50 B Front end wear

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=20281

Printed Date: 01 Jan 2026 at 9:49am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 50 B Front end wear

Posted By: case580

Subject: 50 B Front end wear

Date Posted: 03 Nov 2010 at 8:50am

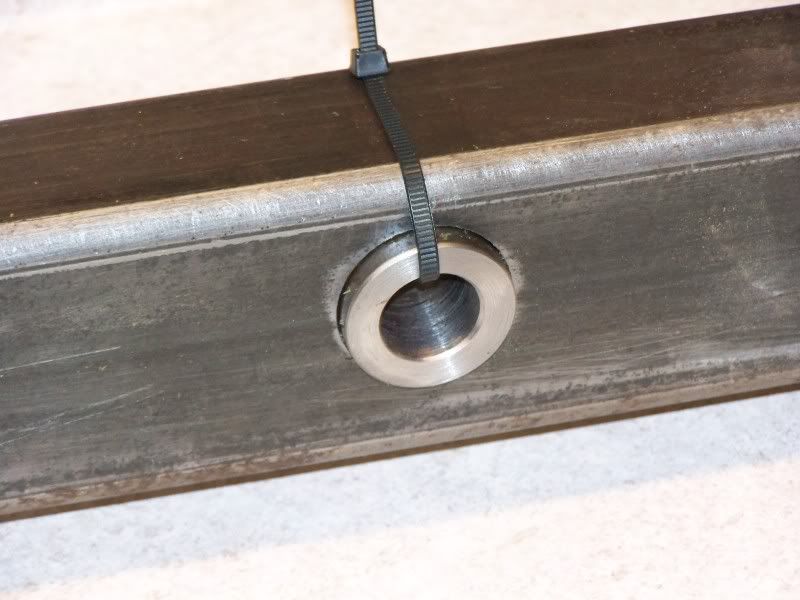

I removed the front end from my 50 B last night and found lots of rust and wear around the bolt securing the front end to the tractor. As you can see from the pictures I clean the area around the bolt (it was packed full of rust and dirt). I noticed one small piece of metal that resembled some type of bushing that was maybe around the bolt at some point but I am not exactly sure. What are my options for repairing the warn parts/area (besides replacing the warn bolt)? What was originally contained within the cavity surrounding the bolt?

|

Replies:

Posted By: Charlie175

Date Posted: 03 Nov 2010 at 9:36am

|

They should have a bushing in there that acts as the wear point. You will need to replace your bushing and bolt ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: Dick L

Date Posted: 03 Nov 2010 at 11:41am

| If it were mine I would weld a piece of pipe in square on center and then fit a bushing inside the pipe. that would beef up the center of the axle. |

Posted By: Ken in Texas

Date Posted: 04 Nov 2010 at 8:48am

| I'm with Dick L on this one. Some of the original AC designs can stand a bit of re-engineering. |

Posted By: GregLawlerMinn

Date Posted: 04 Nov 2010 at 11:12am

|

I usually bore out the hole thru the axle and rebush it with a snug fit bushing (in the axle and for the new bolt) then install a new bolt. ------------- What this country needs is more unemployed politicians-and lawyers. Currently have: 1 D14 and a D15S2. With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC |

Posted By: case580

Date Posted: 04 Nov 2010 at 11:23am

|

do you recall the size of the hole after you have bored it out? I measured the existing hole in my axle and its 1.25", judging from my pictures I have a little more room to expand the hole if I knew what size bushing to size the hole for. Pass along any dimensions if you have any available. |

Posted By: Dick L

Date Posted: 04 Nov 2010 at 12:48pm

|

Unless you custom make the bushings you will have little choice in bushing OD. Start with a bushing that will match your bolt size and then fit whatever you decide to fill the hole back to the bushing OD (outside diameter) Your hole looks to me in the pictures to be larger than any standard bushing that would fit the bolt. That is why I would start with a bushing and then a thick wall pipe that the bushing would press into and then bore the axle for a press fit of the heavy wall pipe before welding in the pipe. It would make the axle stronger at the pivit point and keep from having uneven weld around the bushing. If the hole was not worn as much as it is I might just bore it for a bushing alone.

I broke the axle in the center of my 9523/5020 and built an all new one by welding on the old spindles. I bored the center and welded in a heavy wall pipe bored for a bushing.

I used thicker steel square tubing than what was on the tractor as well.

|

Posted By: GBACBFan

Date Posted: 04 Nov 2010 at 6:25pm

I made a straight axle for my hot rod B project, and Chad (WI)'s Dad Gus made a great bushing from steel for me that stuck out slightly on each side of the 2"x3" rectangular tubing, and was welded into place. It will outlast me.

------------- "The trouble with quotes on the Internet is that you can never know if they are genuine." - Mark Twain |