Can you machine a Allis 160 flywheel

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=203608

Printed Date: 16 Oct 2025 at 8:56pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Can you machine a Allis 160 flywheel

Posted By: CleaningGuy

Subject: Can you machine a Allis 160 flywheel

Date Posted: 11 Oct 2024 at 10:51am

|

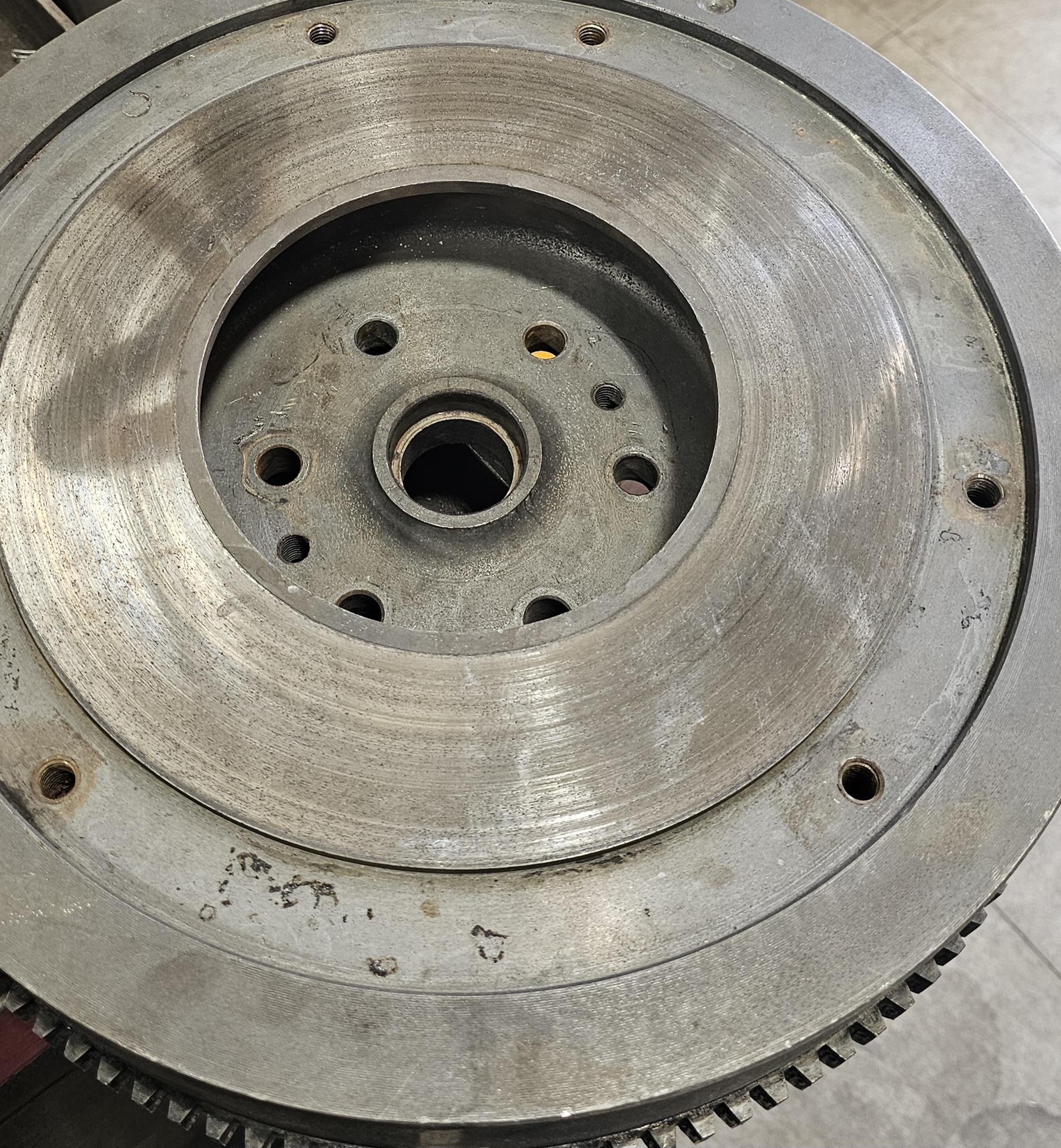

Hi all, I'm working on an Allis Chalmers 160 flywheel (see picture attached) and had a couple of questions about machining it. Specifically: 1. Can the flywheel be resurfaced using a normal stone wheel, or does the pressure plate mounting surface need to be milled separately to maintain proper alignment? 2. If I were to remove about 0.010" or 0.020" from the clutch face, how can I ensure that I maintain the correct clutch clamp force? Are there any adjustments needed to account for the material removed? Any insights or tips from someone with experience on this model would be greatly appreciated.

|

Replies:

Posted By: Alvin M

Date Posted: 11 Oct 2024 at 2:44pm

| Flywheel step must be .175 |

Posted By: CleaningGuy

Date Posted: 13 Oct 2024 at 12:41pm

| Yeah, I understand it can be machined to a .145" step, but how do you machine the middle portion where the clutch assembly mounting bolts? Most machine shops around here only have two types of grinding wheels, and I'm not sure if they have the right equipment for this part of the job. Do you know if there's a special tool or process required for that middle section? Or would milling be the better option? |

Posted By: SteveM C/IL

Date Posted: 13 Oct 2024 at 10:58pm

| Take it to the machine shop and let them determine if they can do it. When they did my Cat flywheel they cut the disc surface then raised up and cut the mount surface to establish the step. |

Posted By: IBWD MIke

Date Posted: 14 Oct 2024 at 5:33am

|

Any competent machine shop will have a grinder that will handle that. Tractor flywheels all seem to have a step. |

Posted By: Fred in Pa

Date Posted: 14 Oct 2024 at 7:07am

|

The problem most common machine shops have doing these is because the pressure plate step is below the disc surface .I have a machine shop that can do these . Been doing these a long time . Maybe post another picture showing this step a little better. ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: CleaningGuy

Date Posted: 14 Oct 2024 at 1:58pm

|

Posted By: Fred in Pa

Date Posted: 14 Oct 2024 at 2:33pm

|

My machine shop resurfaces the clutch surface ,then mounts in a Lathe and cuts the recess . I just wanted you to post a picture of recess so those who never seen this type flywheel clutch set up can understand it's not like most 2 step flywheels. ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: BrianC

Date Posted: 14 Oct 2024 at 3:50pm

|

Ok, I will ask, why is it designed this way? What does the outermost step up do, other than get in the way?

|

Posted By: HudCo

Date Posted: 14 Oct 2024 at 9:53pm

| got to have weight to make torque |

Posted By: ekjdm14

Date Posted: 15 Oct 2024 at 8:52am

| Next (possibly stupid) question incoming. Why the step down for the pressure plate mounting surface? Surely would be more cost effective both in initial manufacture & in subsequent repairs to have it level with the friction surface & have the pressure plate mounting surface .175" less proud of it's friction surface? |

Posted By: Fred in Pa

Date Posted: 16 Oct 2024 at 6:45am

|

Having any luck on flywheel getting anyone to do it . ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: CleaningGuy

Date Posted: 16 Oct 2024 at 12:45pm

| Yeah ended up getting taken care of. The shop said they'd mount it in a lathe to get the step right. |

Posted By: Fred in Pa

Date Posted: 16 Oct 2024 at 1:37pm

|

As I said above been getting them done for years that way . Any good machine shop would know how to do them . ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |