B wheel question

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=19922

Printed Date: 05 Jan 2026 at 7:27am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: B wheel question

Posted By: case580

Subject: B wheel question

Date Posted: 25 Oct 2010 at 2:11pm

|

I let my neighbor borrow my 54 B for a church function this past weekend, unfortunately the rear wheel came off as they were unloading the tractor off the trailer. I made an emergency trip to put the wheel back on but I noticed the raised areas (help me with terminology) where the 4 lugs (bolted to the hub) grab on to are worn down fairly low. My question is how have others repaired these raised areas inside the wheel? Seems like to me I could build them up by making a couple of passes with the welder or maybe weld some solid steel rod in place. I want the fix to look as close to factory as possible yet control cost. Also, most of my lugs (again help with terminology) are in good shape with the exception of a couple that have worn on the sides. Lastly, I noticed a couple of the bolts have decent wear on them as well. Thanks for the help! |

Replies:

Posted By: Dakota Dave

Date Posted: 25 Oct 2010 at 3:16pm

| Take the tire off the wheel when you weld it up. I run a bead down the center of the raised hump than ground down with a angle grinder. It worked ok after welding twice I completly removed the tire and fixed the cracks in the Wheel that could not be seen from the outside. For a Temp fix a piece of sheet metal cut about 1X3 inches and clamped between the wheel and clamp will work. |

Posted By: RyanTN

Date Posted: 25 Oct 2010 at 6:30pm

| Case, are you familiar with how the eccentric bolts are positioned and work to tighten up the wheel? I'm not trying to be overly basic here, but the "couple of worn bolts" comments made me think that you may be describing the eccentric bolts. I can send you a .pdf file from the operator manual tomorrow, if you need more info. |

Posted By: case580

Date Posted: 25 Oct 2010 at 6:44pm

|

Basic is my level! Yes, I noticed

the eccentric bolts (thanks for providing the name) rotated to put pressure

towards the wheel. My comment about the bolts being worn was intended to

identify the eccentric portion of the bolt was worn but I am not sure how much.

I think the bolt wear along with the raised area wearing and maybe some of the

wear on the lugs all added up to contribute to the wheel falling off. Unless someone else post an idea I

will probably build up the raised area with weld and grind to the preferred

shape/height. Kinda hate to remove the tire to do the welding but want to be safe. Yes, please do send the pdf from the owner’s manual that may help me understand. |

Posted By: Bob-Maine

Date Posted: 25 Oct 2010 at 6:45pm

| Case and Ryan, I'm am not in a position to know whether it's a matter of wear on the rim or positioning the eccentrics, but I have had the same problem on my '41 B. I have had to build up the ridges on the rims as well as the stop blocks. Bob@allisdowneast |

Posted By: Gary

Date Posted: 25 Oct 2010 at 7:09pm

|

Normally there are 2 eccentric brackets and 2 that are not.

Sometimes you can replace 1 or both of the non-eccentrics with eccentric type to gain a little more travel and clamping pressure.

Gary

|

Posted By: RyanTN

Date Posted: 25 Oct 2010 at 7:12pm

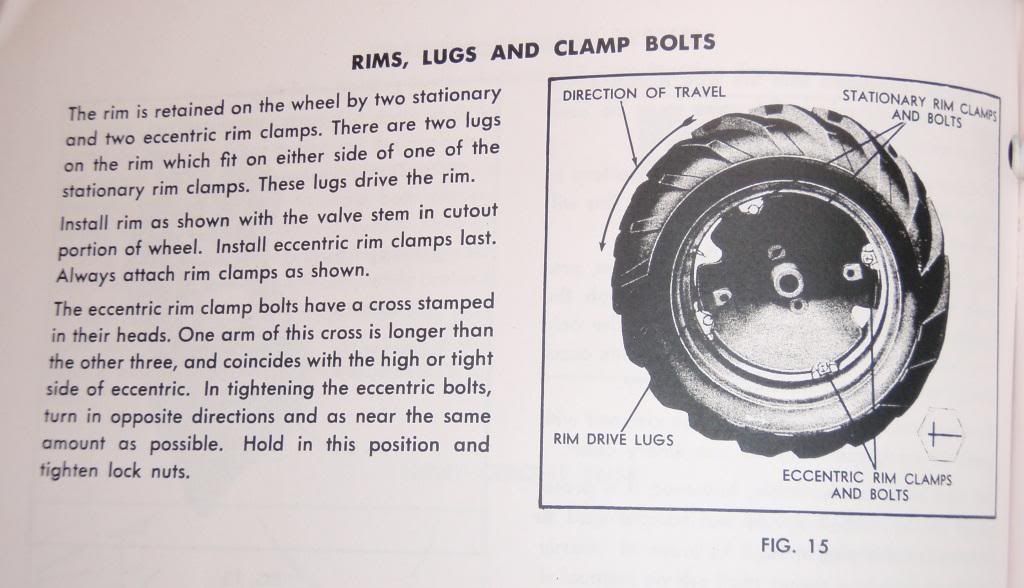

Okay, I took a picture instead. Are you following this procedure to mount and tighten your wheels?

|

Posted By: Ken in Texas

Date Posted: 25 Oct 2010 at 7:20pm

| When the wheel is ready to fall off as you say it did the looseness is usually pretty audible. Hard to imagine not noticing a disaster in the making. To ware out to the point of failier it must have been running loose for quite some time. Put 4 excentric blocks and bolts per rim and try solving the problem. Maybe you won't have to weld up the rims. |

Posted By: case580

Date Posted: 25 Oct 2010 at 7:21pm

|

This could explain part of my problem, I didn't pay attention to the position of the eccentric bolts vs the stationary ones. All I focused on was finding a clamp that would fit between the two square steel blocks welded to the wheel (I think they are to keep the wheel from spinning off the clamps). I will remove the wheels once again and follow the steps from the manual before I start any welding and grinding. Thanks for the picture.

|

Posted By: case580

Date Posted: 25 Oct 2010 at 7:53pm

|

now that you mention it I did hear/feel a popping noise coming from the side that the wheel feel off. I don't drive the tractor very often so maybe the extra stress from being loaded and unloaded from the trailer (and the popping noise I heard) contributed to the wheel finally coming off. Are the eccentric bolts used for other applications? Just wondering where to start looking to buy some new ones.

|

Posted By: Rick of HopeIN

Date Posted: 25 Oct 2010 at 8:01pm

|

I had a worn out hub in both centers on mine and some rust under the rim eccentrics that made them a bit loose. I made shim plates from brass to go in the vee under two of the rim clamps on each wheel (90 degrees apart) You can't even see em when installed. Eventually if rusty rim is the issue you just have to pull them tires off and get that stopped with good paint. A hole rusted in the rim makes a real expensive fix. Two of my three tractors need some work in that area. A common issue on old tractors. I also did some shims on the center splines of the B to tighten them. Took about a year of experimenting with different fixes to make the rims stop 'popping' when I turned, they had been let go pretty bad. ------------- 1951 B, 1937 WC, 1957 D14, -- Thanks and God Bless |

Posted By: Ken in Texas

Date Posted: 25 Oct 2010 at 8:50pm

| Post a "WANTED" add in the classified section of this forum case580. Should be plenty good used standard B/C excentric blocks and bolts somewhere near Mt. Holly NC. See them on Ebay quite often too. |

Posted By: Bee

Date Posted: 28 Oct 2010 at 8:05am

|

Case- do a Craigslist search. there are several guys in the Raleigh area with tractors being parted out.

------------- Bob, North Carolina 1949 B |

Posted By: Chalmersbob

Date Posted: 28 Oct 2010 at 10:18pm

| If you compare the adjustable and the non-adjustable wheel locks, they look the same when the adjustable ones are in the locked position. Bob |

Posted By: 1946WP

Date Posted: 29 Oct 2010 at 9:31am

| there's a cross on the head of the excentric bolt to let you know what direction the excentric is, so you don't go past the high spot when tightening. when tightening the nut make sure the bolt didn't turn also. |