WD45 Hydraulics/3 Point

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=202905

Printed Date: 09 Nov 2025 at 8:24pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 Hydraulics/3 Point

Posted By: jake_g6

Subject: WD45 Hydraulics/3 Point

Date Posted: 27 Aug 2024 at 4:00pm

|

Hey There, So this is my first go round with an older tractor. I bought some property and it came with. The tractor runs great, however I can't quite figure out the 3 point. I can get it to go up and down, but it is either all the way up or all the way down. I have a cultivator that goes far too deep when all the way down. Has anyone had this issue? Can i just chain the arms from going down further? Open to suggestions.

|

Replies:

Posted By: dfwallis

Date Posted: 27 Aug 2024 at 4:48pm

|

Some of them have a depth stop: http://uploads/932/Cult._Depth_Stop.pdf" rel="nofollow - http://uploads/932/Cult._Depth_Stop.pdf Not that this is the right one (I'm not familiar), but illustrates the concept.

------------- 1952 CA13092 |

Posted By: jake_g6

Date Posted: 27 Aug 2024 at 4:54pm

| Yeah this one doesn't. I have looked high low left and right. As soon as t he control arm near the steering wheel get below half way it slowing starts going down and won't stop. If i go up in the slightest it begins to raise back up. If i go down lower it simply lowers faster. |

Posted By: dfwallis

Date Posted: 27 Aug 2024 at 5:16pm

Seems not too difficult to make an adjustable bracket that can set the stop depth if you can't locate one. ------------- 1952 CA13092 |

Posted By: DrAllis

Date Posted: 27 Aug 2024 at 5:20pm

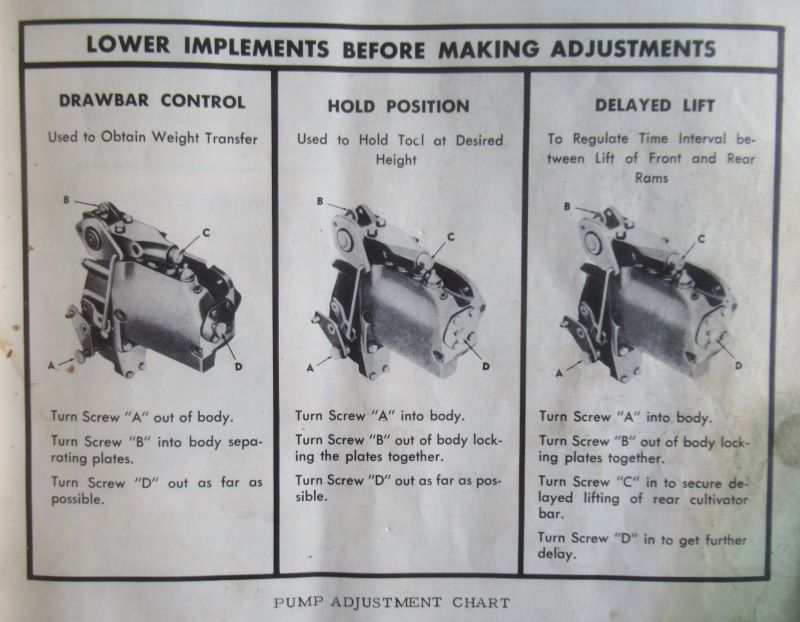

| Not difficult at all to adjust the screws on the hydraulic pump itself to have "HOLD" position in the center of the hand levers stroke. There used to be a large decal on the side of the battery box showing you how to set the pump for whatever job you're doing. Also the owners manual has this information. |

Posted By: mdm1

Date Posted: 27 Aug 2024 at 5:46pm

|

There is a detent in the quadrant. It takes some time with the hydraulics to be familiar with it. Move the lever up and down and see it you can feel it. But as was said find out how to set the pump. I have a loader on my with a diverter valve so I can use either the loader or the rear implement. If I want either one to stay at a certain height I which the valve to the other one. Shuts of the pump to that one and it stays where I put it. Maybe not right but it works for me. ------------- Everything is impossible until someone does it! WD45-trip loader 1947 c w/woods belly mower, 1939 B, #3 sickle mower 1944 B, 2 1948 G's. Misc other equipment that my wife calls JUNK! |

Posted By: dfwallis

Date Posted: 27 Aug 2024 at 5:48pm

|

A CA also has a "quadrant" lock bolt that you can use to control the lever travel. Don't know if WD/45 has that or needs it (given the apparent detents, but they seem too sparse).

------------- 1952 CA13092 |

Posted By: dkattau

Date Posted: 27 Aug 2024 at 7:33pm

| Sent you a PM |

Posted By: Brian G. NY

Date Posted: 28 Aug 2024 at 9:34am

|

Of course the good Doctor is correct. Unfortunately, most original tractors and even some "restored" tractors no longer have that chart on the side of the battery box. So......here is the chart as shown in the owner's manual. BTW, the detent is located here rather than on the Quadrant.

|

Posted By: mdm1

Date Posted: 28 Aug 2024 at 10:30am

|

Thanks for correcting me Brian. ------------- Everything is impossible until someone does it! WD45-trip loader 1947 c w/woods belly mower, 1939 B, #3 sickle mower 1944 B, 2 1948 G's. Misc other equipment that my wife calls JUNK! |

Posted By: Michael V (NM)

Date Posted: 28 Aug 2024 at 10:37am

|

guage wheels an option? |

Posted By: SteveM C/IL

Date Posted: 28 Aug 2024 at 12:30pm

| all Allis cultivators had gage wheels because the system is not designed to hold the lift arms at a given point. If you have a 3pt cultivator hooked up with an adaptor to the snap coupler hitch you will not succeed unless you have gauge wheels. I adapted the gauge wheels from a 4 row AC cult onto a RG6-30 Deere as well as the AC hitch. Very light on the front. |

Posted By: Brian G. NY

Date Posted: 28 Aug 2024 at 1:24pm

|

mdm1, A diverter valve has been working for me for years as well!I have mine connected to a lever within easy reach. I have a backblade and a loader on my WD at all times.

|

Posted By: Dennis J OPKs

Date Posted: 28 Aug 2024 at 4:33pm

| As I've said before, as a last result there's always the stop collars which snap on the cylinders themselves. Work fine as long as you don't need quick or ongoing adjustments. Save fighting the pump. |

Posted By: SteveM C/IL

Date Posted: 31 Aug 2024 at 2:01pm

| Stop collars won't work very well on a 45 the way the lift arm yokes straddle the ram. |

Posted By: Dennis J OPKs

Date Posted: 31 Aug 2024 at 2:38pm

| They work fine for me on a brush hog, have used for years. Granted on tillage or heavy stuff may be a different outcome. On a relatively light load-no problems except you can't adjust anything on the fly. It's either up or down. |

jake_g6 wrote:

jake_g6 wrote: