 and 8000 series had different sealing Orings. The 8000 are larger in diameter than the 7000 series. Make sure you have the correct ones, I learned this the hard way. Even had a parts guy tell me there isn’t a difference but there definitely is. |

Posted By: DrAllis

Date Posted: 20 Jan 2025 at 7:34pm

| For 45+ years I've done it like this. 7000 series ...if either Orings aren't damaged, I don't use the new ones. Wipe the outer Oring with a rag that has brake kleen on it to get all oil residue off that area. Wipe the filter cover LID with the same rag with brake kleen. Run a bead of RTV silicone around the lids edge and put it together. You will have no leaks. |

Posted By: SteveM C/IL

Date Posted: 21 Jan 2025 at 9:25am

| These belly filters are a little intimidating. I've always tried to pay attention to the order of things as they come apart and reinstall accordingly. A good video of the procedure would be helpful. There are instructions with AGCO filters but after Tim and Doc's comments I start second guessing things. Do the filter housings(the big tube) ever get pulled and those orings replaced? I never have. What is the little sender on the rt side return filter head for? Isn't that what turns on the HYD filter light? That light is on a lot on my PD 8070 but everything seems to work ok. I changed both filters when it first started flickering to no avail. I've chased that wire and can find nothing wore through to ground it. Often wondered it some metal particals are in the sender causing it to make contact and ground out. I may be off base and not understand how it works. |

Posted By: SilverShoes

Date Posted: 21 Jan 2025 at 12:47pm

| Oil would have to be drained to change the filter housing seals. I’ve got a 7045 that they leak and need resealed. Just hasn’t been a priority project |

Posted By: Mikez

Date Posted: 29 Jul 2025 at 12:41am

|

Hello. Going to be changing these filters on 8000. New to us and remember this post. Was thinking what if last guy in there did it wrong, so what’s the problem areas to look at and make sure are correct. Thanks   |

Posted By: DrAllis

Date Posted: 29 Jul 2025 at 6:21am

| If the hydraulics and power steering have been working correctly, it is highly doubtful that anything is wrong. Be sure to remove #8 screen from the old filter and transfer over to the new filter. Do NOT assemble either side bass-ackwards. Your owners manual has good pictures showing which way things go. If there were no leaks at the covers, I never use new Orings and lightly RTV the lid. |

Posted By: Mikez

Date Posted: 30 Jul 2025 at 4:41pm

| I haven’t been in it much myself and don’t think any steering issues but hydraulic noise. |