CA Valve Adjustment

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=201631

Printed Date: 29 Oct 2025 at 8:53pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: CA Valve Adjustment

Posted By: 1955CA

Subject: CA Valve Adjustment

Date Posted: 03 Jun 2024 at 2:24pm

|

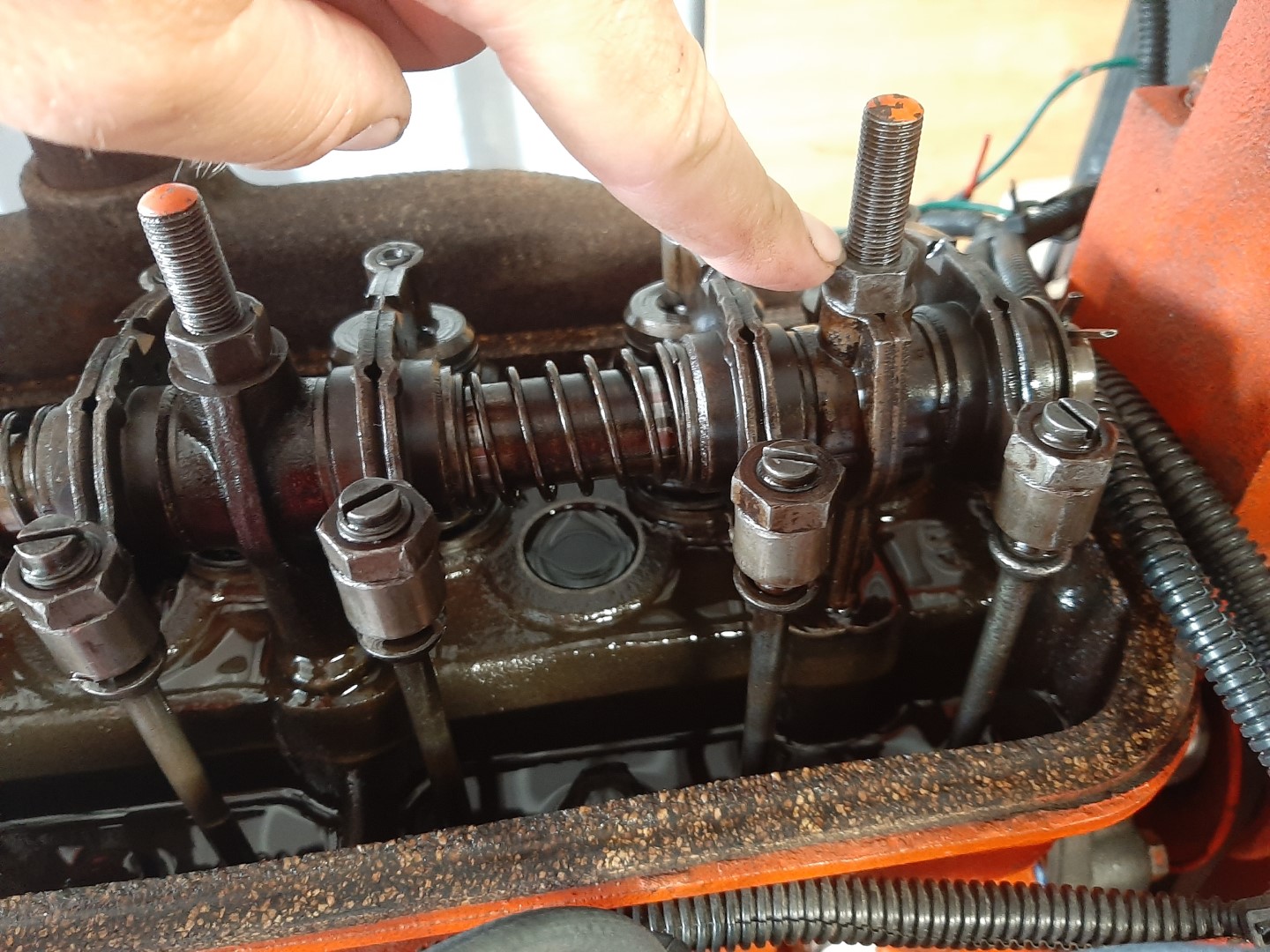

So I mentioned this in my water pump thread. My CA suddenly developed a pop when running that you could hear through the intake. I suspected a valve issue, but hoped for the best as engine was supposedly rebuilt when I bought it and I rarely ever ran it due to the rear wheels being rotten (which I just replaced last summer.) So I just pulled valve cover and was relieved to see the push rod for #4 cylinder was not under the rocker arm. I pulled it out, no marks looks good. So I thought it just came out of adjustment. But then noticed all the nuts on the four (sorry, for lack of a better term) of the "bridges or stands" that holder the rocker shaft were all loose. The nuts on the same studs that hold the valve covers on. Are they known to come loose? Or did the last owner just not tighten properly? And now, how much do I tighten those nuts and should I use Locktite? I haven't looked at my manuals I have for it yet, but hopefully it has the specs for setting the clearances. Any tips would be appreciated. Thanks.

|

Replies:

Posted By: 1955CA

Date Posted: 03 Jun 2024 at 2:26pm

Everything looks nice and clean. I put lifter back in place and started it briefly and even without setting it up properly it runs almost perfect now!

|

Posted By: 1955CA

Date Posted: 03 Jun 2024 at 2:27pm

Sorry, still can't figure out how to post multiple pics.

|

Posted By: steve(ill)

Date Posted: 03 Jun 2024 at 4:21pm

|

I set the valves at .014 COLD.... that makes the clearance about .012 when the engine heats up... I have never heard of the rocker arm nuts loosening up.. I would guess they were never tightened properly. ------------- Like them all, but love the "B"s. |

Posted By: SteveM C/IL

Date Posted: 04 Jun 2024 at 12:16pm

| They don't come loose. 3/8 fine thread? Probably around 30lb/ft. |

Posted By: steve(ill)

Date Posted: 04 Jun 2024 at 12:55pm

|

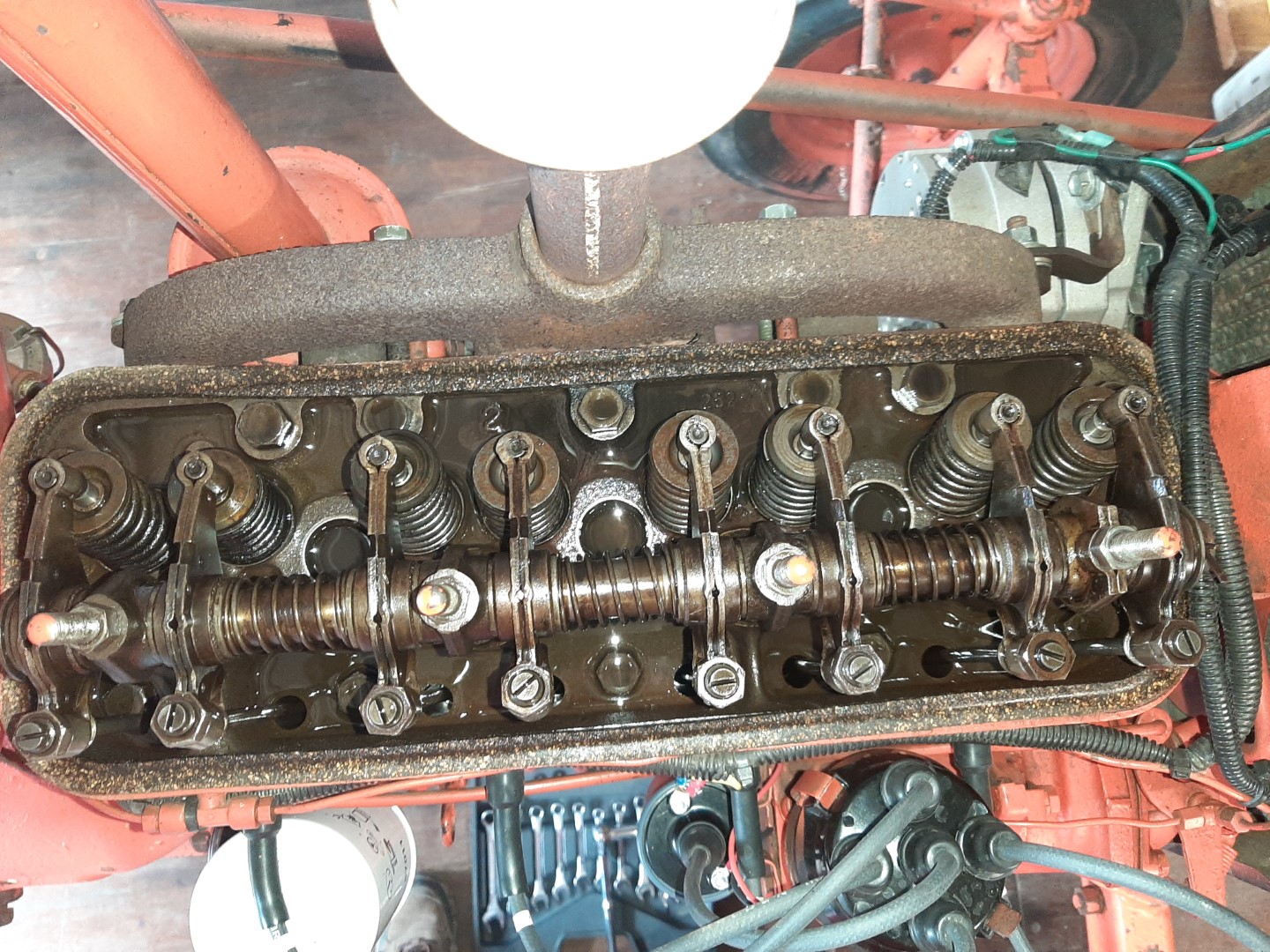

Shawn... one thing i have found interesting over the years... is that many rocker arms dont set dead center over the valve stem.. They seem to be off 1/8 inch or more.. been that way forever.... if you look at your second photo you can see a couple that are obvious. ------------- Like them all, but love the "B"s. |

Posted By: dfwallis

Date Posted: 04 Jun 2024 at 3:52pm

I fixed all of mine, for good or bad. All nice and centered now. No more barely inside the outer edge deep indention wear patterns, I hope. ------------- 1952 CA13092 |

Posted By: 1955CA

Date Posted: 04 Jun 2024 at 5:49pm

| How did you fix them to line up? |

Posted By: 1955CA

Date Posted: 04 Jun 2024 at 5:55pm

| Thanks for all the info everyone. I won't have time until next week to touch it again, but I ordered another timing light so I'll hopefully get her all tuned up. |

Posted By: dfwallis

Date Posted: 04 Jun 2024 at 5:56pm

Nearly all that was required was minor machining of the standoffs on one side (there might have been an exception, I can't recall). Must be sure to get them nice and flat/true. I only removed just enough to center them but no more. ------------- 1952 CA13092 |

Posted By: 1955CA

Date Posted: 04 Jun 2024 at 6:19pm

Oh okay, thanks. Did you have to shim them at all?

|

Posted By: dfwallis

Date Posted: 04 Jun 2024 at 7:11pm

I don't believe that I had to add or subtract any components that were already there (e.g. washers). They pretty much self center via spring pressure. But be sure to think it fully through before you make any modifications. Only do one at a time and see what the overall impact is by reassembling where needed. I only took off thousandths at a time, trued it up, polished it and reassembled to see the result before taking any more off. But it is possible to add shims (washers/machine bushings). ------------- 1952 CA13092 |

Posted By: steve(ill)

Date Posted: 04 Jun 2024 at 8:07pm

my point was it looks "ODD".... but has been that way for 70 years.. IT will probably run another 70...  ------------- Like them all, but love the "B"s. |

Posted By: dfwallis

Date Posted: 04 Jun 2024 at 8:12pm

True, but some of mine were so far off there was only about 1/8 inch of contact area. ------------- 1952 CA13092 |

steve(ill) wrote:

steve(ill) wrote: