N62 Main Bearing Cap Fit

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=203241

Printed Date: 08 Nov 2025 at 9:43pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: N62 Main Bearing Cap Fit

Posted By: jange01

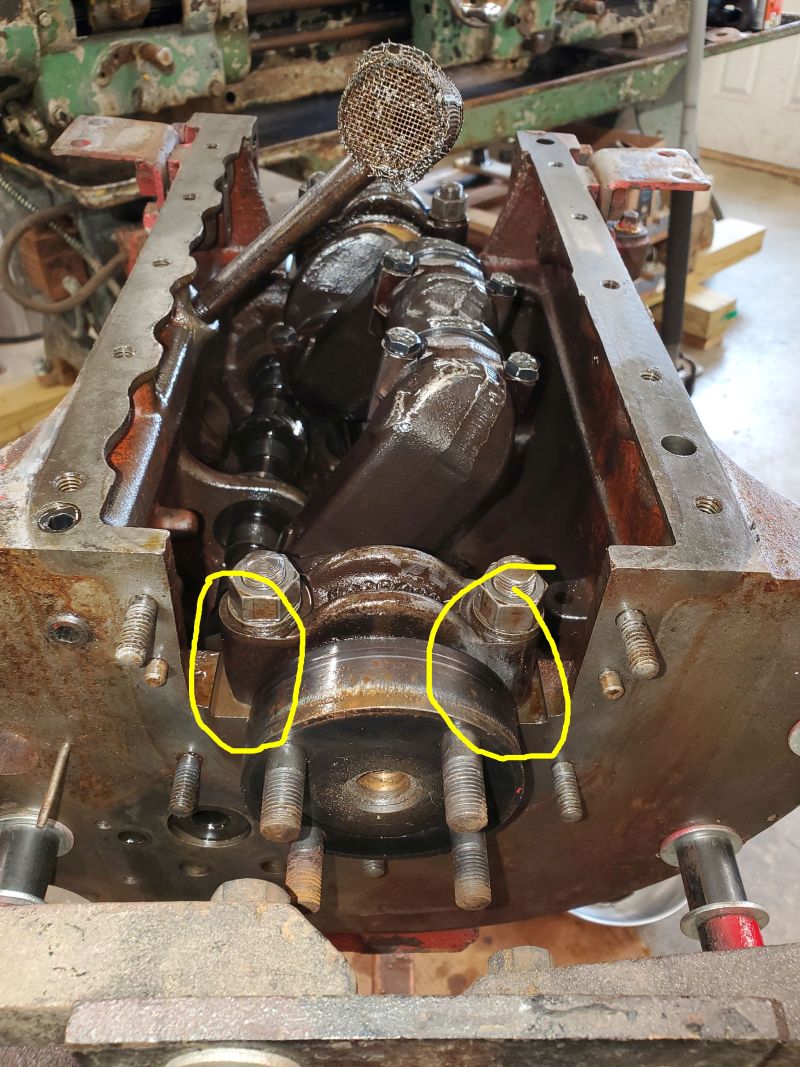

Subject: N62 Main Bearing Cap Fit

Date Posted: 17 Sep 2024 at 1:11pm

|

The main bearing caps on this little N62 don't seem to have any interference fit with the cylinder block. The caps are able to shift sideways on the 1/2 inch studs, because of the clearance holes in the caps. The engine is at the machine shop and requires a line bore. The machinist doesn't feel comfortable because there seems to be no way to get the cap on off and back on in a repeatable manor. Shouldn't there be an interference fit between the cap and the block? All other engines I've rebuilt have this. How would I install the cap and be sure it's centered? And be able to repeatably install the caps? Jim   |

Replies:

Posted By: PaulB

Date Posted: 17 Sep 2024 at 1:21pm

|

As with the BE/CE engines, modern machine shops are not familiar with all of the idiosyncrasies of older design engines. There's nothing wrong with your block. When assembling your engine crankshaft with the correct bearings, snug things down, feel for any binding on the crank, tap the main caps back and froth until binding disappears, sung it a bit more, recheck for binding. Continue snugging and checking until proper main bearing torque is reached. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: steve(ill)

Date Posted: 17 Sep 2024 at 1:56pm

|

tell him to make a 2 inch long shaft that is .002 inch smaller than the bore.... set the shaft into the hole and snug down the bolts.. remove the shaft and bore the hole... do the final assembly with bearings as Paul said. ------------- Like them all, but love the "B"s. |

Posted By: jange01

Date Posted: 17 Sep 2024 at 2:45pm

|

Ok. Thanks The reason I see to need a line bore is because of clearances. Not sure what some one else may have done in years earlier. I was hired for a rebuild of the N62. I disassembled and sent the engine out for machining. The engine sat at the machine shop for months before finally being done. I brought it back to my shop for assembly, as usual. The crank was turned to .020 under, and measures correctly. The rods are .030 under, and pistons are .020 over. During assembly I determined with plasti-gauge that I had .005 -- & .006 main clearances. Rods clearances are fine. I sent the engine back to the machine shop to help figure out what was going on. The engine sat there for over 6 months with out being looked at. I finally pulled it and found another local, recommended shop. The new shop trying to measure the bore in the block, is having trouble depending where the cap tightens down. He figured probably end up shaving the caps and re- line boring. That's where we are now. I'll talk with him again On a side note, to bad about my previous shop. There were two

partners, and I most;y dealt with the main man who for all intent and

purposes ran the shop. Nice, smart, good ole boy, old timer. We did over 35 engines together. He retired

and sold out to his partner, who while a good automotive machinist,

apparently cannot schedule and may have now lost one of, if not his best,

customer. |

Posted By: TeeRex

Date Posted: 05 Dec 2024 at 2:00pm

|

Hello, The machine shop I used to rebuild the lower end on my N62 had the same issue and the problem was determined to be the shell thickness of the bearings. I eventually found a set of NOS TRW bearings and they were able to bring the clearance up to spec but just barely.

|