Gleaner CII/C2

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=200631

Printed Date: 05 Feb 2026 at 3:24pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Gleaner CII/C2

Posted By: wjohn

Subject: Gleaner CII/C2

Date Posted: 31 Mar 2024 at 12:01am

|

First, thanks to the forum for putting up with my random Gleaner questions over the last year or two. AC7060IL - special thanks to you and your knowledge of Gleaners in general. I lucked into a CII that is only about 10 miles from my house. 16' header with no special equipment (just straight bats) and some rust/rock holes in the bottom/floor that I will have to tackle. It has been inside and was supposedly last used 5 years ago. Other than the fans being packed with rat nest, everything seems to move. I did get it to run for 15-20 seconds but only with the choke on, so I pulled the carb off and am cleaning it up. It was converted to a Carter electric fuel pump at some point but after repairing rat-chewed wires and getting good 12V to it, turns out that pump is toast. The cooling system took about 1.5 gallons and later on I discovered a pinhole leak in the radiator just below the top hose connection. The gearbox for the steering shaft at the bottom of the cab seems to be empty. Otherwise the tires all took air and you can steer it with no engine power fairly well. Trans and finals were all full up to the check plugs. I changed engine and air cleaner oil. Still need to hit all of the grease zerks, reinstall the carb, and wait for the new fuel pump to show up. Anything specific on these that I should for sure check before I try to road it 10 miles home? I have done nothing as far as the separating mechanism is concerned - I don't plan on touching that until I have time to clean it out and change some sprockets, chains, and belts. I'll leave it shut off for now. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Replies:

Posted By: DrAllis

Date Posted: 31 Mar 2024 at 7:50am

| Condition of the main drive engine belt and the variable speed transmission input belt. |

Posted By: jiminnd

Date Posted: 31 Mar 2024 at 9:34am

|

My opinion, one of the best combines they made. Don't know what all you need but they are a good machine. ------------- 1945 C, 1949 WF and WD, 1981 185, 1982 8030, unknown D14(nonrunner) |

Posted By: wjohn

Date Posted: 31 Mar 2024 at 2:07pm

Will do. I got a bunch of spare belts, but I think the only wider belts I got were all the same PN and those were for the pivot drive.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 31 Mar 2024 at 2:13pm

I only have ~20 acres in tillable right now, but there's another 60 or so that used to be tillable decades ago but is now pasture. I may convert some of that back to tillable at some point. A CII is bigger than I need but storage wise, they're basically the same height as an A, F, or K. I'm looking at wheat, soybeans, oats, and milo. You had one? What all did you harvest with yours? ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: AC7060IL

Date Posted: 31 Mar 2024 at 5:38pm

|

Wjohn, Thank you for your kind words. Congratulations on your newly acquired gleaner C2. Awesome find! A 10 mile combine drive is very doable. Maybe inspect it’s fuel tank for gunk. If tank has ANY gunky residue, remove its fuel line & discard it. Attach a new fuel line to engine fuel pump & use a portable 5 gal plastic fuel tank instead. Just tarp strap 5 gal tank to a secure position. Maybe add two cups of ATF to 5 gal of 10% ethanol 87 octane gasoline. That combination will operate fine & help clean carb/intake/piston rings as you drive it the 10 miles. You can clean gunky fuel tank later, but probably eliminate any possible roading fuel issues. Shoups Ag Parts sells a 20’x48”roll of 3/32 thick poly sheeting for $132. It’s flexibility allows it to be riveted or bolted onto worn metal areas as a somewhat durable material for patching irregular shaped items like header floor, clean grain auger troughs, raddle floor, grain tank auger floor, etc. https://www.shoupparts.com/29020-White-Poly-Roll" rel="nofollow - https://www.shoupparts.com/29020-White-Poly-Roll When time allows, please update your progress & post some photos of your C2. |

Posted By: SteveMaskey(MO)

Date Posted: 31 Mar 2024 at 7:14pm

I still have one in the barn quit using

it when I bought the L3. They are a good combine and you have been given some

good advice. As the Dr says check the variable speed and engine belts. I had

the variable speed belt come apart on the road and it is not a good feeling

when you coast to the side of the road. |

Posted By: jiminnd

Date Posted: 31 Mar 2024 at 9:17pm

|

Got mine used, ran it for 7 years, wheat, oats, barley, millet, soybeans, and sunflower, was a good machine but was on the custom run before I got it so was really showing a lot of wear. Had to rebuild the rock door and a couple of auger screws. Also replaced the tin between the raddle chain, never touched the motor. ------------- 1945 C, 1949 WF and WD, 1981 185, 1982 8030, unknown D14(nonrunner) |

Posted By: SteveM C/IL

Date Posted: 31 Mar 2024 at 11:04pm

| Might jack up rear wheels and spin them. If they're really noisy you may want to at least pack some grease in then to get home. Would not be good to ruin a wheel bearing and maybe hub on the way. Wheel brgs and pivot shafts seem to get neglected. Pack them before you ruin them....easier and cheaper. |

Posted By: Oldoug

Date Posted: 01 Apr 2024 at 10:43am

|

Might want to check your brake quick also...make sure they are clean and dry and the linkages are all free...I think I have a NOS engine belt if you are interested. ------------- Matt Folkers FOLKERS RESTORATION Restoring vintage things to last so the future can enjoy our past. |

Posted By: DSeries4

Date Posted: 01 Apr 2024 at 2:31pm

|

Crud in the gas tank might be the big problem with the engine not being able to stay running - not the electric pump. Over the years, my dad had an A, K and F. All of them had issues with crud in the fuel tank. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: only AC orange

Date Posted: 02 Apr 2024 at 12:05pm

| Check the main drive belt real close! If combine has sat awhile, belt will be dry rotted and when put under load going down road, will SLIP! I found out by experience driving a "C" home from auction years ago. |

Posted By: wjohn

Date Posted: 02 Apr 2024 at 9:52pm

|

All good thoughts. I will bring a jack to check the rear wheel bearings, and I definitely don't want a belt breaking when I'm halfway up a hill. Regarding the gas tank - it appears to be rusty probably up under the top side of the tank. The sides and bottom look okay, at least from what I can see through the filler hole. That support/baffle is going to make it fun to clean out, and I assume there's another one on the other side of the outlet between it and the other end of the tank. When I got the engine started I failed to mention I was gravity feeding the carb with a short hose from a garden tractor gas tank. The carb is all cleaned up and half back together now (waiting on some gasket sheeting to show up). I also picked up a 6 gallon boat gas tank today, with the primer bulb fuel line and everything. I think that plus a good working new fuel pump should get me home. If it burns through more than 6 gallons of gas in the ~10 miles, I'll have another 5 gallon container with me as well. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 02 Apr 2024 at 9:57pm

I actually think I lucked into a replacement floor that the guy must have purchased. Found it outside the shed and it sure seems to be the right dimensions. That will not be a quick fix so I may order some of that poly if I get into a time crunch. I am seriously debating trying to plant some beans or milo for the first time but I have a few pieces of equipment to get fixed first. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: AC7060IL

Date Posted: 02 Apr 2024 at 11:56pm

I don’t know the Buda gas engine fuel consumption rates. A 6* BTDC gleaner GM 250 will run approximately 8-9 minutes per quart of 10% ethanol 87 octane. That’s just engine at high idle, machine sitting still, & no separator loads. So a gallon would be 32-36 minutes run time. So if Buda 262 is comparable, at 10 mph travel speed, probably 2-3 gallon may suffice 10 mile road trip (1 hour)if stops/go are minimal? |

Posted By: IBWD MIke

Date Posted: 03 Apr 2024 at 9:18am

|

wjohn, on the tank rust; I 'tumbled' the tank on my 756 when it was in process. Strapped it to the wheel/tire on the NF 45 and ran it in low gear 45 minutes or an hour, don't remember now. Anyway, wish I had run it three or four times that long! The big part of the tank got nice and clean but, (I think) the part on the other side of the baffle not so much. I have had trouble with the sediment bowl plugging when running it a lot in rough conditions with a mostly full tank. It's getting better with time. |

Posted By: wjohn

Date Posted: 05 Apr 2024 at 10:18am

|

I know the D-19 gassers were not as efficient HP per gal as their similar-sized competitors so it may be a tad worse than that Chevy engine, but you're right... should be in the ballpark. If 6 gallons doesn't do it I will still have a backup can and for sure have enough. Mike, that's what I'm worried about here with the baffles. I think I will just have to clean and flush the tank as best as I can - maybe acid wash? Then just keep changing sediment bowls and filters. I'm not sure I would feel right just keeping the boat tank on there for eternity and constantly filling it... although for my acreage, that might work - ha. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 05 Apr 2024 at 10:39am

|

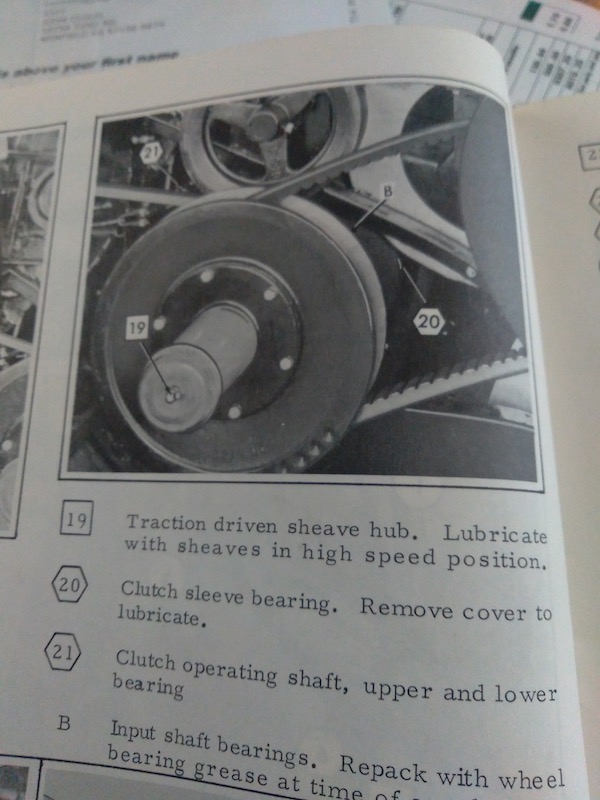

I checked over the main drive belt from the engine and the traction/trans belts. There is no obvious damage or cracking so I will hope I can make it up the couple of hills I have to climb without any issues. The only play I could find at the rear wheels was a little bit in the spindles (not hub bearings), plus some play in the tie rod ends of the steering linkages. It's detectable but not scary so I am okay with it. May need to be fixed some years down the road. I hit as many of the grease zerks for the steering/brakes/engine/trans drive as I could yesterday. The pedal shaft zerks under the cab sure are a bear to access. Filling the steering gearbox also wasn't great but it's full for now. I was unable to find one zerk, though. I think the I got the #20 clutch sleeve bearing assuming that's the one that's on the cast housing going from the pulley on into the transmission, and I know I got #19 on the end of the sheave hub. I don't think I found the #21 clutch operating shaft fitting so I need to maybe crawl under there with a flashlight. That might be on the linkage from the clutch pedal, closer to the clutch?  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 18 May 2024 at 10:40pm

|

It made the drive home today. The radiator leaked slowly enough and the temp gauge works so I was comfortable with the cooling situation and it worked out. I couldn't get the variable speed lever for the ground drive to move and the guy who was in a truck in front of me said I was only doing about 6 MPH, in 3rd gear, so it must be stuck in the slow position. Sure felt a lot faster than that as I was bouncing down the road. The power steering started working after about 1/2 mile which was nice. I think one of the brakes may be dragging a little as there was some slight lurching and rhythmic whining. It seemed to go away on downhills, though.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: AC7060IL

Date Posted: 19 May 2024 at 11:26am

| wJohn, congratulations on a successful drive home. Machine looks great. Thanks for sharing a photo of it. |

Posted By: wjohn

Date Posted: 20 May 2024 at 11:08pm

Thanks. I think your fuel usage estimate must be pretty close. I used about 4 gallons on the drive home, and I should've been going twice the distance in that time if the variable speed would've worked. Now to save up for a shed to put all of this stuff in. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: ac fleet

Date Posted: 22 May 2024 at 10:51am

|

I had one many years ago --- good old machine but did love to eat main drive belt!!!!!!!!!! I loved the power steering on mine --- steer with your pinkie! Mine was 4-38 corn and 16' cutter head. Just stay out of foxtail with them!!!!!!!!!!!!!!!!!!!!!!!!! THAT will have you in orbit! If you see 1 foxtail plant ahead of you in the field,--- stop and go pull it up and toss it aside cause it will NOT go past the rear cylinder beater! I guess it was a gleaner thing. Anyway I ended up getting a 715 diesel to replace it with. ( went to 30" rows and no head for c.) The gas motor on mine started instantly as soon as you hit the key. I always loved that part. You might want to run it around the lot quite a bit before you hit the road with it and see if all feels good or not. I think you will have a lot of carb problems on your way home with it. That was always the problem with mine. I would drive it 50 miles 1 way between jobs and was always cleaning the carb along the road. No big deal but kinda a danger in traffic. ------------- http://machinebuildersnetwork.com/ |

Posted By: plummerscarin

Date Posted: 22 May 2024 at 11:52am

Man, that brings back memories. My uncle was between combines at the time so had a friend of his bring over his CII. There was a patch of foxtail LaVerne got in to and yes that plugged up solid. I think it plugged 3 times. LaVerne was livid by the time they got done. Not sure if even finished that spot. Never came back. |

Posted By: wjohn

Date Posted: 22 May 2024 at 9:52pm

|

acfleet, I totally tore down and cleaned out the carb and it made the trip home just fine. This engine does not start right away - I never did change the plugs or wires, so I need to do that, but I'm also not sure it's getting enough fuel when you try to start. The carb doesn't dump gas out when you pull off the air cleaner hose after cranking, so it's not flooding... But it's a little persnickety about starting. Maybe it's a little worn and compression is low, too. Once started it runs well. plummerscarin, thanks for the story! We don't seem to have foxtail too bad here - Johnsongrass and cheat are the main problems, but point taken. I'm sure at some point I will push the limits and find out what it takes to plug it, ha. I did engage the separating side of things yesterday and augered out a bunch of chaff, baby rats, and nesting material. Got one of the adult rats but there is still at least one more and it's a big one. The raddle for sure was not moving so I have been chipping away at pulling out all the rat junk they packed into it. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Clay

Date Posted: 22 May 2024 at 10:15pm

|

Make absolutely sure the fan bearings are good and the fan drive chains are properly adjusted. My dad and I were doing some in the field maintenance (many years ago). We went to lunch. Forgot to tighten some chains. Next thing we knew, the fan housing was full of wheat. Broke the spiders and fan blades. The nice thing was my dad knew it was his fault and did not yell at me. My CII runs on propane.

|

Posted By: GM Guy

Date Posted: 22 Jun 2024 at 2:16am

|

squirt the sealed bearings with a teflon infused penetrating oil. If the bearings are not shot, dont replace them. most bearings on these old girls are not under heavy load and can last forever if kept clean and lubed. modern replacements are usually not as good of quality. Make sure and remove the cleanout covers if storing outside, and blow EVERYTHING off, any crop residue holds moisture and rots things quickly. Where in KS are you? ------------- Gleaner: the properly engineered and built combine. If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help. |

Posted By: Clay

Date Posted: 22 Jun 2024 at 10:45am

Near Udall. Northwest of Winfield. Made a run to Schmidt and Sons in Winfield, this morning. Great dealership. The have the parts and the answers too. Working the bugs out of a F2 for a friend of mine. The variable speed hydraulic seal started pukeing fluid. Getting ready to go to the field and install the new seals. The a/c works great in the F2. My C2 has a water cooler.

|

Posted By: ac fleet

Date Posted: 22 Jun 2024 at 1:43pm

|

Mine would start as soon as you hit the key! Hot or cold. Carb plugged a few times but no biggie. I found they needed to be choked just the right amount of time then go to half choke and after a few seconds of warmup they ready to go. Mine didnt have many acres ever run thru it before I got it from the looks of it. Any I sold it to a friend who used for many years after that and he too liked it. Just stay out of the foxtail!!!! LOL!!!!!!!!!!!!!!!!!!!!!! ------------- http://machinebuildersnetwork.com/ |

Posted By: tomNE

Date Posted: 22 Jun 2024 at 10:39pm

| not good in soybeans. Can custom hire someone with a draper header and get beans combined for 0$$$$ compared to cutting them with a C2! |

Posted By: nickia

Date Posted: 23 Jun 2024 at 9:02am

| the C2 we bought went down the road very fast to top it off it had a 6 row corn head on it. I remember driving it home when i crossed hwy 69 with dad following me he said the rear wheels didnt even touch the ground crossing so if transferring with a corn head watch the speed weight transfer |

Posted By: wjohn

Date Posted: 23 Jun 2024 at 9:51am

I'm not far at all from Clay. Schmidt and Sons must be one of the best AGCO dealers in the world for covering the older stuff. We are lucky they are so close. Covers are all opened. I still have a mess in the raddle but everything else has been cleaned out and left open. Thanks for those tips on the bearings. What if the bearing is totally gone?  Unfortunately I for sure have one that needs to be replaced. I missed it when I looked the combine over in the dark barn, but it wouldn't have changed what I paid for it. I'll have to build the shaft up or see if the one in the parts combine is still good. Unfortunately I for sure have one that needs to be replaced. I missed it when I looked the combine over in the dark barn, but it wouldn't have changed what I paid for it. I'll have to build the shaft up or see if the one in the parts combine is still good.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 Jun 2024 at 9:55am

Thanks for the tip on the choke. I don't have that down yet but I can tell there is some magical combination that lets it start. It could still be that the ignition needs gone through better or the rings are just worn out, but even with a fresh carb teardown and cleanout, this was the most finicky starting gas engine I've maybe every touched. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 Jun 2024 at 10:01am

I don't think I'd ever get a custom combiner into my 20 acres at a decent time, or maybe ever. Custom hay is just as bad here. You have to do it yourself or you're waiting until months after the time was right. They also probably can't turn those huge headers around in half of my little fields. Ha! I am curious how much loss I will have in soybeans with this rig. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: tomNE

Date Posted: 23 Jun 2024 at 10:17am

|

does corn head have flat chain or roller chain? |

Posted By: ac fleet

Date Posted: 23 Jun 2024 at 11:05am

|

been loss was not bad on mine. Ya in todays world you bout gotta do everything yourself if you dont have a million acres! I used to enjoy my little 137 acres. Had to go with crp since the crop inputs were getting so costly and that was the best move ever! NOW I can enjoy the farm again! ------------- http://machinebuildersnetwork.com/ |

Posted By: SteveM C/IL

Date Posted: 23 Jun 2024 at 1:24pm

| Cut beans with 4 cylinder bars and use the small sprocket on the cylinder beater. That's how I ran my A2 for 19 yrs. Had welded bars and would eat anything green....just better keep an eye on the chopper after a big bite of trash. |

Posted By: wjohn

Date Posted: 23 Dec 2024 at 8:41pm

I do have to look into the beater sprockets still. I keep forgetting to get a tooth count on mine to see what I have, but out here in wheat country, it may not be setup for what is ideal for soybeans. Maybe AGCO still has some of those and the cylinder speed sprockets available if I'm lucky. I hope I can make the 800 RPM slowest speed out of the belt drive cylinder setup work for beans, but it might be good to have the slowdown sprockets and chain setup in my back pocket. It gets awfully hot and dry out here. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 Dec 2024 at 11:29pm

I've been making progress on the CII since the weather has stayed warm enough to work outside. There had been an intermittent lurching when you drove it. After pulling the trans brake drum, it was packed full of wheat and fluffier stuff. I am guessing it was enough to engage the pads to the drum just slightly now and then. I have the axle shafts pulled off and am going to inspect the steering brakes just to be sure they're fine. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: SteveM C/IL

Date Posted: 24 Dec 2024 at 10:17am

| I don't think 800rpm will be slow enough for soys. 5-600 takes care of most beans. I think the lurching is design thing. A lot of connections in the drive line. |

Posted By: wjohn

Date Posted: 24 Dec 2024 at 7:00pm

The manual says to use 800 RPM on them, but I am suspicious that AC stated that mostly because 800 was the slowest you could run with the cylinder belt drive setup that was on the CIIs. To go slower you had to swap on a chain drive with the sprockets you wanted. Not sure if any of the AIIs had belt drive cylinders, so they may have all started off with sprockets and then you could change out easily for slower speeds? The lurching was really bad - put it in first gear, let off the clutch, and it would just lurch over and over again even if you were going up a hill (constant loading on shafts etc.). Granted, I haven't run any other old Gleaners, but it felt abnormal. I decided to pull off the steering brake covers today and I'm glad I did. I decided that milo leaves were wrapping around the axle shaft and were just thin enough to get past the felt seal on the axle. Of course the cylinder must have been leaking too.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: SteveM C/IL

Date Posted: 24 Dec 2024 at 11:49pm

| My A2 had chain drive cyl. Had a small sprocket for wheat and a large one for corn/soys. Pretty sure I ran it in the 5-600 range. |

Posted By: wjohn

Date Posted: 27 Dec 2024 at 8:30am

That sounds more like what I would expect. Hopefully the chain drive setup isn't too expensive to find. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 27 Dec 2024 at 8:42am

|

I noticed the false floor of the raddle was torn up in one of the rear corners. I think it was very slightly bent up which allowed the steel slats to ride on it as the wrapped around the drive sprockets. It seems like a good spot for something to catch and tear things up worse on a day when I'm trying to get wheat in, so I'd rather head that off. I debated trying to repair it in the machine but I'm glad I didn't - I would've driven myself nuts trying to weld the paper thin metal inside the combine, and then I found a couple more cracks along the bends for the sides. I know the book says to pull the false floor out the front but I pulled it out the back since I have the separator beater and straw walkers already out. It seemed easier since the header is still on. It also looks like the one idler had been locked up for a while even when the machine was still in use by the previous owner, as it's worn down. Thankfully you can still buy these new.    ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: SteveM C/IL

Date Posted: 27 Dec 2024 at 2:38pm

| My welding shop rolled new ends and welded them on on both my A2 and F2. |

Posted By: wjohn

Date Posted: 13 Mar 2025 at 11:46pm

|

Got the parts combine that came with the running one home today. I had pulled the axle couplings for the flat tow, but the steering brakes didn't work and the thing rolled way easier than anyone expected. So, after the scariest 30 seconds of my life with the combine blasting down a hill and steering that takes 2 spins of doing nothing and then all of a sudden turns the wheels, I reconnected the shafts and the trans brake at least worked even if we were backdriving the transmission for 5-6 miles. This one is a 19XXX serial number and the air cleaner and other loose parts I found nearby indicate it was a diesel (engine long gone). That must have been a closer to end of production, top of the line Gleaner back in the day and I have to assume it was on the custom cutter circuit when it was new. Then the G replaced it in the lineup if I recall correctly. Lots of parts are worn out but I should be able to pick enough good stuff to cut down on my impending parts order with AGCO. The cab seems decent too but not sure it's worth going to the trouble of swapping it over to the running combine any time soon.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: PaulB

Date Posted: 14 Mar 2025 at 7:04am

|

I have some Gleaner brake shoes, brake linings, many sprockets and a couple C wiring harnesses left in my NOS parts. However I don't have any Gleaner parts books to verify what fits what. Given specific sizes or tooth/chain size I could see if there's anything that matches some ones needs. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: wjohn

Date Posted: 18 Mar 2025 at 10:02pm

|

I was pulling things off of the parts combine tonight and noticed an entire linkage and knob that is not on my running combine. I followed it down and it goes into the side of the transmission, and the transmission has a larger extra case bolted onto it compared to my running combine. Is this some sort of high/low gearbox? I couldn't find any mention of it in my Gleaner literature, but this is a later serial number machine so my books might be too old. Parts combine with larger case and extra shifter knob/linkage setup:   My running combine (no extra shifter and normal-sized gearbox):  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: AC7060IL

Date Posted: 19 Mar 2025 at 7:23am

|

wJohn, congratulations on getting your parts gleaner safely transported. It is a 1967 (sn 17201 & up) CII. No factory CII diesels ~ so maybe someone swapped in a D17 262 diesel, 2800 (301) from a 190, or 2800 (301) from newer 1968&up Gleaner F ??? Guessing it has a gear reduction added to its transmission? Gleaner offered a “Slow Speed Transmission” as one of their “options” to base machine. In slow speed trans mode, all gears (1,2,3 &R) speeds would be about 35% slower than “Standard trans in base models” for certain field conditions such as downed/lodged crop, high moisture grain, etc… |

Posted By: wjohn

Date Posted: 19 Mar 2025 at 7:57pm

I hate to disagree with your vast Gleaner knowledge, but I can for certain say that the 262 turbodiesel was an option on the CII (not sure if it was available yet when the straight C was in production?). Both the gas and diesel 262 motors are covered in my owner's and service manuals, and it's also in the AGCO parts book online. You just don't hardly see any of them so there must not have been too guys many that ordered the diesel back then. Speaking of the parts book, I did eventually find this exact high-low transmission option shown in AGCO's parts book. My paper service manual only mentions the "low speed auxiliary transmission" which has to be what you are referring to. The high-low must have come out later in production. I am not sure if you had only 2 total high and low ranges or if there was a high-direct-low for 3 sets of speeds. I can't find much info on it. I am finding these had a lot of neat options that Gleaner probably didn't make too many of in total over production. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: AC7060IL

Date Posted: 20 Mar 2025 at 7:17am

And yes like I said about the transmission, I was guessing it was called Slow speed which is how Gleaner termed that option in the 1970s. |

Posted By: wjohn

Date Posted: 20 Mar 2025 at 11:35pm

We'll have to get you into a CII sometime! They seemed to have been a really popular combine out here in wheat country. I have lots to learn about the other models as I've pretty well been laser focused on the C/CIIs since I brought this one home and always enjoy reading your posts. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Clay

Date Posted: 21 Mar 2025 at 8:12pm

|

My CII is a 1968 model. Propane engine. CII is a good machine.

|

Posted By: wjohn

Date Posted: 19 Jul 2025 at 10:00am

|

I am finally taking a break to sit down after non-stop combine, grain truck, and other vehicle repairs. The CII did pretty darn well. The wheat did not, but it was a challenging year here. Almost no rain from FEB-MAR and it lost a lot of tillers; then lots of rain the rest of the season. Wheat streak mosaic virus was really bad in this area and some fields were total losses. The weeds were terrible as these couple of little fields hadn't had been fallow for years. I had the air opened up to max to blow the cheat out and I wasn't losing many kernels. I got a good learning experience and am pretty confident in the CII going forward. It did toss the raddle drive chain after the master link clip disappeared - maybe I didn't have it fully locked in due to a burr in the groove or something, or maybe it was just the cheap TSC master link I used. I could tell something sounded different and stopped it fairly quickly, but not before it plugged the thresher beater. Not too bad to unwrap. This thing will eat Johnsongrass no problem. I did plug the feeder beater once in a patch of sweet clover. It doesn't handle that stuff so well. After cleaning the combine out I discovered the separator countershaft had a lot of play in it - the bearing rollers behind the pulley were gone. Luckily no thermal events occurred and it feels like both races are still there, so I'll change it out before next harvest. I am sure I will have more questions in the future but a huge thanks to everyone that chimed in with advice on this thread.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

DrAllis wrote:

DrAllis wrote: