D15 series II hydraulic pump failure

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=204818

Printed Date: 07 Nov 2025 at 7:03pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D15 series II hydraulic pump failure

Posted By: 1950AllisWD

Subject: D15 series II hydraulic pump failure

Date Posted: 04 Jan 2025 at 7:43pm

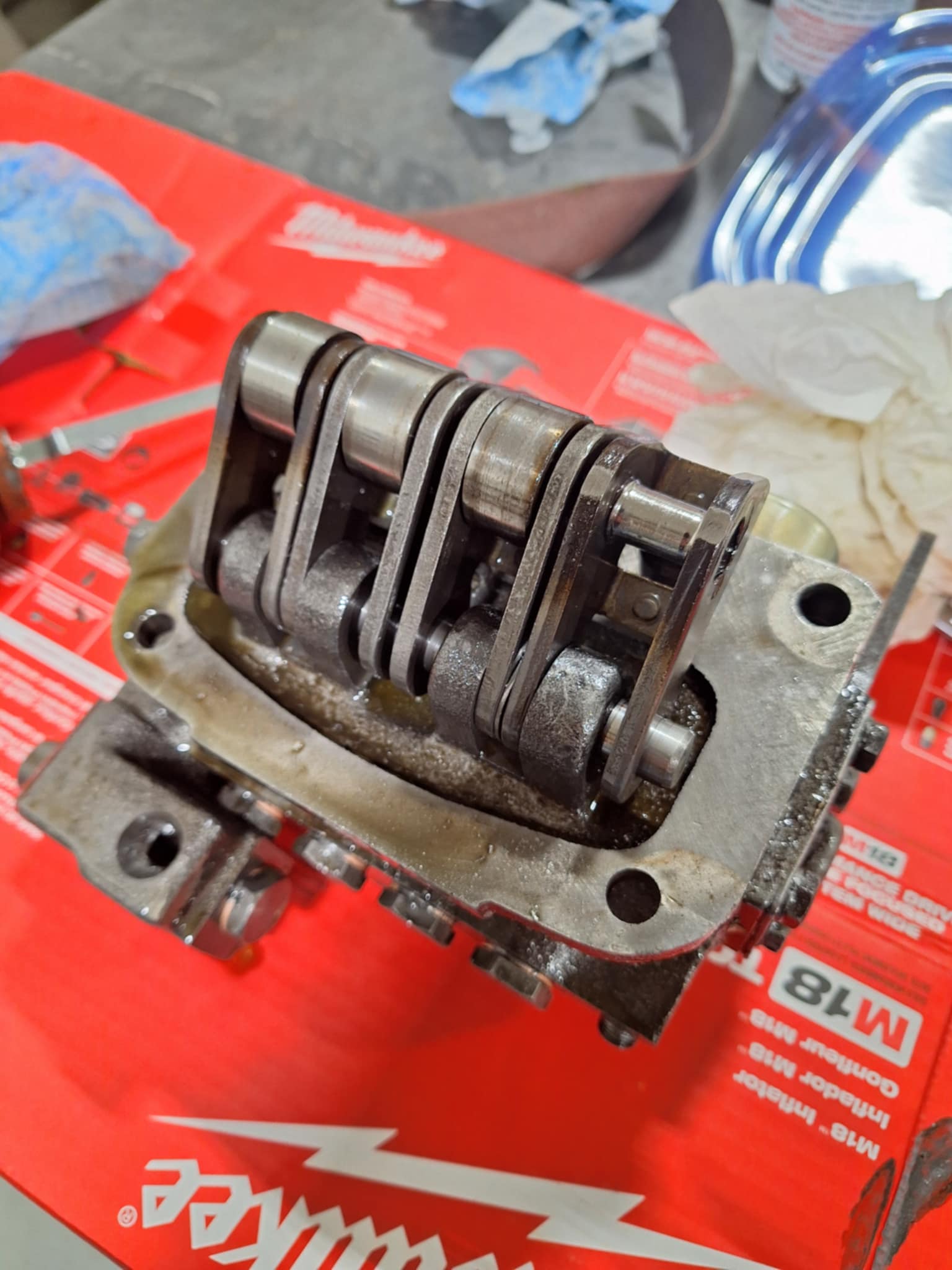

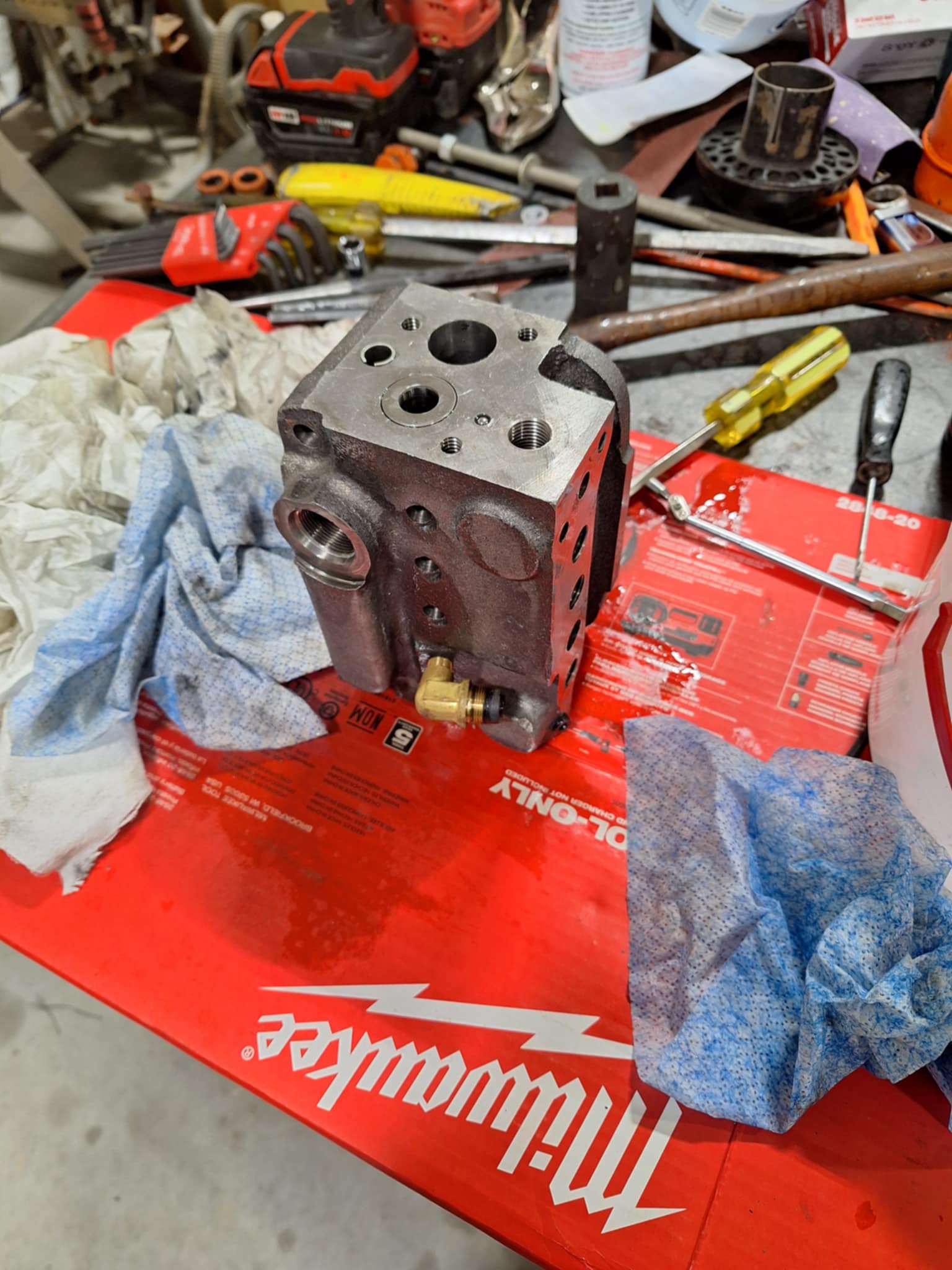

| I've got a 63 Allis D15 that the hydraulics have been weak on since I bought the tractor. It also pushes hydraulic oil from the hydraulic sump into the power director housing. I decided to drop the pump this winter to see what was going on. It would appear the pump had been run low causing damage to the cam lobes on the input shaft and causing total failure of one of the roller followers. The inside of the sump was full of steel shavings. I've got the pump mostly disassembled. The plungers and most of the internals don't look to be in bad shape. I'm looking for input on whether or not I should buy a used pump or if I'll be fine cleaning up the one I have. The tractor still had lifting power, it was just slow and would not lift all the way up in one go. I'm leaning towards replacing the input shaft with a good used unit as I have to tear the torque housing down to replace the seal between the hydraulic sump and power director anyhow. While the tractor is apart I plan on going through everything from the flywheel back. Power director seems to work fine, stays in as long as the oil level doesn't get too high. Tractor doesn't jump out of any gears. I was planning on replacing the hose and cylinder seal on the real lift cylinder while I'm in there. The tractor has a loud and I mean loud howl in 4th gear. Sounds like the final drives. I've heard that this is just how these tractors are but I've never been on another d series. Going to go through all the bearings in the trans and finals. Any thing else I should check out while I have it apart? Sorry for such a long post. |

Replies:

Posted By: AC720Man

Date Posted: 04 Jan 2025 at 7:55pm

|

Not sure how to describe the sound in 4th gear on our series II but it’s made it since it was new. I guess your description seams fitting. Don’t think you have an issue, it’s just how they are. Have 2 neighbors that theirs makes the same sound. How do your brakes function? Good time to check the seals and brakes. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: 1950AllisWD

Date Posted: 04 Jan 2025 at 8:48pm

| I plan on checking the brakes when I go through the final drives. Good to know the howl isn't anything to be too concerned about. I'll post some pictures as soon as I figure out how. |

Posted By: AC720Man

Date Posted: 04 Jan 2025 at 9:57pm

|

Change the oil in the bull gear pan. That is often over looked. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: 1950AllisWD

Date Posted: 04 Jan 2025 at 10:35pm

|

Posted By: DiyDave

Date Posted: 05 Jan 2025 at 4:36am

|

1. clean off the burr on the cam, by whatever means you can. I have bumped the starter, with the plugs out, while an assistant held a strip of emery cloth against the cam. Cam does not look extremely bad. 2. while you have it down, r&r the internal cyl lift hose, in back, if it ain't bad, it will be soon...  ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: Kenny L.

Date Posted: 05 Jan 2025 at 5:58am

|

Also a good time to replace the shaft (70228627) and bushing ( takes 2 70233270) that the clutch pedal rides on if there is a lot of play also the o-ring (70232984) for the pto shifter and both o-rings on the power director shift (takes 2 70232985). If you do the brakes and your tractor serial no. is 9001 & up, watch the washer spring they're 6 of them they're NLA. Also welcome to the forum. What part of Iowa your from? I use Bill Deppe for most of my use parts and after market parts he's located in Maquoketa, Ia 563-652-2949 shop 563-357-2615 cell and Helle Equipment in Dyersville Ia 563-875-7154. for new parts, or Gerry VandeVorde 319-350-6710 after market parts. HTH |

Posted By: PaulB

Date Posted: 05 Jan 2025 at 6:36am

|

If needed: I have a complete used "take out" D14/15 pump available. $100 + shipping. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: DrAllis

Date Posted: 05 Jan 2025 at 8:06am

| If it was mine, and I didn't need to use the lift arms for heavy lifting or a mounted plow requiring the Traction Booster system, I'd probably source a salvage yard hydraulic stack from a D-17 IV, 170 thru 185 and fabricate an under hood belt driven 5 to 6 GPM hydraulic pump. Or go with the hyd loader style crankshaft driven pump and just go without the high pressure system and changing out a clutch shaft, which is a big job. CoggonObrien has a post on this D-15 II live system from about 5 yrs ago. It may have been titled "D-015 series 3 hydraulics" or something like that. |

Posted By: 1950AllisWD

Date Posted: 05 Jan 2025 at 9:27am

I've got to replace the seal between the sump and power director anyway so I'll have the shaft out to deburr and inspect. We'll see what it looks like once it's out of the tractor. I definitely plan on replacing the rear lift cylinder hose while I'm in there. |

Posted By: 1950AllisWD

Date Posted: 05 Jan 2025 at 9:34am

The pedals are actually pretty tight on this tractor. I'll definitely be replacing any seals/orings/gaskets I come across. I'm in north central iowa. Thanks for the good leads on parts sources. |

Posted By: 1950AllisWD

Date Posted: 05 Jan 2025 at 9:35am

I may be interested eventually. I'll message you if I decide to completely replace the pump. |

Posted By: 1950AllisWD

Date Posted: 05 Jan 2025 at 9:42am

I've seen that thread on adding live hydraulics and a d17 IV valve stack to a d15. I'd like to do that eventually to run along side the allis pump. I've got a snap coupler plow I pull at shows from time to time and I would like to keep the traction booster intact.

|

Posted By: DrAllis

Date Posted: 05 Jan 2025 at 11:31am

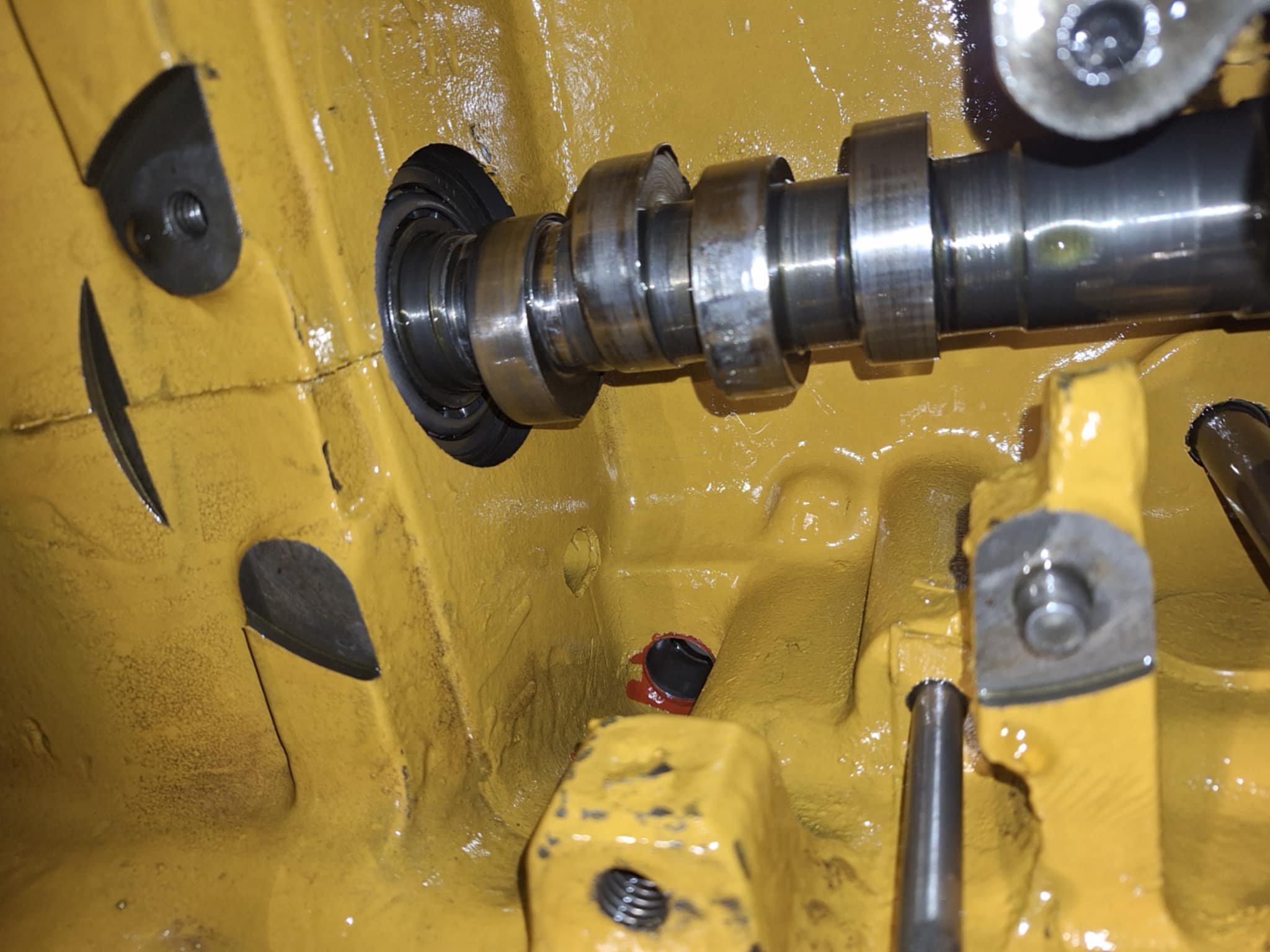

| If the oil transfer problem was on my D-15, I'd just knock out the plug between the compartments and let the oil run between them like a Series 3 D-17 was. Your clutch shaft looks terrible and if you want to keep the old pump system, the clutch shaft seals replacement is a no-brainer while replacing the clutch shaft. This failure didn't happen overnite. It was like that when you got the tractor. Unfortunately, there are many of these vintage tractors that do not use the hydraulics at all and the oil levels aren't maintained properly and who knows how low it might have been on oil. EDIT: and every D-15 I've ever driven down the road howl like he77 at road speed. |

Posted By: SteveM C/IL

Date Posted: 05 Jan 2025 at 4:05pm

| Dad was the local mechanic. Worked on anything that had an engine. Told me a lot of the old retired Allis's ruined hydraulic pumps and cams because nobody checked the oil anymore. Just as Doc stated. |

Posted By: 1950AllisWD

Date Posted: 05 Jan 2025 at 6:33pm

I'm guessing it probably happened when grandpa owned it. Had no trouble lifting a 6ft brush hog when I was a kid. Made a little more progress this weekend. Splitting the transmission from the torque housing will be the next task.

|

Posted By: Mikez

Date Posted: 06 Jan 2025 at 10:50pm

|

Probably your problem with tractor is is that John Deere clock on wall. Haha just kidding

|

Posted By: 1950AllisWD

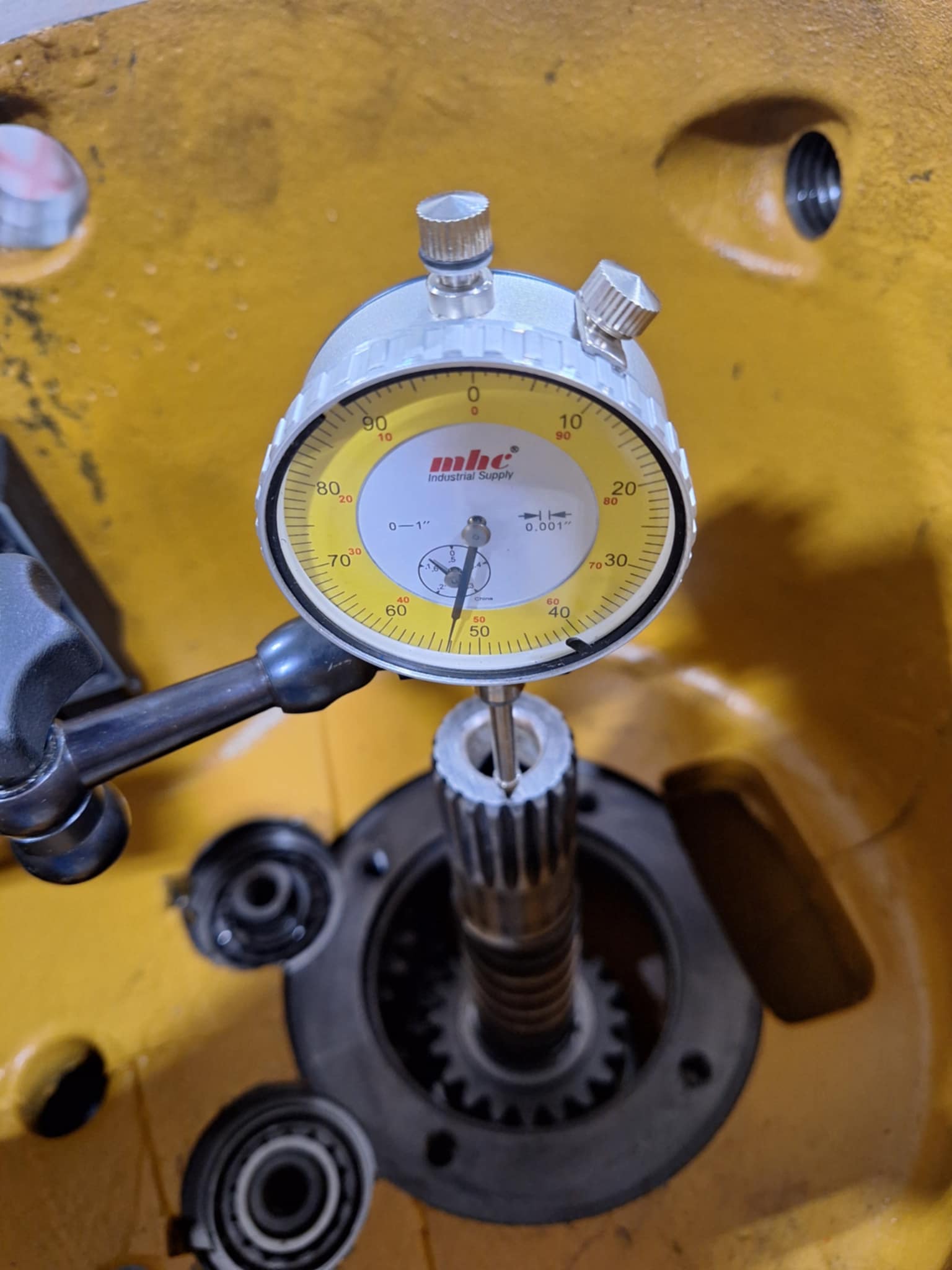

Date Posted: 12 Jan 2025 at 6:51pm

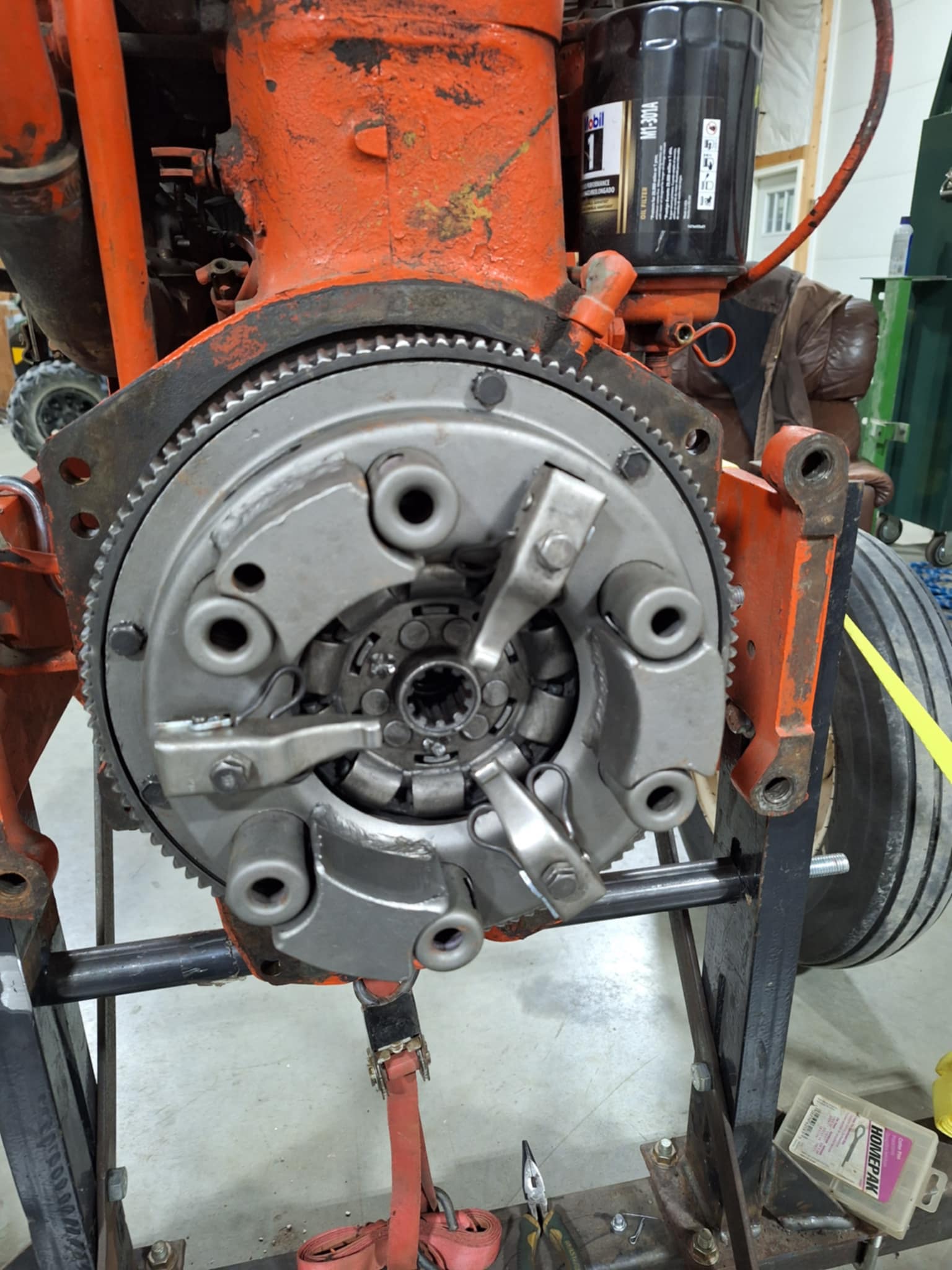

| I've made some progress this weekend. I got the torque housing split from the transmission and got it up on the bench. Spent some time cleaning the hydraulic housing and bell housing out. Was finally able to get the clutch shaft pulled. The seals between the hydraulic sump and the power director were completely gone. The seals on the clutch end were not much better. The clutch shaft cams are real rough. Looks like we will be searching for a replacement. Also pulled the clutch and flywheel off the motor. Clutch disc still has quite a bit of life left in it. Throw out bearing feels good. All of the clutch fingers are worn unevenly. I'm assuming this can be corrected by adjusting them so they all contact the throwout bearing evenly? Ring gear teeth are rounded in a few places. I'm guessing the ring gear can be reversed? Figured I will probably flip it and rotate it a bit so the wear spots are not in the same place. |

Posted By: 1950AllisWD

Date Posted: 12 Jan 2025 at 6:54pm

|

Posted By: SteveM C/IL

Date Posted: 12 Jan 2025 at 7:00pm

| Often only one side of ring gear is chamferd for bendix engagement. Just be aware. |

Posted By: DrAllis

Date Posted: 12 Jan 2025 at 7:35pm

| If the ring gear isn't too bad, rotate it 90 degrees !!! Do NOT turn it over. Engines only stop in two places. Rotate it 90 degrees and you'll have new meat. |

Posted By: 1950AllisWD

Date Posted: 13 Jan 2025 at 4:10pm

|

Yep, looking at the picture of it I believe it's only chamfered on one side. I'll just rotate it 90 degrees. Thanks! Does anyone know if the clutch shaft is shared between the d14/d15 series I/II? Is the hydraulic pump assembly the same as well? Looks like Agco still stocks most of the seals and gaskets. |

Posted By: IBWD MIke

Date Posted: 16 Jan 2025 at 9:22am

| Nice bumping into you yesterday, what are the odds!? I'd check with Bill for that shaft. Contact info shouldn't be hard to find here. The parts-man's idea of welding it might be viable but I'm staying with 'who has a cam grinder'? |

Posted By: 1950AllisWD

Date Posted: 16 Jan 2025 at 6:12pm

| Yeah, small world isn't it! I gave Bill a call that afternoon. He's going to see what he can come up with. |

Posted By: 1950AllisWD

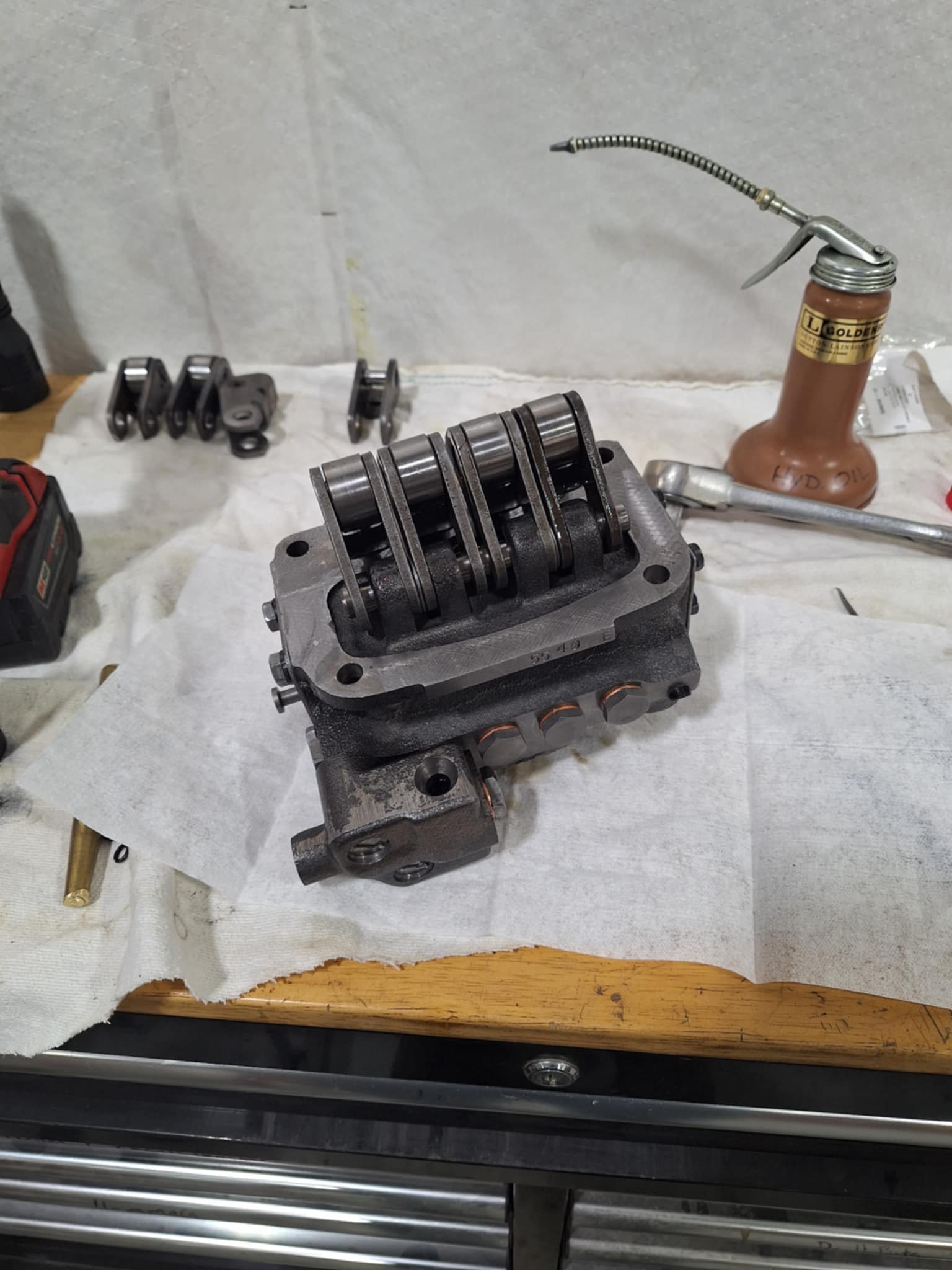

Date Posted: 09 Mar 2025 at 5:11pm

I've made a little progress. Bill Deppe was able to get me a clutch shaft and a set of roller followers. I've got the torque tube mostly back together with new seals and gaskets. Just have to get the power director sorted out and then I can get the trans, torque tube and motor mated back together.

|

Posted By: DrAllis

Date Posted: 09 Mar 2025 at 5:23pm

| Pretty cool foot clutch pressure plate. I have never seen one with extra weight welded to the pressure plate !!! |

Posted By: Alex09(WI)

Date Posted: 12 Mar 2025 at 11:49pm

|

Wow, that pressure plate is interesting. I've seen so many of them in my neck of the woods with the weights welded on, I thought it may have been factory on the D15 II tractors. Looks like the project is coming along very well! ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: 1950AllisWD

Date Posted: 20 Apr 2025 at 8:52pm

Well, Bill Deppe was able to get me the power director parts I needed. Made a lot of progress over the last couple of weekends. Got the power director back together with the new detent plates and clutch disks. Was able to get it shimmed to spec. Got rear lift back together with new cylinder seals, rocker shaft seals and a new internal hose. Tractor went back together without too many hickups. Every compartment in the rear-end has fresh utf. I was able to get it running this weekend and take it for a test drive. Everything works well! Just a few little odds and ends to wrap up before the side panels can go back on.

|

Posted By: 1950AllisWD

Date Posted: 20 Apr 2025 at 8:59pm

|

One thing I was wondering about that I couldn't find in the manual. Do you check the fluid level in the power director by threading the dipstick all the way in? Also does anyone have any experience with aftermarket tachs? My tach has never worked (makes bad grinding noises when you hook the drive up) and I was wondering if it would be worth having this one restored or just ordering a new one? They seem to be inexpensive enough. |

Posted By: AC720Man

Date Posted: 20 Apr 2025 at 9:35pm

|

Personally, I wouldn't waste my money on a aftermarket one. I've heard quite a few folks getting less than 50 hours out of them before they malfunction. Star Speedometer in Fla can repair your factory tack like new. If your bezel, decal, and pointer are in good shape then that will save you some money. Haim is not cheap but I think for what he does its a fair price. He totally tears it apart and repairs whatever it needs. 1 year warranty. He has done 4 for me over the years and his work is excellent. I highly recommend him. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: DrAllis

Date Posted: 20 Apr 2025 at 10:14pm

| Screw the dipstick clear IN to check the oil. |

Posted By: 1950AllisWD

Date Posted: 20 Apr 2025 at 10:18pm

I've seen them recommended many times on the forum. That'll probably be the route I end up taking. |

Posted By: 1950AllisWD

Date Posted: 20 Apr 2025 at 10:19pm

Thanks! |

DiyDave wrote:

DiyDave wrote: