Getting ready for some engine work on 7020

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=199865

Printed Date: 01 Jan 2026 at 3:25am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Getting ready for some engine work on 7020

Posted By: Wbenchfarms

Subject: Getting ready for some engine work on 7020

Date Posted: 17 Feb 2024 at 7:59am

|

Have had my 7020 PS for 3 or 4 years. Has been good to me, used mainly in the hay field. Showing around 3900 hours. Has always been hard to start. Had the injection pump rebuilt last year, and planned on injectors this year. Had a pop through the exhaust when under a load. Originally thought it was because of the straight pipe on it, but started thinking otherwise last year. Decided it was time to look deeper in to it before the spring rush gets here. Pulled injectors and checked compression yesterday. #1-150 #2-200 #3-260 #4-0 #5-180 #6-260 These are cold psi, turned over with starter. Definitely have a #4 issue. Thinking a valve. Everything on top is good, no rocker or push rod issues. This tractor used very little oil last year, doesn't get hot, and actually ran very good for only firing on 5 cylinders. Does have a fuel haze, but mostly only at idle. Planning to get head off this week and see where we are. Although the compression numbers seem low across the board, the lack of oil consumption and no major blow by makes me think rings are not a huge issue. Unless I can't find a problem with the head I'm leaning towards not doing a complete O/H. Tractor gets 100-200 hours a year, and may not even run all winter. Will be looking for a good machine shop to send head to. I'm in Eastern Ohio, south of Youngstown, so would like to find someone within driving distance to save on freight. I would like to find someone who knows these old tractors. I've dealt with several shops over the years that I have not been confident in their ability to diagnose and repair the issues that comes with this older equipment. |

Replies:

Posted By: GSTROM99

Date Posted: 17 Feb 2024 at 8:14am

|

I assume you adjusted the valves. Get yourself a leakdown tester. Rent, buy, borrow or find someone with one. https://www.harborfreight.com/cylinder-leak-down-tester-64918.html" rel="nofollow - https://www.harborfreight.com/cylinder-leak-down-tester-64918.html This test will identify where the pressure is going. If the leak is coming back through the intake or exhaust, it's a head/valve issue. If it's coming back through the crankcase, it's piston/ring/cyl issue. It'll be good to know before you dive in.

|

Posted By: WF owner

Date Posted: 17 Feb 2024 at 8:24am

|

First of all, to get an accurate compression test, you would need a fully charged battery with a battery charger running to maintain full charge. I find it very hard to believe that you have zero compression in a cylinder and it is not a top end problem. Somehow, you have a valve not closing to get zero compression.

|

Posted By: rw

Date Posted: 17 Feb 2024 at 9:01am

| Have you ran the engine and cracked open the fuel injection lines at the nozzles one at a time to find the cylinders that are contributing and the ones that are not? The sound of the engine will be noticeably different if a contributing cylinder is opened. It seems like you would have a bad vibration if 4 is really at zero compression. |

Posted By: DrAllis

Date Posted: 17 Feb 2024 at 5:56pm

| Many times a push rod adjustment screw has backed off allowing a push rod to jump out of place. Pull the valve cover and check all tappets .017" COLD. |

Posted By: HudCo

Date Posted: 17 Feb 2024 at 10:29pm

| low numbers any way leak down test is in order and then like dr. says run over head pay attention any of the adjustment screwsthat are a differant hieght than the rest when you are done ,that will be an indication of a valve thats getting to deep in the seat or carboned up or somthing bent |

Posted By: WF owner

Date Posted: 18 Feb 2024 at 7:15am

|

I, personally, don't have a lot of faith in leakdown tests. In this case, I don't see what good a leakdown test is going to do, especially when you are showing no compression on one cylinder. All a leak down test will tell you is if there is some kind of a leak in the cylinder (rings, valves head gasket or a crack in the head or sleeve). I agree with the OP when he says he believes the rings are not a problem because oil consumption and blowby are low. To me, the symptoms have to be something in the top end.

As others have said, check the obvious (easy) things first. At the point where you are, I, personally, would pull the head off and have it checked for cracks and flatness, especially if you already have the injectors out for the compression test. When it's off, valves and seats can be checked and resurfaced. |

Posted By: injpumpEd

Date Posted: 18 Feb 2024 at 10:54am

|

The leakdown will tell you whether you need to pull the pan and pistons out. There can be a lot of piston issues that will not be visible from the top with the head removed. I don't worry too much about the leakdown percentages, but the difference from cylinder to cylinder. A low use tractor like this is certainly not one I'd be doing an overhaul on just because. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: HudCo

Date Posted: 18 Feb 2024 at 11:33am

| every time i have not done a preasure test or air check on somthing whether it be on a engine or a transmission hydralic syestem because i thought i knew better it has allways cost me more money and time and that dont bring home the pay check |

Posted By: WF owner

Date Posted: 18 Feb 2024 at 12:24pm

| So how do you do a leak-down test on a cylinder that is testing zero compression? |

Posted By: SteveM C/IL

Date Posted: 18 Feb 2024 at 12:53pm

| How would this work? Before ripping it apart,pull 4 injector and valve cover to be sure 4 is on TDC compression. Rig a hose you can jam down injector hole with a blow gum attached and force air into cylinder to see if you can hear it leaking past valves or piston into crankcase. Listen to manifolds and breather. |

Posted By: Wbenchfarms

Date Posted: 18 Feb 2024 at 1:08pm

|

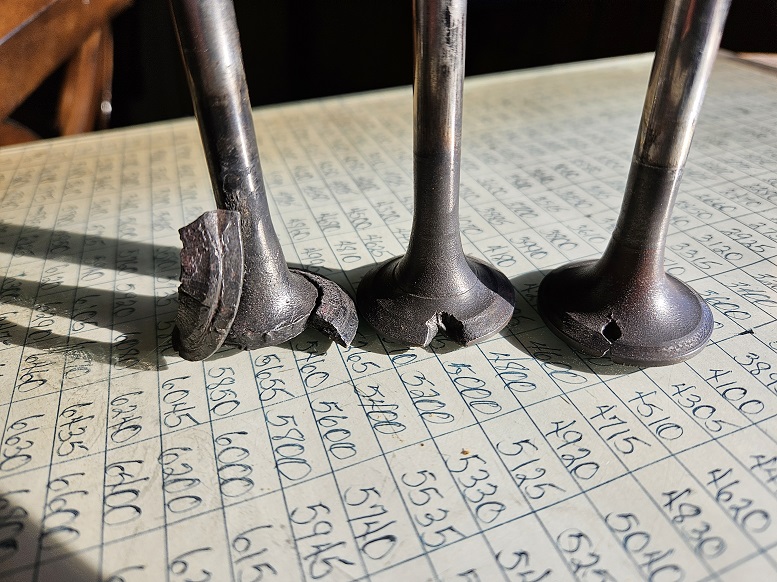

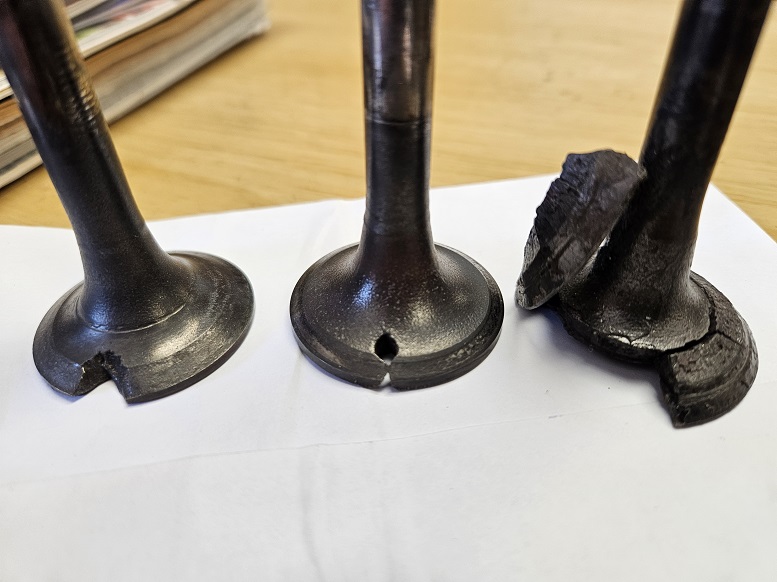

Decided to tear into things today, as the sun was out and we had a heat wave of 36 today after a high of 20 and snow yesterday. I did not do a leak down test for a couple of reasons. #1 the cylinder that is the main issue at the moment has 0 compression. If it's not a head/valve problem, I'm going into the bottom end, so may as well do an O/H at that point. If it is a valve problem, I'm going to have to fix the head first anyhow, and then put it back together and see if it solves the issue. If not, it's an O/H at that point as well. #2 I don't have a leak down test setup yet. Did get the head off. #4 exhaust valve has 2 edges off of it. 2 other cylinders (two that were lower on compression as well, had valves that are looking a little rough. @injpumpEd this is the tractor you did the pump for me last year. I will be getting ready to send injectors you way pretty soon. Any recommendation on a machine shop to send this head to? Not sure if it matters that I send this to someone who know old tractors, or if anyone can tackle it.

|

Posted By: injpumpEd

Date Posted: 18 Feb 2024 at 1:51pm

|

That will do it! lmao! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: WF owner

Date Posted: 18 Feb 2024 at 2:00pm

| I'm surprised the top of the piston, head and sleeve aren't damaged. Apparently, the pieces went out the exhaust. |

Posted By: DrAllis

Date Posted: 18 Feb 2024 at 2:09pm

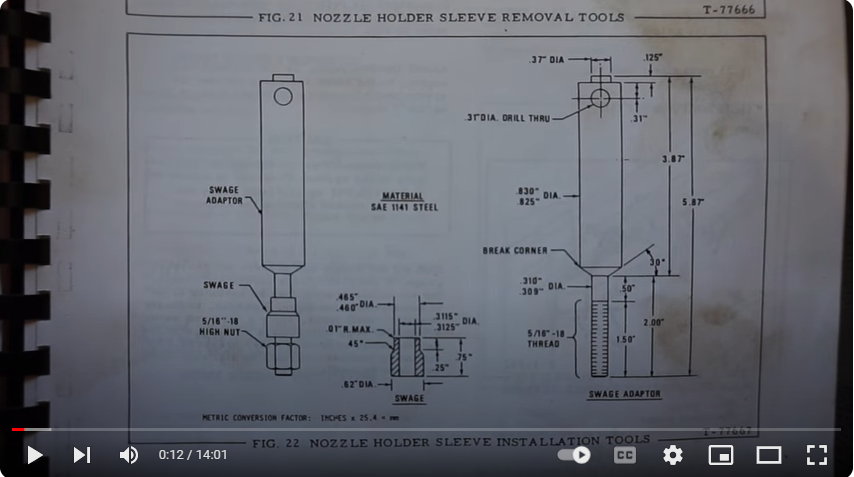

| If the head isn't cracked, it would get new copper sleeves for the injectors if it was mine. |

Posted By: Leon B MO

Date Posted: 18 Feb 2024 at 4:43pm

|

I've been watching this thread to see if anyone was going to mention the copper sleeves. Not every machine shop will be have the tools and know how for this repair, correct? I had the head redone on my 7020 5 years ago. Wish you the best. Leon B Mo ------------- Uncle always said "Fill the back of the shovel and the front will take care of itself". |

Posted By: DrAllis

Date Posted: 18 Feb 2024 at 4:49pm

| Allis dealers (not all) had the tooling. Not most machine shops. |

Posted By: DanWi

Date Posted: 18 Feb 2024 at 4:57pm

| Just curious What would cause damage like that detonation or something going thru the engine? Timing off causing it to run hot. I suppose a person can get all the head stuff in order and put it back together with a good pump and injectors, but I would wonder what caused it. |

Posted By: Wbenchfarms

Date Posted: 18 Feb 2024 at 5:44pm

I'm curious myself. A little background on this tractor. Bought it 3 years ago. Has always ran pretty good, but hard to start. Gave $5k for it with a set of duals and another set of 16.1 4 rib front tires. Used it for tillage, mowing hay, baling, picking corn, you name it. Would lug down and black smoke on a hard pull, but never let me down. Has always had a pop in the exhaust, and a fuel haze. I figured injectors on the haze, and straight pipe on the noise. Put close to 200 hours on it last year, and used 2 gallons of oil. I don't consider that bad for a 1978 model tractor that is showing close to 4000 hours. Couldn't get it started last spring, and no fuel to the injectors. Had the pump sent out to injPumpEd and he did an excellent job on it. Found out that pump was off of a combine, and not set up correctly for the tractor. Got that part fixed. Planned on doing a set of injectors this year. Started really thinking about things last summer and fall, and tried figuring out what could be the issue. Really thought it was a valve or head issue, just from the noise and the way it ran. Compression test verified that. Have the injectors boxed up and ready to send out. Need to find a machine shop that is competent in working on these. Time to round up some parts and get it ready for spring.

|

Posted By: Wbenchfarms

Date Posted: 18 Feb 2024 at 5:46pm

I'm on the lookout for a good machine shop. We have an Agco dealer close, but not sure how they are for Allis repairs. Mayer farm equipment is about 3 hours from here, and I know they are pretty good on Allis equipment. Hoping to find a shop close to home. Have a couple contacts, so will make some calls in the morning. If anyone has any recommendations, I'm open to them. Had to get too far from home because of shipping, but will sure do it for the right shop.

|

Posted By: Leon B MO

Date Posted: 18 Feb 2024 at 6:22pm

|

I am very fortunate. I have a very good retired AC mechanic with all the AC specialty tools to help me. You're 7020 head is one of very few models with the copper/injector tube set up. Make sure you find the right shop to do your head. I do like my 7020, it's the 301 at it's best. IMHO. By the way, if you have time, while your tractor is down, pull the pan and check rod bearings. We replaced them on the 7020 and 8070 this winter. Really not that expensive. Leon B Mo ------------- Uncle always said "Fill the back of the shovel and the front will take care of itself". |

Posted By: injpumpEd

Date Posted: 18 Feb 2024 at 6:40pm

|

Ask your local Agco dealers where they send their machine work to. Mayer's might have a great shop on tap that is familiar with the Mk2 301 heads. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Lynn Marshall

Date Posted: 18 Feb 2024 at 8:38pm

This is another of those kind of rare problems. Gas exhaust valves were more frequently replaced because of burning. The diesels, not so much, but it does happen. That particular valve hasn't been doing its job for some time. Hard starting and low power go with that sort of damage. A trained ear can hear that wheezing, when the engine is turning over, quite easily. Your popping noise is the compression going right out the exhaust. When an intake valve does something similar, it pops back through the air cleaner.

|

Posted By: Dirt Farmer

Date Posted: 18 Feb 2024 at 11:40pm

| Good call on where to start, I started a wall of mayhem in my shop several years ago of odd carnage that happens throughout farm life such as a broken fan shaft on a blue tractor that sent the fan into the radiator or severely worn elevator chain sprockets, odds and ends that later you look at them and say yep I did that. Those valves are prime examples of inductees. I write the cost of repair and the date, it serves as a reminder to stay safe and on top of maintenance. Good luck with your project, I always say it's better to fix these things now rather than when the machine is needed |

Posted By: SteveM C/IL

Date Posted: 19 Feb 2024 at 9:53am

| I would guess that it started as a tight or warped valve which started leaking combustion gasses which quickly leads to cutting torch effect. Burned it away not a chunk broke out. |

Posted By: Hurst

Date Posted: 20 Feb 2024 at 6:16am

|

Not sure how it plays out on a 7020, but I replaced the head on my 7000 with one from a 190xt/200 (no copper sleeves) and had Ed put new tips on my injectors to match. Again, 7020 has a different thermostat housing and potentially different injectors, so may not be possible, or advisable due to the higher hp output (more heat). But maybe someone with more expertise could comment. I had cracks forming around the copper sleeves to the valve seats on my head, so it was no good. Get the machine shop to check around the injector holes for cracks if you do keep that head. Where it's machined out for the copper sleeve to be swaged there, the injector hole is bigger so less material between it and the valves. Hurst ------------- 1979 Allis Chalmers 7000 5800 Hours |

Posted By: GSTROM99

Date Posted: 20 Feb 2024 at 7:55am

WOW! Good job. You'll be happy when it's fixed. Should start good and run "like new".  |

Posted By: Hurst

Date Posted: 22 Feb 2024 at 7:04pm

|

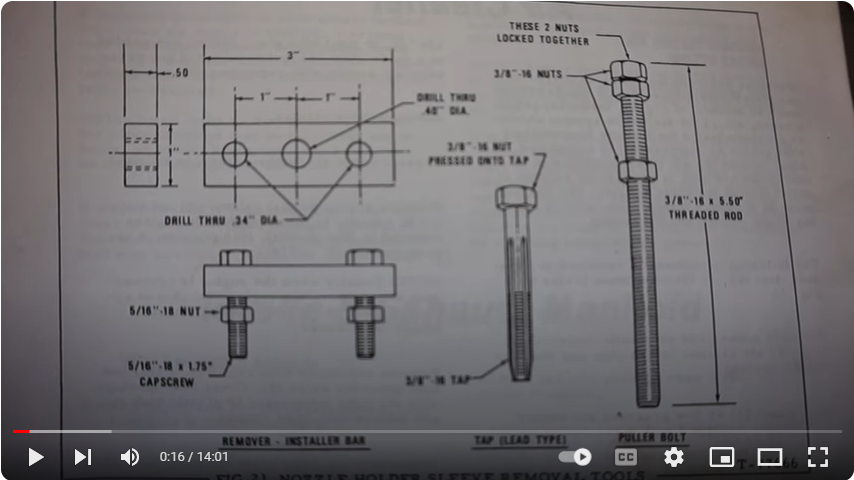

Found a video on youtube showing how to make the swage if you have trouble finding someone with one. Doesn't look too bad for someone with some decent lathe skills. Here's a link and the screen shot of the swage and the puller: http://www.youtube.com/watch?v=idCTPRgiVYc" rel="nofollow - https://www.youtube.com/watch?v=idCTPRgiVYc   Hurst ------------- 1979 Allis Chalmers 7000 5800 Hours |

Posted By: injpumpEd

Date Posted: 27 Feb 2024 at 8:34am

|

I received the injectors, and they are AC holders, so no chance of installing them backward. I'll hold off a while until you verify the head is usable. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Wbenchfarms

Date Posted: 27 Feb 2024 at 8:45am

Sounds great! I sure do appreciate it! |

Posted By: Acdiesel

Date Posted: 29 Feb 2024 at 12:10pm

|

I believe that there are two good machine shops in the Akron Area, Also you can talk to Wellerts AC parts, in West Salem Ohio, I know he does cylinder head work. Wellerts: 1-330-262-6991. ------------- D19 Diesel,D17 Diesel SER.3 2-D14, 2-D15 SER.II WF/NF D15 SER.2 DIESEL D12 SER.I, D10 Ser.II 2-720'S D21 Ser. II Gmc,caterpillar I'm a pharmacist (farm assist) with a PHD (post hole digger) |

DanWi wrote:

DanWi wrote: