Selector valve install

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=199052

Printed Date: 11 Nov 2025 at 11:01am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Selector valve install

Posted By: MadCow

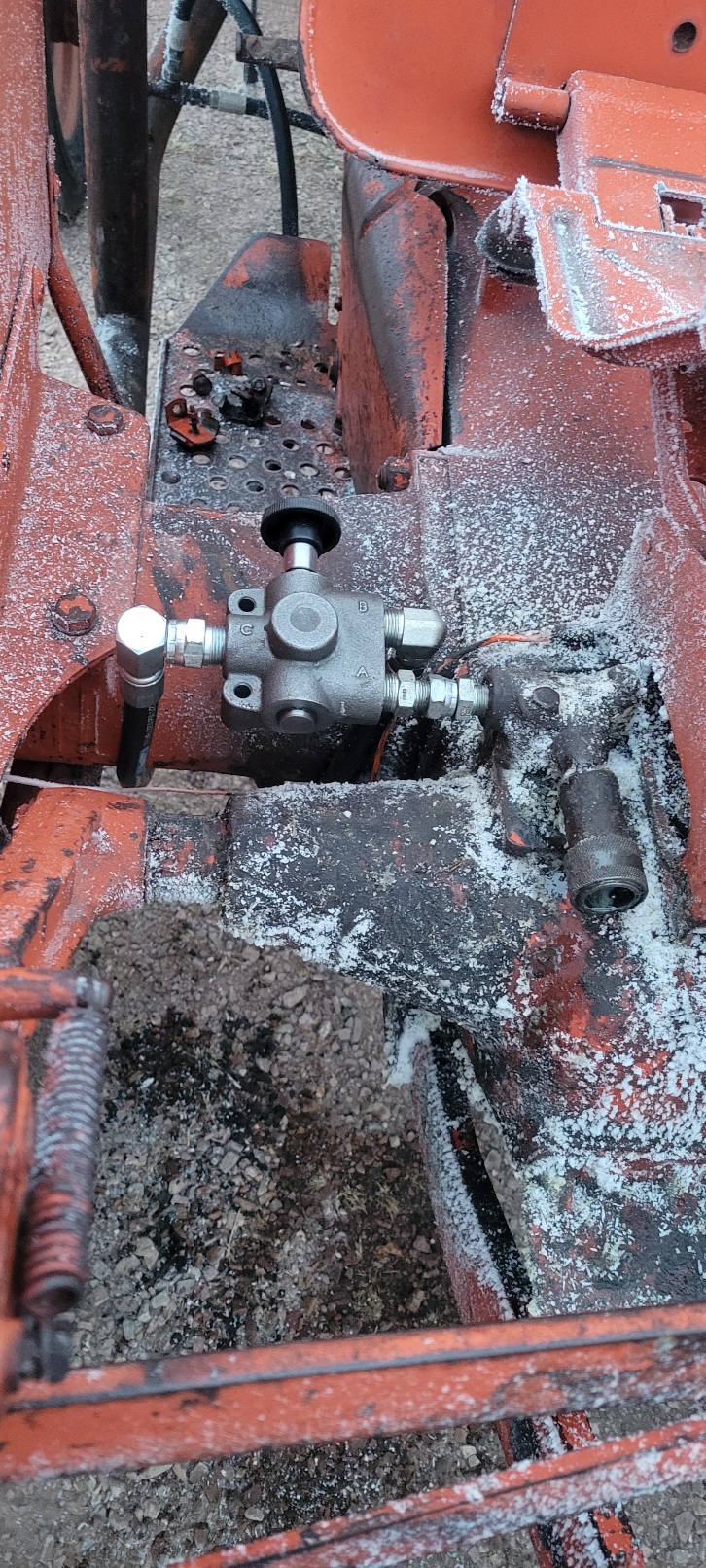

Subject: Selector valve install

Date Posted: 04 Jan 2024 at 5:58pm

|

I wanted to install a selector valve on my D15 Series I so switching from rear arms to lower bucket was faster, and didn't have to tie up the arms to use the bucket. Because the original selector valve is hard to find and expensive. I decided to go this route. 1) it's not strong and I highly recommend mounting the valve solidly. That's the first thing I'm gonna do when it's not below freezing in my workshop. 2) The original tube uses 1/2" inverted flare. Which is hard to find. The only adapter I've found is 1/2" inverted flare to 6AN (3/8" JIC I believe). It may be a different connection to the side of the pump housing, but connecting where I did was simplest for routing and I think the original tubing looks cleaner around the tight bends under the gas tank/steering wheel area. 3) I had the local hydraulic shop cut off the end of my old tube flare it to JIC, and then make a hose for me the right length. The length was the same as the tube +4". It works amazing! And I love it. Now I just need a better place to mount the valve come spring. But for winter going from grader blade to loader while moving snow will be a breeze.

|

Replies:

Posted By: steve(ill)

Date Posted: 04 Jan 2024 at 7:00pm

|

Im not overly familiar with the D15.... I take it your factory 3 point hydraulics is capacity enough to run the loader bucket... How did you run the loader before the valve was added ? I guess you dont need an extra pump running off the crank ? ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 04 Jan 2024 at 7:02pm

|

OK... i guess we had a tractor many years ago that might be setup as your "before".... the 3 point had to raise all the way up and stall out, then the bucket hydraulics worked ? .... so your "before" was just a TEE in place of the new valve ? ------------- Like them all, but love the "B"s. |

Posted By: dfwallis

Date Posted: 04 Jan 2024 at 7:14pm

| Cool, I'm working on two very similar looking 6 port selectors to route the CA pump to either the original circuit or to an external pedestal (and the pedestal back to the lift circuit). Turned out easier than I thought. Both controls in, original circuit, both controls out, remote pedestal control. The pedestal will have 2 single acting spools and 4 dual acting spools. But of course the cultivator timing circuit won't function when the pedestal is active (I could probably add an external delay, but don't think I'll need it since it will be easy to restore normal lift operation). Once I get over this RSV vaccine, I'll get back to work on it. |

Posted By: MadCow

Date Posted: 04 Jan 2024 at 7:20pm

The loader is single acting cylinders, power up, gravity down, trip bucket. There was a quarter turn valve connecting into the quick connect remote. So I could turn off the bucket and just run the rear if I wanted. But to use the loader I would either have to wait for the rear to go all the way up then the loader would go up, then the rear would have to go all the way down before loader would. So I would put the rear all the way up and wrap a chain around it and hook it to the seat. So the and were tied up and I didn't have to wait for the rear to drop. This is full control of one or the other. |

Posted By: MadCow

Date Posted: 04 Jan 2024 at 7:24pm

You must have a return on the CA? Everything I see says the Ds are high pressure low flow. So I'm not sure I can run more than one "thing" at a time. And nothing more than cylinders. No motors and certainly not a vacuum pump on a planter. |

Posted By: dfwallis

Date Posted: 04 Jan 2024 at 8:14pm

Initially I plan a return via the dip stick cap. I plan to mod a new one with a bulkhead fitting and a pipe and hose to a quick disconnect to the pedestal. If that doesn't work well enough (flow rate), then I have another idea to mount a bulkhead fitting to another access plate (I'll buy a used one and not mod the original). Since the pedestal is designed to be easily removed, the dip stick cap will just be removed and the original dip stick inserted when in the "OEM" pump setting. Yes, high pressure, low flow. But I believe a tiny bit higher flow than some give credit. But it's fairly easy to get smaller bore cylinders in just about any length and configuration if something is a little too slow. I don't really anticipate that, but I'm fine if I need to make additional mods/pump additions in the future. I've also made provisions for an external tank if it becomes necessary. |

Posted By: DiyDave

Date Posted: 04 Jan 2024 at 8:34pm

The loader I got for my D-15(II) has a simple gate valve, (in the line to the cyls) that does the same thing. You turn the valve closed to disable the loader (at a convenient height), and enable full use of the lift arms. Yours is, however, a lot prettier... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

steve(ill) wrote:

steve(ill) wrote: