Allis Chalmers b Ross steering box

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=204237

Printed Date: 08 Nov 2025 at 9:25pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Allis Chalmers b Ross steering box

Posted By: Hardwater000

Subject: Allis Chalmers b Ross steering box

Date Posted: 20 Nov 2024 at 5:55am

|

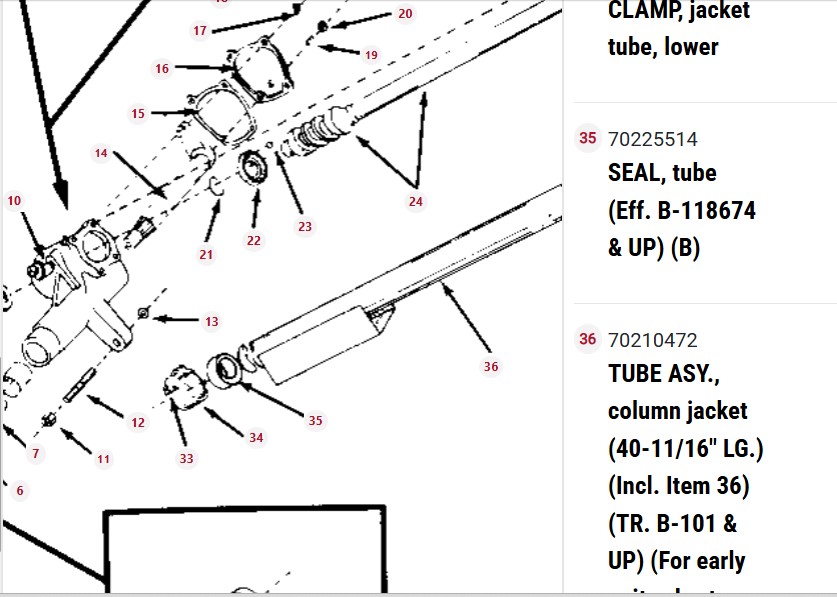

What type of seal is everyone using for the shaft that the steering wheel rides on, where it goes into the steering box (Ross)? Tia |

Replies:

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 8:42am

some have a seal, some dont... i think its more to keep water from leaking down the shaft ??? Not a seal for the BOX... ------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 20 Nov 2024 at 9:02am

| Yes just to keep water out |

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 9:28am

|

Google search does not show that part number.. Sandy Lake or other AGCO dealer might be able to locate it... I think MOST people would get the ID and OD and just buy generic....i think i did that many years ago on one box... normally mine did not need replace.. ------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 20 Nov 2024 at 1:03pm

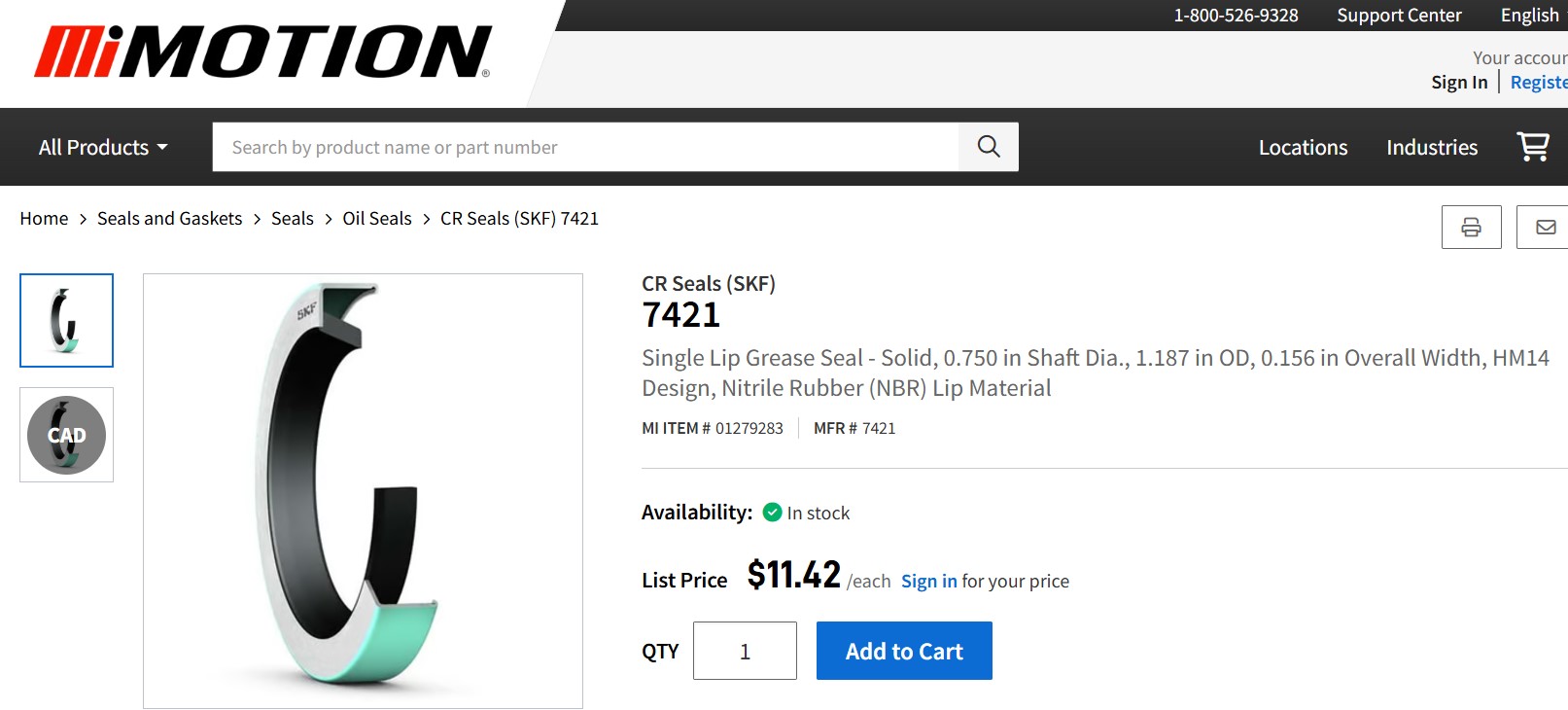

| Cr 7421 .75id 1.187id wat I measure we will see |

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 3:33pm

thats a good number... sounds close..... that seal is not very THICK ... but the OD and ID are right. ------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 20 Nov 2024 at 5:36pm

| Let's hope, I have looked at the book like u said that part number wasn't working and after I posted I decided to take it to work and measure it all and have another set of eyes to make sure a regular seal would work, most say to use felt... Really I'm worried more about outside leaking in more so than out. |

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 5:54pm

|

make sure there is a pin hole in the TUBE on the bottom, just above the seal... any rain / moisture that gets inside and runs down the tube should STOP at the seal and drain outward.... put a thimble full of grease all over the seal prior to sticking the shaft thru it.. The grease should be there forever and help the seal.

------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 20 Nov 2024 at 6:01pm

| I need to-do that I'm using PVC for the column, original was rusted out. I'm in the fitting stage not sure it will fit right and or look good. |

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 6:11pm

|

steel conduit is a good replacement... exact size. ------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 20 Nov 2024 at 9:06pm

| I have located some conduit in case this doesn't pan out. I hate to spend that kinda money on the regular bushing that the shaft rides in. I lucked into finding one that fits the PVC worked out perfect for that, the only thing that worries me is mounting the top around the throttle the regular mounts seem to fit it fine. I am missing the piece that the column sits on was missing when I bought the tractor so that will be another thing to build or try to locate. |

Posted By: steve(ill)

Date Posted: 20 Nov 2024 at 9:24pm

|

I hate to spend that kinda money on the regular bushing that the shaft rides in I have made a couple in the past out of brozne, turned on the lathe... New ones seem to be nylon / plastic .... --- 100 years ago they use to make bushing out of oak wood.. Maybe you could get a piece of oak ( fire wood) and drill a 3/4 inch hole in it and grind down the outside ? ... piece of ash from an old baseball bat ?

------------- Like them all, but love the "B"s. |

Posted By: Hardwater000

Date Posted: 21 Nov 2024 at 5:14am

| That's is a good idea, I didn't think of that. The tractor for the most part is waiting on the steering box to get sealed up (seal is ordered) so I can get it back together to fit the column. I hav took it all apart and wire brushes it all down to metal. Lol I went threw 2 angle grinders and numerous wire brushes after thought I shud have drug out the sandblaster. Just a ruff estimate with labor and parts I shud be just under 10,000 in it lol.jk thanks for the help Steve. U always take the time on any questions I have asked to give me and a lot of other people good answers and advice. I usually read a lot of post on here bf I ask anything... |